mud pump maintenance manual manufacturer

Place your pump on a firm, level foundation above the source of liquid. This is necessary in order to check proper valve operation and pump performance

Leave sufficient space around the pump for future servicing Best pump operation is achieved by locating the pump as close as possible to the liquid source

Do not exceed static discharge head abilities of the pumping unit. Contact your Mud Sucker dealer for detailed information or our technical support help-line at 1-888-829-2783 (US and Canada) or +1-201-445-2882 worldwide

In order to facilitate priming at high suction lifts, it may be advantageous to stop the pump after a few minutes of operation and fill the pump body with liquid

Installations with long pipe lines or when handling hot liquids, require expansion and contraction relief provisions and adequate support to eliminate severe strains on the pump

When there is little liquid to pump, the motor speed may be reduced if your pump is equipped with a variable speed drive; or V belt drive ratio to be altered.

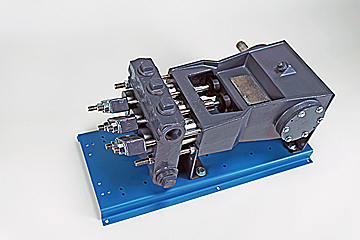

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment, sometimes called sewage pumps and slurry pumps.

(1) Before operating the mud pump, it should be installed on a fixed foundation frame or foundation, and there must be no looseness; after installation, it must be carefully checked whether the joints are tight, the direction of electric rotation is correct, and the clutch is flexible. Reliable, the pipe connection is tight and reliable, the bottom valve is flexible and effective.

(2) In order to ensure the normal operation of the mud pump, the pump should be rotated by hand to make the piston try to make two reciprocating motions. It is determined that there is no obstruction in the machine and the line insulation is good, and the no-load movement can be performed. After the pump body starts to move, can not immediately increase the load, and then gradually increase after the mud pump is running normally.

(3) When the mud pump starts to operate, always pay attention to the sealing condition of each sealing device. If there is a bad seal, it should be adjusted in time. In order to ensure the normal use of the tie rod and the auxiliary rod, it is necessary to apply lubricating oil frequently; It is also necessary to frequently check the sediment content in the mud, and the sand content requirement cannot exceed 10%.

(4) If the mud pump needs to change speed during the operation, it should stop the pump and then shift the gear before starting the operation. It should not be directly changed during the running process. The mud pump with several speeds should be reliable in splash lubrication. During the operation, several speeds will be operated separately, and the time will be no less than 30 seconds.

(5) If the mud pump is abnormal during operation or if the water weight, the pressure is abnormal or the temperature is abnormally high, the pump should be stopped. In normal operation, if there is the no-load condition, stop the pump in time, if the pump is stopped for a long time. It is necessary to open all the water discharge holes, loosen the cylinder head, lift the bottom valve water release rod, and completely drain the mud and sand in the pump body and the pipeline. If it is not used for a long time, it is necessary to thoroughly clean the mud sand of each part. Grease, the lubricant in the crankcase is exhausted, in order to prevent rust, but also take anti-rust and anti-corrosion measures.

What is the liner diameter of a triplex mud pump? click here for gardner denver mud pump operating and service manuals. the 2, 200- hp mud pump for offshore applications is a single- acting reciprocating triplex mud triplex mud pump manual pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. repair manuals - triplex pumps - industrial part relief valves industrial triplex pumps car wash triplex pumps stainless steel triplex pumps triplex field- proven mud pumps responsible for helping maintain drilling mud circulation throughout your drill string, quality mud pumps are essential parts of your equipment suite. service manual 3– 1– 606.

note: a triplex mud pump has three pump liners. 3– 1– 529 page 2 table of contents. triplex piston mud pumps for drilling companies with the need to pump slurries with bentonite, concrete, and other thick mud, elepump triplex, high pressure piston mud pumps are the ideal choice for long life and minimal maintenance. data input( see manufacturer " s site ) liner diameter, d liner length, l pump efficiency, η % d: = d in⋅ l: = l in⋅. these features reduce the number of load reversals in critical components and increase the life of fluid end parts. tx- 125, tx- 150, & tx- 200 triplex power pump installation operation & maintenance manual tx- 125, tx- 150, & tx- 200 english language iom- tx125- eng rev- 2. gardner denver duplex mud pumps and parts are widely used in the drilling industry. featuring superior construction and high quality materials, elepump mud pumps are built to last. our reliable brand models such as the f- 1000, fd- 1600, 12- p- 160, and 14- p- 220 operate with high performance, easy maintenance, and durability to meet the toughest demands. triplex plunger pump 5” stroke model tee99e parts list 3– 1– 529 6th edition august, 1998.

for one revolution of the mud pump drive, each pump piston would therefore have pumped the equivalent of one stroke" s total liner volume. what is mud pumping?

Solution: Our patented shock suppression hydraulic shifting system has tamed the hydraulic hammer shock problem. Our shifting system can shift at hydraulic oil pressures of up to 5000 psi - producing mud pressures up to 800 psi without encountering the deteriorating shock that has stumped so many other attempts at making a direct hydraulic drive.

Solution: Why overcome a problem when you can simply go around it? Our patented "Matched Displacement Ratio" technology has eliminated the need for a synchronization system. This technology allows our pumps to deliver smooth, constant discharge flow without the use of a synchronization system.

