3000 hp w 7500 psi discharge mud pump manufacturers in stock

Single Acting Triplex pumps come with three cylinders and are commonly used for various applications requiring low to medium flow rates including mud pumping, cement pumping, salt water disposal, descaling, high pressure pumping, Frac pumping and pipeline systems for the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors. We have new, used and rebuilt API 674 triplex pumps of all leading manufacturers like Union, Gaso, Emsco, Apex and Wheatley.

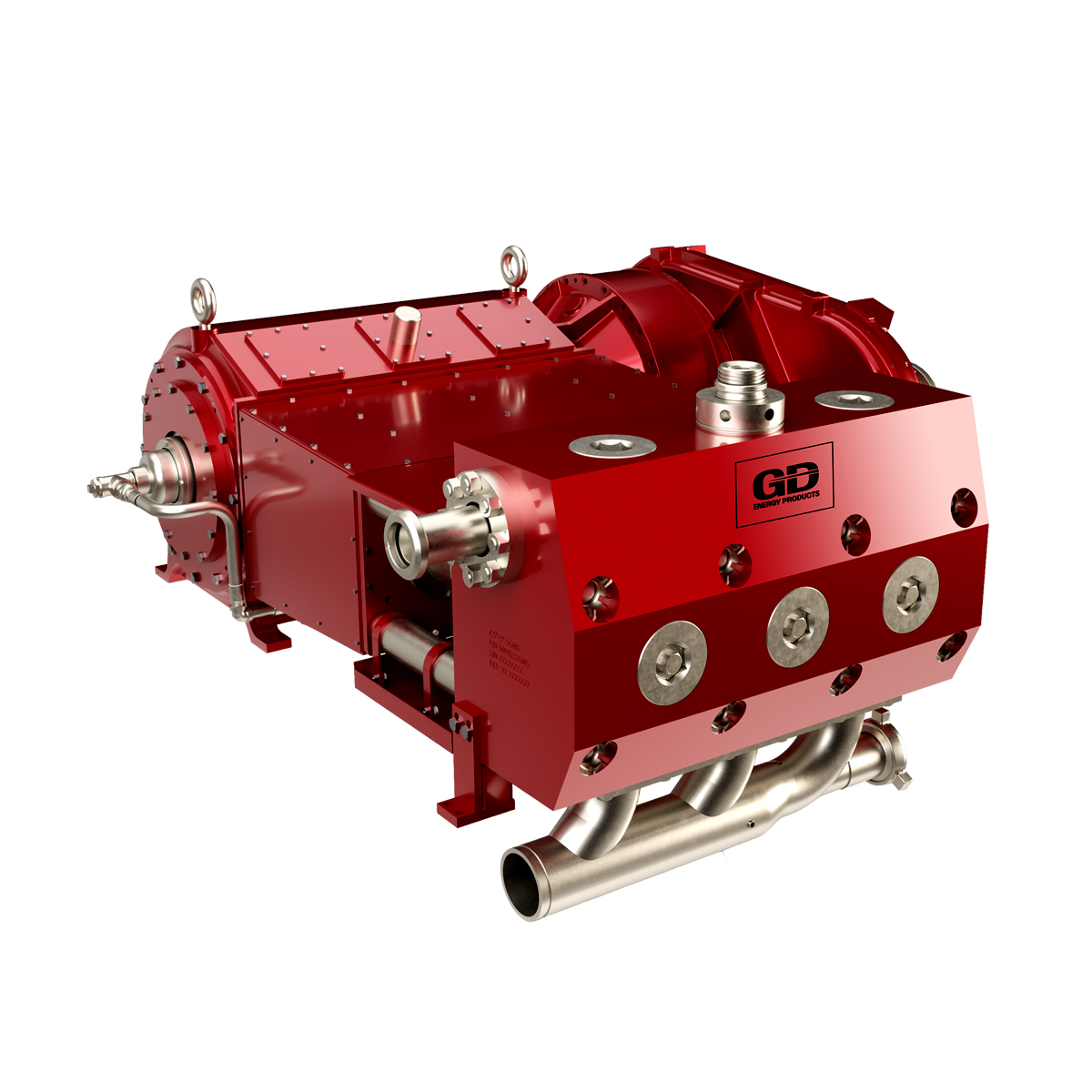

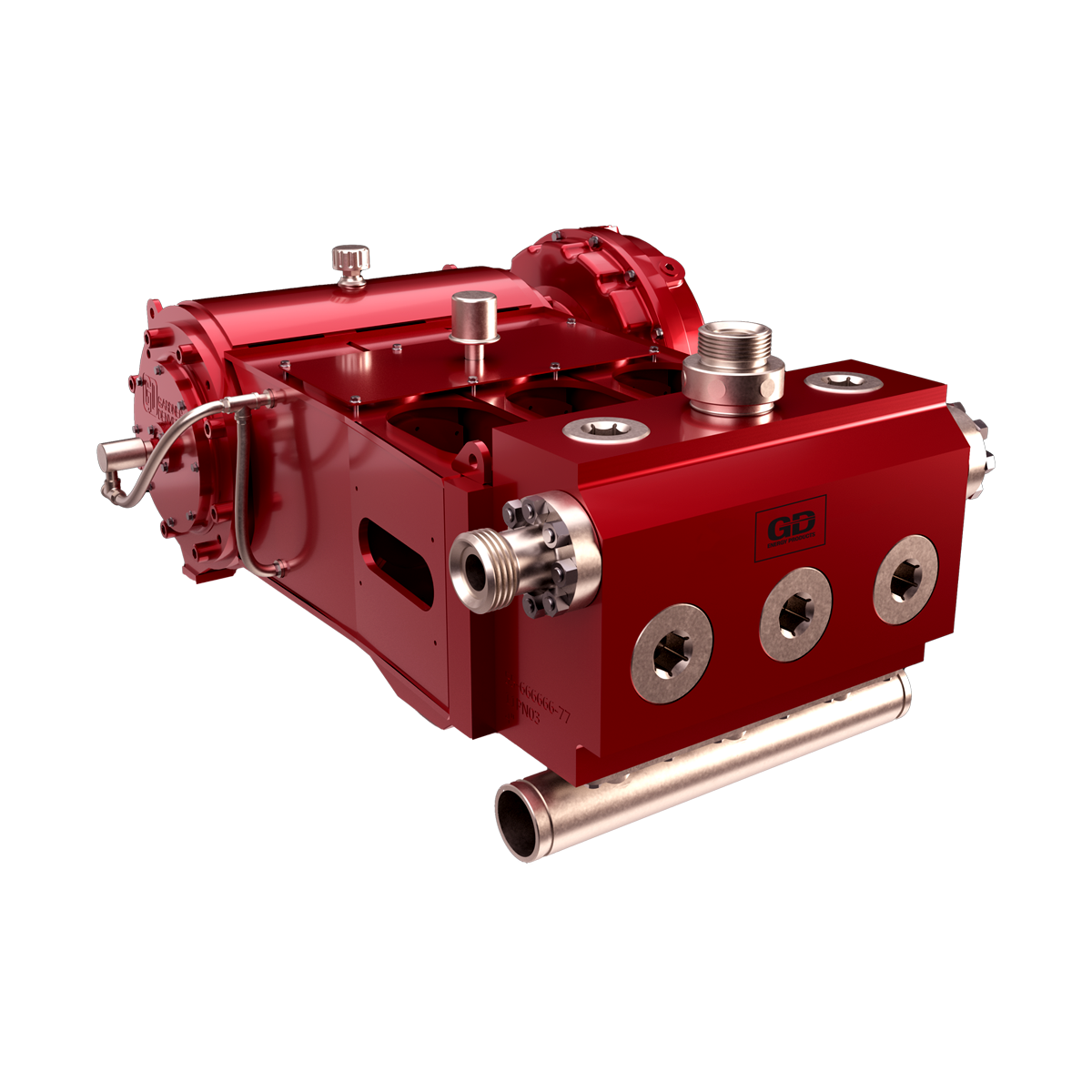

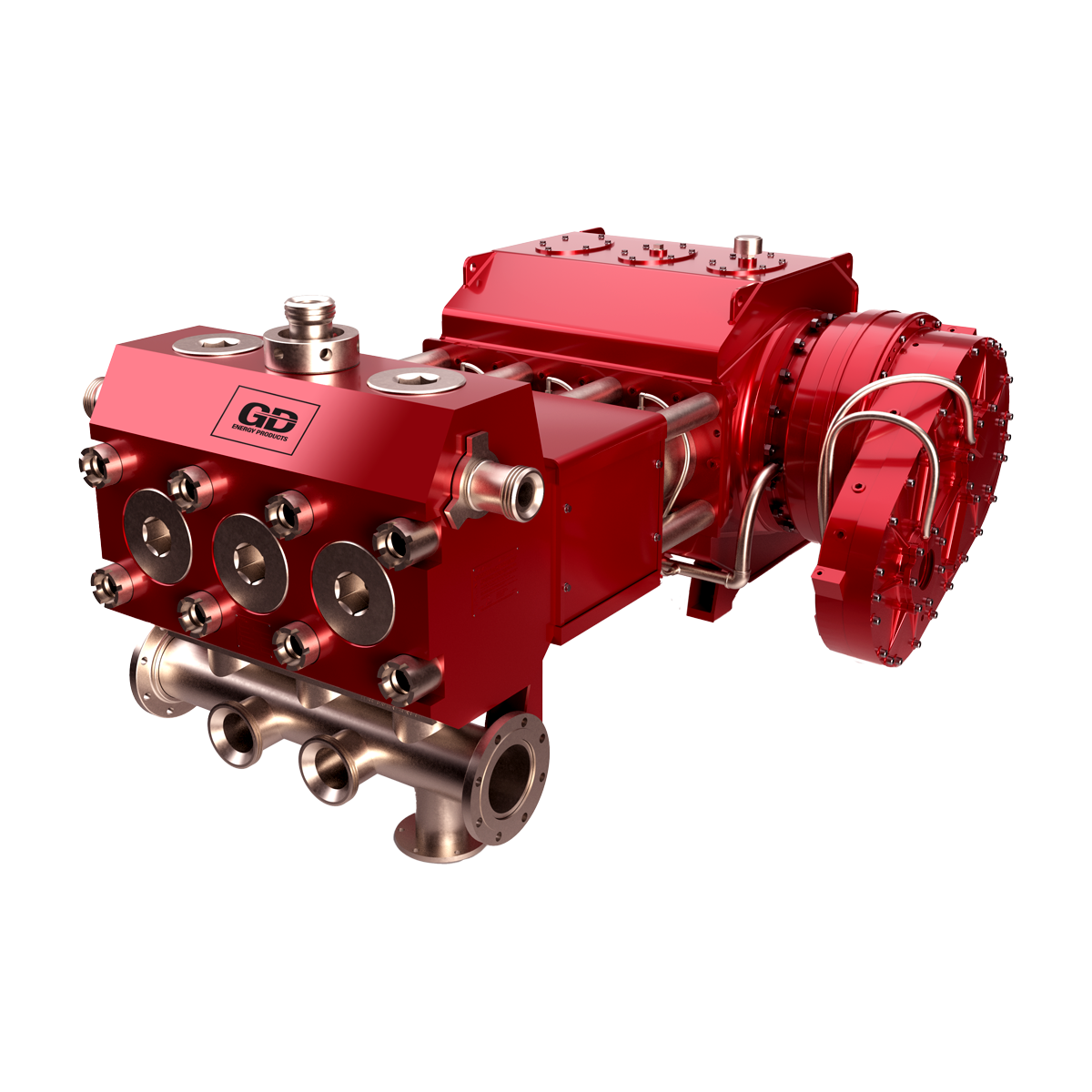

The GD 3000 is a heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of 40+ years, this high-performance pump is durable, strong, and time proven.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We noticed you"re using an unsupported browser which may result in limited or no functionality for portions of our website. We recommend using Google Chrome, Mozilla Firefox, Microsoft Edge, or Safari for the best experience.

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 406b4f95116c28dca247da206ca234ea 63.210.148.230 02/25/2023 09:09 PM UTC

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

In 2011, the Kuwait Oil Company (KOC) considered enhancement of equipment specifications for deep drilling rigs to integrate state-of-the-art technologies. UPDC Rig 776 was the first to be upgraded, and this work was handled as an integrated project by the rig contractor working closely with the field operator. With regard to the rig design, major changes were made to enhance safety, capacity, and automation of the drilling functions.

The drilling of future deep high-pressure/high-temperature wells in Kuwait will become more challenging. New frontier areas with increased depth and formation difficulty are being targeted. To ensure that the deep drilling rigs will be able to meet these future challenges and to improve safety and operational performance, KOC has enhanced the deep-drilling-equipment specifications for their new contracts.

