mud pump fluid end modules supplier

Premium Oilfield Technologies takes the responsibility of listening to our clients’ concerns very seriously. Acting on those needs enables Premium to offer robust solutions to customer issues at the rig. The Caliber® DS-7500 Fluid Ends bring together our years of field experience and unmatched client interface to represent the NEW standard for your Gardner Denver pumps.

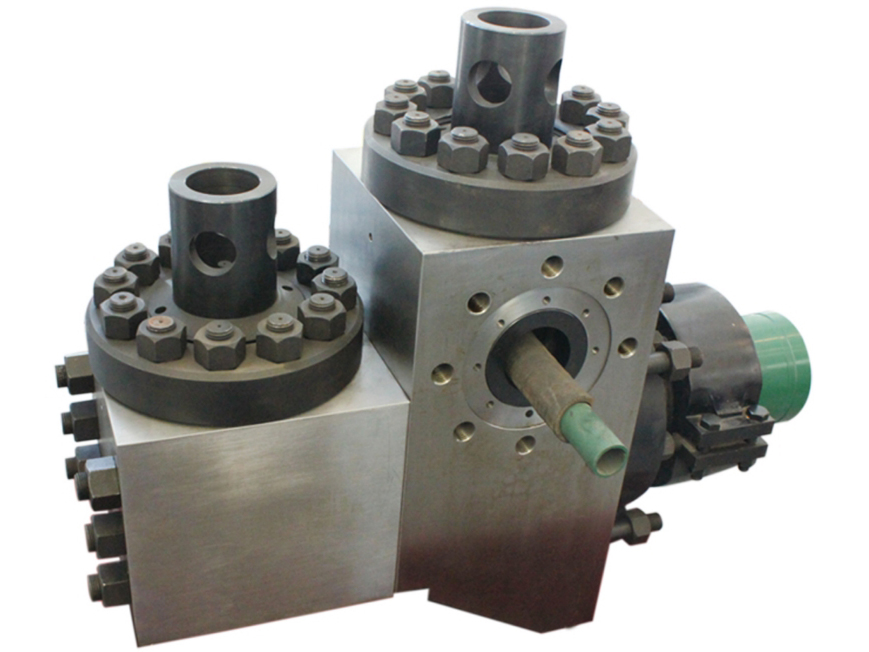

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

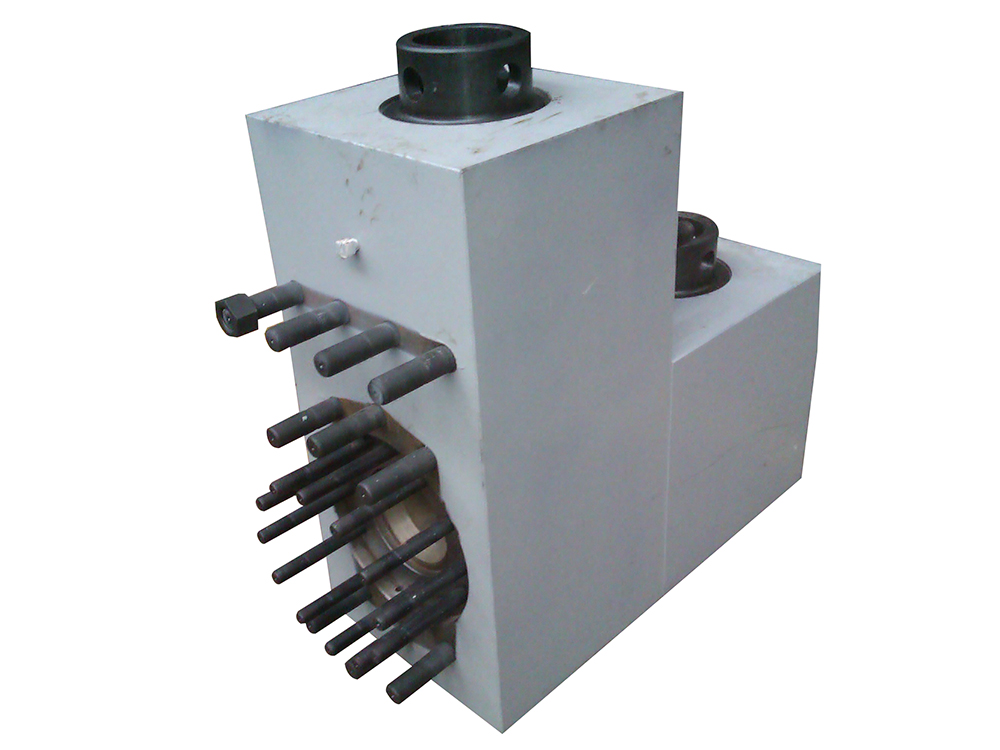

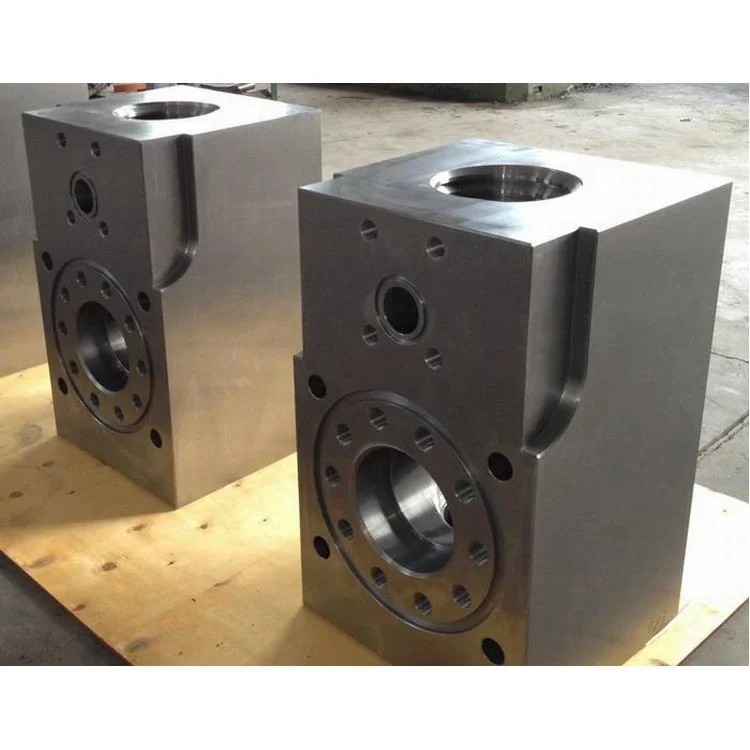

Mud Pump Fluid End Module is forged by high-quality alloy steel 35CrMo or 40CrMnMo. It has no defects such as interlayer, crack, impurity, looseness and over-burning. Welding is not allowed. The Mud Pump Fluid End Module is in full compliance with API7K standard and is inspected according to the third-grade forging and internal hardening treatment, high durability. Above process is strictly checked and strict non-destructive testing.

GPM International is a supplier of durable oilfield replacement parts for a wide variety of drilling mud pumps. Inventory products including mud pump fluid end parts, handling tool, etc. All of our products are fully exchangeable with O.E.M. standards.

A wide variety of mud pump fluid end modules options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mud pump fluid end modules,as well as from energy & mining, construction works , and machinery repair shops mud pump fluid end modules, and whether mud pump fluid end modules is 1.5 years, 6 months, or unavailable.

A wide variety of mud pump modules options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mud pump modules,as well as from energy & mining, construction works , and machinery repair shops mud pump modules, and whether mud pump modules is 1.5 years, 6 months, or unavailable.

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

P-Quip products are recognized throughout the globe as the premier line of patented fluid end assemblies, which through design, innovation and attention to detail, improve the safety and efficiency of modern drilling operations.

Designed to meet the extreme challenges of higher-pressure drilling, our Banded Bore Fluid End Modules are crafted with industry leading materials and technologies to extend the life of your assets.

HHA is the exclusive agent and distributor in the Americas for our parent company HongHua Group(HH), which is a world-leading company in designing and manufacturing oilfield equipment. HH manufactures Drilling Rig Packages, Mud Pumps, Drawworks, Top Drives, Hydraulic Catwalk, and other oilfield equipment and Parts. HHA also represents other quality products made in China.

