mud pump near me quotation

Manufacturer of standard and custom high viscosity and bulk solid handling pumps for pumping sand, gravels, fly ash, sludge, mud, grit, muck, paste and rocks. Types include flooded suction, self-priming, submersible and booster pumps. Available in 2 to 12 in. discharging sizes with vertical, horizontal, trailer and skid mounting options. Features include non-clog, low ph pumping design, electric or hydraulic powered, automated control and close coupled. Dredge pumps are offered for rent. Suitable for fracking, wastewater treatment, irrigation, municipal, dredging, barge unloading, sewage and commercial applications. Serves the agriculture, paper and pulp, mining, navy, oil, gas, chemical and energy industries. Made in the USA.

We have attained huge reputation as prominent manufacturer and supplier of Portable Dewatering Submersible Pumps. These pumps are well accepted in the market for their light weight, robust construction and excellent functional accuracy. We design these pumps by utilizing latest tools and techniques as per latest industrial norms with quality tested raw materials. We supply these machines in wide specifications at affordable price range to our customers.

• Portable submersible pumps are one of its kinds. We have a wide range of selection within the same Horse Power rating for these pumps. Our construction is robust compared to other make pumps and has proved its self in the market with its trouble free Operation

• Motor – submersible pumps are available in Single phase and three-phase squirrel cage induction dry motor with ‘F" class insulation and IP 68 protection

• We provide pumps with Aluminum MOC, which will make the pump very light and will be extremely handy for the operator. Trolley mounted construction is also an available option

