suction dampener mud pump manufacturer

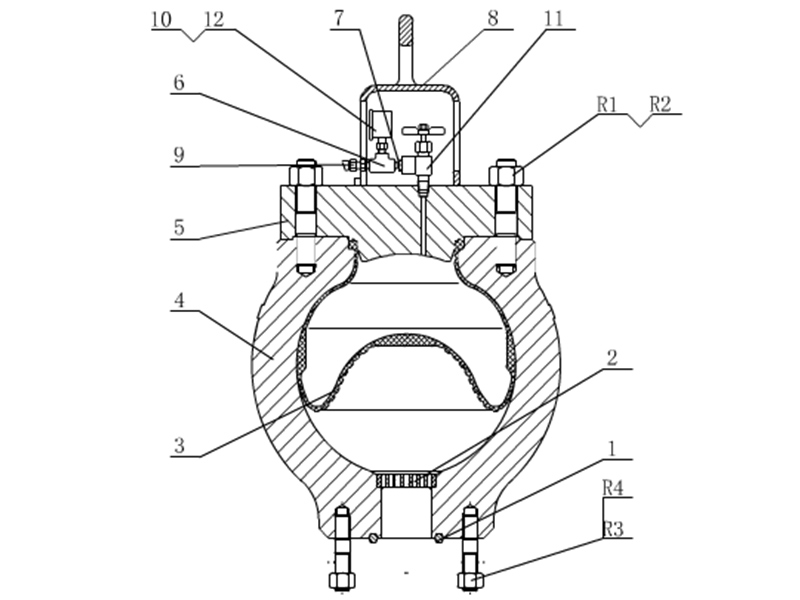

In order to reduce the fluctuation of pressure and displacement of the drilling mud pump, air bag are usually installed on the discharge line. The air bag manufactured by our company has advanced structure and reliable performance, which can make the mud pump achieve the best inhalation effect and is widely used in petroleum, high-pressure pipeline of chemical transportation. This product can also be used as a stabilizer and shock absorber for air extractors.

The pulsation dampener can be divided into discharge pulsation dampener and Suction Dampener.Discharge pulsation dampener- reduces displacement of pump and fluctuation of pressure.

In order to reduce the pressure and displacement of drilling mud pumps, air bags are usually installed on the discharge pipeline. The suction air bags produced by our company have advanced structure and reliable performance, which can make the mud pump achieve the best suction. The effect is widely used in high-pressure pipelines for petroleum and chemical transportation. It can balance the peak pressure of high-pressure fluid in mud pumps, stabilize the pressure, and reduce losses. This product can also be used as a stabilizer and shock absorber for air extractors.

The mud pump is installed on the discharge line, which can balance the peak pressure of the high pressure fluid of the mud pump, play a role in stabilizing the pressure, reducing losses and ensuring safety, so that the mud pump can achieve the best suction effect.

Drain buffer: Installed at the drain end of pumps and compressors, it can avoid fatigue damage of cylinder pistons, valves, bases and pipelines due to pressure fluctuations, thereby extending the service life of the equipment.

Absorption of oscillation: The opening of the valve in the fluid system and the sudden closing of the valve for various other reasons will cause a huge impact pressure to form a water hammer phenomenon, causing the rupture of the pipe and the pipe seat and the damage to the downstream equipment. After installing the suction air bag, it can act as a buffer to avoid this phenomenon.

Reverse Oscillation: When the head of the water pump reaches a certain height, the reverse oscillation caused by the impact of the fluid into the pump valve will cause the pump to suddenly shut down. A suction air bag is installed to absorb part of the vibration.

A properly serviced pulsation dampener is critical for your mud pumps’ efficiency, safety, and performance. Unfortunately, there aren’t many resources available to educate personnel on executing safe and effective servicing procedures. Please review the following steps with your personnel for safe pulsation dampener maintenance.

Should you or your personnel have any questions regarding pulsation dampener maintenance, please don’t hesitate to ask. Sigma is more than happy to help you to ensure safe and proper care is being completed on your pulsation dampening equipment.

All pulsation dampeners utilize one of two methods for mitigating energy produced by reciprocating pumps; compression or exchange. The traditional gas-charged dampeners use a compressible gas cushion, either by a gas over liquid or gas-filled diaphragms, bladders, or cartridge. As the reciprocating pump produces pressure spikes, the gas compresses, thus absorbing the pressure difference and smoothing the pumped media flow. For maintenance free pulsation dampeners, rely on energy exchange. There is a common misconception regarding maintenance free pulsation control devices that the pumped media is compressible enough to absorb the reciprocating pumps’ pressure spikes. This is not true. However, the maintenance free pulsation dampeners work by utilizing the kinetic energy exchange. This kinetic energy exchange can only happen if the pulsation dampener’s volume is large enough to dissipate enough energy to reduce the adverse effects caused by the reciprocating pump. This is why maintenance free pulsation devices require massive volumes to be effective. Sigma Drilling Technologies has developed a pulsation dampening system that utilizes both methods for reducing the harmful effects of positive displacement pumps, both compression and exchange.

