mud pump power end parts supplier

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

We also served as the acting shop and field repair representative for the Western Gear Company and as a manufacturing facility for Wilson Manufacturing Company based in Wichita Falls, Texas. Wilson was a manufacturer of well service rigs and mud pumps. SMC Inc. has served and currently serves as a manufacturing and repair center for Oil Well Supply, Cabot-Franks, National, Halliburton, The Western Company, B.J. Hughes, Gardner Denver and many others. We manufacture a triplex pump of 165 H.P. with parts interchangeable to the Gardner Denver model TEE and are currently developing a 500 H.P. pump with parts interchangeable to Oilwell"s SA-644-5 pump. SMC has a large warehouse full of quality replacement parts for various types of equipment such as Triplex Plunger Pumps, Mud Pumps, Swivels, Drawworks and Rotaries.

We manufacture positive displacement pumps and replacement parts vital to the oil industry worldwide. We have customers that include both domestic and foreign oil companies. We also manufacture and repair a variety of products used in routine maintenance by customers with rock crushers, aggregate and commercial cement manufacturing plants.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

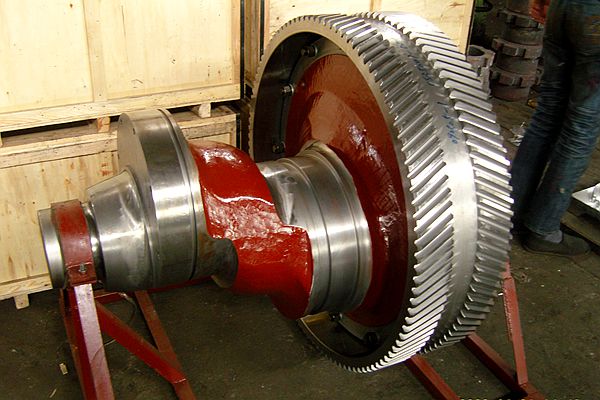

We manufacture and offer power end parts of triplex mud pumps for our clients all over the world. Power End includes frame, pinion shaft, crankshaft, crosshead and extension rod.

The frame is made of welded steel plate to provide the frame with high strength, good rigidity and lightweight. The extension rod packing is of duplex seal structure to provide the good seal result. The power end uses the combined lubrication system of forced lubrication and splash lubrication.

The crankshaft is made of cast alloy steel and is furnished with big geared ring, connecting rod and bearing. The tooth form of the big-geared ring is herringbone gear. The gear bore and the crankshaft surface is interference fitted and they are both fastened with bolts and lock nuts. The big end of the connecting rod is mounted on three eccentric straps of the crankshaft through single row short cylindrical roller bearings and the small end on the crosshead pin through double row long cylindrical roller bearing. Double row radial spherical roller bearings are mounted at both ends of the crankshaft.

Pinion shaft is made of forged alloy steel on which a herringbone gear with the medium-hard tooth surface is machined. For easy maintenance, the single row radial long cylindrical roller bearing with inner ring (without sides) is used. Both ends of the pinion shaft extend out, so that the sheave or the sprocket can be mounted on either end.

The crosshead and crosshead guide are made of ASTM A48-83 meehanite cast iron featured by good abrasion resistance and long service life. Upper and lower guides are used on F-800 and F-1000 mud pumps, so that the concentricity can be adjusted by adding shims beneath the lower guide. F-500 mud pump is the cylindrical structure. Bolted flange is used at the connection between the crosshead and the extension rod. The rigid connection ensures the concentricity of the crosshead and the extension rod. The coupling is used for connecting the extension rod to the piston rod. The lightweight coupling enables the extension rod and the piston rod to connect to each other easily and reliably.

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

Rig Parts Oilfield Supply Co., Ltd ( RPS ) is committed to providing the world with the best drilling equipments and services at the best prices, especially mud pump and parts, plunger pump parts, handling tools and solid control equipments.

If you work in oil and natural gas, you know what the two most valuable resources are – Time and Money. With our new Parts on Demand program, you can save more of both.

As part of Experience 360, our Parts on Demand program lets you manage your replacement parts inventory at your regional location, pump site, or even via GD Energy Products Parts on Demand mobile trailers.

These Frac and Mud Pump Consumables are OEM-certified parts, designed, manufactured and tested by our Pump experts, and proven to maximize the performance on your operation. Our parts are always available, ensuring you have what you need, whenever and wherever you need it.

5280 mud pump parts products are offered for sale by suppliers on Alibaba.comAbout 25% % of these are mud pump, 1%% are grapples, and 1%% are other construction machinery attachments.

A wide variety of mud pump parts options are available to you, You can also choose from electric, diesel engine mud pump parts,as well as from high pressure mud pump partsand whether mud pump parts is oem, or odm.

At BOPM, we constantly maintain 5 million worth of mud pump parts on the shelf at our Houston warehouse location. It includes modules, liners, extension rods, piston rods, pistons , threaded rings, caps, valve covers, valve guides, valves, seats etc. for all major brands of pumps: Gardner Denver®, Ideco®, Emsco®, National®, Oilwell®, Skytop Brewster®, Lanshi(3NB1300C) ®, Bomco ®, HH ®.

BOPM offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps, such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends.

Our high-strength, triple reduction, forged steel triplex fluid end modules are made from highest alloy steel. Heat treated for long working life, they are machined to perfection and packaged for delivery with anticorrosion protection. The precisely made jewelry-like exterior finish reflects our superior quality.

BOPM piston rods are made with premium grade, heat treated alloy steel. The rods offer excellent resistance to fatigue, corrosion and heavy loads. A full line of piston rods are available for various pumps.

BOPM extension rods are made from high strength alloy steel, and are either heat treated or chrome plated. The rod offers excellent resistance to fatigue, corrosion and heavy loads. BOPM extension rods are machined and polished to ensure a perfect seal to protect the mud pump gear end.

All of our gear set adopt high-end carburization heat treatment and precise grinding machining to offer unparalleled durability; first we use high strength alloy steel, then adopt the Carburization heat treatment to enhance the hardness and wearability, finally adopt the grinding fine machining to ensure the smooth gear teeth surface; Resulting in consistent and rugged performance throughout pump operation.

BOPM bonded urethane pistonsare constructed of urethane, bonded to a steel hub. The double durometer urethane is designed to provide optimal performance in oil or water based mud and high drilling pressures.

BOPM Replaceable Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

BOPM Bonded Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

8613371530291

8613371530291