mud pump drawing manufacturer

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

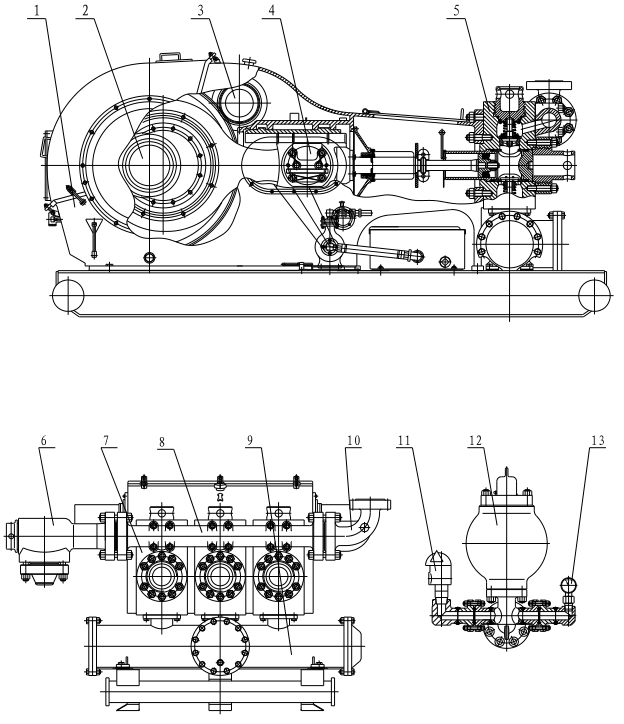

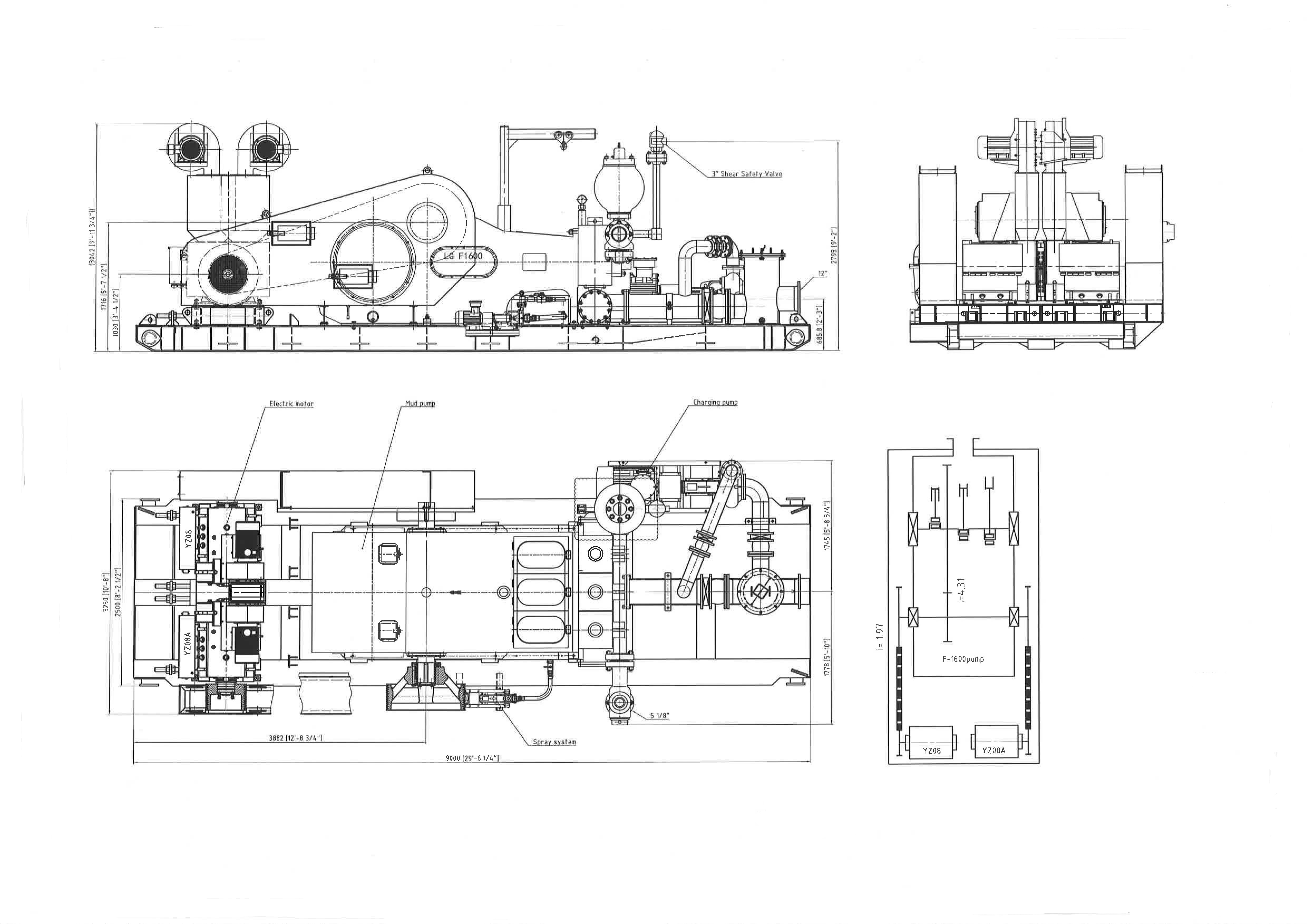

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

Solution: Our patented shock suppression hydraulic shifting system has tamed the hydraulic hammer shock problem. Our shifting system can shift at hydraulic oil pressures of up to 5000 psi - producing mud pressures up to 800 psi without encountering the deteriorating shock that has stumped so many other attempts at making a direct hydraulic drive.

Solution: Why overcome a problem when you can simply go around it? Our patented "Matched Displacement Ratio" technology has eliminated the need for a synchronization system. This technology allows our pumps to deliver smooth, constant discharge flow without the use of a synchronization system.

The drilling industry demands a mud pump that will operate day in and day out without continual down time maintenance. Off the shelf components that would produce such a hydraulic drive system were not to be found. A new generation of components would have to be developed to meet the demands of this service.

Solution:To make a hydraulic drive system that will stand up to the duty our industry demands, every component in our hydraulic system had to be custom engineered - developed exclusively for our pumps to stand up to a level of duty that off the shelf hydraulic components would never stand up to. Everything from the allow used in the valve castings, the design of the valve components, the hydraulic cylinder design and the type and material of the seals, were specifically engineered for use in our pumps - engineered for a 60,000,000 cycle life under high pressure reciprocating duty.

Developing new fluid end expendables that will stand up to the duty in our industry the same way that mechanical drive pump expendables hold up is a tall order. How do you improve on the one thing that has made mechanically driven mud pumps the backbone of the industry