For Rig 776, this required a major upgrade or replacement of all core rig components.The subbase height had to be increased to be able to incorporate a full 15,000-psi blowout-preventer (BOP) stack rig-up.

These improvements were aimed at enhancing safety, capacity, and automation of the drilling functions. In addition to these major changes, the rig camp was completely refurbished and the camp power generation was upgraded to silent packages.

Once Rig 776 finished drilling the last well before the upgrade, the rig was prepared for the yard work. As the rig commenced to rig down for the move to the project yard, all equipment had to be cleaned properly. The mud tanks had to undergo sand blasting before inspections could be conducted. The cleaned equipment was then moved to the project yard. The rig offices were set up in the project yard to provide extra office space.

Subbase and Mast. The subbase height had to be increased by 10 ft. This was accomplished by changing out all existing subbase legs. With the new subbase height, all stairs, escape slides, piping and hoses, and the personnel elevator to the rig floor had to be modified or replaced and the V-door ramp had to be extended.

In addition to increasing the height of the subbase, the entire subbase and mast underwent inspection and recertification. This required sand blasting of all components, inspection, and repainting. Any defects found had to be repaired, with parts replaced as needed.

Once work on the subbase and mast was completed, a new 120-ton BOP hoist system had to be installed. The spill containment (drip pan) was replaced under the rig-floor area.

On the rig floor, the existing ST-80 iron roughneck had to be replaced with a large-capacity IR10-100 roughneck. A new 20,000-lbm air tugger also was installed.

