high pressure mud pump factory

Cameron provides a range of integrated pump packages, including top- or rear-mount AC- or DC-electric drives, controls, manifolds, piping, and accessories for onshore and offshore applications.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

However, quality and service are always put in the priority of “fast growth”, by implementing the principle of quality control to every production process, we can ensure that every water well drilling rig and equipment we put out is a high quality one.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

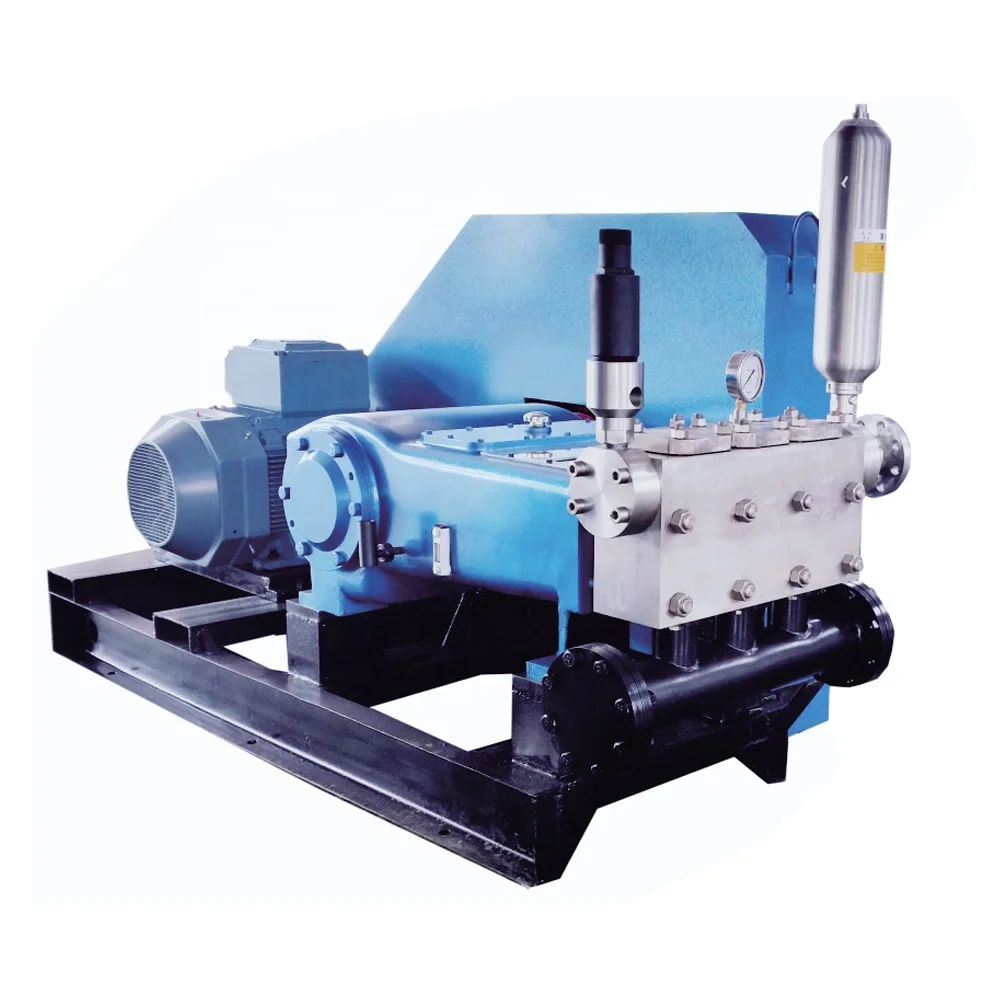

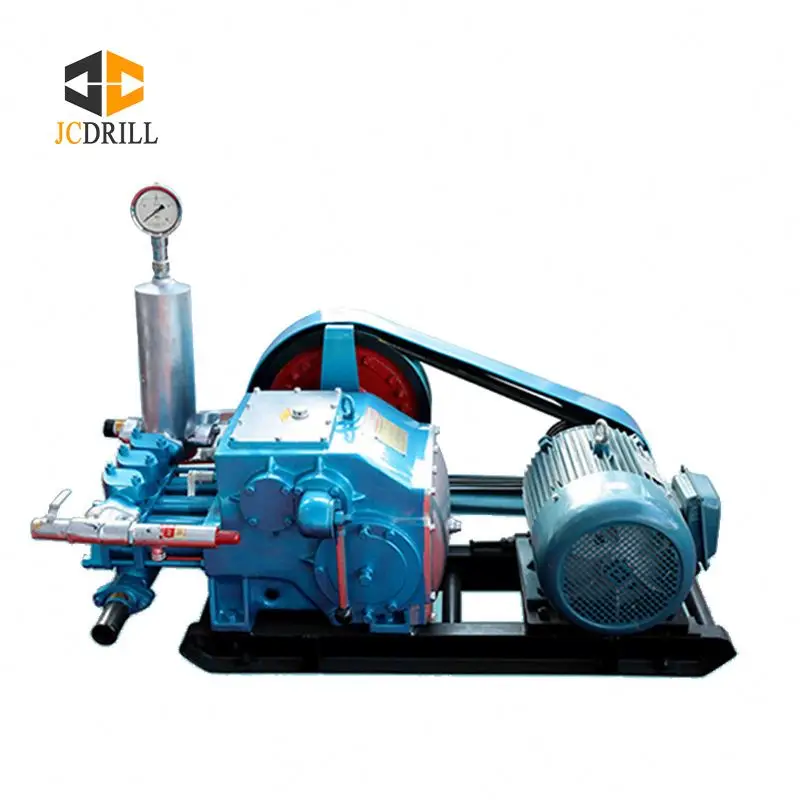

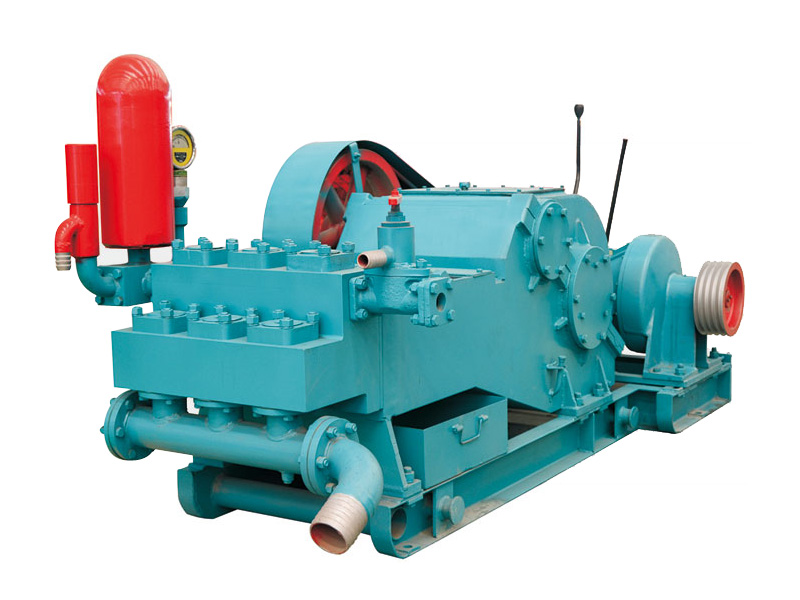

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

Gaodetec is a drilling rig high pressure mud pump equipment company located in central China. We have been in business for more than 6 years. Many of our employees have over 20 years of background and experience in the design and manufacture of piston mud pumps. We can create custom packaging and modify it, as well as provide specially designed reciprocating mud pumps. We provide our customers with pumps suitable for drilling projects.

As a world-renowned manufacturer of high pressure mud pumps, we offer a wide range of high-pressure mud pumps to meet different construction needs. BW series of high-pressure mud pump is an energy saving, special structural equipment, widely used in mining, drilling, coal, railways, roads, water and hydropower, bridges, high-rise buildings, foundation reinforcement projects.

They are also the main equipment for geological surveys, and their primary role in the drilling of boreholes in the heart is to supply fluids (mud or water) that circulate during drilling and transport rock waste back to the ground to achieve and maintain bottom cleanliness and to lubricate drill bits and drills by cooling them.