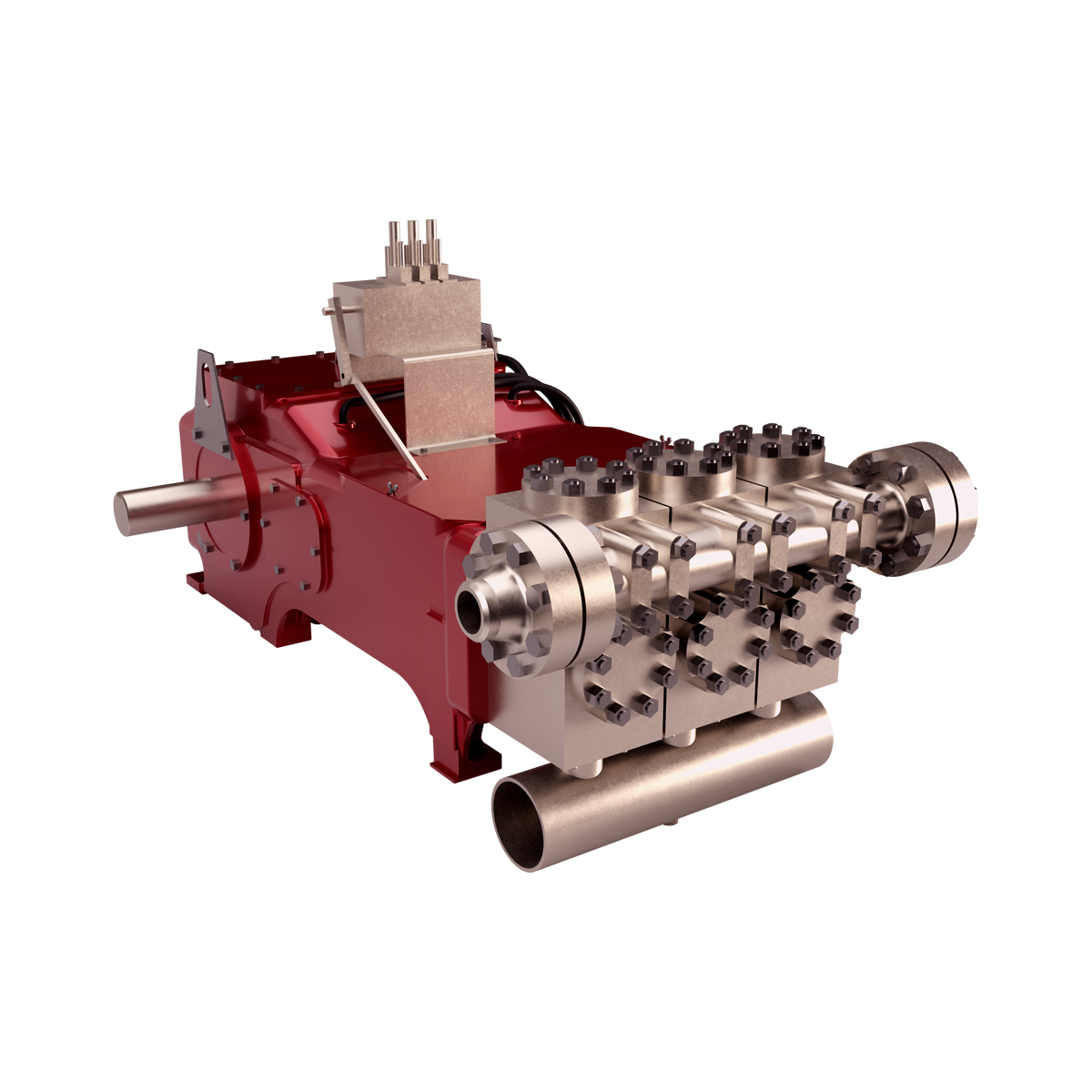

The Baoji/Bomco F1000 Triplex mud pump has a max. working pressure of 5,000PSI and a 6-3/4" liner size. This model is the first choice for the medium and deep dr... More Info

The Baoji/Bomco F1600HL Triplex mud pump has a max. working pressure of 7,5000PSI and a displacement of 46.5L/S with 6" liner size. This model is the f... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Emsco/Bomco 1600 Mud Pump, Unitized 1600 Mud Pump Powered by Two GE 752 Motors Charging Pump, Liner Flush Pump, Relief Valve, Mud Gauge, Etc. ....Call For Price More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - 1 - Rebuilt Gardner Denver PZ-9 Mud Pump Package, New Caterpillar C-27, 1050 HP diesel engine. Belt-driven. comes with pulsation dampener, discharge block, precharge, li... More Info

Mud Pumps - 1 of 3 used Gardner Denver PZ-8 triplex mud pumps. This would be a good rebuildable core. We also have new, rebuilt and good used pumps and packages available for sale ... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Customers said they wanted long-lasting, easy-to-use valves and seats, and we delivered. Made from domestically sourced steel, GD Energy Products valves feature a two-piece friction-welded design, proprietary bonded inserts, and innovative geometry to deliver significantly longer life. GD Energy Products’ field proven Valves & Seats meet API Standard, and come with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

Ramnath Industrial Park, Rajkot Ramnath Industrial Park, Kothariya Ring Road, Beside Murlidhar Way Bridge Aaji dem, Near Ramvan, Ramnath Industrial Park, Rajkot - 360002, Dist. Rajkot, Gujarat

Amraiwadi, Ahmedabad No. 16, Bankar Estate, Near Anup Estate, Behind Bharat Party Plot National Highway No. 8, Amraiwadi, Amraiwadi, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

Hatkeshwar, Ahmedabad No. 4, Behind Ramdev Estate, Opposite Baroda Express Highway & Glass CTM, Near Green Market, Hatkeshwar, Ahmedabad - 380026, Dist. Ahmedabad, Gujarat

KATHWADA., Ahmedabad SHREENATH ESTATE, NR.NIKOL-KATHAWADA CROSS ROAD, NR.SP RING ROAD. VISHALA EASTATE ROAD KATHWADA GIDC., KATHWADA., Ahmedabad - 382415, Dist. Ahmedabad, Gujarat

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

The DAE Pumps Submersible Drainage Pumps support a variety of dewatering applications. Their robust design provides the highest level of performance, reliability, and ease of use. The submersible drainage pumps offer a range of sizes up to 10-inches with over 80 HP and a volume capability of pumping as much as 6100 GPM.

Submersible Sludge Pumps are peak performers in pumping thick mud, clay, and waste. These energy-efficient pumps run at low horsepower, pumping as much as 420 GPM. Available in 3-inch and 4-inch sizes, the heavy-duty DAE Pumps Submersible Sludge Pumps are capable of moving abrasive solids as large as 2-inches. Our Submersible Sludge Pumps provide the support you need for for your toughest jobs.

