mud pump liner size pressure in stock

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

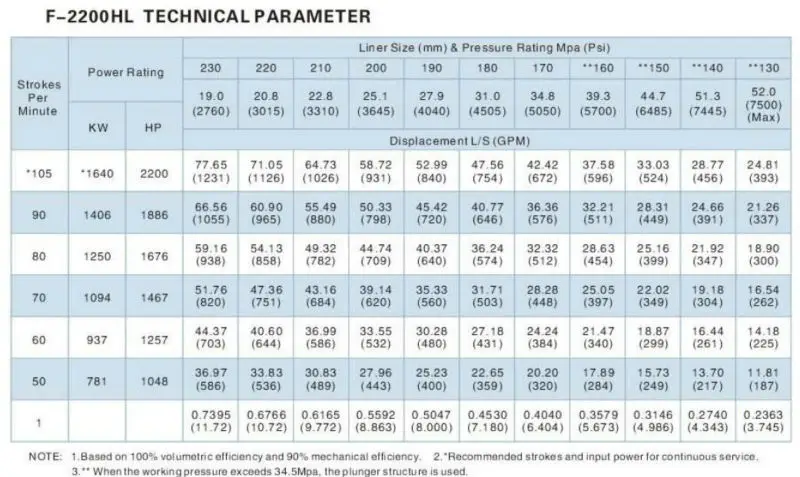

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

Mud pump liner selection in today"s drilling operations seldom (at best) considers electrical implications. Perhaps, with more available useful information about the relationships between mud pump liner size and operational effects on the electrical system, certain potential problems can be avoided. The intent of this paper is to develop those relationships and show how they affect an electrical system on example SCR rigs.Introduction

There, seems to be little consideration for the relationships between liner size and demand on a rig"s engine/generator set(s). Yet, consideration for this relationship can prove to be very helpful to drillers and operators in efficiency of a rig"s electrical system. In order to develop the relationships and help drillers and operators understand the importance of each, relationships between liner size, pump speed, pump pressure, and electrical power will be developed. Only basic physical laws will be used to develop the relationships; and, once developed, the relationships are readily applied to realistic examples utilizing a mud pump manufacturer"s pump data. Finally, conclusions will be drawn from the examples.DEVELOPMENT OF RELATIONSHIPS BASIC RELATIONSHIPS

where HHP= Hydraulic horsepower, GPM = Mud pump volumetric flow rate in gallons per minute, and PST Mud pump output pressure in pounds peer square inch.

Hydraulic horsepower is reflected to the mud pump motor via a multiplier for mechanical efficiency. it follows that motor horsepower is then represented by

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

Seal Rings for Liner packing are also important. Liner Seal Rings is designed and made with hard corner which is an integral part of seal rings and soft nitrile element rubber center. We could provide reliable liner Seal Rings for our customers could order them at the same time.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

The effectiveness of triplex mud pumps for sale determines the success of drilling operations in rigs. Circulation of the drilling fluid or mud is a continuous process that calls for uninterrupted operations of the mud pumps. Finicky about how our equipment work, we at ShalePumps, go to extreme lengths before engineering modern beasts for continuous drilling operations in rigs.

Our state of the art Houston facility develops high performing mud pumps for drillings rigs by a combination of the best materials, and structural dynamics to put together some of the best equipment. Designed to be adapted for various drilling applications in rigs through designs that incorporate various liner sizes, the triplex mud pumps for sale that leave the assembly line at ShalePumps are mean and mighty workhorses. The triplex mud pumps feature high performance steel power ends, balanced forged steel crankshaft, steel herringbone gears and anti-friction roller bearings. Striking the right balance between weight and performance, the triplex mud pumps for sale we make are best for drilling operations in rigs.

The triplex mud pumps manufactured at ShalePumps have extended continuous duty cycles, and foolproof lubrication systems for smooth drilling operations in rigs. With mud pumps from ShalePumps the drilling operations in rigs will never be the weak link, but a pivot that spells success.