Solution:Honestly, we couldn"t develop better fluid end expendables than those used in mechanical pumps - so we used theirs. Our fluid end expendables are the same components that have been used in mechanical pumps for decades. These expendables are proven, reliable, and available - how could we improve on that? Well, actually, by using bigger pistons and running them at half the speed of mechanical drive pumps we can get about twice the life from them!

Developing respect for a new mud pump technology doesn"t come easy. Despite their weight, size and performance limitations, the mechanical pumps that had been the standard of the industry had been getting the job done for over 50 years. How could we convince our industry to adopt our pump as the new standard for our industry?

Solution: We can claim that our pumps perform like no other pump on the market. We can claim that we use the best components and materials. But in the end, respect only comes from earning it. It doesn"t matter what we say. What matters is what our customers say. Centerline pumps are getting the job done from Canada to Australia. Are you ready for the mud pump you"ve always needed?

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

Features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps or Sludge pumps, diaphragm pumps are designed to pump mud, slurry, sewage, and thick liquids that have the ability to flow. AMT Diaphragm pump Honda GX120 OHV gasoline engines. Built-in molded polyurethane flapper / check valve assures self-priming to 20 feet after initial prime. Each unit includes a 3" NPT steel suction strainer, two 3" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Was 3357-96. Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve. OBS, see other model

