mud pump relief valve for sale

The CORTEC Model CRV Choke Relief Valve (CRV) line offers users the safety, reliability and quick response function required to meet the demands of today’s drilling operations. Our robust designs are manufactured with superior performance and field serviceability in mind. CORTEC Model CRV Choke Relief Valves are compatible with API 6A and NACE MR0175 requirements. Full third-party review is available upon request.

Available with a range of options for orifice sizes, end connections and control methods, CORTEC is certain to have a CRV model to suit your application needs. Whether you’re configuring a deepwater Managed Pressure Drilling (MPD) system, protecting mud pumps or relieving frac systems CORTEC’s CRV line is designed and proven to provide the highest level of reliability in the industry. Hydraulic and pneumatic control packages are configurable to suit customer and project specifications

Power washer pressure relief safety valves from trusted brands such as General Pump, Giant, Fluid Controls, and more are available in options from 1/4 to 1/2 inches and 1200 - 6000 psi. Contact us for help choosing the right pressure unloader valve to suit your pressure washing application.

Pressure washing thermal relief safety valves from trusted brands like AR, Cat, General Pump, JE Adams, and Giant are a great way to keep pressure cleaning pumps within a safe temperature range during operation. Available in sizes from 1/4 to 1/2 inch, and up to 190 degrees (F). Contact us for help choosing the right thermal relief valve for your pressure washing need.

The Patriot Harsh Duty Valve is a bonded urethane valve that will hold up in the most extreme drilling environment. The Patriot HD offers the strongest urethane bond of any valve for increased service life and a stronger seal.

Superior Performance, Long Run Life, Excellent Abrasion Resistance and Sealing Surface coupled with the highest rated chemically resistant urethane make the Patriot HD Valve an excellent choice for any drilling application.

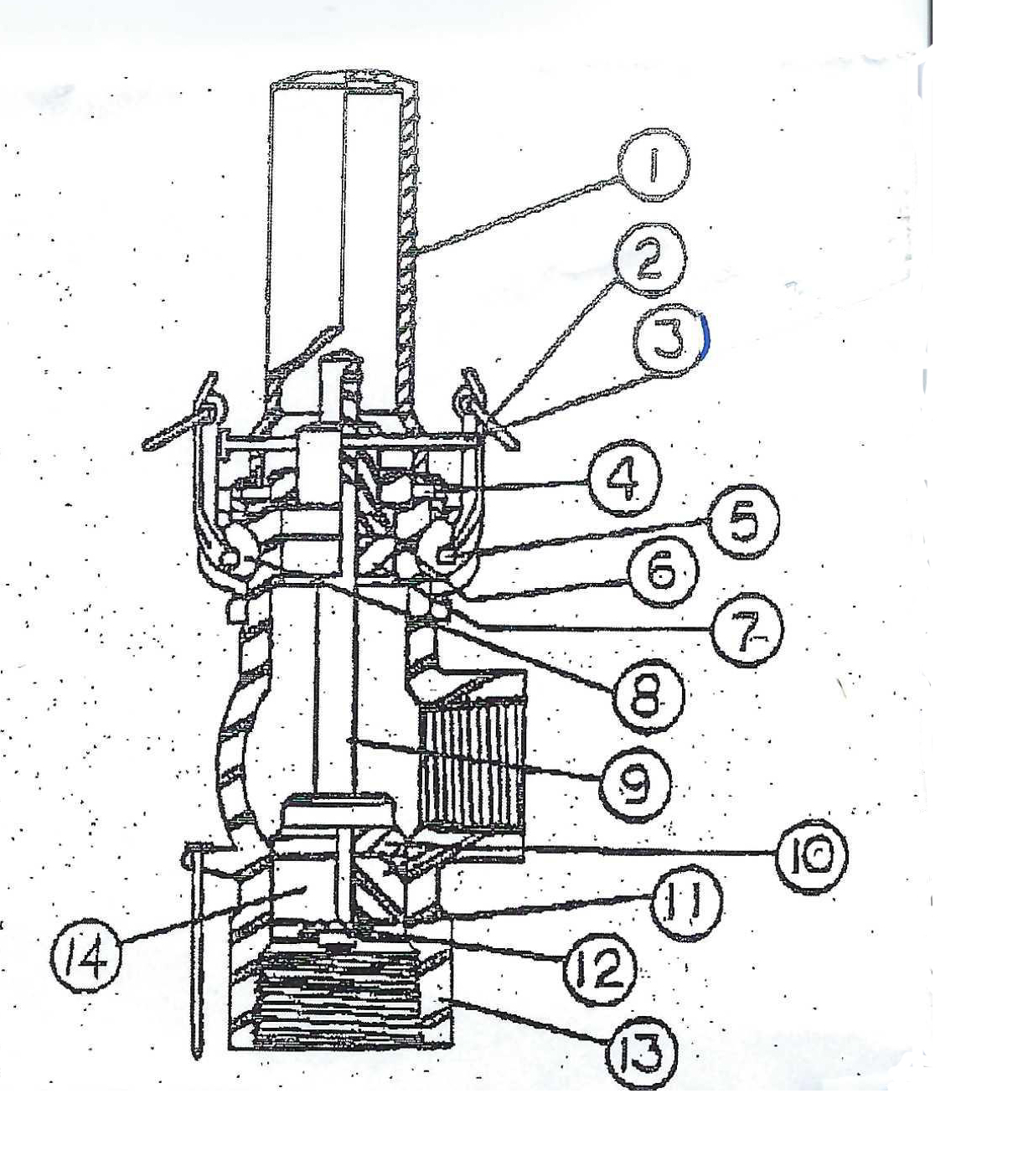

(2) Pumps - Triplex W/ Forged Steel Fluid End & Quick Change Caps, 5M Pulsation Dampner, Oteco 3" Shear Relief Valve, Pressure Gauge, Mission 6 X 5 Charge Pump P/B Cat C-18 Diesel Engine, Allison CLT6061 Transmission, Fitted W/ 7" Liners, & Pistons, Master Skidded, (1) Pump No Power or Transmission. Good Condition.

All New Parts In Both Gear & Fluid End, Pump Will Have New Style Gear End, Primered & Painted Buyers Choice, Hyd. Gearbox Available. Rebuilt Condition.

Your pressure relief valves (PRVs) are some of the most important pieces of equipment in your plant. They are what protects your systems from overpressure events that can damage your systems and, in some cases, have catastrophic consequences.

One of the most common questions we get is about relief valve testing frequency. There is no single answer that’s right for every valve or application. It depends on the service conditions, valve condition, and level of performance desired.

The required testing frequency depends on the service. For example, a valve used in a corrosive or fouling service needs to be tested more often than the same valve used in a noncorrosive, nonfouling service. Other conditions that call for shorter testing intervals include:

It’s also important to look at the valve testing history over time. If the valve consistently passes the test, then it can be tested less often. If the results are inconsistent, then the valve should be tested more often. For new processes, especially those where the service conditions (corrosion, fouling, etc.) can’t be accurately predicted, the initial inspection should be performed “as soon as practical after operations begin to establish a safe and suitable testing interval.”

Our valve technicians are factory-trained and ASME and National Board certified to test PRVs from all valve manufacturers.Contact us to learn how we can help you keep your plant up and running.

8613371530291

8613371530291