mud pump repair pricelist

Pump material– Plastic pumps are cheaper and lighter but not designed for high pressure. Metal pumps are stronger and last longer but cost twice as much as plastic.

Sump pump maintenance costs $100 to $250 per year for cleaning, testing, and weatherizing. Purchasing a multi-year service plan may reduce the annual cost. Routine maintenance extends the pump"s lifespan and improves its dependability.Cleaning– Sump pump cleaning should be performed annually as part of a routine maintenance plan to ensure the system is clear of debris.

Clearing– Annual maintenance should include clearing the check valve and float trigger. This check valve prevents water in the discharge pipe from emptying back into the sump pit. A float trigger turns the pump on or off, depending on the water level.

Additional costs and considerationsInsurance– Most homeowners insurance policies don’t cover sump pump failure and repairs. Separate water overflow policies are available.

Filters– Sediment filters cost $10 to $30and prevent clogs and debris from damaging the sump pump. Filters must be cleaned or replaced every six months to one year.

Reserve pumps– In flood-prone homes, a second reserve pump costs $1,000 to $4,500and assists the main pump during heavy rainfall. Back-up pumps come in water-powered, battery-powered, and Wi-Fi-enabled models that alert the homeowner if the system stops working.

Sump pump replacement costs $500 to $1,200, depending on the location and pump type. Submersible sump pumps replacement costs $500 to $1,200 on average, while pedestal sump pump replacement costs $500 to $600.

The following warning signs indicate a sump pump needs repairing or replacing:Motor– The most common sump pump problem is typically a worn-out motor. A pump motor that constantly sucks up sediment may also get stuck. A filter helps prevent the problem but requires regular cleaning or replacement.

Long-running cycle– A long-running time indicates the pump has insufficient horsepower for the amount of water it must extract or the distance it must pump it.

Unfamiliar noises– Excessive pump motor noise may indicate a failed bearing. Rattling or grinding noises may mean the impeller fan is damaged or jammed.

Excessive vibration– A damaged or bent impeller causes the pump to wobble and vibrate. Fixing a bent impeller is complex, and a sump pump replacement is recommended instead.

Test the check valve – Pour water into the sump pit and confirm the pump removes the water from the pit. If the water returns to the pit, replace the check valve.

Clean the impeller – Unplug the sump pump and remove the screen from the bottom of the unit. Remove any debris that could block the impeller rotation.

Plumbers fix sump pumps, but repairs are not always cost-effective. Plumbers often recommend replacing a failed sump pump instead due to the comparable repair and replacement costs.

A sump pump needs annual servicing to avoid flooding and water damage. Homeowners can perform routine maintenance quarterly, like cleaning the filters and testing to ensure the pump functions properly.

Some basements stay dry without using a sump pump. However, homes in areas with excessive snow, rainfall, or high groundwater levels often need a sump pump or drainage system to prevent flooding or moisture damage.Waterproofing a basement costs$3 to $9 per square footand may prevent the need for a sump pump.

Sump pumps last 7 to 10 years on average if properly maintained. A sump pump that runs frequently or must displace a large volume of water may only last five years.

Homeowners" insurance typically does not cover sump pump failure or water damage. Homeowners must purchase separate coverage for water backup and sump pump overflow.

Sump pumps1 come in two types: submersible and pedestal. The type you have directly impacts the cost of your repairs because each has unique features and characteristics. Different problems can occur with each type, and the costs vary accordingly.

The average cost of pedestal sump pump2 repairs is between $150 and $500. They have the motor at the top, where it stays dry, with the drawtube at the base of the sump pit. These types are less expensive to install and maintain, and there is less risk of motor issues. However, problems can still occur with these pumps, such as impeller faults and valve issues.

Homeowners pay between $175 and $550 for submersible sump pump repairs. They are designed to be submerged in water and sit right at the base of the sump pit. They are more expensive to purchase and repair because these pumps are usually complex and involve extra labor. Common problems include motor issues, float problems, and broken impellers.