The DAE Pumps Submersible Slurry Pumps are the toughest and most durable submersible pump. Built for pumping the worst slurry and materials, these pumps have the highest rating in ruggedness. Our Submersible Slurry Pumps are made for dredging the most abrasive media with high solid content in quarries and mining operations. With up to 102 horsepower, these powerful unit are capable of moving 2112 GPM of solids as large as 2.5-inches, and are available in 3-inch, 4-inch, 6-inch, and 8-inch sizes.

The DAE Pumps Payload Electric Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Payload Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

The DAE Pumps Hydraulic Submersible Slurry Pumps are the industry’s best-performing hydraulic submersible pumps. Capable of pumping up to 1325 GPM our hydraulic pumps provide the reliability you need. Because these 3-inch and 4-inch pumps are compact, their lightweight design makes them necessary tools for all site operations. They are non-clogging and are also available in a high head performance of up to 350 feet

The DAE Pumps Hauler Hydraulic Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Hauler Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

DAE Pumps is committed to providing you with the highest quality of pumps at affordable prices. We build our submersible pumps with you in mind. We use the strongest material inside and out to withstand the harshest conditions for getting the job done. Over the years, we built a modular platform of submersible pump that allows us to provide the highest performing pump with the same durability and reliability from one size and power to the next. This means you get the best pump each time.

Our low-cost submersible pump lines are an extension of our commitment to affordably priced pumps. These pumps are built with the same types of metal inside and out as our modular lines, but use a different technology design that brings the performance of these pumps close to those of the other models. We offer these pumps with a lower guarantee so you can get very high-grade pumps at the best prices.

Submersible pumps are the industry’s most durable pumps for underwater operations moving solids and liquids. They can withstanding everyday use of processing water, rocks, sand, mud, sludge, slurry, and other abrasive materials. DAE Pumps provides a variety of submersible pumps for mining, dredging, minerals processing, ash pumping, wastewater, dewatering, and pumping chemicals, oil, sludge, paste, and many other applications. We offer light-duty to heavy-duty submersible drainage pumps, submersible sludge pumps, and submersible slurry pumps.

The submersible drainage pump is built for general dewatering, groundwater, raw water, and construction site use. Construction companies and various municipalities use drainage pumps for removing water from heavily flooded areas and as sump pumps when rainwater or groundwater collects in low-lying and below ground work areas.

DAE Pumps drainage pumps are designed for flexibility and ease of use. Capable of pumping solids up to .5-inches, the durable design is made to move large amounts of water. DAE Pumps drainage pumps handle clean and dirty water with the best performance and efficiency on the market. Our drainage pumps provide powerful performance with minimal maintenance, and their durable body ensures continued use in harsh environments. We offer a variety of drainage pumps in 3-inch, 4-inch, 6-inch, and 10-inch discharge outlets with a horsepower of over 80 HP, and capable of pumping up to 6100 GPM.

Made to pump thick mud and other similarly viscous mixtures of liquids and solids, submersible sludge pumps are used for moving sludge or light slurry, tank clean-outs, trench and pond cleaning, mining dewatering operations, and various other applications. The sludge pump moves the material that can clog ordinary drainage pumps.

DAE Pumps heavy-duty sludge pumps can move water, but they are made for moving solid material and are built with a high wear resistance inside and out. The high-chrome (55HRC) impellers and base of the pump ensures stability while allowing the passage of large solids. The high-quality components for the mechanical seal guarantees a watertight seal and trouble-free operation. Our submersible sludge pumps move up to 420 GPM and come in multiple sizes and power options. These sturdy sludge pumps provide the reliability you need and the performance you can trust for your dewatering, cleaning, and transferring needs.

The submersible slurry pump is the catch-all of submersibles. Capable of pumping the most abrasive media with high solids content, the slurry pump is the workhorse for quarries and settling pond operations. These ultimate pumps are used for everything from dewatering to dredging.

DAE Pumps non-clogging submersible slurry pumps provide the ultimate in toughness.They have the largest apertures to facilitate the handling of slurry with the most challenging solids and the high-efficiency high chrome agitator can lift settled solids up to 2.5-inches. The robust design uses heavy-duty bearings to withstand shocks and overloads and a double silicon carbide mechanical seal for duty application. Our slurry pumps are available in 3-inch, 4-inch, and 6-inch models, with the ability to move up to 2112 GPM.

Sand is one of the most abrasive materials for any type of pump to manage. The beating of sand on the impeller, volute, and even the hose cause extreme wear and tear on pump components. Thesubmersible sand pump is designed to minimize the effects of blasting sand. However, over a period of extended time, the submersible sand pumps will show signs of wear on these parts from the constant pounding of sand and will require replacement.