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

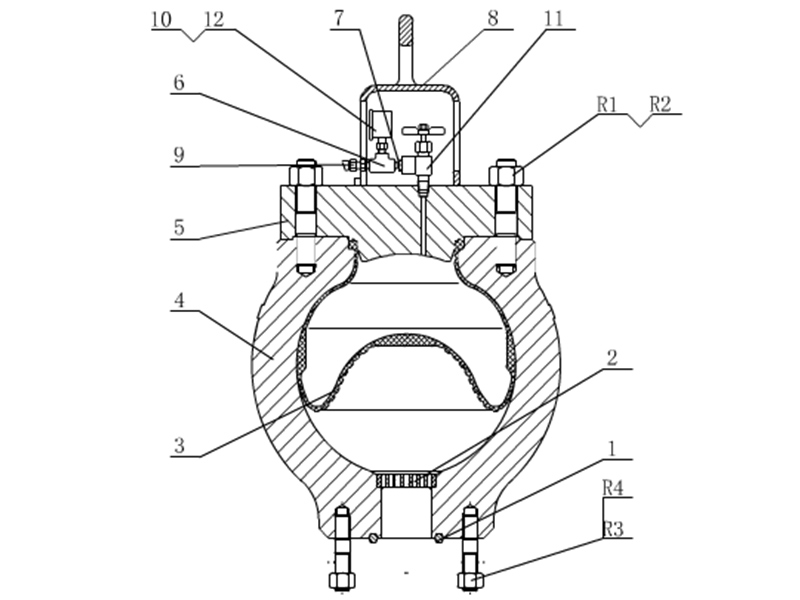

Triplex plunger-type mud pumps feature a reciprocating, positive displacement pump design utilizing three plungers to safely transfer high-viscosity fluids under high pressure over an extended depth. Although they have many industrial applications, these pumps have become an essential part of oil well drilling rigs where they’re used to provide smooth discharge of mud and debris from oil wells.

In addition to their use in drilling and well service operations, mud pumps are also frequently used to handle corrosive or abrasive fluids, as well as slurries containing relatively large particulates, in applications like commercial car washes, wastewater treatment, cementing, and desalination operations.

DAC Worldwide’s Representative Triplex, Plunger Mud Pump Dissectible (295-418) is an economical, conveniently-sized triplex plunger-type mud pump assembly that teaches learners hands-on maintenance activities commonly required on larger mud pump assemblies used in upstream oilfield production operations.

For example, mud pump assembly is used on well sites maintain downhole backpressure, to lubricate the rotating drill bit, and to help recycle and remove rock debris resulting from drilling activities. These heavy-duty, high-pressure pumps require regular refurbishment, inspection, and repair in the field.

DAC Worldwide’s dissectible mud pump assembly is a realistic sample that’s similar in geometry, design, and operating characteristics to the larger varieties learners will encounter on the job. DAC Worldwide chooses popular name-brand pumps for its dissectibles to ensure industrial and oil and gas training relevancy.

Using the dissectible mud pump, learners will gain hands-on experience with the operating principles, regular maintenance activities, and nomenclature/parts identification at a more convenient scale in the classroom or lab.

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Representative Triplex, Plunger Mud Pump Dissectible features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Representative Triplex, Plunger Mud Pump Dissectible is a sturdy unit with a complete triplex, reciprocating, 20+ bhp plunger pump with .75" plunger, 1.5" stroke, and 3" cylinder sleeve. The unit allows for complete disassembly, assembly, and inspection, including removal of plungers, packing, and valves.

The dissectible mud pump comes with a formed-steel, powder-coated baseplate. It can also be mounted on a compatible DAC Worldwide Extended Electromechanical Workstation (903). Each unit comes with the manufacturer’s installation and maintenance manual.

GPM International is a supplier of durable oilfield replacement parts for a wide variety of drilling mud pumps. Inventory products including mud pump fluid end parts, handling tool, etc. All of our products are fully exchangeable with O.E.M. standards.

Since 1933, Gorman-Rupp has manufactured the high-performance, high-quality pumps and pumping systems required for lasting service in the municipal, water, wastewater, sewage, industrial, construction, petroleum, mining, fire, and OEM markets.

containing sand, mud or solids in suspension; clean or dirty low viscosity petroleum product or solvents; milk of lime, caustic soda; washing, cooling, circulation; smoke scrubbing; emergency duty.

• pumping polluted, hot or corrosive waste water containing sand, mud or solids in suspension; dosing neutralizing liquids; pumping out settled sludge.

5-13, smoke scrubbing, water emulsion for machine tools or grinders, cutting or quenching fluid circulation, cooling water circulation in steel mills or drawing mills, neutralizing liquid dosage, pumping out settled sludge, sump pumping liquid manure transfer and circulation.

8613371530291

8613371530291