Drillers Cabin. The old driller’s console was to be replaced with a modern enclosed driller’s cabin that holds joystick controls for the drawworks. This cabin incorporates touch-screen controls for all major rig functions (Fig. 1).

Topdrive. The topdrive was stripped down, and all parts were inspected. The main shaft had to be upgraded from 3 in. to a new large-bore 4-in. shaft with a 7,500-psi pressure rating.

Drawworks. The existing drawworks had to be completely stripped down and inspected and overhauled. The old drum shaft and drum had to be replaced. A new disk braking system was installed. New semiautomated controls were installed for the driller.

Mud Pumps and Discharge Piping. The three original 1,700-hp mud pumps were replaced with new 2,200-hp pumps with 7,500-psi output. These new pumps include a quick liner and piston change system. Also, an independent charge-pump skid was added to the system. These new pumps can deliver more mud volume at higher pressures, as required for the new drilling program.

All old 5,000-psi mud-discharge lines, mud-discharge manifold, stand-pipe manifold/lines, and rotary hoses had to be changed to larger-inner-diameter and higher-rated 7,500-psi lines.

Mud System. The existing mud tanks were cleaned, sand blasted, inspected, and repaired as required. The mud-volume capacity was increased to 4,500 bbl with the incorporation of additional tanks. New larger 20-hp agitators were installed to improve agitation of the heavy muds (up to 20.5 lbm/gal) used in Kuwait. Also, one new shale-shaker unit was installed to provide better solids removal.

Rig Engines, SCR System, Accumulator Unit.To cope with the higher power demands of the new mud pumps and mud system, the five existing 12-cylinder engines were replaced with larger, 16-cylinder engine packs. The old SCR system was replaced with a new SCR system that integrates automated engine control in the driller’s cabin.