Our submersible sand pump wear components are built with a high chromium iron, an extremely strong alloy that is mainly used in mining, milling, earth-handling, and manufacturing industries which require materials with exceptional wear and corrosion resistance. The exceptional wear resistance of high chromium cast iron is due to the high volume fraction of hard chromium carbides. The toughness of the matrix also contributes to the wear resistance and makesit very suitable for pumping sand.

DAE Pumps non-clogging submersible sand pumps provide the ultimate in toughness and sand pumping capabilities. Ourpumps move up to 1664 gallons per minute of material and are available in 3-inch, 4-inch, and 6-inch models.

After using several of the “Big Name” pumps I was sure there wasn’t a product on the market that could move our drilling mud. I was having to use an excavator and two dump trucks to move the mud. We found Gator Pumps and purchased a 12″ PTO driven pump. We were able to move our mud in half the time with less effort. What used to require three pieces of machinery and three operators now requires one tractor and one worker checking on the pump periodically. We also use our Gator Pump to pump rain water off our pits. The pumps are almost maintenance free and absolute workhorses. Save yourself the frustration of trying to find the right pump for your operation. Just call Dale and the guys at Gator. They’ll fix you up and you won’t be disappointed.

GATOR Pumps have been used by agricultural producers worldwide for over 40 years. Our pumps were originally designed to give the farmer a portable, reliable pump that he could quickly employ for all pumping operations.

Our pumps operate in canals, ditches, ponds, streams and lakes without suction lines or priming. We can filter out materials that clog sprinklers and nozzles that feed pivot systems. GATOR Pumps can be trailer mounted or in 3-point tractor hook-up for easy and portable one-person operation.

At GATOR Pump, Inc., our pumps have been used by agricultural producers worldwide for over 40 years. They were originally designed to give farmers a portable, reliable solution for all of their pumping operations. While they’ve since found use in many other demanding industries and applications, they continue to serve as a key piece of equipment in the agricultural industry. Whether your application involves pumping water from flooded fields, supplying water to flood and furrow-irrigated farmland, or driving pivot sprinkler systems, there is a GATOR pump to fulfill your needs.

In the agricultural industry, industry professionals make extensive use of pumps for irrigation and other water management purposes. The equipment enables them to move massive quantities of water quickly. Compared to older water management methods, it accommodates much higher volumes (typically hundreds or thousands of gallons per minute), which is necessary to keep various growing and harvesting operations running smoothly and efficiently.

There are many types of water pumps for agricultural applications. Each one varies slightly with regard to design and configuration, making them suitable for different operations. Some of the key factors to keep in mind when choosing one for a particular operation include a water source, desired flow rate, desired total suction head, and desired total dynamic head. Irrigation pumps for small fields located immediately beside a water supply do not have the same requirements as those used to flood large fields from a distance. Portability and compatibility with existing equipment are also essential. The former is important for operations that require the distribution of water from several different water sources to several different sites, while the latter is important if the operation already has an existing irrigation setup.

One of the most commonly used types of irrigation pumps is the power take-off (PTO) pump. It is designed to connect to tractors and use the power from the driveshaft to move water. They serve as an easy and convenient pumping solution for agricultural professionals with existing tractor equipment or power sources.

General water management, such as water transfer (from ponds, canals, ditches, and rivers to agricultural sites for crops and livestock as well as towns and villages for homes and businesses), sludge/sediment removal, water intake dredging, and tail-water reuse

GATOR Pump serves the agricultural industry by providing durable, reliable, and easy-to-use pumps. Our products can be used in canals, ditches, ponds, streams, and lakes without suction lines or priming. Additionally, they can filter out any materials that clog the sprinkler and nozzle components of pivot systems to reduce the risk of blockages occurring and can be configured for trailer-mounting or three-point tractor hook-up to facilitate multi-person or one-person operation.

Our standard pump offering is the GATOR power take-off (PTO) water pump. It was designed specifically for use in the agricultural industry, providing excellent power and performance while requiring minimal setup and maintenance. Its portability and compatibility enable agricultural workers to transfer water in any application that accommodates a trailer, from flooding water to farm fields to removing water from flooded fields.