Location is another factor impacting the cost of sump pump repairs. Pumps can be placed in various spaces around the home, such as crawl spaces, basements, and outdoor areas. Some areas are easily accessible, while others require more work to get to, leading to higher labor costs.

The average cost of basement sump pump repair is between $150 and $550. The basement is the most common location for nstallation. This is because the basement is the lowest point in the house, ideal for collecting water building in the sump basin and removing it. Repair workers are used to working in basements and should charge standard fees for working with this pump.

To repair a sump pump in a garage, expect to pay between $150 and $550 to have it fixed. Just like the basement, the garage is another common location to install them. The costs are generally identical to basement pump repairs because garages are easy to access and do not pose unique challenges.

If you have a sump pump in the bedroom, repairs range from $175 to $575. The bedroom is not common for installation, but you can have pumps in bedrooms, typically in a closet space. You may want to install one in your bedroom if it is on the ground floor or the basement due to the risk of flooding. Accessing these pumps can be a little harder because they are in the closet, leading to slightly higher repair costs.

Repairs for crawl space sump pumps average $200 to $600. Crawl spaces are common locations for installation, but the costs of repairing these are often higher because access can be restricted. This makes it harder for workers to do the repairs, leading to higher labor costs.

Homeowners pay between $200 and $600 for outdoor sump pump repairs. These pumps require special landscaping and usually must be installed in their own trenches under the surface. This means accessing outdoor units can be difficult. More problems can occur with them because they are exposed to the elements. Issues like freezing and rust are common.

Sump pumps have a range of components, including the motor, impeller, and discharge pipe. Issues can arise with each major component of your unit, and some repairs are much simpler and cheaper to complete than others. The table below shows common repairs and the average prices for each.

Expect to pay between $75 and $125 to fix a sump pump float switch. The float switch is the part that controls the pump’s function. The float rises as the water level rises, and at a certain height, the switch opens a circuit that starts the pump. Switches can fall out of position and may require repositioning.

Homeowners pay between $100 and $225 for sump pump impeller repairs. The impeller pushes the water out of the sump pit. It performs a lot of work and can be exposed to tough conditions, meaning the impeller may break or become stuck or dirty. This component may require cleaning, readjustment, or patching to repair minor damages.

The average cost of sump pump discharge pipe repair is between $125 and $300. The discharge pipe transports water from the sump basin and out of the home. Like other pieces of piping, it can become damaged with cracks or holes. It may also become clogged. Plumbers may need to patch superficial damages or flush the pipe to remove the blockages.

To repair a sump pump motor, expect to pay between $150 and $300. The motor is the workhorse of the unit, providing the power the system needs to drain water via the discharge pipe. Several issues can arise with motors, but some simple readjustments and rewiring can solve minor issues.

In some cases, the parts of your unit may be damaged or broken beyond repair and must be replaced with new components. The price of replacements depends on the parts because some are small and cheap to replace while others are more expensive. The table below shows examples of different replacement parts for sump pumps and the costs of each.

The average cost of sump pump float switch replacements is between $100 and $150. If it is not draining correctly and water is building in the pit, the float switch may be broken and must be replaced. Luckily, this is a simple and affordable job because replacement switches are inexpensive and easy to install.

Sump pump valve replacements range from $125 to $200. The check valve controls the flow of water and prevents the pump from re-pumping water that has already been discharged. Valves can be damaged and may need to be replaced if water flows back into the pit after being discharged.

The cost of sump pump impeller replacements averages $125 to $250. The impeller is a vital part of the system, and if yours is broken, you need to replace it as soon as possible. New impellers are relatively cheap, but it can take time to install them, so most costs are for labor.

The cost of replacing a sump pump discharge pipe is between $175 and $600. The total price of the replacement depends on how much piping must be replaced. Some units have short discharge pipes, but others have longer sections of piping. It mostly depends on the location. Longer pipes cost more and take longer to install.