Camp Refurbishment. The entire main camp and rigsite camp underwent refurbishment in the project yard. One by one, the cabins were cleaned and repaired and refurbished, as required. Several cabins were replaced with new-built cabins.

24-Hour Testing and Final Inspection.Once all work was completed, the rig entered into a 24-hour maximum-load test, which was witnessed by KOC representatives and a rig-inspection contractor. The test was set up to simulate heavy drilling conditions. To draw maximum power from the engines, all three mud pumps were pumping, the topdrive was running, and all agitators and shale shakers were running. The rig systems had to withstand this 24-hour load test without any shutdown of more than 30 minutes.

The rig was then rigged down and moved to the first location in the South Burgan field (Fig. 2 above). During rig-up, the remaining smaller outstanding jobs were completed and a final prespud check was conducted by KOC. Once all was accepted, the rig spudded the first well on 18 January 2012.

Yard Operations and Multiple Projects. Many challenges of this project stemmed from the fact that, concurrently, there was a second upgrade project (Rig 3) and two new rigs being built. To deal with this, three project managers with their teams were used (one for the new builds and one each for the upgrades). The upgrade teams for Rig 776 and Rig 3 worked at the yard in Kuwait, while the new rigs were built in Dubai.

Rig 776 was the first rig to undergo the upgrade works, followed by Rig 3. The rigs were expected in the yard in Kuwait within a month of one another, so the available yard space had to be used efficiently. The project yard was separated into two areas to keep equipment and materials from getting mixed during the project.

Materials and Logistics. Another substantial challenge was the coordination of all purchasing activity. Large quantities of equipment and parts were ordered for all four projects. This required the use of dedicated warehouse and logistics teams to process the ordering, tracking, and shipping of materials. A major problem was slippage in promised delivery times from various vendors, some of which resulted in delays to the project work. To overcome these problems, some equipment had to be urgently air-freighted and some had to be shared or borrowed from other rigs until the new equipment arrived in Kuwait. The main lesson from this is that the sooner the equipment is ordered, the better.

Refurbishing Existing Equipment. While planning for the upgrade, all efforts were made to establish the condition of existing equipment accurately and to anticipate what work and which parts were required. But some of the equipment conditions remained unknown until the particular item was completely dismantled in the yard. On a few items, equipment conditions were found that were worse than expected, and replacement parts had to be ordered on an urgent basis.

For future upgrade projects, it is recommended to negotiate with the parts vendors to provide all possible required critical parts ahead of time and then return the parts that are not needed. This will avoid waiting-for-parts project delays.

Connecting Systems From Different Vendors. The new driller’s cabin and controls and the SCR house were made by one manufacturer, and the main rig equipment was supplied by other vendors (drawworks, topdrive, mud pumps, and main engines). Getting the equipment set up properly to ensure smooth communications between these systems was vital and had to be done with care, using service technicians from all involved manufacturers.

Initial Results. After final testing and commission of the upgrade, the first deep exploratory well was drilled with the modified rig in the Kuwait South Burgan field. While drilling the first well, no major problems were experienced with the newly installed instrumentation system or other upgraded equipment. The initial well was drilled under planned time, with no lost-time injuries or environmental incidents.

This article, written by Special Publications Editor Adam Wilson, contains highlights of paper SPE 164019, “Re-Engineering and Upgrade of Semiautomated 3,000-hp Drilling Rig for KOC HP/HT Exploration Program in Frontier Areas—Case History of UPDC Rig 776,” by A. Al-Saleh,SPE, M.D. Al-Khaldy,SPE, A.A. Shehab,SPE, F.A. Al-Naqa,SPE, and S. Baijal, Kuwait Oil Company; M.F. Karam and S. Schmidt,United Precision Drilling; and D.C. McKinnell, SPE, Total Kuwait, prepared for the 2013 SPE Middle East Unconventional Gas Conference and Exhibition, Muscat, Oman, 28–30 January. The paper has not been peer reviewed.

Providing you the best range of 100m 25 HP Heavy Duty Mud Pump, GMT15 15HP Heavy Duty Mud Pump, GMT10 Heavy Duty Mud Pump, GMT25 25HP Heavy Duty Mud Pump, GMT30 30HP Heavy Duty Mud Pump and GMTN21 Granite Block Cutter Mud Pump with effective & timely delivery.

Drilling of deep HPHT wells in Kuwait requires both local and international drilling contractors to adhere strictly to overall required capacities of equipment for safely and efficiently drilling Jurassic and deeper exploratory prospects from depths of 15,000 ft to more than 22,000 ft TVD. This requires use of 3,000-hp rigs due to heavy casing hookloads for the 24-in. and 18 5/8-in. casings, high mud weights at relatively deep depths in 16-in. and 12 ¼-in. hole sections, and fairly high torques throughout the well. Likewise, mud volumes in these wells require adequate capacities and processing capabilities for the larger hole sections, especially when dealing with 19.5-ppg mud systems with a solids content of around 45% in the 12 ¼-in. hole section at 14,000 ft.

Typical casing loads of 1.3 MM lbs occur during lowering of the 18 5/8-in. intermediate casing, maximum flow rates of 1,200 to 900 gpm (depending on mud weight) with surface pumping pressures greater than 4,500 psi are seen in the drilling of the 16-in. hole section utilizing PDC bits in conjunction with performance type mud motors, and on bottom drilling torques of over 20,000 ft-lbs occur in the drilling of the 28-in. hole section for these wells.

