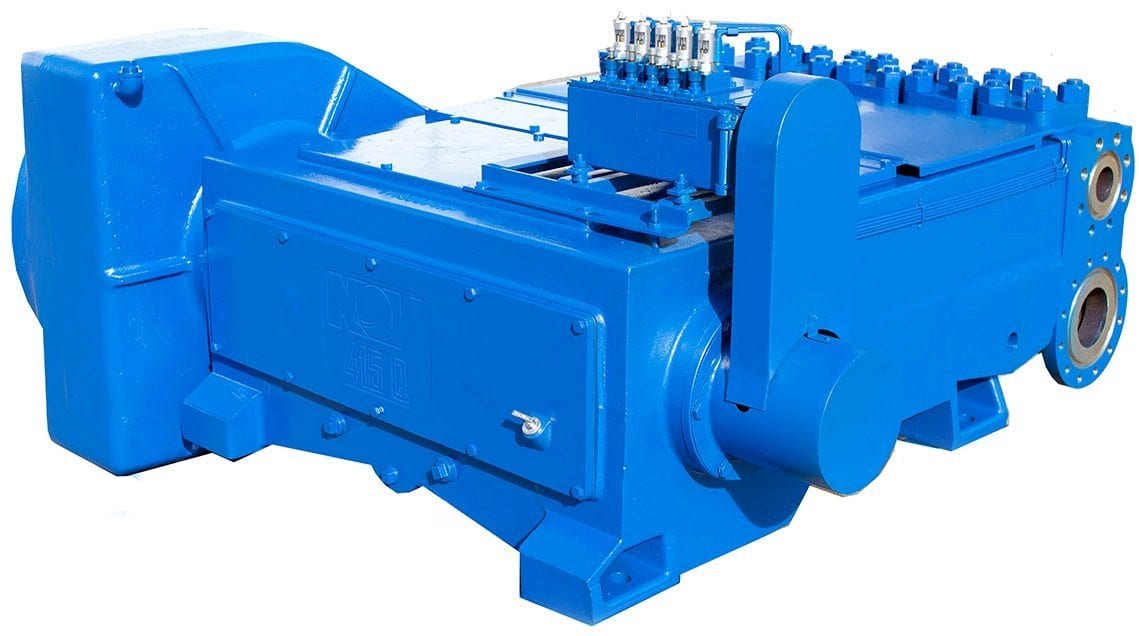

quintuplex mud pump for sale

A quintuplex pump has a crankshaft supported in the pump by external main bearings. The crankshaft has five eccentric sheaves, two internal main bearing sheaves, and two bull gears.

A quintuplex pump is central to oil drilling and exploration due to the nature of operations. This pump circulates the mud to and from the surface, supporting the process for oil well operations.

The quintuplex pump is designed to circulate mud or drilling fluid under great pressure down the drill hole and back up. The pump is a reciprocating model that features five pistons, hence the name quintuplex mud pump. The right degree of pressure and precision is crucial for efficient well operations.

Despite the fact that all mud pumps have pulsation dampeners, noise levels are likely to be high and require modifications to keep noise pollution levels low. This is important, considering the long-running hours of equipment and the need to protect personnel from constant and high noise levels. With a quintuplex mud pump, the pulsation noise and the mud telemetry noise come down by as much as half, making operations less noisy.

Quintuplex pumps can be used in various applications including salt water disposal, descaling, high pressure pumping, Frac pumping, pipeline transfers in the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors.

Mud pumps comes in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pumps are the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers.

Duplex, triplex and quintuplex pumps all have an enviable history of sound engineering, designed to exceed the rigorous requirements of API 674 and customer satisfaction.

Quintuplex Pumps - Used Bethlehem TP-6 triplex pump. 6" stroke, aluminum bronze fluid end, 4 1/2" plungers, gear reducer. 279 max gpm, 629 max psi, 225 max rpm. More Info

Quintuplex Pumps - 350 HP, 5" Stroke Quintuplex Pump, Forged Carbon Steel Fluid End With 2 1/4" plungers, 4" 300 # Suction, 2" 2500 # Discharge.155 GPM MAX, 3483 PSI MAX, 360 rpm max. More Info

Quintuplex Pumps - Used Oilwell B-558 quintuplex plunger pump, same as NOV 630Q-8L, steel billet fluid end, with 4.5" plungers, 619 gpm max, 1575 psi max, 225 rpm max. More Info

Quintuplex Pumps - Used Wheatly 5p-323 quintuplex, aluminum bronze head, 2.5"" steel plungers, power end in excellent condition, mounted on skid, bull wheel and 40 hp electric motor. More Info

Quintuplex Pumps - Used Wheatley HP-375L quintuplex plunger pump, steel billet fluid end, with 4" plungers, 500 gpm max, 995 psi max, 300 rpm max. More Info

Pivotal to drilling and production, multiplex drilling pumps for sale have increased operational efficiency through the ability to ferry large volumes of fluid. At the heart of the quintuplex drilling pump developed by ShalePumps, lies a design that exploits the output of additional cylinders to curb pulsation variance.

Packed into physically smaller dimensions, the power packed quintuplex drilling pump assures a steady flow at the surface. With proven reliability, the quintuplex pump keeps the fluid in circulation, maintaining optimal pressure and volume, fetching debris effortlessly from the wellbore.

The featured quintuplex drilling pump combines structural superiority and engineering knowhow for enhanced life expectancy in continuous operations. Additionally, Measurement While Drilling (MWD) and Logging While Drilling (LWD) operations are substantially improved by the increased data transfer rate bandwidth.

