mud pump pressure relief valve manufacturer

The Premium Oilfield Technologies Caliber® RV7500 Relief Valve was designed for today"s higher-pressure drilling conditions. The valve utilizes a pin buckling system to determine the relief pressure. Each pin is designed to deform when the pressure reaches a predetermined load. All pins go through a stringent quality control process and batch testing to ensure performance at the correct pressure rating.

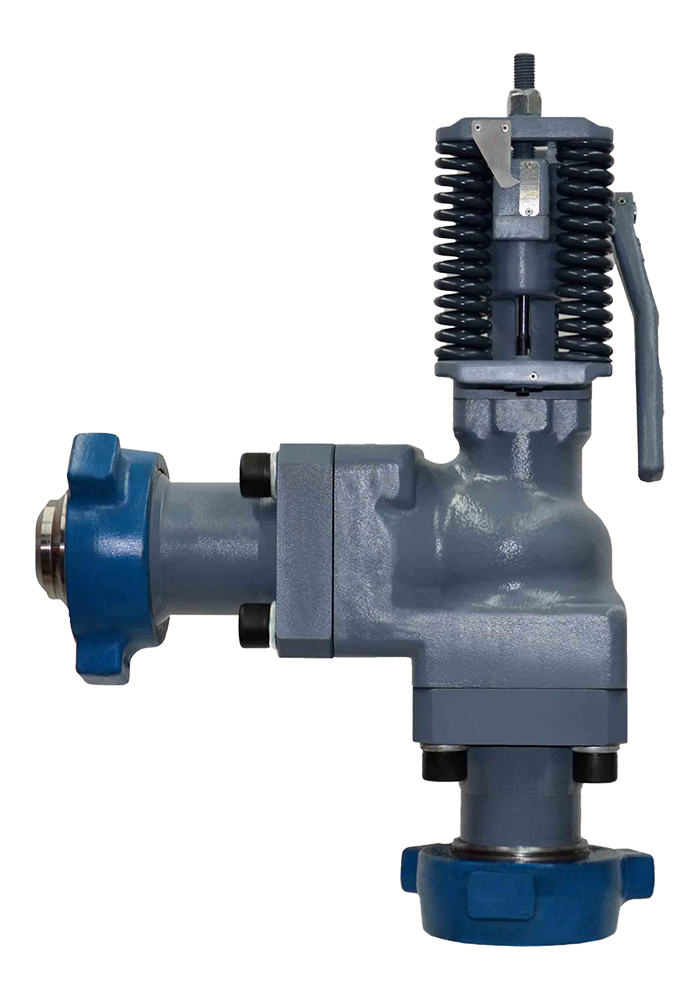

The CRV26 PRV is a product of the CORTEC Fluid Control division of CORTEC, which provides a complete line of high-end valves designed and manufactured according to specific project specifications. CRV26 PRV is engineered to protect drilling systems against the dangers of over pressurization and is the first of its kind to be rated to 10,000 PSI systems.

Stephen Corte, Vice President, CORTEC, said, “Automated PRVs provide the highest level of accuracy and reliability and are automatic or manually resettable for thousands of cycles. Our CRV26 PRV offers a competitively priced alternative to other remotely-operated PRV models, along with a degree of service life, precision and repeatability that conventional burst disks and manual spring reset valves cannot provide.”

The CRV26 PRV is suitable for frac system relief, mud pump relief and managed pressure drilling (MPD) and is compatible with API 6A and NACE MR0175 requirements.

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

With a low pressure setting, ie, 1000psi, by adjusting the top nylon self lock nut to move on the vertical scale to get the same setting than the scale.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,as well as from energy & mining, construction works , and machinery repair shops pressure relief valve for mud pump,and whether pressure relief valve for mud pump is 1.5 years, or 3 months.