In addition to the basic load requirements in the present Jurassic and Khuff well designs, possible future well design for exploratory HPHT gas wells over 25,000 ft deep dictates that use of even more pumping horsepower as well as semi-automated control system to allow the smoothest transfer of surface parameters to the bit is recommended. Offset data from the Khuff well tended to justify the requirement for more power and capacity if the target depth of 25,000 ft is to be met, and this was a key driver for designing a state-of-the-art rig.

Even more importantly, upgrading or building new 3,000-hp rigs to reduce overall nonproductive time (NPT) and related unscheduled events was an achievable goal that KOC began pursuing in 2001. A prime example of NPT operations improvement can be seen in the reduced instances of stuck pipe by utilization of the top drive to reduce the critical time delay from when the pipe initially sticks to when torque can be applied to free it. Another example is picking up drill pipe offline, using either the iron roughneck or rotating mouse hole, as well as the decreased connection time overall while drilling with stands instead of single joints of drill pipe.

Above all, safety was given the utmost consideration when looking at an upgrade or building of these 3,000-hp rigs. An example of equipment used to reduce risk of repetitive motion injuries can be seen in the iron roughneck and automatic slips used in tripping operations. Use of these devices, from a safety perspective, to reduce the risk of predominant repetitive motion type injuries to the lower back and fingers has been taken into account as a safe working rig environment and has proven to be a more productive rig environment.

Partly as a result of the successes from the earlier rig upgrades, KOC began pursuing a newbuild 3,000-hp rig in mid-2002. Kuwait Drilling Company was awarded the contract, and newbuild KDC Rig 15 was built during 2003 and commissioned in April 2004 as the first Kuwait contractor-owned advanced 3,000-hp drilling rig. This rig has proven to be an asset to deep-drilling strategy and continues to deliver ongoing improvements in performance.

With the anticipation of even deeper exploratory prospects to 25,000 ft in the not-too-distant KOC future, and with the successes of rigs KDC-15 and KSF 24, a deep-drilling contract strategy was developed and presented to management in 2003 to build an even more sophisticated semi-automated 3,000-hp drilling rig for Kuwait.

Item 4 was viewed as key to Kuwait’s future success in building and maintaining a localized 3,000-hp deep-drilling fleet capable of competing in any world market, and this idea was combined with Item 3 to help secure approvals to pursue a single-source local contract for a newbuild state-of-the-art 3,000-hp rig, which offered the following technical advances:

Contracting strategy also involved a detailed justification for the increased dayrate that a proposed rig of this nature would require to be commercially acceptable to both KOC and the contractor, Hamad Al Hamad and Partners (HAH). Therefore, each upgraded component would have to be shown to have a value added benefit over its respective cost increase to the dayrate. This cost comparison was performed using the presently contracted 3,000-hp rig KSF 24 as the reference base rig for dayrate.

One item that became evident in the initial estimated pricing of the components and estimated value added was that the primary contract term needed to run over a longer period than that of the normal rigs in order to allow the commercial risk to be spread out for payout.

In early 2004, meetings were held within the KOC Deep Drilling Team to formulate a strategy to work with the drilling contractor to obtain the best-value equipment for the proposed rig. The criteria included looking at such things as past lessons learned with respect to KDC Rig 15 and KSF Rig 24, adaptability of the equipment with respect to Kuwait’s environment (hot weather and sand), interchangeability of equipment with other 3,000-hp rigs in Kuwait, and detailed technical specifications of the equipment.

The objective of the technical specification was to state what equipment was required to obtain a deep-drilling rig at a competitive dayrate that provided technical advantages over the deep-drilling rigs presently working for KOC.

This was accomplished by specifying items such as model numbers and technical ratings of the equipment so that minimal contract negotiations would be required to minimize any future problems due to equipment generalities. Original equipment manufacturer (OEM) was repeatedly consulted during the technical discussions in respect of the specification of equipment and parts for that equipment.

Meetings with several rig-building companies were held with both KOC and HAH in attendance to discuss technical details of equipment specifications. Likewise, meetings with mud solids processing companies, BOP companies and drill pipe manufacturers were held to compare specifications. Basically, the tender document from KOC to HAH reflected choices of technically superior equipment similar to a pre-qualification, from which competitive bidding was used to get to the final product.

3,000-hp drawworks – The requirement for enough drawworks to handle the 18 5/8-in. casing loads in a smooth manner led to studying the use of AC versus DC power. Although AC power has become increasingly popular with drawworks and top drive systems, it was ultimately decided in 2003 to continue with DC power in the drawworks, mainly due to familiarity of the same with the present local electricians and mechanics.

Top drive system (TDS) – As with the previous upgraded or newbuild deep rigs, a TDS was deemed necessary with the semi-automated control system to provide more efficient and safer operations while drilling in stands with fewer connections, and to provide faster response to tight hole and differential sticking situations to lower NPT.

The TDS system was also looked at from the viewpoint of AC versus DC power requirement, and DC was chosen again with the previous experience of the local electricians and mechanics being a driving factor.

Automation – The semi-automated drilling control equipment was planned with several items in mind. Safety with respect to block incidents striking the crown or rig floor was a high priority on this list due to several incidents that occurred with respect to crown-o-matic use in late 2003 and early 2004. The proposed control equipment was designed to give a second “barrier” via position control stop to the traveling block as it approached the crown or rig floor.