The design accomplishes the added objective of extending life of downhole tools through operational precision of the quintuplex drilling pump. Improved rate of flow helps in cutting overall costs, dispensing with the need for many pumps. ShalePumps, possessing the technical expertise with an extensive range of proven solutions, takes great care to incorporate high quality components in every quintuplex drilling pump. The crankshafts, piston rods, liners, connecting rods, bearings etc are all of the highest quality. Each quintuplex drilling pump, despite the composition of high wear components, is guaranteed to offer longer continuous life.

ShalePumps is proud to bring the quintuplex design to a new level. Built to be smaller, lighter and smoother than any conventional triplex design. The addition of a fourth and fifth cylinder decreases pulsation variance to a minimal level. This increases accuracy and precision during LWD and MWD applications and increases the life expectancy of down-hole tools.

The plunger pump is an important device for the hydraulic system. It relies on the plunger to reciprocate in the cylinder to change the volume of the sealing working chamber to achieve oil absorption and oil pressure. The plunger pump has the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment.

Piston pumps are widely used in applications where high pressures, high flow rates, and flow rates need to be adjusted, such as hydraulic presses, construction machinery, and ships.

Used National Oilwell NOV J-250-H Quintuplex Injection Pump, (J-275-H, 300Q-5H), s/n 220, 1 3/4" Metal Plungers x 5" Stroke, Bronze Fluid End, c/w Reducer, 4.84:1 Ratio

All CategoriesBuildings (4)Drilling Equipment (168)Additional Drilling Equipment (1)Block (4)Centrifugal Pumps (2)Drilling Equipment - Misc. (1)Duplex Pumps (13)Power Swivels (14)Pump Parts (1)Pumps (57)Pumps - Misc. (12)Rotary Tables (7)Rotating Equipment (21)Sheaves (1)Traveling Equipment (5)Triplex Pumps (29)Drilling Equipment - Misc. (3)Fluid End Modules (2)Hoisting Equipment (5)Oilfield - Misc. (3)Additional Oilfield Equipment (1)Catwalks (2)Power Equipment (10)Air Compressors - Industrial (2)Engine Accessories (2)Engines - Other (3)Gear Boxes | Drives (1)Generators | Electric Power (2)Production Equipment (26)Compression Equipment (3)Gas Compressors (3)Tanks (6)Tanks - Misc. (4)Vessels - Horizontal | Vertical (2)Well Service Equipment (4)Well Service - Misc. (4)Pumps (69)Centrifugal Pumps (4)Duplex Pumps (12)Pump Packages (2)Pump Parts (3)Pumps - Misc. (18)Quintuplex Pumps (4)Triplex Pumps (24)Water Injection Pumps (1)Rig Structures (1)Rotating Equipment (28)Power Swivels (16)Rotary Tables (12)Support Equipment (20)Air Compressors - Industrial (4)Buildings (1)Catwalks (3)Doghouses (1)Generators | Electric Power (2)Oilfield - Misc. (3)Power Equipment (6)Tanks & Vessels (15)Tanks - Horizontal | Vertical (1)Tanks - Misc. (12)Trailers (15)Traveling Equipment (16)Block & Hook Combos (4)Blocks (5)Sheaves (7)Triplex Pumps (4)Saltwater pumps (1)Trucks (2)Flatbed Trucks (1)Water Trucks (1)Well Service Equipment (9)Power swivels (1)Swabbing Unit (1)Triplex Pumps (1)

Now we has a complete series of high pressure plunger pumps, ranging from 500 hp to 7,000 hp, suitable for various applications such as cementing, acidizing and fracturing. Spare parts mainly include fluid cylinder, valve, valve insert, valve seat, plunger, packing set, junk ring, valve spring and seal. Such complete inventory effectively guarantees quick delivery. Besides, good interchangeability of spare parts can meet customer’s unique requirements.

JR1000QS pump is a quintuplex plunger pump with offset design similar to JR600S in configuration, yet with higher horsepower and larger displacement under the same pressure. The compact structure enables twin-pump layout on one unit, making it the top choice of cementing and fracturing unit.

Under high pressure and large displacement, plunger pumps are easy to fail, among which fluid cylinders are key components in pumping operation. Based on years of field research and verification, Jereh engineers have improved product design, analyzed fatigue, strength and material and successfully developed many types of fluid cylinders, either made of conventional materials or stainless steel. Besides, Jereh has a large inventory of spare parts with many varieties and good interchangeability. Customized design is also available.

F04B15/02—Pumps adapted to handle specific fluids, e.g. by selection of specific materials for pumps or pump parts the fluids being viscous or non-homogeneous

"Triplex Mud Pump Parts and Accessories;" Product Information Brochure; copyright 2007 Sunnda LLC; downloaded from http://www.triplexmudpump.com/triplex-mud-pump-parts.php on Sep. 5, 2008.

"Triplex Mud Pumps Triplex Mud Pump Parts for Sale;" copyright 2007 Sunnda LLC; Product Information Brochure located at http://www.triplexmudpump.com/.

"Triplex Mud Pumps Triplex Mud Pump Parts;" copyright 2007 Sunnda LLC; downloaded from http://www.triplexmudpump.com/F-series-triplex-mud-pumps-power-end.php on Sep. 5, 2008.

China Petrochemical International Co., Ltd.; "Quintuplex Mud Pump;" Product Information Brochure downloaded from http://www.intl.sinopec.com.cn/emExp/upstream/Quituplex-Mud-Pump.htm downloaded on Oct. 2, 2008.

FMC Technologies; "Fluid Control: Well Service Pump;" Product Information Brochure; downloaded from http://www.fmctechnologies.com/-FluidControl-old/WellServicePump.aspx on Sep. 5, 2008.

National Oilwell; "Triplex Mud Pumps;" Product Information Brochure; downloaded from http://nql.com/Archives/2000%20Composite%20Catalog/pg-32.html downloaded on Sep. 5, 2008.

8613371530291

8613371530291