ShalePumps, LLC is proud to introduce the SP-1614 1600 HP Continuous Duty Triplex Drilling Pump. Engineering and rated for 1600 horse power at 110 strokes per minute with a 14” stroke capable of 7500 PSI. Manufactured in our Houston Texas facility, this pump defines longevity, quality and capability. The SP-1614 is designed to incorporate minimum weight and maximum performance using a high performance steel power end, a balanced forged steel crank shaft, steel herringbone gears and anti friction roller bearing throughout. Multiple liner sizes are available to allow variance in pressure and output volume for a variety of drilling applications. Download the performance chart for more detailed information.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

Function: Mud Pump Liner also called the cylinder liner. The cylinder liner is the core accessory of the mud pump, which has the functions of storing mud, bearing pressure and completing the suction and discharge of mud. Because the cylinder liner is in direct contact with the mud, it is easy to be worn and corroded by the tiny sand particles, acid and alkali liquid in the mud during work. As a result, the inner diameter of the cylinder liner becomes larger, leakage occurs in the seal between the cylinder liner and the piston, and the pressure is reduced. The cylinder liner is scrapped eventually. Cylinder liner is a one-time wearable part that cannot be reused, and its life span directly affects the normal operation and cost of the drilling operation.

Bimetal Liners are also known as double metal liners. Forged steel pipe 45# (ASTM1045) is used for the outer sleeve, the normalizing hardness: 160BHN (HB180-200); elongation: 17%; tensile strength is not less than 85000PSI; yield strength is not less than 60000 PSI; The inner sleeve material is high chromium wear-resistant cast iron, with chromium content of 26-28%; thickness is 0.25 to 0.35 inches (6.35-8.89 mm), and the standard thickness is 7 mm. Usually, the service life is 800 hours under normal drilling conditions.

The inner liner is made of zirconia or aluminium oxide, and the outer sleeve is made of 45# (ASTM1045) forged steel. It has the advantages of more wear resistance, corrosion resistance, high-pressure resistance, high-temperature resistance, high strength and high hardness than metal cylinder liners. The service life is more than 4000 hours under normal drilling conditions.

The piston assembly is one of the main parts of the hydraulic end system of the mud pump, and it is also one of the vulnerable parts of the drilling work. The discharge pressure of the mud pump is generated by the reciprocating linear movement of the piston assembly in the piston.

NBR rubber is suitable for an ordinary drilling working environment with working pressure below 20Mpa, and the working temperature is not higher than 120℃. Excellent wear resistance, chemical resistance and long service life.

Polyurethane rubber has excellent oil resistance and wear resistance. The working temperature is not higher than 120℃, which is suitable for oil-based mud with working pressure below 35Mpa and working environment with high sand content.

Lake Petro has over 10 years of experience in Liners and Pistons, we export a large amount of mud pump parts to many countries and regions in the world. If you are interested in any of our products, please contact sales@lakepetro.com.

We stock fluid end parts for the5×6 mud pump, 5×6-1/4 FM45 mud pump, 5×8 mud pump, 5-1/2×8 mud pump, 5X10 mud pump, 4-1/2×5 mud pump, 7-1/2×8 mud pump, and 7-1/2X10 mud pump. The Gardner Denver mud pump model numbers for the above pumps are as follows: 5X6-FGFXG, 5X8-FDFXX, 5-1/2X8-FDFXX, 5X10-FDFXD, 4-1/2X5-FFFXF, 7-1/2X8-FYFXX, 7-1/2X10-FYFXD. We also handle Wheatley, Gaso, Worthington, Failing and Centerline parts and pumps. We also stock Foot Valve, Liner Puller, Valve Seat Puller, (4″ Inline Check Valve. Our Gardner Denver mud pump parts are not only competitively priced, they are also made in the USA. Oil Recommended by Gardner Denver. Call any of our experienced representatives to get the help and knowledge you deserve.

[fusion_builder_container type=”flex” hundred_percent=”no” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” overlay_color=”” video_preview_image=”” border_color=”” border_style=”solid” padding_top=”” padding_bottom=”” padding_left=”” padding_right=””][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ background_position=”left top” background_color=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”true” min_height=”” hover_type=”none” link=”” border_sizes_top=”” border_sizes_bottom=”” border_sizes_left=”” border_sizes_right=”” first=”true”][fusion_text]Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

With a low pressure setting, ie, 1000psi, by adjusting the top nylon self lock nut to move on the vertical scale to get the same setting than the scale.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

8613371530291

8613371530291