Improvements concerning “on-bottom” rate of penetration (ROP) utilizing performance mud motors and PDC bits were also an important item discussed in the meetings. Semi-automated driller (electronic driller) was a feasible way to improve ROP. Use of the pump pressure differential feedback created by on-bottom motor torque as the primary ROP control has been shown to be most effective in both directional and performance type mud motor drilling. This is especially true with slip-stick phenomena where ROP is sacrificed due to manually attempting to control WOB.

The use of a joystick disk brake system to allow proportional control was also agreed upon as the way to better control block speed, especially while running heavy drilling and liner strings with respect to control of surge pressures. As shown in top graph above, mud weights of 19.5 ppg and higher are anticipated in the Gotnia salt section with pore pressure/frac gradient extremely close, and lost-circulation problems, which usually require over a week to cure with associated concerns of well control.

The fine-tune control of the ECD surge, especially with a compressible diesel oil-based drilling fluid as used in deep drilling Kuwait, was deemed as critical for the maintaining of full returns during tripping and liner or casing running operations above and through the Gotnia.

The possibility of drilling a very deep 25,000-ft exploratory gas well in Kuwait required a rig that could deliver more hydraulics in hole sizes even bigger than currently planned. Likewise, future deep directional delineation or development holes targeting intersection of vertical fractures in the Najmah/Sargelu formations required more than 5,000-psi surface pumping pressure to effectively drill with mud motors. For this reason, a comparison was made between 1,700-hp and 2,200-hp mud pumps used in conjunction with drill pipe sizes bigger than 5 in. As the figure to the right indicates, hydraulics availability increased dramatically with the use of 2,200-hp pumps with the added benefits of being able to run the pumps at lower speeds thus reducing wear and tear.

Also, if pump liner change-out was required due to wear and tear in the larger hole sections, the ability to continue drilling at optimum pump rate will be realized with two 2,200-hp pumps. With the 1,700-hp pumps in larger hole sections, the flow rate from two pumps must be restricted while working on the third mud pump.

Rig floor iron roughneck – Safety was a prime consideration with respect to hand injuries during discussion of the iron roughneck as an addition to the newbuild rig. The ability to make up or break out various rotary connections at slightly different heights above the rig floor with more ease than traditional tongs, catheads and spinning chains has proven to be more time effective as well. The challenge with iron roughnecks has always been where to put them with regards to space and access on the rig floor. This is especially true where pipe is picked up offline and racked in the derrick while drilling hole, thus saving time and money.

It was decided to utilize a post-mounted hinge type iron roughneck to access both the rotary table for drilling/tripping connections as well as the mousehole for offline work.

In conjunction with the iron roughneck, the latest design power slips were installed for increased rig floor safety and to allow the running of many of the casing strings without the need to rig up casing slips that protrude above the rig floor.

A KOC Deep Drilling Mud System Workshop was held in early 2004 with an IOC mud consultant to gain insight as to solids control requirements and discuss various solutions for the newbuild rig. The consensus was for high-speed shakers with decanting centrifuges over traditional hydrocyclone equipment.

Discussions with several solids control companies confirmed this consensus. The number of shakers required for the largest hole sections was thoroughly researched, and consensus was to use four high-speed shale shakers for worst-case scenario in 28-in. hole section at 1,500 gpm. This was balanced with the realization of sizing the sand traps to the shakers and downstream plumbing troughs plus feed lines to take into account gas in the mud and other factors. A multi-flow diverter was also proposed to evenly distribute the mud returns from the flowline to each shaker to prevent overloading one or more shakers.

The solids control companies as well as mud companies were invited to visit a deep-drilling rig in Kuwait to gain insight as to what was unique about the fluids systems on these rigs and discuss what could be done to improve the capacity and handling requirements. Reducing the plumbing or dead volume within the pits and optimizing placement of processing equipment within the return flow streams was given top priority.

Reserve mud capacity was also discussed, especially with the requirement to switch from water-based mud to oil-based mud in the 16-in. hole section and problematic mud losses in the 16-in. and 12 ¼-in. hole sections. Agreement was to have at least 3,000 bbls of reserve capacity for the system for worst-case scenario, with a total mud capacity of 4,500 bbls.

Also discussed was the proper mix of valves and plumbing to access each compartment for manipulation of the system. Balance again was struck between too much plumbing and valves on the inside of the tank, which compromises space and useful volume versus not enough manipulation ability with reduced plumbing and valves. The size and weight of the tanks were also considered with respect to transport of same on Kuwait rig roads.

Finally, safety on the mud pits and around the solids processing equipment was detailed with such items as double grating (false upper deck) for reduction of trip hazards, mist system for cooling the people working on these pits during the hot Kuwait summers, and roofs over the pits for the same reason, included in the design. These were again balanced with issues such as weight/space limitations on rig moves, access to valves below the upper deck and safety concerns, plus safety glass fogging with the mist system in place.

Another important safety item with respect to the mud pits, especially with the use of flammable oil-based mud systems, was the agreement to install a dedicated foam deluge system on the mud pits to snuff out any fire break-out.

In conjunction with the bigger pump design proposed, larger drill pipe was used to justify the anticipated hydraulics improvement in drilling. Especially for deeper deviated wells, the use of 5 ½-in. and 4-in. drill pipes has been proven to provide better hole cleaning and improved ROP via increased bit hydraulics. The use of premium high torque connections was also seen as critical to reduce NPT due to differential sticking by being able to apply more downhole torque to overcome sticking force. The bigger pipe sizes, although more costly, have proven themselves time and time again with respect to getting the hole drilled through problematic sections.

