drillmec mud pump manufacturer

Drillmec designs and manufactures high-performance triplex mud pumps for onshore and offshore drilling applications to enhance drilling rates and reduce costs, remarkably minimizing the environmental impact.

Drillmec triplex mud pumps can be equipped with the P-Quip fast release system for valve cover, rod and liner. All the mud pumps can be mounted on a oilfield heavy duty skid or can be trailerized according to the client’s need.

Mud pumps are akin to the heart, they are key equipment in oil and gas drilling that pumps and circulates the drilling mud. As a key player in the manufacture and sales of oilfield equipment, we have a complete range of triplex mud pumps with compact design, reduced carbon emission, and improved performance.

Our classes of onshore and offshore mud pumps range from 450 to 2,200 hp diesel or electric (AC or DC) powered with 3000 to 5000 psi ratings. We design our mud pumps to match different rig types, work optimally and safely both onshore and offshore.

Mud pumps are akin to the heart, they are key equipment in oil and gas drilling that pumps and circulates the drilling mud. As a key player in the manufacture and sales of oilfield equipment, we have a complete range of triplex mud pumps with compact design, reduced carbon emission, and improved performance.

Our classes of onshore and offshore mud pumps range from 450 to 2,200 hp diesel or electric (AC or DC) powered with 3000 to 5000 psi ratings. We design our mud pumps to match different rig types, work optimally and safely both onshore and offshore.

As a leading OEM Drillmec has been designing and building drilling equipment for many years. All our components are designed to mechanize and automate complex drilling rig processes. Our complete portfolio includes top drives mud pumps, drawworks, iron roughnecks up to the latstst innovative Stinger, Drillmec"s innovatite pipe handling system.

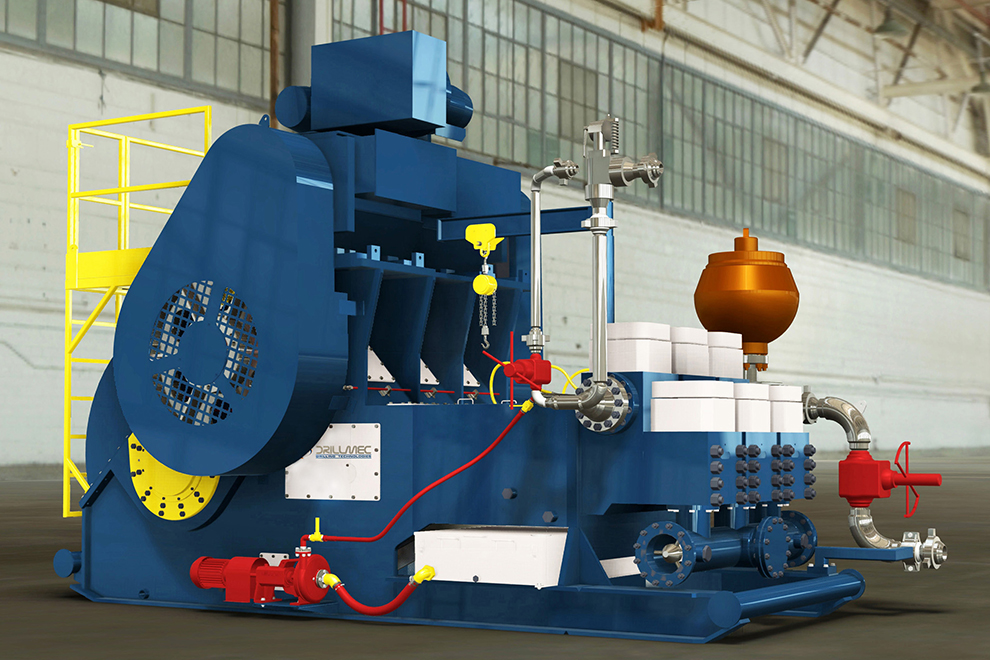

DRILLMEC’s GD Series is the new generation of Gear Driven Triplex Mud Pumps in the ranging from 1600 to 2400 hp for both onshore and offshore drilling operations. The direct gear driven transmission between the AC motor and the cranshaft together with the top mounted configuration gives to the GD Series Mud Pumps a very compact design despite their high volume and high pressure capabilies.

DRILLMEC’s GD Series is the new generation of Gear Driven Triplex Mud Pumps in the ranging from 1600 to 2400 hp for both onshore and offshore drilling operations.

The direct gear driven transmission between the AC motor and the cranshaft together with the top mounted configuration gives to the GD Series Mud Pumps a very compact design despite their high volume and high pressure capabilies.

Drillmec is a worldwide leader in design, manufacturing and integration of full drilling rig and workover packages for onshore and offshore applications. Drillmec’s drilling equipment and services close to the circle to provide drilling contractors and oil companies a one stop shop for reliable and innovative solutions based on more than 100 years of experience and history.

Drillmec offers a comprehensive line of offshore equipment for platforms, jack-ups, barges, semisubmersibles and drill ships that can handle a wide range of E&P and production requirements. From well head to crown, Drillmec supplies mud systems, mud pumps up to 2,200 hp, drawworks packages up to 4,600 hp, control rooms, derricks, pipe handling systems, power tongs, and rotary tables. On top of this, it complete Pre-FEED, FEED and EPC of drilling packages.

We specialize in complete Drillmec restoration of internal wear parts Offering thermal spray coatings and specialty welding processes OD & IS Grinding & Machining To OEM Size.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

We keep your Drillmec mud pumps running in first class condition - providing onsite inspections, repairs and complete overhaul as well as all associated

Drillmec parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where Drillmec overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

High chrome liners of drilling mud pumps are manufactured by the highest-grade materials. The outer shell is made of forging high-strength carbon or alloy steel. The inner sleeve is manufactured from a proprietary high chrome content iron alloy that offers excellent resistance to wear, chrome content is not less than 27%.

8613371530291

8613371530291