The high strength forged triplex fluid end modules are made from 4130 or 4135 metal and heat treated to a hardness for long wear. The clean exterior finish reflects the superior inside quality.

MISSION ceramic liners offer longer run times, lower operating costs and reduced risk exposure when compared to operating with chrome iron liners. The ceramic sleeve material is manufactured from alumina oxide, known for its wear resistance, and has proven run times in all types of operating conditions. The outer hull material for large bore liners is manufactured from alloy steel to increase yield strength and aid n fatigue resistance. MISSION ceramic liners are corrosion resistant and have a smoother surface finish for reduced friction and heat. Combining these features, the extensive history of NOV in ceramics, and proprietary pump technology, results in a liner unmatched by any other in the industry. MISSION ceramic liners are field proven as the longest running liner ever manufactured.

The MISSION L 7500 modules are designed as an upgrade solution for existing mud pumps equipped with 5000 psi fluid ends. They can also be specified as original equipment for certain new NOV mud pumps and as original equipment on new pumps from other manufacturers. These modules create added value by increasing the operating range of existing mud pumps and by reducing maintenance and pump down time. Added features can include the BLAK-JAK liner retention system, MISSION ceramic liners, and ROUGHNECK valves and seats.

The MISSION WHITE LIGHTNING bonded piston is manufactured from a highly engineered elastomeric compound that provides high resistance to water, oil and synthetic based drilling fluids. The compound provides superior resistance to tear, abrasion and extrusion and is capable of operating in fluid temperatures up to 230 ̊F (110 ̊C).

The MISSION BLUE LIGHTNING piston is a super premium bonded polyurethane piston designed for operating in all drilling environments. It is manufactured for an engineered elastomeric compound that delivers excellent resistance to tear, abrasion and extrusion while maintaining high mechanical properties. The BLUE LIGHTNING piston is capable of operating in fluid temperatures up to 220 ̊F (104.44 ̊C)

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

Houston, Texas -- To eliminate equipment compatibility issues and the prospect of additional spare-parts inventories for drilling contractors, the LeTourneau Ellis Williams Company (LEWCO) can factory-equip its heavy-duty W-Series and general-duty WH-Series mud pumps with virtually any major brand of fluid end module. Customers not specifying a particular brand receive LEWCO"s standard one-piece or two-piece fluid end modules made of quenched and tempered forged steel, featuring "off the shelf" expendables readily available from domestic and international sources.

LEWCO mud pumps are in-house manufactured. For maximum quality assurance -- with job-ready performance verified in advance -- every pump is tested under full load prior to shipment, in the company"s fully equipped, million-dollar "mud pump laboratory." LEWCO pumps provide input ratings of 300 to 3,000 horsepower (224 kW to 2,237 kW) and deep-drilling discharge pressures as great as 7,500 pounds per square inch (527 kg/cm2). Their premium components include a pressurized lubrication system that force-feeds lubricant to all power-end bearings including upper and lower crosshead slides; a balanced forged steel crankshaft that reduces noise and vibration and helps extend component life throughout the pump; and a robust frame of double-wall, welded-steel, mounted on a heavy-duty oilfield skid.

The LeTourneau Ellis Williams Company builds high-performance mud pumps for oil and gas drilling (on land and offshore), petroleum production and processing, well-servicing, and horizontal directional drilling; as well as ancillary drilling products including pulsation dampeners; drawworks; rotary tables, transmissions, and drives; and swivels. Located in Houston, Texas, LEWCO is a wholly owned subsidiary of LeTourneau Incorporated, a leading manufacturer of self-elevating offshore drilling rigs, forestry equipment, and wheel loaders.

For more information, contact the LEWCO Sales Department at 6500 Brittmoore Road, Houston, TX 77241-1343; telephone 1-888-MUD-PUMP (683-7867), fax 713-856-5341; e-mail pumps@lewco-equip.com. Or visit www.lewco-equip.com.

JL Offshore AS keep inventory and provide a full range of Fluid End Expendable Pump Parts for every drilling condition and different Mud Pumps from well known manufacturers.

8613371530291

8613371530291