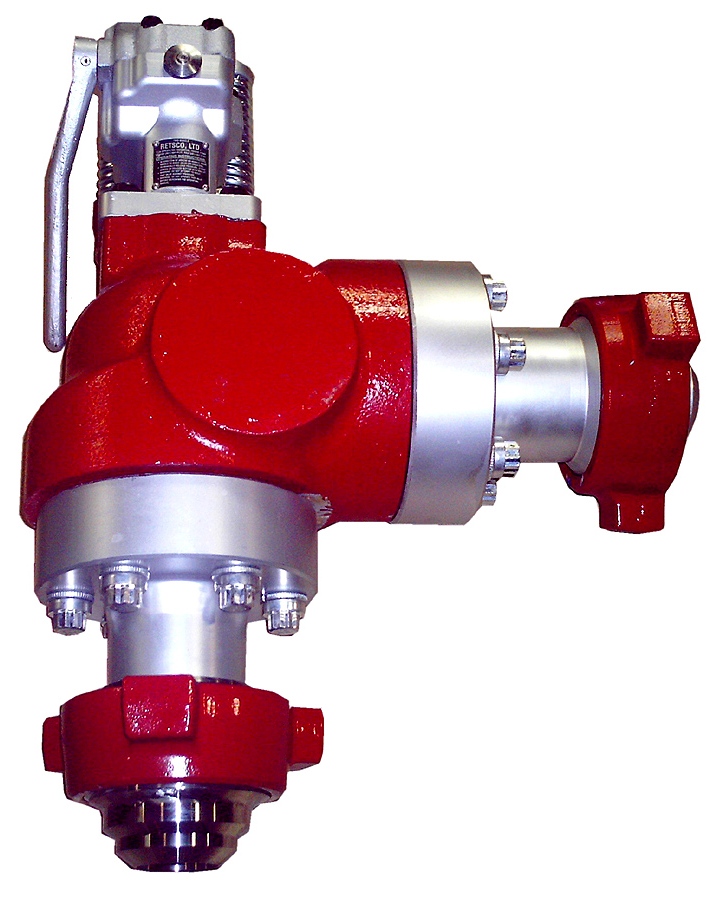

mud pump pop off valve manufacturer

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

Over-pressurization is a looming factor that can cause significant damage to drills and machinery, making quality drilling pop-off valves a must. Drillmax, Inc. specializes in pop-off and relief valves, ensuring that your equipment is adequately protected during the course of your application.

In fact, since 1996, Drillmax, Inc. has specialized in a wide range of quality gate, float, relief and drilling mud valves. We have built strong ties working with a wide range of clients, including:

We our proud of the fact that our drilling pop-off valves are used all across the world in the industry, providing superior performance and longevity for the clients we service. As an aftermarket manufacturer of drilling mud valves and other components, we are able to offer superior service at a lower price point than OEM.

We offer drilling valve 2” aftermarket replacement parts, along with a wide range of other essentials that ensure your machinery and equipment runs efficiently and with minimal downtime. We offer:

Bring efficiency to your drilling application with DEMCO style mud gate valves and other important valves and components. Drillmax, Inc. is a leader in after market manufacturing of generic valves, gauges, cones for desanders/desilters and more.

We provide a wide selection of Shear pin relief valves and gate valves that are of the highest quality, OEM-compliant and come at an economical price point.

Nothing is more important to a drilling application than the safety and wellbeing of personnel. High pressure relief valves are one of the primary components that ensure that safety for these men and women. That’s why it’s important to only trust a reliable after marketing manufacturer for these important components.

Much of the efficiency of your drilling operation hinges on the ability to make quick in-line repairs. With our high-quality mud gate valves, users are able to instantly shut off flow so that personnel can administer the needed repairs and maintenance. This ensures that your process continues moving along without any major disruptions.

Drillmax, Inc. has been in the business since we opened our doors in 1996. We have walked in step with the evolving technology associated with drilling operations. We use this knowledge and experience to provide our clients with, not just high quality Shear pin relief valves and other components, but with the knowledge and insight needed to enhance their application.

