high pressure mud pump quotation

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

Mud pump are mainly used for irrigation agricultural machinery.the main characteristic is the high pressure,lift much,less engergy consumption,easy operation,high quality and duarable,easy to move,especially for mountain terraces of irrigation.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

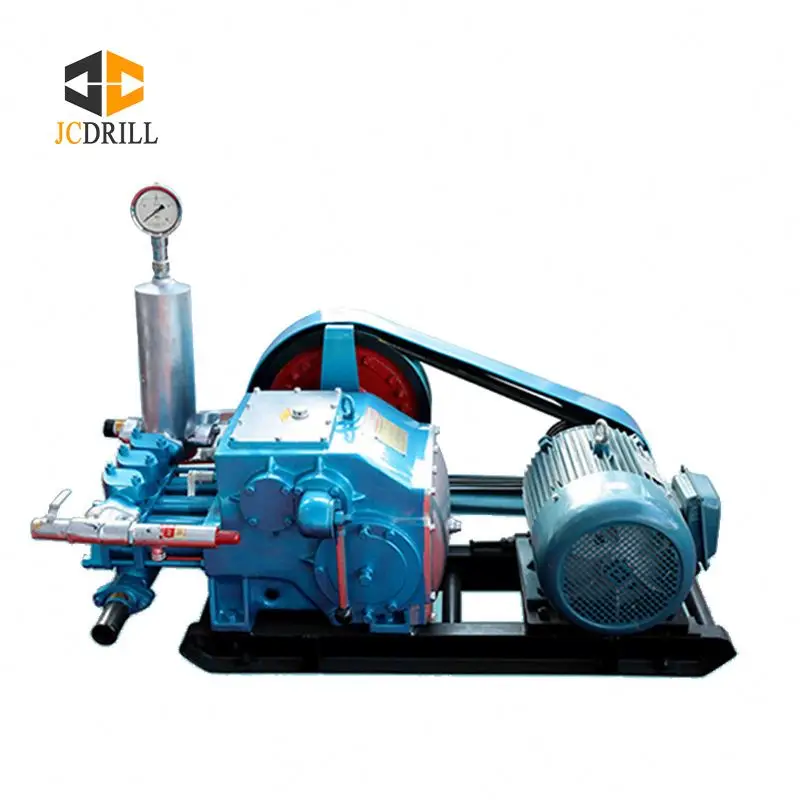

BW-250 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

With the addition of a high pressure mud pump to the pipeline equipment lineup, Vermeer offers contractors a one-stop shop for major components of pipeline drilling operations. On a job with tight deadlines, contractors can work easier knowing they are supported by quality equipment and a knowledgeable dealer network.

RS-250 Mud Pump is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

1. RGF series mud pump has advanced structure, compact, small volume, good performance, and is suitable for drilling technology requirements of high pump pressure and large displacement in oil field.

2. RGF series mud pump has a long stroke, which can be used at a low stroke number to effectively improve the water-loading performance of the mud pump and prolong the life of vulnerable parts at the hydraulic end.Advanced structure of suction air bag, reliable use, mud pump can achieve the best suction effect.

3. RGF series pump cylinder, crankshaft, herringbone gear and other important parts are made of high-quality alloy steel, the frame is welded with plates, high strength, good rigidity, light weight.

4. RGF series mud pump has high interchangeability. All vulnerable parts at the hydraulic end are interchangeable with parts of the same specification and model that meet the requirements of API specification.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Mud pump, refers to the drilling process to the drilling mud or water and other washing liquid machinery. The main components are volute, impeller, pump seat, pump case, support cylinder, motor seat, motor and other components. Impeller nut is cast iron, so corrosion resistance is good, and convenient processing technology. Pump seat is equipped with four skeleton oil seal and shaft sleeve, prevent shaft wear, prolong the service life of the shaft.

High quality vertical mud pumps with thick, solid shaft and copper motor can be provided in ATO shop. Various models are available, such as 2 inch mud pump, 3 inch mud pump, 4 inch mud pump and 6 inch mud pump. Here is the price list of vertical mud pump.

Sewage mud pump is used in mining, papermaking, printing and dyeing, environmental protection, ceramics, refining, petroleum, chemical industry, farm, dyeing, brewing, food, construction, gold mine, mud, quicksand, mud pond, sewage pond, turbid fluid to send suction thick liquid, loading and suspended matter sewage operation, can also be used for mine drainage and fluid containing mud blocks.

If the mud pump and high-pressure water pump, water gun with the composition of hydraulic mechanized earthwork unit, can be used for land leveling, river and pond dredging, digging and other small water conservancy projects, as well as urban air defense engineering, underground engineering.

"High Pressure Mud Pump Market" Insights 2023 - By Applications (Onshore, Offshore), By Types (Duplex Mud Pumps, Triplex Mud Pumps, Qunituplex Mud Pumps), By Segmentation analysis, Regions and Forecast to 2029. The Global High Pressure Mud Pump market Report provides In-depth analysis on the market status of the High Pressure Mud Pump Top manufacturers with best facts and figures, meaning, Definition, SWOT analysis, PESTAL analysis, expert opinions and the latest developments across the globe., the High Pressure Mud Pump Market Report contains Full TOC, Tables and Figures, and Chart with Key Analysis, Pre and Post COVID-19 Market Outbreak Impact Analysis and Situation by Regions.

1. Does this report consider the impact of COVID-19 and the Russia-Ukraine war on the High Pressure Mud Pump market?Yes. As the COVID-19 and the Russia-Ukraine war are profoundly affecting the global supply chain relationship and raw material price system, we have definitely taken them into consideration throughout the research, and in Chapters 1.7, 2.7, 4.1, 7.5, 8.7, we elaborate at full length on the impact of the pandemic and the war on the High Pressure Mud Pump Industry

This research report is the result of an extensive primary and secondary research effort into the High Pressure Mud Pump market. It provides a thorough overview of the market"s current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends.It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the High Pressure Mud Pump Market.

The Global High Pressure Mud Pump market is anticipated to rise at a considerable rate during the forecast period, between 2022 and 2029. In 2021, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

The High Pressure Mud Pump market has witnessed growth from USD million to USD Multimillion from 2017 to 2022. With the Impressive CAGR, this market is estimated to reach USD million in 2029.

The report focuses on the High Pressure Mud Pump market size, segment size (mainly covering product type, application, and geography), competitor landscape, recent status, and development trends. Furthermore, the report provides detailed cost analysis, supply chain.

Technological innovation and advancement will further optimize the performance of the product, making it more widely used in downstream applications. Moreover, Consumer behavior analysis and market dynamics (drivers, restraints, opportunities) provides crucial information for knowing the High Pressure Mud Pump market.

This High Pressure Mud Pump Market Research/Analysis Report Contains Answers to your following Questions ● What are the global trends in the High Pressure Mud Pump market? Would the market witness an increase or decline in the demand in the coming years?

● What is the estimated demand for different types of products in High Pressure Mud Pump? What are the upcoming industry applications and trends for High Pressure Mud Pump market?

● What Are Projections of Global High Pressure Mud Pump Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

● What are the factors contributing to the final price of High Pressure Mud Pump? What are the raw materials used for High Pressure Mud Pump manufacturing?

● How big is the opportunity for the High Pressure Mud Pump market? How will the increasing adoption of High Pressure Mud Pump for mining impact the growth rate of the overall market?

Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

8613371530291

8613371530291