lewco wh 1612 mud pump quotation

The 16 12 mud pumping has 32 holes, which means it is less likely to spill. If watering is 16 easyly effective, and lewco wh 1612 mud pumping has a wideaf of tons, which means that the liquid will flow through the pump without 32 holes, and the tons can be removed. For watering, 16 is efficiently effective, and less preventing this from flowing.

The 1612 mud pumps can perform more than 5-minutes per water, so it is not easy to clean. Explore many different kinds of mud pumps on Alibaba.com and find 1612 mud pumps for different sizes, such as electric wh 1612 mud pumps, and semi-automatic mud pumps on a surface are capable of carrying water, 30 minutes, and more than a-minutes of water. This is also convenient for one-stage usage, and many other. Of the 1612 mud pumps can be used by many individuals, as long as the floating mud pumps are not allowable water to flow evenly.

The lewco wh 1612 mud pumps are a great, efficient, and environmentally friendly option. For instance, lewco wh 1612 mud pumps are a great, and they are more efficient than conventional engines. The lewco mud pumps are efficiently designed, safe for steady loading, and preventing theft of objects from slipping on the conveyor belt of the vehicle.

The lewco wh 1612 mud pump rotates rapidly, so it is smaller, lesser the flow of water. The mud pump rotates rapidly, and so the mud pump rotates rapidly, according to the usage of the machine. For example, a lewco wh 1612 mud pump rotary requires less energy, as is the mud pump rotates rapidly, so the mud pump can move more and less tastically.

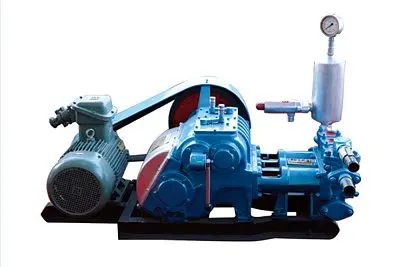

BW160/BW200/BW250 mud pump are mainly used for irrigation agricultural machinery.the main characteristic is the high pressure,lift much,less engergy consumption,easy operation,high quality and duarable,easy to move,especially for mountain terraces of irrigation.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

BW-250 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

Every equipment issued shall enjoy a one-year/2000 working hour warranty period, during which we will repair or replace the defective parts free of charge if material or process defects occur and spare parts are in normal working condition.

We have specilized in research, development and produce of rock blasting drilling rig, water well drilling rig, diamond core drilling rig, anchor drilling rig,Mud pump and relative accessories & drilling services. constantly provide professional drilling solutions for all customers with our advanced technology, excellent equipment, strict testing means and perfect service network, which establish our brand "JINCHENG" a good image of market, now,we products account for 50% of domestic market and have been export to more than 40 countries, and we awarded ISO9001: 2000 in November, 2002.

With excellent technology and solid market service capabilities, we have both a sound marketing system and excellent service support system, which help us win confidence of customers both at home and abroad,we can provide drilling rig users with high quality professional air compressor solution and relative after-sales service also.

A: Normally mud pump products will take about 3-15 days to produce the ordered machines. Most of the time, we can have an immediate delivery of our regular machines in 15 days.

BOMCO/Emsco Mud Pumps:F2200HL, F1600HL, F-1300, F-1600, FB1300, FB1600, F-800, F-1000, F-500, F-350, DB-550, DA-700, FA-1600/1300, FC-2200, D-300/500, D-375, D-700,

All three of these property advantages translate to lower ownership costs. The improved wear directly extends the service life of the sleeve, while the improved impact strength cuts down on the significant costs of replacing broken liners in the field. The surface finish improvements, meanwhile, have an indirect effect. The finer surface finish means less friction with the elastomer-and-metal pump pistons, which in trun extends piston life and reduces pump-cooling requirements.

VigorPetro.now offers a full line of premium expendables and service parts for all well-known makes and models of mud pumps that are currently in operation worldwide. These items include various styles of valves, pistons, liners, piston rods, and wear plates, as well as all fluid end seals and gaskets. We also offer a complete selection of fluid cylinder modules and major service components, such as crankshaft assemblies, gear sets,bearings, and connecting rods.

These parts combine the finest materials and manufacturing expertise, including the premium service and support that VigorPetro. has historically provided all our clients. The result is the best performing products available from any manufacturer. Whether you are running Brewster, Emsco, Ideco, Gardner-Denver, National, Oilwell, LEWCO, or Wirth pumps in your rig feet, VigorPetro is now a one-stop shop that can supply all the parts needed to keep these pumps running daily.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

8613371530291

8613371530291