self priming mud pump in stock

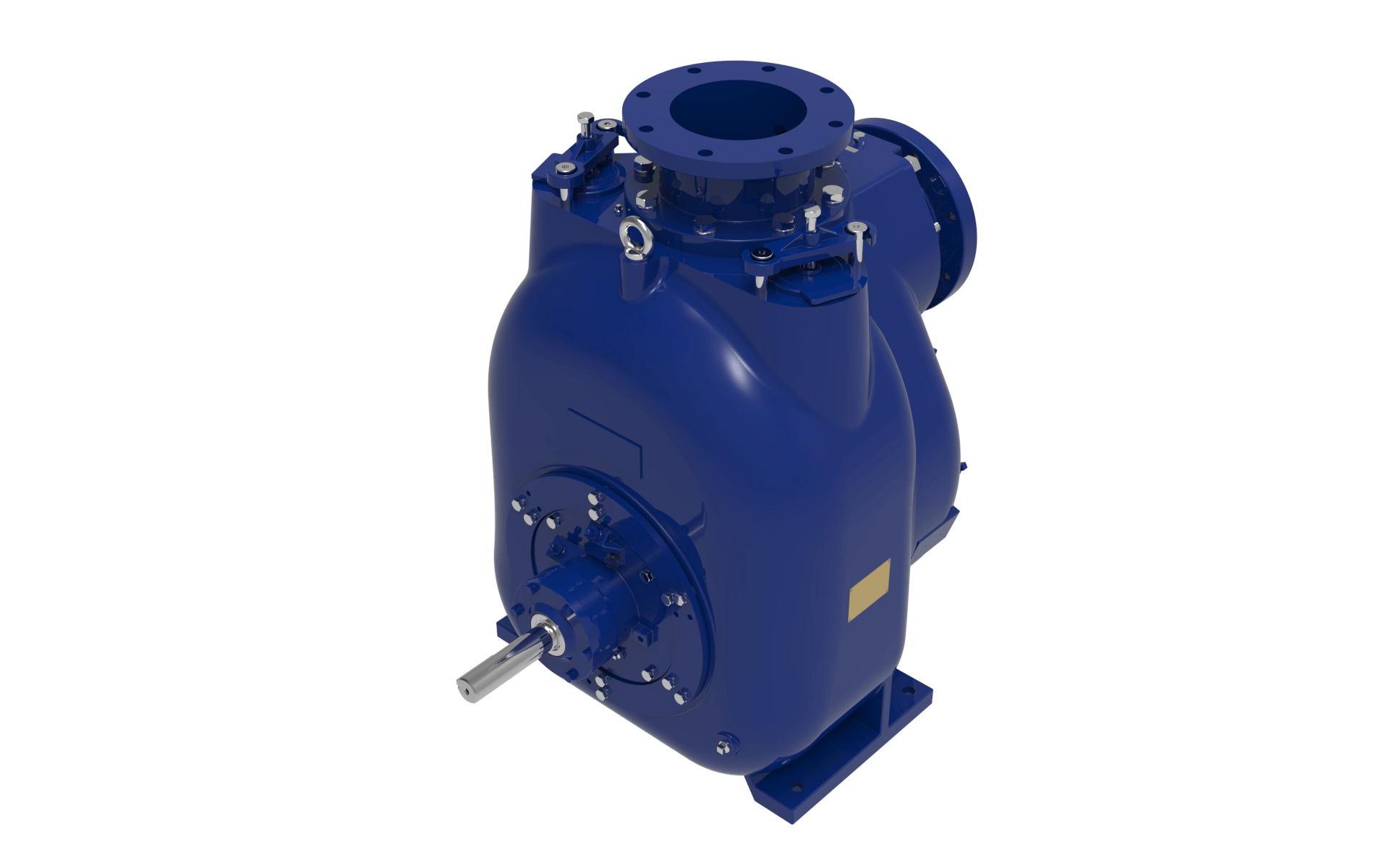

The "VIRAJ" make "VSPM" series is designed in self priming Non-clog Horizontal pump of Mono Block and only pump construction. This series pumps available with semi open type impeller s per customer application. This pump future is quick self priming action, long life due to replaceable wearing parts and for priming no need foot valve and easy maintenance and spare available.

Self priming Centrifugal pumps are a type of end-suction centrifugal pump which can operate in a suction-lift configuration without requiring an external priming system. A standard pump needs to have a suction pressure to operate. If a pump is situated above the liquid level such as on top of a tank then the pump needs to self prime to draw the liquid in to the inlet. Self priming centrifugal pumps should have the casing filled with liquid prior to start up. Upon starting, the pump creates a vacuum ensuring liquid is drawn towards the inlet of the pump, separating the air from the water. The air is discharged through the outlet with the liquid remaining in the pump until sufficient liquid enters the pump.

The liquid placed in the pump head prior to start up is needed to allow the pump to cool and assist with priming. As well as light fuels and water, self priming centrifugal pumps can also handle solids, and liquids with entrained air.

Self priming water pumps should be positioned as close as possible to the suction surface as the maximum distance any pump is able to self-prime is 10 metres at atmospheric pressure.