Items such as derrick finger space and handling equipment for these pipes had to be discussed with respect to racking capacity and TDS ease of pipe handling, change-out of jaws, etc.

On the other 3,000-hp deep drilling rigs in Kuwait, two separately sized BOPs are utilized in the drilling of the two different sized higher pressure sections of the well. Below the 18 5/8-in. intermediate casing, a 21 ¼-in. 10M BOP stack is utilized to allow drilling 16-in. or 17-in. hole section and passage of the 13 ½-in. casing string. This has consisted of two each 10M rams with a 5M annular on top. There have been wells drilled in Kuwait that have shown the requirement for a three ram stack, especially with mud losses and kicks in the same 16-in. hole section. This is difficult in the present 3,000-hp rig setup due somewhat to height restrictions as well as winching capacity of the BOP hoists beneath the substructure. The 12 ¼-in. hole section through the Gotnia utilizes a 13 5/8-in. BOP consisting of four sets of rams and an annular.

It was decided in the pre-planning of the HAH 124 rig to order an 18 ¾-in. 15,000-psi BOP stack configuration to allow placement of additional rams to reduce risk in well-control situations in the 16-in. hole section. Another important efficiency consideration in the selection of this stack was to reduce the nipple-up and nipple-down time by not having to change BOPs from 21 ¼-in. 10M to 13 5/8-in. 15M after the 13 1/3-in. casing is run and cemented in place. While it is true that the weight of the 18 ¾-in. BOP is higher, thus requiring bigger BOP winch capacity and more costs, it was felt that the cost savings were more than justified, comparing the advantages of a single 18 ¾-in. stack versus two stacks.

Advantages to the drilling contractor for a single stack in these hole sections include fewer spare parts. Disadvantages in this stack include no other rig having the same stack for interchanging parts if required, as well as more active hours over the well with respect to fatigue life.

HAH Rig 124 design discussions also centered on several items based on past experiences within Kuwait Deep Drilling. The substructure was a sling shot type design with a cantilevered type mast, considered the most weight- and cost-effective for the high floor requirements given the BOP stack and HPHT wellhead stack-up. This type design allows for the ability to rig-up and rig-down with lower-capacity requirements and can be split up into easily manageable movable components for the rig move, an important consideration in the desert environment in Kuwait.

One feature on this rig, which is not on the other 3,000-hp rigs, is the addition of a sixth 1,450-hp engine. This provides a total available horsepower of 8,750, which gives increased flexibility of operation.

A Kelly was also maintained in the tender as a back-up for the TDS due to high torque encountered in the 28-in. and 24-in. hole sections in the deep wells that might have damaged TDS systems. This kelly system required modifications to the rig floor and substructure, allowing rathole space and a hook for the traveling block to latch the kelly.

The doghouse on the rig floor was twice the normal size for 3,000-hp land rigs in Kuwait. This doghouse was air conditioned by large roof units and can comfortably accommodate the entire drilling crew for safety meetings prior to critical jobs where proper noise level is essential to hear the details. The driller’s console was chosen similar to those seen on deepwater drillships, with voice-activated microphone to communicate with the rig floor.

Larger rig site trailers with increased office and sleeping quarter space, fitted with the latest specification computer and communications equipment, increased comfort for rig personnel.

Once the design and tender were finalized, the construction of HAH 124 began in earnest in mid-2004 under the direction of National Oilwell in Edmonton, Alberta, Canada. While the substructure, derrick, power train, SCR, semi-automatic controls and mud system were being built Edmonton, the top drive system was being constructed in Norway, and the 18 ¾-in. 15K BOPs were being built in France.

Hamad Al-Hamad hired several key drilling and rig building personnel to monitor the progress of the construction in Canada, with a major issue being proper meshing of the TDS system in Norway to the rig power and electrical system in Canada. Likewise, fitting of this torque tube design TDS provided major challenges to the final overall design of the derrick, and changes were required during the actual building phases to allow easier rig-down and rig-up with respect to electrical connections.

Progress reports were sent on a periodic basis from the rig builders to HAH and KOC with time estimates for completion. Third-party inspection and pre-commissioning of the rig was also planned in Edmonton prior to shipping the rig to Kuwait for assembly. Delays were encountered primarily due to obtaining the prime movers for the rig and due to an increase in requests for drilling rigs in this time frame, which in turn caused delays in equipment arrival and stretched out rig-building personnel.

The original construction planning included mating of the TDS and derrick in Canada, as well as commissioning the entire system together prior to shipment to Kuwait, but delays in Norway prevented this from happening. Therefore, plans were changed to assemble the TDS onto the derrick in Kuwait on the initial well.

A team of KOC deep-drilling representatives met with the third-party inspectors as well as HAH personnel and National Oilwell rig builders in Edmonton at the end of January 2005 to finalize pre-commissioning plans and inspection procedures. The derrick was raised and preliminary inspections performed on the rig without the TDS, which remained in Norway.

There were some issues concerning pre-commissioning with such items as full-load testing of the mud pumps within the National facility due to safety regulations, but most of these were discussed and resolved in daily meetings. The rig was impressive in terms of size, power and pumping capacity with the big question the mating and operation of the top drive.