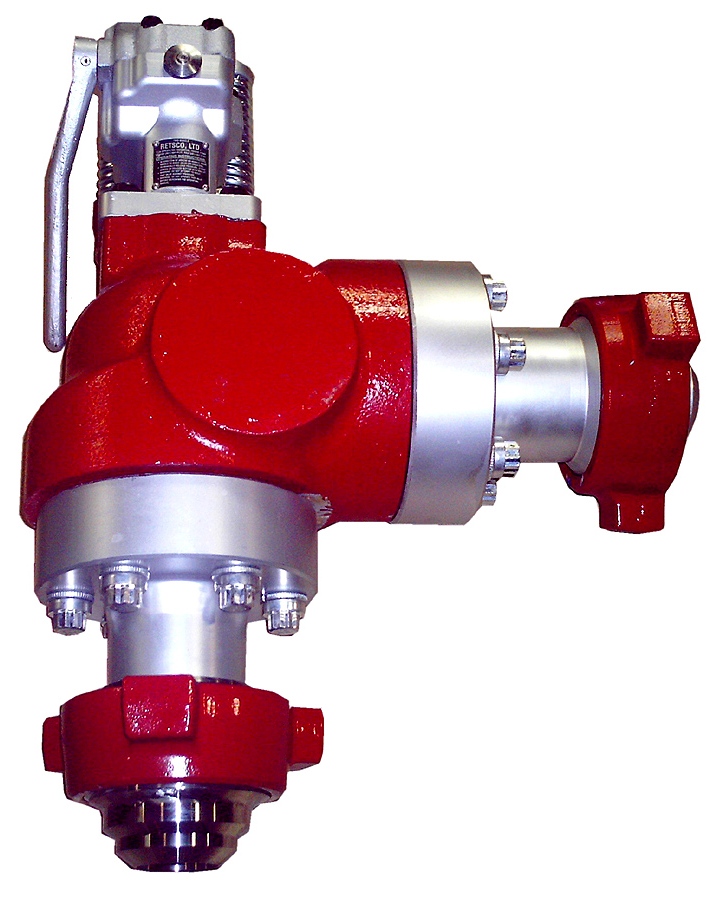

Leading international oilfield services company Expro announces today the introduction of a new Power Relief Valve (PRV) system which reduces the man hours and rig down-time historically associated with operating and maintaining traditional mud pump relief valves and systems.

Known as the PRV MAX, this mud pump pressure relief valve system is an accurate and automated relief valve with an integrated hydraulic actuator, separate hydraulic power unit that can be mounted directly to the valve or within 20 feet of the valve, and a remotely mounted �touchscreen� control panel.

�The Expro PRV MAX is an innovative pressure relief valve system that combines the highest durability and reliability standards,� said John Loafman, Expro Equipment Sales Vice President.

�The system brings innovative solutions to the problem of protecting positive displacement mud pumps from excessive pressures. It increases relief pressure accuracy, increases repeatability, and allows reset to occur in a time-efficient and cost effective manner for our customers.�

The PRV MAX is constructed using non-interacting mechanical components, which means that a single point of failure will not spread to other valves. During tests, the PRV MAX fully opened in under 375 milliseconds after mud pressure exceeded the set point.

The patent-pending PRV MAX is virtually maintenance-free; Tungsten carbide sealing components provide high-erosion resistance and extended trim life, without the use of elastomeric components. This extends service life between maintenance periods, which was validated by DNV witness-testing to 250 pressure relief cycles. Seal integrity was maintained throughout.

A relief valve is a Valve which is installed on a pump or pipework to relieve excessive pressure in a positive displacement pump which could cause damage to a pump or system. Relief valves (also known as bypass valve or safety valve) are known as an Internal Relief Valve if installed on the pump itself, and if installed on the system they are known as an External Relief Valve.

Such valves are used on positive displacement pumps as the pumps are designed to prevent recirculation of fluid back to the inlet, meaning the displacement is always forward. However if a valve is closed on the outlet of the pump, or a blockage occurs the pump will continue to build pressure in the outlet pipework and within itself. This can cause pressures to reach dangerously high levels, and the pressure will vent at the weakest part of the system, causing a leak, damage or pump failure.

Such valves work in different ways depending on where they are installed. If installed on a pump the fluid is recirculated within the pump head, preventing the buildup of pressure, however the fluid begins to heat up, and is something which should only be done temporarily as it can lead to pump failure. External relief valves should be used in conjunction with internal relief valves to relieve any excessive pressure in the pipework either back to a vented tank or to dump contents in an emergency to atmosphere.