The centrifugal pump is the most used pump type in the world. The principle is simple, well-described and thoroughly tested, and the pump is robust, effective and relatively inexpensive to produce.

An increase in the fluid pressure from the pump inlet to its outlet is created when the pump is in operation. This pressure difference drives the fluid through the system or plant.

The centrifugal pump creates an increase in pressure by transferring mechanical energy from the motor to the fluid through the rotating impeller. The fluid flows from the inlet to the impeller centre and out along its blades. The centrifugal force hereby increases the fluid velocity and consequently also the kinetic energy is transformed to pressure.

Our Non-Clog Self Priming Mud Pump Is Prime Quality Of Industrial Pump Used To Circulate The Mud. It Is A Non-clog Gland Packing Type Pump Also Known As SSPP Series Of SUJAL ENGINEERING. Basically MUD PUMP Is Mainly Applicable For To Circulate Drilling Mud On A Drilling Rig At High Pressure.APPLICATIONS:ETP, STPWater From MarineCeramic IndustriesPumping Of Domestic Sewage PlantsSwimming PoolsMERITS:Low MaintenanceQuick Priming Of Dirty WaterAutomatic Air Release Du Continue

Self-priming centrifugal pumps are unique. As the name suggests, they have the ability to prime themselves under suction lift conditions. They draw fluid up from tanks or pits below, making them easier and safer to work on than those that work below ground. Under the right conditions, they’ll free themselves of entrained gas and function normally on their own, but sometimes, they can’t.

A BRIEF NOTE OF CAUTION:Just because self-priming pumps able to pull fluid into them, doesn’t mean that they should start up dry. Self-priming, centrifugal pumps need fluid in the casing to get started. Running dry, even for a short while, will cause damage to the mechanical seal, and pump failure.

Once the pump is turned on, the impeller begins to turn in a counter clockwise rotation. The fluid inside, or the “initial prime”, flows through the volute into the discharge cavity. Here, the air and fluid separate, the air evacuates through an open ended line, or air release line, while the fluid returns to the impeller through a recirculation port.

As fluid moves up the suction line, the air ahead of the fluid is pushed into the casing and handled as the initial prime was handled through the recirculation process. Once the fluid arrives in the pump, it operates as normal.

As fluid recirculates in the pump and forces air out of the discharge chamber, it’s trying to create an area of low pressure. However, if there’s a leak in the suction line, air continues to be drawn into the pump, never allowing it to release enough to create that area of low pressure.

If a valve on the air release line is closed, and the valve on the discharge line is closed, again, it"s giving no place for the air to go and get out of the pump.

If there is excessive clearance between the impeller and the wear plate, the pump has a difficult time creating a low-pressure area. This is typically caused by wear, but could also be due to improper reassembly.

During the priming process, as discussed above, fluid is recirculated through the volute casing. If the recirculation port becomes plugged, the eye of the impeller is unable to create an area of low pressure in which to pull liquid up the suction line.

If you’ve undersized the pump for the suction line, it will not be able to create the low-pressure area it needs to prime. It’s important to understand the suction lift requirements before selecting a pump for the application. Use Gorman-Rupp’s Pump Selection Guide for the calculations you’ll need.

The ability for self-priming pumps to prime hinges on all the right conditions. The pump must be able to evacuate air from inside the pump, create a low-pressure area at the eye of the impeller, and also be properly sized for the right NPSHconditions.

Engineers and experts rely on Crane Engineering for insight and help with centrifugal pumps and positive displacement pumps. Our in-house team of engineers can answer questions related to not only pumps but valves and skid systems. We provide a complete service and repair team who will fix pumps back to OEM standards. We are ready to assist you, contact us, today!

The XR316 is part of the North Ridge XR series - a line of self-priming centrifugal pumps that are designed for heavy duty operation within the construction, industrial, emergency and marine industries.

Designed for the handling of clean, solid laden, flammable and abrasive liquids, its unique internal armoured volute protects the main pump casing from wear and fluid contact, by absorbing any impact from the pressurised liquid.

The XR series are rapid self-priming pumps, capable of priming from 4M in under 2 minutes due to its uniquely designed double-curved impeller optimised for high efficiency (up to 74%) without compromise to solid passage and priming time. This model can handle solids up to 35mm x 25mm in size.

Each pump within the XR series is also constructed with an enduring design philosophy. A wide range of material options are available ranging from Cast Iron to Bronze, Stainless Steel and hardened material alternatives. This allows for maximum efficiency in any application as well as providing reliability and longevity. Our unique construction means many ranges share the same internal parts reducing stock holding of associated spare parts across models.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

“EXCEL Self Priming Mud pumps are available in variety of materials like Cast Iron, Stainless Steel or CI/SS combination. Pumps from 1.5″ to 6″ offered for various pumping needs. Manufactured using the finest raw materials EXCEL Self Priming Centrifugal Mud Pumps are known for their impeccable functionality. The offered pumps are widely praised for their low energy consumption and easy installation, operation & maintenance. Further, their sturdiness and resistance to corrosion, render them a longer lifespan.

8613371530291

8613371530291