mud pump china manufacturer

6 inch Diesel Engine Mud Pump Connected By Clutch Belt 1) 6 inch D iesel engine mud pump specifications DIESEL ENGINE MUD PUMP QUOTATION Model of Diesel pump set V115DPD05H ( H=43m) Model Diesel Engine R6105ZDS Brand RICARDO Rated Output 84KW/115HP Speed 1500rpm Displacement 6.49L Bore/stroke 105*125mm Compression ratio 16:1 Cylinders 6 Type Water cooled, inline, 4 stroke, direct injection Clutch RX-120 Model Pump VS100J-36A Treated Water Mud pump The Sand Maixmum diameter 30mm Outflow 245m3/h Head lift 43m Speed 1480rpm Shaft power 45kw Suction lift 3.0m Inlet diameter 150mm (6 inch) Outlet diameter 150mm (6 inch) Impeller and expeller High Chrome Alloy Shaft 45#steel Casing HT200 Volute casing High Chrome Alloy Control System Display and protect oil pressure,speed, water temperature,oil temperature. 2) Picture of 6 inch diesel engine mud pump 3) We also produce connection flange, elbow, foot valve, black spiral rubber pipe, and quick coulping, the range from 3 inch to 32 inch 4) Our Factory Picture 5) Any requirements about diesel water pump, pls contact with me, i will choose the best solution for you

Mud Pump is also a popular concept of a wide range of pumps. Different regions, habits, and ultimately the pump type will not be the same. The mud pump described in this entry is a pump type in most sense: Applied mud pumps in the field of oil drilling. In fact, some non-clean water pumps and mud pumps, such as sewage pumps and slurry pumps, are also commonly used when they are called.

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

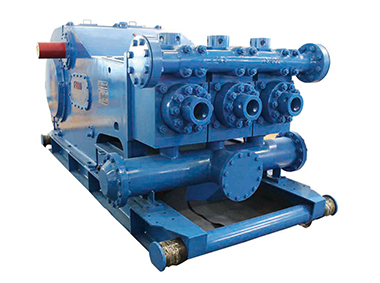

The commonly used mud pump is a piston type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

3,ifwith high pressure pump,water gun,a hydraulic mechanized earth work unit,used for ground leveling,river and pond dredging,drilling and other small-scale water conservancyengineeringexcavation and transportation,and the city"s air defenseengineering,underground engineering.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

8613371530291

8613371530291