pony rod mud pump brands

Pony rod also called the intermediate rod, is an important part of the connection between the crosshead and the piston rod. It is the key component that connects the power end and the hydraulic end of the mud pump. One end is connected to the crosshead and the other end is connected to the piston rod by a clamp. Its outer circumference is filled with a packing box assembly. In the reciprocating motion, the outer circle of the intermediate tie rod and the sealing member in the packing box rub against each other. To ensure it"s wear resistance, the outer surface of the intermediate rod is hard chrome-plated.

We can offer a wide range of extension (pony) rods for triplex mud pumps that are made of high quality alloy steel (40Cr). After strict heat treatment of quenching and high temperature, the rods have the features of high intensity on surface and high tough inside. The surface is treated with galvanization or nitrogen for high intensity and low abrasion.

31 mud pump pony rod products are offered for sale by suppliers on Alibaba.comAbout 70% % of these are mud pump, 12%% are pumps, and 9%% are mining machine parts.

A wide variety of mud pump pony rod options are available to you, You can also choose from new, mud pump pony rod,as well as from energy & mining, construction works , and machinery repair shops mud pump pony rod, and whether mud pump pony rod is 1.5 years, 6 months, or 3 months.

8 pony rod for emsco mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 75%, mining machine parts accounts for 25%.

A wide variety of pony rod for emsco mud pump options are available to you, You can also choose from new, pony rod for emsco mud pump,as well as from energy & mining, machinery repair shops, and manufacturing plant pony rod for emsco mud pump,And whether pony rod for emsco mud pump is 3 months, {2}, or {3}.

The Sur-Lock Rod Link System was developed to provide a safer and faster way to unfasten the piston rod and remove the piston from the liner. The sub rod contains a proprietary “wedge lock” mechanism that allows the piston and pony rods to be connected by simply inserting pins and turning a bolt. No hydraulic fitting, seals, or pumps are necessary.

The system uses rods and rod extensions that are 100% compatible with the same parts from the P-Quip system. Additionally, our torque module can completely replace the P-Quip hydraulic module in plug-and-play fashion.

We developed the Sur-Line system to prevent mud and other fluids from passing into the power section from the fluid end section of the mud pump, and to prevent fluid from going from the power section into the fluid end section.

The Sur-Line system uses a unique floating seal system that bolts into the wall between the power section and the fluid end section. The seals inside this housing seal against the OD of the pony rod, thus preventing fluid from passing between the two sections of the mud pump.

We carry parts to fit pumps from most major manufacturers. Sur-Line® systems are simple enough to be installed by the rig crew, or can be installed by our technical service department at the rig site.

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

We carry mud pumps, connecting rods, and more than 2,000 drawings and blueprints of oilfield equipment and supplies. We can fill your orders with one-of-a-kind designs for:

Our vast inventory of fluid-end and gear-end parts for duplex pumps includes more than 500 duplex liners, as well as cages and stuffing boxes. If you can’t find the model you are looking for below, let us find it for you.

We carry more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. Though we keep in stock connecting rods primarily for GA550 and GA750 models, other options are available, including custom connecting rods for most duplex and triplex mud pumps.

We now offer crossheads and guides for both EMSCO D-375 and DB-550 duplex pumps. We also have slides and shoes for certain models. If you don’t see a part you need, let us find it for you.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

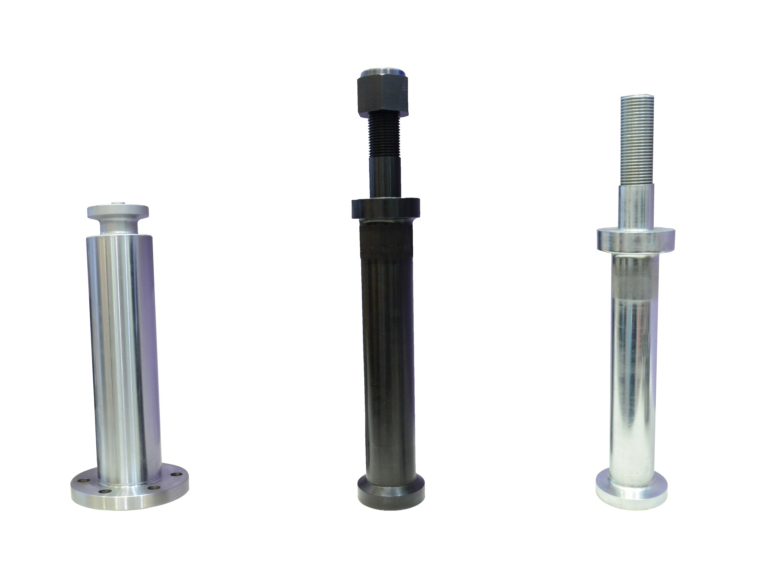

Best-all provide OEM style piston rod and pony rod (extension rod) including clamp type and thread type, for most popular triplex mud pumps in the world.

Manufactured by quality forged alloy steel , heat-treated and precision machining assure our piston rod and pony rod with high strength and good concentricity.

Plunger pumps are the workhorse of oil and gas fracking and drilling operations. They circulate high pressure fluid down the well and back up the annulus in both land and off-shore operations. When pumps are offline for planned or unplanned maintenance to replace leaking fluid, or worn seals, your operations stop.

Parker’s patented pony rod seal extends continuous service with a longer lasting, reliable design that retains lubrication and prevents leakage of hydraulic fluid in the power end and also serves as a rod wiper to keep contaminants out.

This system significantly improves safety and installaion / maintanance time as individual rod pieces can be removed and replaced for fast access to the Fluid End.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Our piston rods are manufactured from high quality alloy steel. Surface is induction hardened for maximum case hardness and core strength - hard on the outside, tough on the inside. Precision ground mirror surfaces meet rigid quality control standards and minimize wear.

High quality Grayloy material is used on all HNA Duplex Piston Rods. This corrosion-resistant, high-density, long-wearing surface results in fewer packing changes and longer life for gland bushings and junk rings. HNA rods are furnished with a heavy duty Piston Lock Nut.

HNA offers a full range of clamps for mating the piston rod to the crosshead extension (pony) rod. Machining tolerances are tightly held to assure proper fit and alignment of the adjoining components. HNA clamps are furnished complete with all required hardware.

8613371530291

8613371530291