Homeowners pay between $250 and $500 for sump pump battery replacements. Batteries are not always necessary, but it can be a good idea to have a battery as a backup power source for your pump if a storm knocks out the power. The price depends on the battery size and type, with higher-powered batteries costing more.

To replace a sump pump motor, expect to pay between $250 and $500. The motor is usually the most expensive component, so it can be an expensive part to fix. You may need a new motor if the existing one burns out or is seriously damaged and no longer works.

Many problems can arise with your unit. It might make a strange noise, spring a leak, or emit an unpleasant smell. The cost of repairs varies depending on the problem. The table below shows examples of problems and average repair costs for each.

Homeowners pay between $100 and $175 for sump pumps with the float stuck. If the float is stuck on, there are a few possible issues. The float may have become rusted or damaged or the switch may not be working correctly. There might also be dirt or debris interfering with the system, so it may need cleaning or the float might need replacing.

Fixing a sump pump that is making a loud humming noise averages between $100 and $250. They emit a humming noise naturally as they run, but you may have an issue with the check valve or a clog if the humming is unusually loud. The valve might need to be checked or replaced, the clog may need to be cleared, and the impeller might also need to be cleaned.

If your unit is not pumping, expect to pay between $100 and $250 for repairs. Your pump may not be pumping for a few reasons. It could be caused by a clog or issue with the impeller. The pipe may need flushing, or the impeller might need cleaning, readjusting, or replacing.

Sump pumps that smell of rotten eggs cost from $100 to $250 to repair. It is very unpleasant when a unit starts to smell, and it usually happens because the pit dried up and sulfur smells are rising from the sewer. Usually, the pipes may need cleaning, and water may need to be added to the pit to deal with this issue.

If you have mold in your sump pump pit, expect to pay between $125 and $250 to have it removed. Mold can build up in the sump pit if it is not maintained properly and cleaned regularly. This can be unsightly and unpleasant, and the mold spreads if left untreated, so you need to bring in professionals to remove it.

If your unit is clogged, repair costs range from $150 to $300. Theycan clog in several ways. Clogs can build in the pit, pipes, float switch, or other parts. Certain parts may need repair or replacement, and clogs must be flushed.

The average cost of repairing a rusted unit is between $150 and $450. Since they are constantly exposed to water, rust can occur. If rust is spotted early, it could be scrubbed away. However, the affected parts may need to be replaced if the rust is deeper and more extensive.

Leaking sump pump repairs range from $150 to $500. There are a few possible explanations behind a leak. A clogged or leaky pipe could be causing the issue or caused by cracks or loose parts in the system. Usually, a plumber must inspect the pump, find the leak source, and take action like tightening valves or patching the damaged pipe.

If your unit is constantly running after a period of heavy rain, expect to pay between $150 and $500 for repairs. They normally run during periods of heavy rain, so there might not be anything to worry about or any problem to fix. However, there could be an issue with the check valve or motor if the pump continues running, which might need to be repaired or replaced.

Frozen sump pump repairs average $200 to $400. It is usually only outdoor units that freeze. But this can also happen in those located in basements, and it can be a very serious problem to deal with. The pump must be defrosted as soon as possible, and the lines need to thaw. Debris and blockages must be removed to free the system and get it running again.

You need a plumber or sump pump repair specialist to fix your unit. Labor costs usually run between $50 and $100 per hour. Costs vary based on the location and worker experience. Some plumbers have set fees for certain repairs, while others charge by the hour. You need to pay extra for emergency repairs and travel if you live in a remote location. You may also need to pay a minimum fee or call-out fee of $50 to $75.

If you need your sump pump repaired urgently, you typically pay an extra $100 to $200 on top of the usual repair price. This is because plumbers and repair companies may have to adjust their schedules and delay other appointments to rush to your home and deal with the emergency. Emergency repairs may be needed in serious situations like when the pump is broken and water is collecting in your basement or another part of your home.

Sump pump inspections cost between $50 and $100. During an inspection, a sump pump specialist or plumber inspects your unit for damages, looking for things like cracks and clogs. They also check key components of the pump to ensure everything is working correctly. They provide a full report of their findings and recommendations for repairs or sump pump servicing you may require. It is best to get inspections once a year or after heavy rains and storms.

