homemade mud pump brands

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Preferred Pump offers the best rewards program in the water well equipment industry. Check out our social media pictures to see what you"ve been missing!

Tired of changing mud pump pistons? We have your solution. The TD will work in all types of drilling mud including oil based, synthetic and water based. It was specifically designed to work in applications where water based mud is used or in situations where WBM is used on the top side & OBM is used on the bottom end. This eliminates the need for changing the piston midway through the drilling program. The “TD” or “Total Depth” name reflects our commitment to make a single piston that will last from “spud” to “TD”. This piston has been engineered with a unique friction reducing material bonded into the urethane of the sealing lip. Because the TD is built to withstand friction in the liner, wear on your parts is minimized and savings is maximized. The Patriot™ TD is also designed to meet pressures of 7500 psi as well as temperatures up to 220 degrees.

BW320 mud pump are mainly used for irrigation agricultural machinery.the main characteristic is the high pressure, lift much, less energy consumption, easy operation, high quality and durable, easy to move, especially for mountain terraces of irrigation.

BW320 type mud pump is a horizontal triplex single acting reciprocating piston pump, which has two bore and fourth gear speed. Displacement and hole depth can be adjusted according to the application, the deepest can be adjusted to the application, the deepest can be used with 1800meters drilling rig, it also can be used cement perfusion.

They are also the main equipment of the geological survey, the main role in the process of core drilling boreholes is to supply fluid(mud or water), making it circulate during drilling and carry rock waste back to the ground, in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

BW320 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

We manufacturer of mud pump, are presenting our range under “Vijay” Brand name. The offered mud pump is designed to circulate drilling fluid under high pressure and promote the variegated crude oil and mud slurry handling applications in oil & cement segments.

Handling of the mud during the drilling crude oil has become easy with the offered range of the mud pump, thanks to the ingenious configuration of thereof, wherein the inner curvatures of pump casing have been customized to reduce the load on the impeller, whereas raise the discharge volume. In order to prevent the corrosion and early aging, all the wet end parts of this mud pump are engineered using the considerably applauded PP (polypropylene) material attributing excellent corrosion resistance and hence is also perceived as the PP pump or polypropylene pump in the variegated industries.

The effectiveness of this mud pump ensures that drilling mud is circulated profoundly to the bottom of the home at sterling pressure and volume to bring drilling debris out of the well hole and thereby is immensely popular in the domestic as well as global market. Owing the fame of this mud pump (PP pump), we have made it available in the miscellaneous specifications as below.

BW1500-12 mud pump used for various engineering drilling rigs, geological drilling rig when drilling would like to nip the circulating fluid (mud or water), which is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground.

BW1500-12 mud pump is a horizontal single-acting cylinder reciprocating piston pump with variable speed to change the displacement and pressure selected for use.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

I’ve run into several instances of insufficient suction stabilization on rigs where a “standpipe” is installed off the suction manifold. The thought behind this design was to create a gas-over-fluid column for the reciprocating pump and eliminate cavitation.

When the standpipe is installed on the suction manifold’s deadhead side, there’s little opportunity to get fluid into all the cylinders to prevent cavitation. Also, the reciprocating pump and charge pump are not isolated.

The suction stabilizer’s compressible feature is designed to absorb the negative energies and promote smooth fluid flow. As a result, pump isolation is achieved between the charge pump and the reciprocating pump.

The isolation eliminates pump chatter, and because the reciprocating pump’s negative energies never reach the charge pump, the pump’s expendable life is extended.

Investing in suction stabilizers will ensure your pumps operate consistently and efficiently. They can also prevent most challenges related to pressure surges or pulsations in the most difficult piping environments.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

A mud pump is a reciprocating piston or plunger device designed to pump drilling fluid under high pressures and volumes down the drill string of a drilling rig. The main functions of drilling fluid are to provide hydrostatic pressure to prevent formation fluids from entering and to stabilize the bore, to keep the drill bit cool and clean, to carry drill cuttings back out to the surface, and to suspend the drill cuttings while drilling is paused or during the pullback process.

Mud pumps consist of two main sub-assemblies- the fluid end and the power end. The fluid end performs the pumping process with valves, pistons, and liners, or plungers and stuffing boxes- depending upon the type used. These components are considered expendables, and are designed to be easily replaced in the field. The power end contains the eccentric or crankshaft, along with the connecting rods, and cross heads/slides.

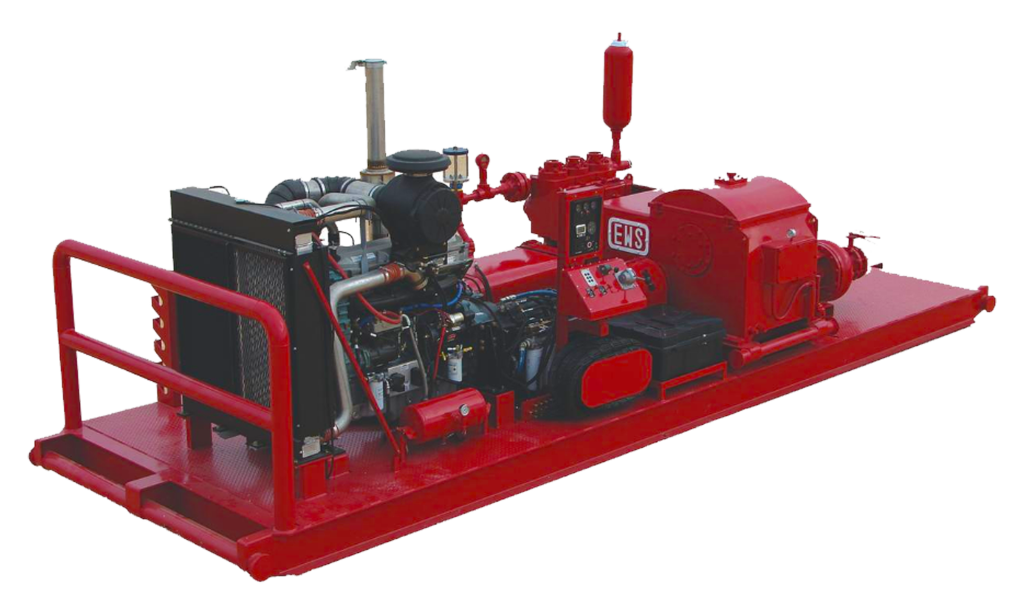

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower that are designed to be easily maintained and are capable of being completely rebuilt. Our pumps feature a smaller footprint and lighter weight than competing models, making them completely legal load size and weight in most instances. They are available as a bare pump, with chainbox, or a complete skidded package.

8613371530291

8613371530291