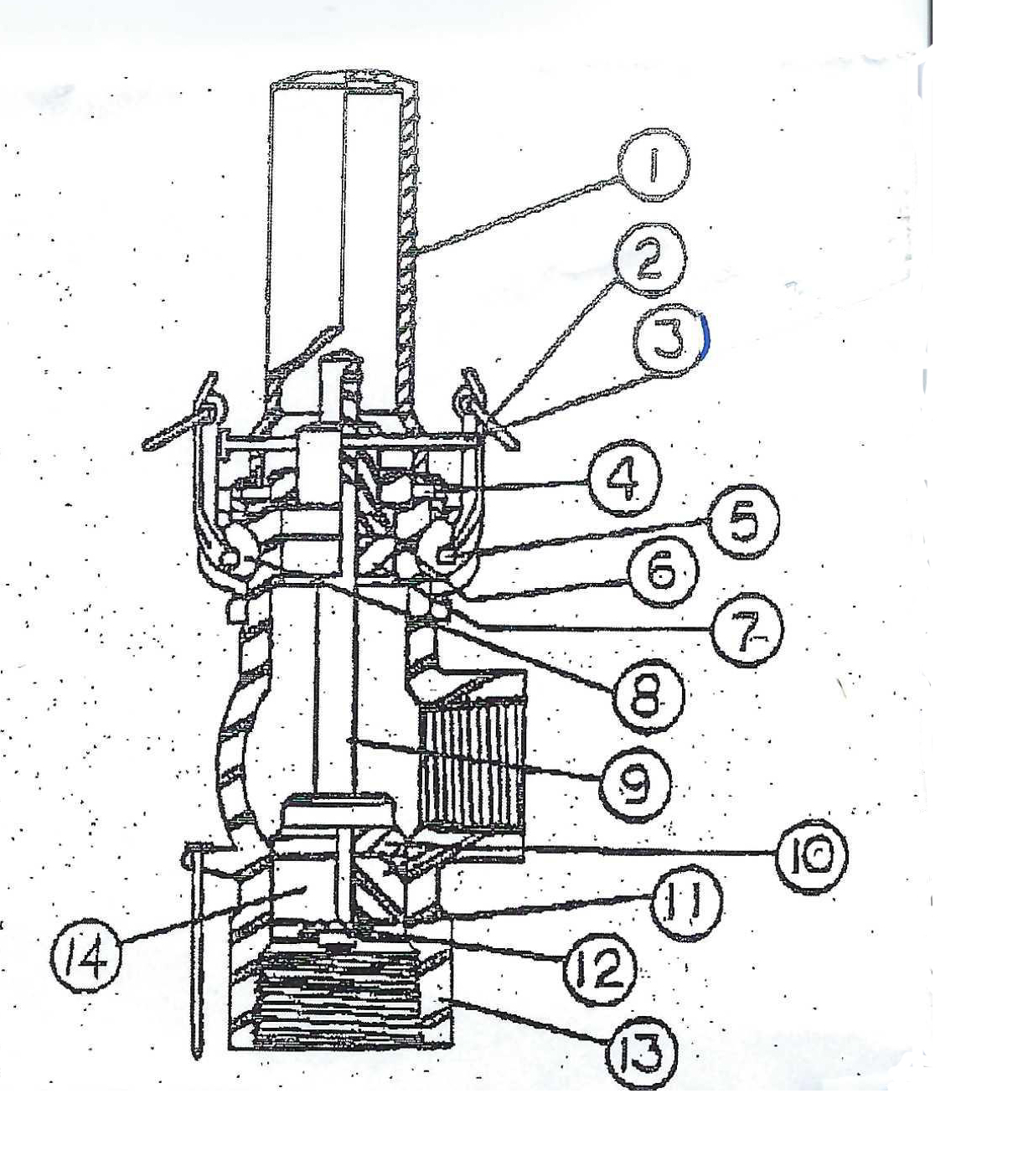

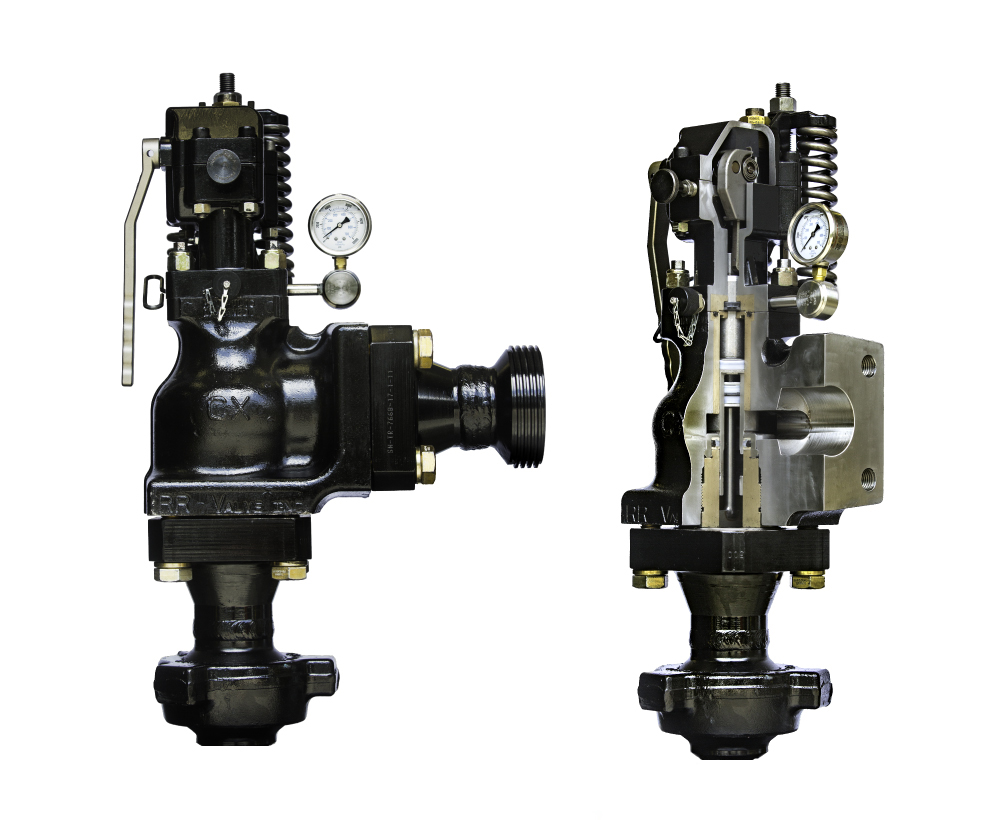

Marathon Valve designs and manufactures high-pressure safety reset relief valves for installation on heavy duty mud pumps to protect the pumps against over-pressurized conditions and damaging pressure surges. As the OEM for the Guardian® valve line, Marathon Valve ensures all specifications and tolerances are met. Our valves are highly effective at holding high pressures and deliver exceptional repeatable performance. To meet the drilling industry’s operating and safety standards, material traceability and specialized material testing is maintained throughout the manufacturing process. A primary drilling industry objective is all equipment utilized on vessels and installations meet rigorous industry operating and safety standards. This focus on equipment safety and integrity is how Marathon Valve’s Guardian® valve line can deliver the proven performance and reliability our customers expect.

The Guardian® reset relief valve series underwent rigorous R&D to produce impressive results and successfully obtained multiple U.S. patents. The primary focus was engineering out all the field problems that were prevalent with other relief valves, also known as pop-off valves in the industry. Our valves have the 3″ industry standard connectors to facilitate swap outs, are simple to operate, and utilize the systems pressure to fully open when a pre-set relief pressure is reached. Marathon Valve’s line of reset relief valves are the only valves on the market today with unique patented technology that is making our valves the new standard in high-pressure relief valves.

We offer a product line of land and offshore pressure control safety valves, to learn more about how our reset relief valves can help your success, contact us today.