The average cost of professional sump pump maintenance is between $100 and $300. You can also do maintenance yourself to save money. Professional maintenance fees usually cover cleaning the unit, cleaning loose debris, checking the valve, and removing standing water in the sump pit.

If you prefer to do maintenance yourself, you can do several tasks to keep your pump in good condition. Clean the pit, removing debris and loose items. It is also a good idea to test the check valve by pouring water into the pit and checking that the pump responds. The impeller may need to be cleaned. It is also wise to check the float by pouring water into the pit and seeing if it rises.

In some cases, you may hesitate between having your unit repaired or replaced. Usually, the first thing to think about when making this decision is the cost. It typically costs between $700 and $1,600 to replace a sump pump, including the new pump and labor. This process can take a few hours but is simple. So if the estimated cost of your repairs is higher than the cost of a new pump or you have repeatedly paid for repairs, it may be a good idea to purchase a new one.

Also think about the age. Sump pumps last from 5 to 30 years. Submersible models are less long-lasting, with estimated lifespans of around 5 to 15 years. Pedestal pumps can run for around 15 to 30 years. If your pump is old and approaching the end of its lifespan, it may make sense to purchase a new one to save money and avoid problems.

Sump pump removal should cost around $100 to $200. This fee should cover uninstalling the pump and disposing of it. You may want to have a sump pump removed if you are planning on installing a new one in the same location later or want to install a new unit in a different location.

The cost of professional sump pump cleaning is between $100 and $200. This fee usually includes a range of cleaning processes, including cleaning the valve, getting rid of standing water in the pit, and cleaning loose dirt and debris from around the pump. It is a good idea to professionally clean your pump annually, or you can save money by cleaning it yourself.

The cost of sump pump freeze protection ranges from $125 to $250. It can be important to have freeze protection fitted to sump pumps at risk of freezing in areas like crawl spaces and backyards. Different freeze-protection accessories, such as overflow devices and drains, can fit to the pump to allow water to escape even if ice or snow builds up and blocks the main line. Insulation may also be installed around the line to reduce freezing.

Additional Considerations and CostsInsurance. You can have your unit insured, and some homeowner’s policies include sump pump coverage as standard, but others do not. Read the fine print and be aware of what your policy covers. You could customize your existing policy to add sump pump protection.

Permit. You do not usually need a permit for minor repairs and maintenance like fixing impellers and cleaning the unit. However, for more extensive jobs that involve alterations to the pipes, a permit may be needed. Consult with your local building authority for more information.

High bills. Sudden and unexpected rises in utility costs can often be a sign of problems. If you notice your utility bills are suddenly high, it may be a sign the sump pump has sprung a leak and must be repaired.

Lifespan. The lifespan depends on its type, location, and amount of maintenance. Pumps last from 5 to 30 years, with submersible pumps lasting around 5 to 15 years and pedestal pumps lasting 15 to 30 years.

DIY. You can do minor repairs and maintenance on your unit if you know what you are doing. Big issues like fixing broken motors and replacing components should always be left to the professionals.

Troubleshooting. There is a simple test you can do to troubleshoot your unit . Pour water into the pit and check that the float rises to ensure it is working. You should also check that the pump triggers and starts working to ensure the check valve is functioning.

Several things could cause a unit to stop working. The float switch or impeller might be jammed, the pump may not be getting power, a part might be broken, or dirt and debris could be interfering with the system.Does insurance cover sump pump failure?

It can, but it depends on the details of your specific policy. Some home insurance policies cover sump pump system failure, but others do not.How do you reset a sump pump?

There is usually a reset button on the motor you can press. Otherwise, you must turn the pump off or unplug it, clean and inspect it before plugging it back in, and switching it on.Do sump pumps need maintenance?

Yes, they require some maintenance to remain in good working order. They usually must be cleaned and inspected regularly.Is it normal for a sump pump to run every 15 minutes?