Considering there are no suction lines, no priming or check valves, no mechanical seals, and no internal parts other than an impeller, the GATOR Pump is by far the most durable, maintenance-free, cost-efficient option for the farmer or agricultural producer. In addition, our in-house artisanal manufacturing means that customization is easy at the time of purchase. For example, we’ve had previous customers add a diesel engine or electric motor, relocate/swivel the discharge pipe onto one of our pumps to aid in mobility.

As you browse our selection of pumps, please keep this in mind and don’t hesitate to include your customized modifications when you request a quote. We pride ourselves on the easy and flexible design that our pumps offer; customer design modifications and longer models are available upon request. We are always happy to provide custom engineering services to ensure that our pumps do exactly what customers need them to do.

While our standard water pumps are engineered to suit a variety of workflows, modifications we have made for our customers’ unique operational needs have often led to new product lines.

While our standard water pumps are engineered to suit a variety of workflows, our customers often request modifications to meet their unique operational needs. We are always happy to provide custom engineering services to ensure that our pumps do exactly what customers need them to do.

The GATOR 3-pt Tractor Canal Pump: In response to a request for a PTO pump that would work alongside tractors in canals and ditches, we created the 3-pt Tractor Canal Pump. It is now available in 6-inch, 8-inch, and 10-inch discharge sizes with peak flow exceeding 5,000 US gallons per minute.

The GATOR Pivot Pump: This pump was designed for pivot sprinkler operations that utilized groundwater sources. It features a flotation mount that keeps the inlet at the top of the water and double-screened filters to keep out materials that would otherwise clog nozzles and lines.

The GATOR Cart Pump: Not all of our clients have large operations. The GATOR Cart Pump arose from a request for a portable pump that could easily be loaded and operated by a single worker. The resulting light, portable cart pump is now available in gasoline and electric variations with either a 2-inch or 3-inch discharge.

As these examples illustrate, GATOR Pump puts customer needs front and center in our engineering process. We are always happy to develop custom irrigation pumps for challenging agricultural situations. Whether you need to access a specific water source, remove problematic sediment, or workaround another unique constraint, we’ll build on our reliable base designs to yield a custom solution that works for you.

* The above specifications and figures are calculated on the transfer of ordinary plain water. Although increased solids content or denser viscosities will require slightly more fuel and power to achieve similar flow results, these calculations are suitable for estimating the power required and time/flow rates.

At GATOR Pump, we specialize in the design and manufacture of high-quality pumps for a variety of industries and applications. One of our core markets served is the agricultural industry.

The Original GATOR Trailer PTO Pump is recognized globally as a high-performance option for agriculture, boasting a rugged design that withstands years of use in demanding operations. Our in-house manufacturing team reviews each order, offering customization options to ensure that our pumps integrate seamlessly into existing irrigation or other water management systems. Custom orders extend these capabilities even further, allowing our team to offer unique designs that still reflect our commitment to compatibility, low operating cost, and lasting performance.

GATOR Pump has proudly served the agriculture industry for over 40 years, and we still provide replacement parts for all of our original clients. To learn more about our products and services and how they can benefit your agricultural operations, contact us or request a quote today.

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

Mud pump is qualified to be repaired, if not we have the capabilities and expertise to manufacture shafts rotors and impellers for your Gardner Denver Mud pump.

The condenser water pumps take hot water from the condenser to the cooling tower, and the chilled water pumps take cold water from the chiller to your AC unit.

When the pump fails, water is not circulated as efficiently or at all, compromising the performance of your entire system. Thankfully, pumps often signal that there is something wrong, and these signals usually come in the form of odd and loud pump noises.

Loud and unusual sounds emanating from circulating pumps are always a red flag, a sign that something is wrong either with the pump or in the water lines.

If you don’t have an air separator installed, you will most likely have to deal with air in your system at some point. When this happens, it’s important to inspect the water lines and bleed the system.

Modern pumps have bleeder valves that make the process very easy. Slowly open the valve until you start hearing a hissing noise. Once the hissing ceases, you will see a slight dribble of water, indicating that the pump no longer has air. At this point, you can close the valve.

After doing this, make sure that the pump has been installed correctly. Even a few degrees of inclination or misalignment will allow air to get locked in the pump.

