discharge module mud pump quotation

Explore a wide variety of mud pump modules on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump modules are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump modules is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump modules for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump modules to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

A wide variety of mud pump module options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mud pump module,as well as from energy & mining, construction works , and machinery repair shops mud pump module, and whether mud pump module is 1.5 years, 6 months, or unavailable.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

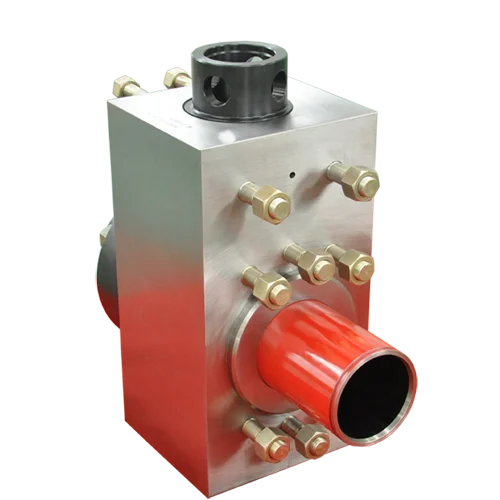

NOV 9-P-100 Mud Pump Fliud End Discharge Module 1293240 1293241 standard one-and/or-two-piece configuration, with designs available for pressure of 5000psi(35.1Mpa), 7500psi(52.7Mpa), and 10000psi(70.3Mpa); discharge connections available on each side; suction connections on each side or front center.

YINDA offers a complete line of accessories for OEM fluid end modules, CNC machining makes these accessories uniformly dimensional and interchangeable with OEM.

Heat-treated and internally hardened for high durability; available in various materials to meet a wide range of applications; standard one-and/or-two-piece configuration, with designs available for pressure of 5000psi(35.1Mpa), 7500psi(52.7Mpa), and 10000psi(70.3Mpa); discharge connections available on each side; suction connections on each side or front center.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

YINDA offers a complete line of accessories for OEM fluid end modules, CNC machining makes these accessories uniformly dimensional and interchangeable with OEM.

YINDA offers a complete line of accessories for OEM fluid end modules, CNC machining makes these accessories uniformly dimensional and interchangeable with OEM.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

Topland"s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel, heat treated for a long working life, machined to perfection and packaged for delivery with anti-corrosion protection.

Hydraulic cylinder is also called the valve box, it is a major part to the fluid end parts. Blank forged by highstrength alloy steel. After heat treated, with multi-channel processes. The three cylinders of each pump is interchangeable. The following key parts: cone sawtooth thread of cylinder head, connect of the curve of all the screw hole and inner cavity.

We can also supply modules forged by alloy 35CrMo or 40CrMoMn. It is of high quality with secondary smelting, and with deoxygenates treatment. It is manufactured according to JB/TQ252-81 Specification and with high mechanical performance. Topland suppliesa complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such as National, Emsco, Gardner Denver, Bomco, Ideco,Weatherford, Drillmec, Texma, Mud King, Honghua, RG, RS, GPM, LS-NOW, Wirth and Oilwell.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

HNA"s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel, heat treated for a long working life, machined to perfection and packaged for delivery with anti-corrosion protection. The precision-made jewelry, like the exterior finish, reflects the superior quality inside.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

.jpg)

BRAND NEW SURPLUS mud pumps for immediate sale. These are (3) three New National NOV 12-P-160 Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. These NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service. The pumps have never been installed or used.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

mud pump parts ,shale shaker screen ,drilling handling tools ,frac plunger pump parts ,triplex mud pump liner ,triplex mud pump piston ,triplex mud pump valve seat ,oilwell repair piston pump

8613371530291

8613371530291