1. Electric high-pressure piston double mud pump using advanced product design, reasonable structure, pressure, large flow, multi-shift variable, energy saving, small size, high efficiency, long service life, safe operation, convenient maintenance.

Gaode Equipment now has BW series three-cylinder mud pump inventory. Different flows and pressures are available. And meet the flow and pressure requirements of different projects. High-value, high-performance drilling mud pumps are ready for your project. For more information about diesel engine three-cylinder drilling mud pumps, feel free to email us at info@gaodetec.com

LEC mud pumps use hydraulic power to convert hydraulic energy into the power that can convey high pressure mud. It’s self-suction plunger pump. The parts without rotation make piston linear motion.

•High reliability: no rotating parts, less moving parts, longer free maintenance time, high abrasive resistance and self-lubricating ability, which decrease the operating cost. When the hydraulic power less than max. rated power, the pump will decrease the output power automatically thus make the pump safe.

250 high pressure mud sucking pump products are offered for sale by suppliers on Alibaba.com, of which pumps accounts for 90%, mud pump accounts for 6%.

A wide variety of high pressure mud sucking pump options are available to you, You can also choose from new, high pressure mud sucking pump,as well as from energy & mining, construction works , and machinery repair shops high pressure mud sucking pump,and whether high pressure mud sucking pump is 1.5 years, or 6 months.

8613371530291

8613371530291