spm mud pump brands

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

1. Usage and Application Range SB series Centrifugal Sand Pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer,to assure these equipment work efficiently. The SB10×8×14...

Mud Pump Spare Parts We can offer the mud pump spare parts covers the liners, valves and seats, pistons etc to match the most types of mud pumps in the market, like Emsco, Gardner Denver, National, Oil well, Continental, Ideco, and China 3NB etc Brand Model Emsco F-350 F-500 F-650 F-800 F-1000

Carbon/ Stainless Steel Triplex 600HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 1,550LB Approx. Size: 28”x12”x19”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing...

Carbon/Stainless Steel Quintuplex 1000HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 2,500LB Approx. Size: 46”x12”x20”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing...

Carbon/Stainless Steel Triplex 2250HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 4”,4.5”,5”,5.5”,6” Load Weight: 3,350LB Approx. Size: 36”x19”x23”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing job....

Carbon/Stainless Steel Quintuplex 2500HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 4”,4.5”,5”,5.5”,6”, 6.5” Load Weight: 4,800LB Approx. Size: 52”x19”x23”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the...

Carbon/Stainless Steel Quintuplex2700HHP Basic Parameters: Stroke: 10” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 3.75”,4”,4.5”,5” Load Weight: 5,500LB Approx. Size: 59”x24”x26”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing job....

Carbon/Stainless Steel Y block Quintuplex 2800HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 3.75”,4”,4.5”,5” Load Weight: 6,300LB Approx. Size: 63”x20”x24”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the...

Trailer Concrete Pump LV-HB-20S Product Advantages: One machine with multi-purpose, it can transport mortar/fine stone concrete and spray mortar/fine stone concrete. It is small but flexible. It is mostly used for exterior wall spraying, slope protection spraying, etc. Technical Specification Maximum vertical...

Trailer Concrete Pump LV-HB-40S Product advantages: One-piece stamping hopper, no material accumulation. Electric double lubrication, no distributor, point-to-point lubrication. Panel operation and wireless remote control dual control. Super air cooling, no water cooling required. Technical Specification

Trailer Concrete Pump LV-HB-45S Product advantages: Hydraulic control equipment. One-key switch between high and low pressure, one-key return piston. Ultra-stable performance, no need for proximity switches. External junction box, wiring is more convenient. The speed is adjustable, 4-45m3 can be adjusted arbitrarily....

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Established in the year 2004, TianyuMfg has been manufacturing high-quality well service pumps and parts for hydraulic fracturing and downhole drilling for over 16 years. We are supplying aftermarket frac pump parts and high-pressure flow irons of all major pump makers including Weir SPM, Gardner Denver, Halliburton, FMC, OPI. All our products are 100% interchangeable with these original makes and we are supplying them with the market-leading quality warranty.

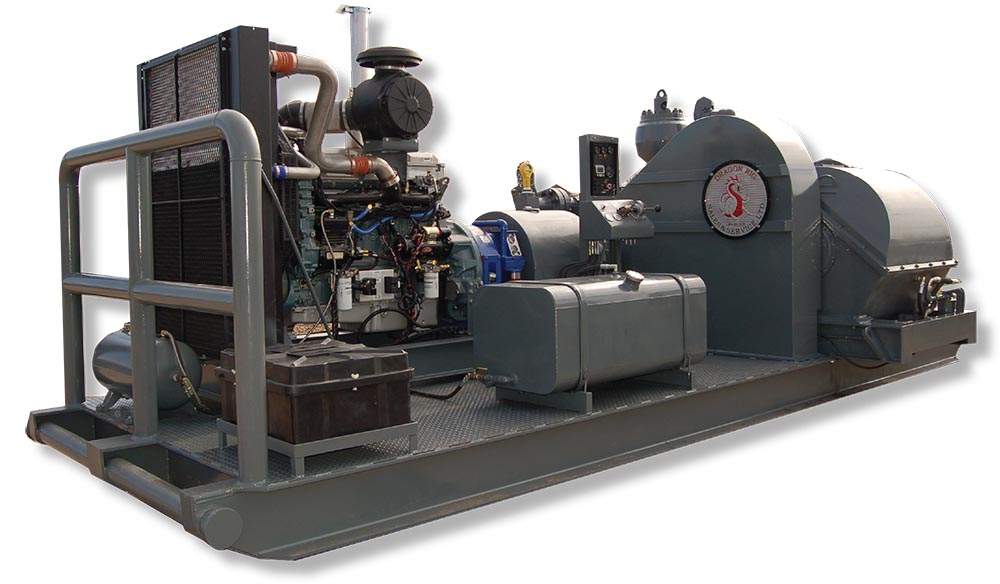

Mud pumps are akin to the heart, they are key equipment in oil and gas drilling that pumps and circulates the drilling mud. As a key player in the manufacture and sales of oilfield equipment, we have a complete range of triplex mud pumps with compact design, reduced carbon emission, and improved performance.

Our classes of onshore and offshore mud pumps range from 450 to 2,200 hp diesel or electric (AC or DC) powered with 3000 to 5000 psi ratings. We design our mud pumps to match different rig types, work optimally and safely both onshore and offshore.

8613371530291

8613371530291