Pumps can be oversized for several reasons. It could happen due to a degree of error in the planning and design stage when engineers need to “guesstimate” piping length and fittings, or it could be purposely designed this way so the system can expand in the future and the “right-size” pump today would not be able to meet the future demand of tomorrow.

Sometimes a pump replacement is needed right away, and the supplier didn’t have the perfect replacement in stock, or the engineers choose an oversized pump already considering an expected build-up of corrosion in the pipes that require more pump head.

Regardless of the reason that led to an oversized pump, having one can always cause excessive noise and vibration, loosing up connections and joints and causing piping fatigue.

Under sizing a pump presents a more serious issue. That’s because you, unfortunately, don’t have much choice other than replacing the pump and installing a larger one.

If the system is undersized, it can’t provide the duty needed, it can also lead to deadheading - when a pump’s discharge is closed because of a blockage in the line or an unintentional closed valve. When this happens, the fluid churns inside the pump until it heats up into a vapor, causing noise and damage. Deadheaded pumps can lead to motor burn out, a damaged impeller, seal leakage, cracked bushings, and compromised elastomers, ultimately killing the pump.

In systems with undersized pumps, you can verify if the existing pump can handle a larger motor to avoid dead head. Even though it may be the cheapest way to handle the problem, it is not the best and the solution would just be temporary.

Only some pumps have bearing assemblies, not all. However, all electric pump motors have bearings, and the excessive wear of bearings – whether on the assembly or inside the motor - can cause pump noise.

The good news is that pump models with bearing assemblies usually have the components available for purchase, and they are inexpensive and easy to replace.

The life of a bearing is determined by how many hours it takes for the metal to “fatigue,” but many factors can affect this, such as static overload, corrosion, lack of excess of lubricant, overheat, misalignment, and contamination. So, the best way to avoid bearings from wearing out too fast is via preventive maintenance and a comprehensive inspection of your system.

Water with rust and other sediments can wear out the circulating pump and clog the impeller. When this happens, noise is a consequence. To get rid of it, there is no magic bullet: the solution is in cleaning the system.

Many HVAC systems have dedicated filtration systems and dirt separators to prevent clogging from happening. Sediments can be easily removed from the system through water blowdown.

High-quality and modern pumps usually have 3 flow settings, while older pumps may have only one or two. That’s why older pumps are typically noisier than others. They are less efficient, and the energy loss is usually translated into a humming noise.

If your pump is making this noise and you have more than one option of flow setting to work with, locate the flow switch and turn it down one level. Then check the radiators and tower rails to verify if they are still getting up to the temperature they should. If so, then leave it this way.

If you operate with a VFD and your pump is still making a humming noise, check to see if you have a correct grounding of the motor to the VFD. In many cases, incorrect grounding allows the system to act as a noise transmitter.

To understand this, we need to take a step back and take a quick look at pump operation. Bernoulli"s principle shows us that fluid flows from areas of high pressure to areas of low pressure.

HVAC pumps operate by creating low pressure at the inlet, allowing the water to be pushed into the pump. As the fluid flows through the pump, the pressure decreases. If the pressure at the inlet happens to fall below the vapor pressure of the fluid, air bubbles form at the inlet. These bubbles can cause cavitation, leading to pump noise, damage, and lower capacity.

Net Positive Suction Head or NPSH is the difference between liquid pressure at the pump suction and liquid vapor pressure and is expressed in terms of the height of the liquid column. NPSH needs to be usually 3 to 5 feet to avoid cavitation.

If detected in an inspection that there’s a problem with the NPSH, basically two things can be done: first, there’s the option to choose a more appropriate pump for the application (our recommendation if the pump has already suffered irreparable damage due to cavitation). Second, the system can be reevaluated to see if elevating the cooling tower can increase NPSHa (the absolute pressure at the suction port of the pump) or if fittings that rob current NPSHa can be reduced.

If you need assistance with anything related to circulating pumps, contact us. We have 3 offices in California, and we can go wherever you are to inspect your pump if you are experiencing loud and unusual noises.

The Vertical Systems team of sales engineers and technicians can point out the cause of pump noises, and determine the best solution to eliminate it. Experts in all types of circulating pumps, our professionals can solve any problems with installation, worn components, leaks, and issues related to water temperature, pressure, and air bubbles. They can also recommend energy-efficient upgrades that will make your system perform better and save you money.

8613371530291

8613371530291