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

Rundong provides discharge pulsation dampener assembly, discharge pulsation dampener capsule and suction pulsation dampener capsule and related accessories, which all could be applied on different types of mud pumps such as F series, PZ series and P series, etc.

BW Series Mud Pumps are mainly used for supplying flushing fluid to the borehole in core, geothermal, water resource, shallow oil, CBM and other drilling process. The fluid can be divided into mud, water, etc. They also can be used as transfer pumps of the above-mentioned medium. This series of mud pumps are with simple structure and easy to maintain and operate. Piston, lip-shaped and self-sealing type, is made of rubber or PTFE and nylon pads, equipped with shock-resistant pressure gauge, necessary spare parts and special tools. Bi-metal liner can be used to extend service life of pump greatly.

NBB Series Mud pumps are mainly used for the core, coal geology, metallurgy geology, hydrogeology engineering hole drilling fluid is supplied, flushing fluid can be divided into mud, water, etc., may be used as the above medium pump.

The mud pump is crank structure, horizontal triplex single acting piston pump, the piston is self-sealing lip, made of rubber or PTFE and nylon protective pads pressed, the pump adopts auto gearbox, variable five kinds of flow, the pump is compact, high efficiency, durable, safe, reliable, easy maintenance, low maintenance costs.

ZB Series grouting pumps are mainly used for kinds of weak corrosivity viscous and nonviscous liquid grouting(such as water, mud), especially for vertical shaft working face grouting, goaf filling, coal mine water inrush governance and so on.

The pump is triplex single-acting plunger high pressure pump, fitted with international first-class gearbox, which is of features like compact structure, multistage speed regulation, realizing different flow rate and pressure, meeting the grouting requirements of different formation. Electric motor drives triplex pump through transmission system. It has many advantages, like convenient adjustment for pressure and flow rate, long service life and so on.

3NB & 5NB Series Mud Pumps are mainly used for oil, water well, geothermy, CBM, shale gas, coalfield exploration, freezing well as well as well other drilling ,well cementation, work-over and other operations in industrial and mining enterprises. It is used for transferring mud, clay gum, mortar and other medium to the borehole. The pump adopts international advanced technology. It is characterized by advanced structure, reliable operation, good suction performance, long service life of wearing parts, easy for maintenance and repairing and so on.

F Series Mud Pumps are mainly used in oil field and geological prospecting for well drilling, well work-over, cementing, water shut off, water flooding and sending mud, clay, grout and so on.

173 pulsation dampener mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 49%, pumps accounts for 10%.

A wide variety of pulsation dampener mud pump options are available to you, such as 1 year, not available and 2 years.You can also choose from new, pulsation dampener mud pump,as well as from energy & mining, construction works , and machinery repair shops pulsation dampener mud pump, and whether pulsation dampener mud pump is 1.5 years, 6 months, or unavailable.

173 pulsation dampener for mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 49%, pumps accounts for 10%.

A wide variety of pulsation dampener for mud pump options are available to you, such as 1 year, not available and 2 years.You can also choose from new, pulsation dampener for mud pump,as well as from energy & mining, construction works , and machinery repair shops pulsation dampener for mud pump, and whether pulsation dampener for mud pump is 1.5 years, 6 months, or unavailable.

This equipment plays an important role as an accessory to Yamada air-operated double diaphragm pumps. The pulsation dampener serves to reduce pulsation produced in operation and to assure stable discharge flow and pressure.

When pulsations occur with pump operation, it will result in the pressure in Chamber Bbeing greater than that in Chamber A. The diaphragm will act as an air cushion and automatically adjust to this pressure change and absorb the pulsations.

This operation will shift the center rod position upwards and allow more air in Chamber Athrough the air inlet, returning the diaphragm to a neutral position. If liquid pressure decreases, air pressure in Chamber Acauses the diaphragm to move downward, shifting shaft location and changing valve position, releasing excess air pressure in Chamber Awhich returns diaphragm to a neutral position. This action causes a reduction in surges and pulsation caused by a air operated double diaphragm pumps

TSC offers a broad range of drilling and production spherical pulsation dampeners. Volumetric size ranges from 10 gallon to 20 gallon capacities and pressure ranges from 3000 psi to 7500 psi. The body of the TSC spherical pulsation dampeners is manufactured from a one piece steel forging, thereby eliminating the possibility of weld fatigue failure.

8613371530291

8613371530291