The Premium Oilfield Technologies Caliber® RV7500 Relief Valve was designed for today"s higher-pressure drilling conditions. The valve utilizes a pin buckling system to determine the relief pressure. Each pin is designed to deform when the pressure reaches a predetermined load. All pins go through a stringent quality control process and batch testing to ensure performance at the correct pressure rating.

For 50 years, Giant Pumps has offered the most dependable positive displacement high-pressure triplex pumps available. Designed and built to the highest quality standards, customers count on Giant Pumps products to keep their equipment running. Every design detail of Giant Pumps products is optimized for long-life and reliable performance, making Giant Pumps the most trusted name in high-pressure pumps and systems.

RR Valve stands behind its products offering 2-year warranties on all new products and a 1-year warranty on all refurbished products. Our in-house staff of skilled craftsmen refurbish all products offered by RR Valve. Fast turnaround times and precision quality in manufacturing and service result in reduced downtime and cost savings.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,as well as from energy & mining, construction works , and machinery repair shops pressure relief valve for mud pump,and whether pressure relief valve for mud pump is 1.5 years, or 3 months.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A Relief Valve, or Pop-Off Valve, is a secondary pressure regulating device used to back up the primary regulating device. If the primary regulating device fails to by-pass at a set system pressure, the relief valve will open and allow liquid to flow freely. A relief valve can save costly pump and system damage, and more importantly it’s an added safety feature to protect those working around the equipment.

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required.

8613371530291

8613371530291