mud pump images free sample

There are many different ways to drill a domestic water well. One is what we call the “mud rotary” method. Whether or not this is the desired and/or best method for drilling your well is something more fully explained in this brief summary.

One advantage of drilling with compressed air is that it can tell you when you have encountered groundwater and gives you an indication how much water the borehole is producing. When drilling with water using the mud rotary method, the driller must rely on his interpretation of the borehole cuttings and any changes he can observe in the recirculating fluid. Mud rotary drillers can also use borehole geophysical tools to interpret which zones might be productive enough for your water well.

The mud rotary well drilling method is considered a closed-loop system. That is, the mud is cleaned of its cuttings and then is recirculated back down the borehole. Referring to this drilling method as “mud” is a misnomer, but it is one that has stuck with the industry for many years and most people understand what the term actually means.

The water is carefully mixed with a product that should not be called mud because it is a highly refined and formulated clay product—bentonite. It is added, mixed, and carefully monitored throughout the well drilling process.

The purpose of using a bentonite additive to the water is to form a thin film on the walls of the borehole to seal it and prevent water losses while drilling. This film also helps support the borehole wall from sluffing or caving in because of the hydraulic pressure of the bentonite mixture pressing against it. The objective of the fluid mixture is to carry cuttings from the bottom of the borehole up to the surface, where they drop out or are filtered out of the fluid, so it can be pumped back down the borehole again.

When using the mud rotary method, the driller must have a sump, a tank, or a small pond to hold a few thousand gallons of recirculating fluid. If they can’t dig sumps or small ponds, they must have a mud processing piece of equipment that mechanically screens and removes the sands and gravels from the mixture. This device is called a “shale shaker.”

The driller does not want to pump fine sand through the pump and back down the borehole. To avoid that, the shale shaker uses vibrating screens of various sizes and desanding cones to drop the sand out of the fluid as it flows through the shaker—so that the fluid can be used again.

Some drillers use compressed air to blow off the well, starting at the first screened interval and slowly working their way to the bottom—blowing off all the water standing above the drill pipe and allowing it to recover, and repeating this until the water blown from the well is free of sand and relatively clean. If after repeated cycles of airlift pumping and recovery the driller cannot find any sand in the water, it is time to install a well development pump.

Additional development of the well can be done with a development pump that may be of a higher capacity than what the final installation pump will be. Just as with cycles of airlift pumping of the well, the development pump will be cycled at different flow rates until the maximum capacity of the well can be determined. If the development pump can be operated briefly at a flow rate 50% greater than the permanent pump, the well should not pump sand.

Mud rotary well drillers for decades have found ways to make this particular system work to drill and construct domestic water wells. In some areas, it’s the ideal method to use because of the geologic formations there, while other areas of the country favor air rotary methods.

To learn more about the difference between mud rotary drilling and air rotary drilling, click the video below. The video is part of our “NGWA: Industry Connected” YouTube series:

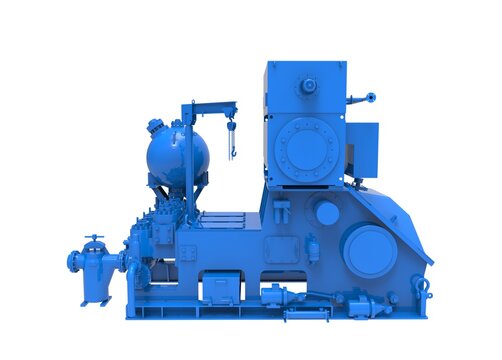

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A mud pump is a reciprocating piston/plunger device designed to circulate drilling fluid under high pressure (up to 7500 PSI) down the drill string and back up the annulus.

Our triplex and quintuplex pumps, cementing and fracturing equipments are interchangeable to global famous brands: Weir spm, Serva, BJ, Gardner Denver, Halliburton, Oilwell, OPI and so on. We also make a full line of Module assy and fluid end expendables for popular mud pumps in the world, including continental Emsco, National, Gardner Denver, Oilwell, Ideco, Wheatly, Wilson,with, opi, Ellis Williams, etc.

New Jersey, United States,-This Double Acting Mud Pump Market research stud offers proper industry viewpoint, market size, growth, future trends and trading. All this are taken into consideration while preparing the market report with the forecast period from 2022 to 2029. This report contains a complete and generic market scenario along with the factors that may have a great effect on it. Market entrance methodologies, industrial processes chain structure and rate of growth of the global market all is expressed in this all-inclusive market report. Recently, many developments have taken place with regards to technology that drives the market to go across exponential progress paths.

This Double Acting Mud Pump market report also gives an overview of market criteria such as sales strategies, key players, and investments. Knowing the buying preferences of consumers is crucial for key players who want to introduce new products to the market. Primary key market players, consumer buying preferences, and sales methods are all covered in this Double Acting Mud Pump market report. This Double Acting Mud Pump market report also discusses the dynamic market"s expanding prospects and opportunities in the future. This type of market analysis allows for a fast assessment of the global market situation. The Double Acting Mud Pump market report offers useful information about the key contributors, company strategies, consumer preferences, and improvements in customer behavior. Furthermore, it provides an exact sales count as well as the customer"s buying patterns. The COVID-19 Pandemic has an effect on a wide range of industries.

National Oilwell Varco, Schlumberger, Gardner Denver, Weatherford International, Flowserve Corporation, Honghua Group, China National Petroleum, Trevi-Finanziaria Industriale, MhWirth, BenTech GmbH Drilling and Oilfield systems, American Block, White Star Pump, Ohara, Herrenknecht Vertical, Mud King Products

The Double Acting Mud Pump market is segmented as per the type of product, application, and geography. All of the segments of the Double Acting Mud Pump market are carefully analyzed based on their market share, CAGR, value and volume growth, and other important factors. The report also provides accurate estimations about the CAGR, revenue, production, sales, and other calculations for the Double Acting Mud Pump market. Each regional market is extensively studied in the report to explain why some regions are progressing at a high rate while others at a low rate. We have also provided Porter’s Five Forces and PESTLE analysis for a deeper study on the Double Acting Mud Pump market.

The Double Acting Mud Pump report provides information about the market area, which is further subdivided into sub-regions and countries/regions. In addition to the market share in each country and sub-region, this chapter of this report also contains information on profit opportunities. This chapter of the report mentions the market share and growth rate of each region, country and sub-region during the estimated period.

8613371530291

8613371530291