Yes, but it depends on the water level in the area. During rain and storms, sump pumps can run very regularly. They may also run frequently in the spring when the water table is higher from winter run-off.How often should you check your sump pump?

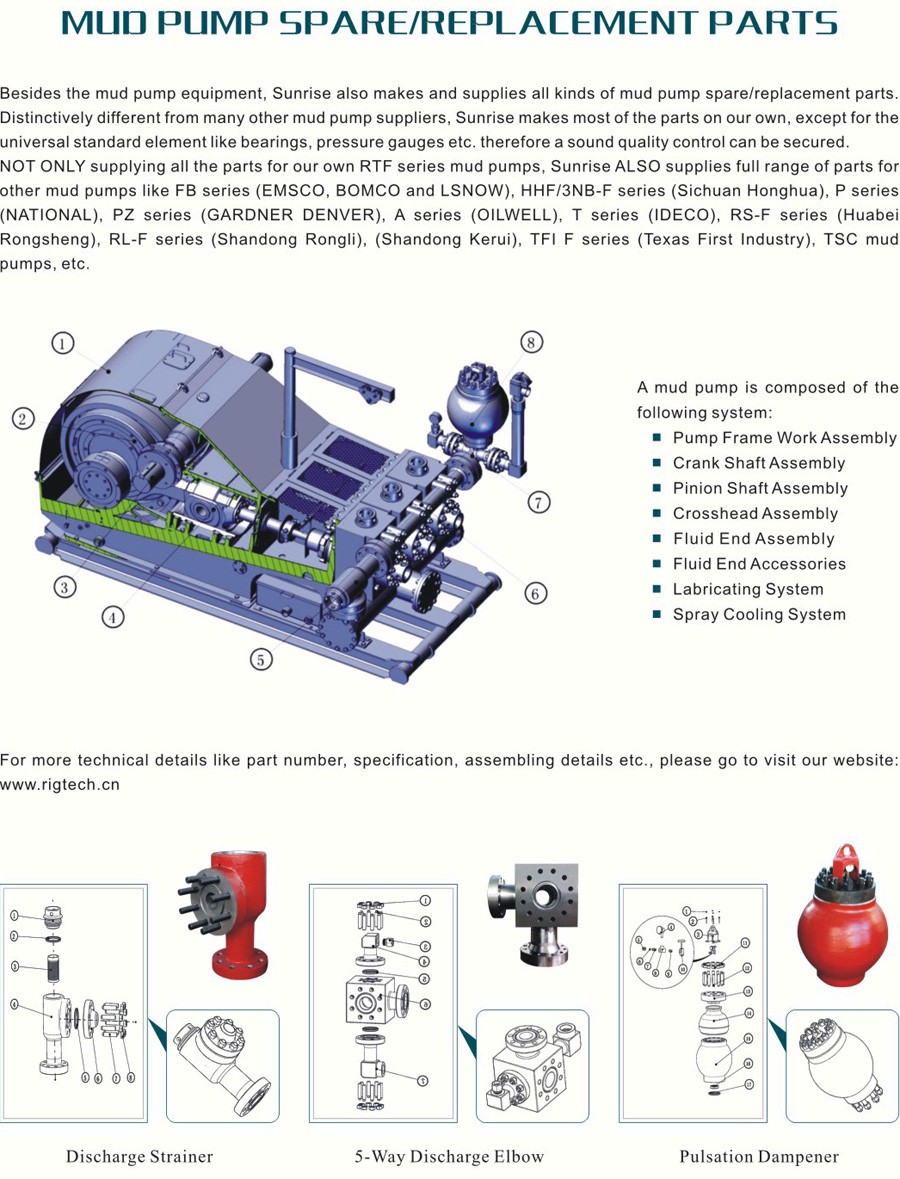

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

Suction stabilizer units can mitigate most of the challenges related to pulsations or pressure surges, even in the most complex piping conditions. The resulting benefits prevent expensive unplanned downtime and decrease costs and inconvenience associated with system replacements and repairs.