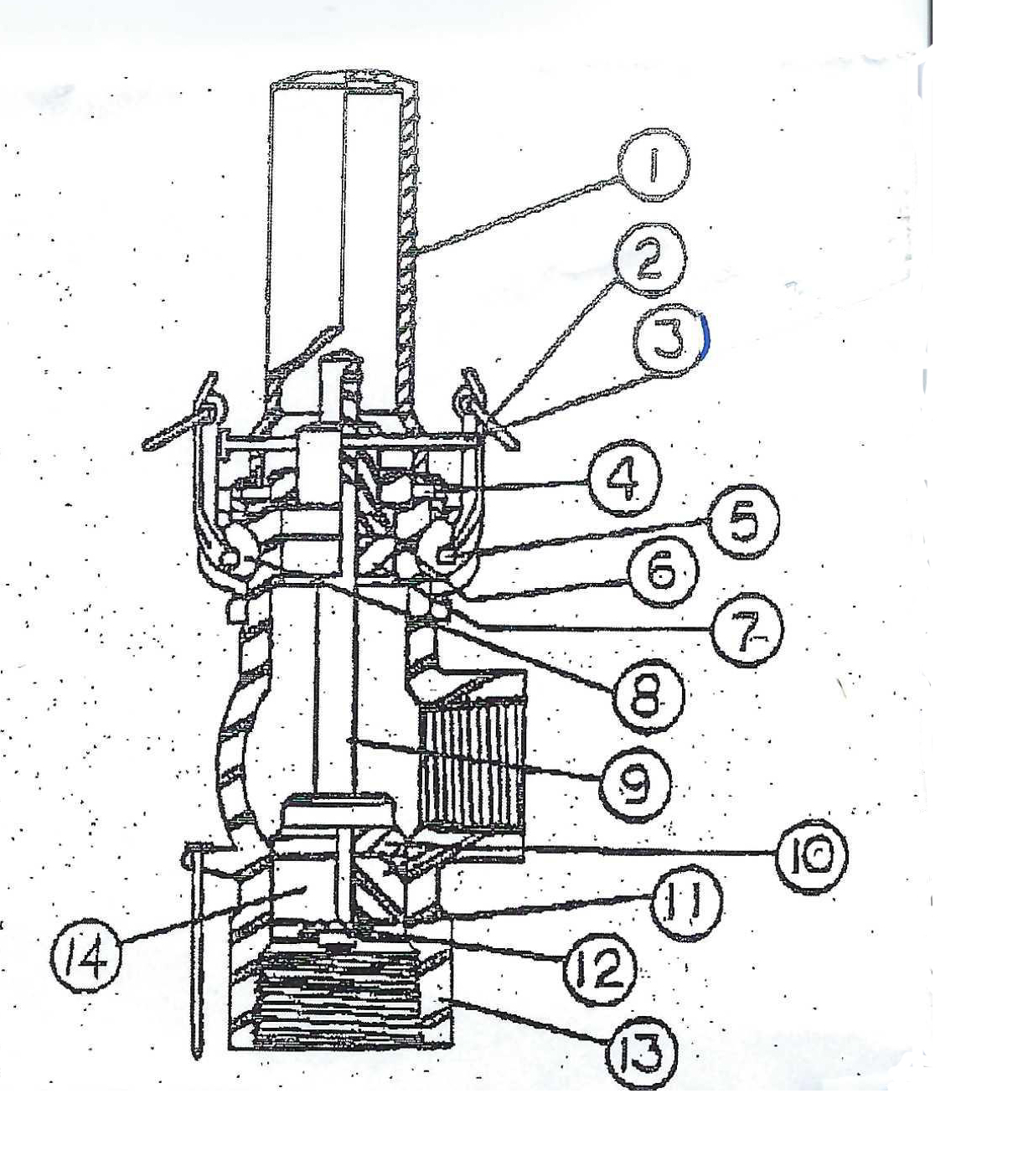

A relief valve design consists of a housing with inlet and outlet connections, a spring within a chamber which keeps a plate in place sealing the discharge. When the valve reaches the set relief pressure, the pressure plate causes the spring to compress revealing the discharge, causing the pressurised contents to vent through the discharge. A set screw or nut is used to set the relief pressure, at the top of the housing and when screwed clockwise, compresses the spring increasing the amount of pressure required to compress the spring and open the valve.

Internal relief valve set pressure is usually set at 10% above the operating pressure of the pump, and external relief valves should be set at 10% higher than the relief valve on the pump to prevent nuisance tripping. Valves are typically calibrated during manufacture and can be set on site with the use of pressure gauges during commissioning. Valves are rated in ranges such as from 0-10 bar, or 10-15 bar so should a valve pressure rating require recalibrating, checks should be made to ensure the setting is inline with the rating of the valve. Equipment should be checked at regular intervals to ensure succesful operation during an emergency.

Relief valves are not always required if the pressure capability of the pump is low, but also if used in conjunction with a product which can solidify when cooled if it enters the relief valve such as Chocolate or Bitumen. If fluid sets within a relief valve this will prevent it from operating as normal as any material which hardens will form a plug and can also cause contamination as it can be very difficult to clean thoroughly.

On some pumps a pressure relief valve is used in conjunction with a pressure regulator which regulates the pump to deliver the required pressure for the system. An analogy often used to describe a pressure regulator is akin to brakes in a car, with and the relief valve being the seat belt. A relief valve should only be relied on for use in emergencies to prevent damage to the pump or system and not as frequent protection for the system.

Thanks for visiting the website of Dezhou Rundong Company. We are an ISO9001 and API 7K certified safety valve manufacturer, located in China. Our location in Dezhou city gives us access to convenient transportation by sea, air, and land. This guarantees lower transportation cost, thus reducing our production costs and saving customers on shipping charges. An extensive line of oil equipment is available at Rundong, such as valve, downhole drilling motor, mud pump parts, and many others. If you require more information, please contact us. The staff at Rundong is happy to assist you with whatever you may need.

Since 2006, Envirovalve has been changing the game for safety relief valves. Our innovative designs for pressure relief valves have already made significant impacts on the industries we service. The most impactful of those designs has been our Accu-Shear Pin Device.

Our ASME certified Accu-Shear pressure relief devices have a revolutionary design that is different from other traditional Buckling Pin Devices and Valves like Rupture Pin, Buckling Pin, Rupture Disc and BPRV. The device does what its name implies; it shears or breaks the pin as opposed to compressing or bending the pin that you see in most pressure relief valves.

The Accu-Shear device opens and closes like a butterfly valve, and the pin is situated on the outside of the device which allows for easy and efficient replacement. The Accu-Shear pin is designed to break cleanly every time. During the manufacture process, every fifth pin is broken to insure the material or tolerance has not changed. Our Accu-Shear pins are less costly than our competitor’s pins and are easily replaced without needing to tear down the entire system.

8613371530291

8613371530291