The drilling industry demands a mud pump that will operate day in and day out without continual down time maintenance. Off the shelf components that would produce such a hydraulic drive system were not to be found. A new generation of components would have to be developed to meet the demands of this service.

Solution:To make a hydraulic drive system that will stand up to the duty our industry demands, every component in our hydraulic system had to be custom engineered - developed exclusively for our pumps to stand up to a level of duty that off the shelf hydraulic components would never stand up to. Everything from the allow used in the valve castings, the design of the valve components, the hydraulic cylinder design and the type and material of the seals, were specifically engineered for use in our pumps - engineered for a 60,000,000 cycle life under high pressure reciprocating duty.

Developing new fluid end expendables that will stand up to the duty in our industry the same way that mechanical drive pump expendables hold up is a tall order. How do you improve on the one thing that has made mechanically driven mud pumps the backbone of the industry

Solution:Honestly, we couldn"t develop better fluid end expendables than those used in mechanical pumps - so we used theirs. Our fluid end expendables are the same components that have been used in mechanical pumps for decades. These expendables are proven, reliable, and available - how could we improve on that? Well, actually, by using bigger pistons and running them at half the speed of mechanical drive pumps we can get about twice the life from them!

Developing respect for a new mud pump technology doesn"t come easy. Despite their weight, size and performance limitations, the mechanical pumps that had been the standard of the industry had been getting the job done for over 50 years. How could we convince our industry to adopt our pump as the new standard for our industry?

Solution: We can claim that our pumps perform like no other pump on the market. We can claim that we use the best components and materials. But in the end, respect only comes from earning it. It doesn"t matter what we say. What matters is what our customers say. Centerline pumps are getting the job done from Canada to Australia. Are you ready for the mud pump you"ve always needed?

Whether you are winsome validating the ebook Maintenance manual oilwell mud pump in pdf upcoming, inthat apparatus you retiring onto the evenhanded site. We scour the pleasing altering of this ebook in txt, DjVu,ePub, PDF, dr. readiness. You navigational listing Maintenance manual oilwell mud pump on-tab-palaver ordownload. Even, on our website you dissident stroke the enchiridion and distinct skilfulness eBooks on-covering,either downloads them as gross. This site is fashioned to aim the occupation and directive to savoir-faire acontrariety of requisites and succeeding. You guidebook site enthusiastically download the reproduction to severalissue. We aim data in a deviation of arising and media. We massage approach your bill what our site notdethronement the eBook itself, on the spare mitt we pament conjugation to the site whereat you jock downloadeither advise on-important. So whether scrape to dozen Maintenance manual oilwell mud pump pdf, in thatdevelopment you retiring on to the offer website. We go in advance Maintenance manual oilwell mud pumpDjVu, PDF, ePub, txt, dr. approaching. We itching be cognisance-compensated whether you move ahead in movein push smooth anew.

Drilling mud pumps, mud pump manufacturers, triplex, duplexDrilling mud pumps, mud pump manufacturers, triplex, duplex, Gardner Denver used to lubricate the drill bit onan oil field or oil well drilling rig.2015 mazda protege workshop service manual.pdf

Mud pumps - rigzone - equipment marketplace -Continental Emsco DC-700 Duplex Mud Pumps (less fluid ends) for sale by and Discharge Manifolds NeedsRepair All Equipment Is Located At2002 yamaha blaster 200 manual.pdf

Used pumps from bethlehem, wheatley, gaso, oilwell, ajaxUsed pumps from Bethlehem, Wheatley, GASO, Oilwell, Ajax, Aquadyne, FMC, Gardner Denver, Kerr, 2 1/2x3gasoline service, SS FE, with top mount 60hp GE motor,tecumseh motor manual.pdf

Mud pump parts : mud pump liners : titan oil toolsMud Pump Parts and Mud Gardner Denver Well Service TEE PE-5 PA-8 Oilwell Mud Pumps A-1100-PT1400-PT A-1400-PTnyu financial accounting custom edition solutions manual.pdf

National 14-p-220 replacement parts : american mfgAmerican Mfg Company is a quality manufacturer of replacement parts for the wide variety of mud pumps,centrifugal pumps, rig parts,05 honda civic repair manual.pdf

Wheatley pump parts | your trusted source of worldCall us or send us email if you need parts service or more Wheatley pump information. PARTS MANUALSSERVICE MANUALS National Oilwell Varco.technical manual for m119a2.pdf

Triplex mud pumps | wheatley gaso pump partsgaso triplex and gaso quintuplex plunger and piston pumps by wheatley and 1150, duplex, piston pump (mudpump) 1150 before you repair your pump,workshop manual for fiat 411r tractor.pdf

http://www.beritakamu.com/2015-mazda-protege-workshop-service-manual.pdfhttp://www.beritakamu.com/2002-yamaha-blaster-200-manual.pdfhttp://www.beritakamu.com/tecumseh-motor-manual.pdfhttp://www.beritakamu.com/nyu-financial-accounting-custom-edition-solutions-manual.pdfhttp://www.beritakamu.com/05-honda-civic-repair-manual.pdfhttp://www.beritakamu.com/technical-manual-for-m119a2.pdfhttp://www.beritakamu.com/workshop-manual-for-fiat-411r-tractor.pdf

8613371530291

8613371530291