Repairing your pumps quickly and efficiently to get your operations back up and running is GD Energy Products’ top priority. If your pump requires immediate attention, our field engineers and service technicians can be deployed to your job site or facility. Our experienced technicians are trained to identify and inspect your pumping issue and conduct as-needed service, repairs and preventative maintenance at your preferred location.

GDEP offers a full range of 24/7 on-site pump maintenance and repair offerings tailored to your individual needs. We offer comprehensive repairs for fracking pumps, drilling pumps, well service pumps, fluid ends and modules. Additionally, our customers have access to 24/7 service, ongoing parts support and product maintenance.

GDEP’s inspection program offers a comprehensive and proactive approach to solving your pump issues. Our field service technicians can utilize advanced troubleshooting procedures to uncover various underlining issues with the capability of performing onsite repairs using genuine, high-quality OEM replacement parts to guarantee maximum performance

If you have a large fleet or pumps that simply require more attention, we can provide you with a dedicated field service technician with either half-day or full 24/7 coverage.

Our state-of-the-art repair facilities operate in a constant state of readiness to provide your pumps with the most comprehensive and cutting-edge repair and maintenance services. With facilities strategically located in all major shale plays throughout the United States, we are able to provide our customers with efficient service on a local level.

If you have a large-scale repair that cannot be completed in the field, bring your pump to any one of our repair facilities and expect the same level of service and expertise. A highly trained and experienced team of field engineers, service technicians and repair mechanics possess all the necessary skills and insights required to overhaul any pump, all under one roof. Backed by our satisfaction guarantee, you can have the confidence your pumps will operate at peak performance after it leaves our facility.

Our dedicated customer support team ensures the whole process is transparent and efficient, from the initial call and throughout the entire repair process.

Our team of experts is available 24/7 to service and repair any brand of pump. Whatever your repair needs, GDEP will bring the proper experience, tools and equipment needed to get the job done.

As part of Experience 360, our Parts on Demand program lets you manage your replacement parts inventory at your regional location, pump site, or even via GD Energy Products Parts on Demand mobile trailers.

These Frac and Mud Pump Consumables are OEM-certified parts, designed, manufactured and tested by our Pump experts, and proven to maximize the performance on your operation. Our parts are always available, ensuring you have what you need, whenever and wherever you need it.

Typically, well pumps can be broken down into two categories: jet pumps and submersible pumps. Each design is built to fit the needs of various well sizes and conditions.

Most shallow well pumps are found in wells that are less than 25 feet deep and in areas with a high water table. These pumps have few running parts and require little maintenance.

This type of pump is located above the ground, typically just inside the well house, and generates high pressure to pull the water from the well and into the home using an inlet pipe. A tank or well booster pump is recommended to accompany this type of well pump to increase water pressure to the home.

Unlike its shallow counterpart, a deep well jet pump is located within the well, though its motor stays in the well house. This pump uses two pipes: one for drawing water out of the well and another for directing the water to the home. Deep well jet pumps are typically used in wells that are 110 feet deep.

A deep well submersible pump sits at the bottom of the well directly in the water. Using its motor, the pump draws water from the bottom and pushes it out of the well into your home’s water lines. These pumps can be used in wells up to 300 feet deep. The pumps work similar to sump pumps, which draw water and pump it out.

Although professional well pump replacement comes with high pump installation costs, you may have no choice but to call a professional depending on the well pump you have. Certain pumps, like deep well submersible pumps, require special equipment to get them out without damaging components or wiring. In addition to the fragility of the well’s components, removing a well pump can be very labor intensive, with some pumps weighing more than 100 pounds.

Even if you’re considering replacing your well pump on your own, call a plumber to confirm that the well pump is the issue with your system before removing it. This will prevent any unneeded work or unintentional damage to your well system.

Use the tool below to find a well service contractor who can diagnose your well pump problem and help you determine whether or not you can replace it yourself:

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

8613371530291

8613371530291