The hiring of some HAH drillers and toolpushers was also done prior to the rig building to allow as many key people as possible who would run the rig to be in the rig-building process. This was also a challenge with respect to the upturn in the drilling industry with the price of oil.

HAH 124 was shipped from Canada in the spring of 2005, and rig-up began under the trying Kuwait desert summertime heat. As the rig was being assembled on the initial well in southeast Kuwait, HAH rig personnel were being hired with increasing difficulty due to the oilfield drilling boom now in full swing.

The rig-up of HAH 124 was a slow and tedious process for several reasons, including the complexity of the semi-automatic control system and unfamiliarity of this new rig to the contingent of new-hires. A team of National Oilwell rig-building experts worked on the more complex parts of the initial rig-up, as well as training the newly hired electricians and mechanics.

The marriage of the Norwegian-built TDS system to the rig electric power and fit into the derrick was probably the biggest single issue during the rig-up on the initial well. This was not totally unexpected with the difficulty in accurate communications of technical requirements and dimensions from long distance versus being there to actually witness the meshing at the rig-building yard with access to better infrastructure and technology.

Other problems during this period were mainly electronic/software ones affecting the drilling instrumentation, power assignment and auto driller controls.

Commissioning of HAH 124 was completed in October 2005, and the first well spudded on 10 October 2005. The initial well was a vertical exploratory Jurassic test with moderate difficulty in the high-pressure sections of the wellbore. The well was successfully drilled to a depth of 14,260 ft in 152 days and made an exploratory discovery in the Marrat formation. The well timing was reasonable compared with the initial well that KDC Rig 15 drilled in 2004, especially considering that it was the first deep HPHT well ever for HAH using a new high-tech rig with new drilling crews.

The rig was found to have the usual bugs associated with all newbuild systems, and several are still being rectified as drilling on the second well progresses. For the desert environment in Kuwait, several items built in Canada were not adaptable to the heat and sand and therefore changed out, including:

In all, performance of the rig equipment shows indication of being top-class in the 3,000-hp field once the various issues with electronic connections, software for the automatic drilling function computers, and final sensitivity between the electric system and TDS are fine-tuned.

The mud system is performing as planned, and solids control is not an issue with the high-speed linear shaker system. Some adjustments were made in plumbing to prevent aeration to the drilling mud and cavitation to mud pumps with suction valves too close to discharge in the pits.

1. The most important lesson learned is to build or mate the entire rig system, including top drive, at the rig-building yard and to perform the final commissioning at that yard with the improved infrastructure and technical expertise available.

2. The second most important lesson learned is to hire and, more importantly, maintain the key drilling people for a rig such as HAH 124 from design discussion to the actual drilling of the first well. The oilfield boom had a very adverse impact on continuity of the key electronic technicians and electricians who are required to understand and maintain the semi automatic control system and electronics. Mechanics were a close second to the key people who came and went with better offers each month.

3. The TDS design would be better as a track design versus a torque tube as built due to ease of rigging up and rigging down, and also ease of parking the top drive. Vibration has also been an issue with the torque tube. The IBOP and pipe-handling functions and change-out of same on the HAH 124 TDS have been problematic from the start and a different built system should be considered. Changing out wash pipe has been a challenge due to lack of easy access point.

4. The TDS system might be better if designed for making connections 15 ft off bottom using a guide racking grip, as on many offshore drilling rigs. This will allow less risk in freeing up differential sticking on connections by being able to work the torque down off bottom.

5. The doghouse requires a better line of sight from the driller to the entire rig floor as the window does not extend far enough down to permit view of the rig floor immediately adjacent to the driller. The drilling communications system is difficult with the various nationalities on the rig floor with limited English proficiency.

7. The 18 ¾-in. BOP stack worked as anticipated and, with a little more planning, will prove itself more cost-effective than the two stack system being used on other deep-drilling rigs in Kuwait.

8. The 2,200-hp mud pumps have not been put to the full test with 7,500-psi rating but are proving themselves as one liner size is possible for the entire hole (if desirable), and drilling the 28-in. hole has not been adversely affected due to liner change-out since the same gpm can be use with two mud pumps.

9. Training on the semi-automatic control system should be performed during the rig build with the drillers as this system takes more time to get used to compared with the band brake system. This is especially true for operations such as slipping and cutting drilling line.

10. A dedicated task force for the newbuild rig from both KOC and the proposed drilling contractor solely dedicated to this task should be considered for future rig builds. This could include a contracts person with technical background to expedite contracts questions.

11. Retaining a kelly in case of total TDS breakdown, especially in the 28- and 24-in. hole sections, where severe rig vibration occurs even with shock subs, had not required and resulted in problems with spacing of the rig mousehole and resulting ease of BHA connections while picking up same.

12. The other problem that occurred due to the design of a back-up kelly into the rig was the use of a hook on the traveling block that resulted in lack of clearance for connections while running cementing strings inside the larger casing with the false rotary rigged up. An adaptor (Becket) was ordered to connect the TDS to the traveling block after the rig was put together in Kuwait to allow more space for these connections.

This article was adapted from “Kuwait Oil Company’s Latest Semi-Automated Deep Drilling Rig — HAH Rig 124, the Middle East’s Most Modern 3,000-hp Land Rig” (SPE/IADC 103943), presented at the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition held in Bangkok, Thailand, 13–15 November 2006.

OPI 700 HDL TRIPLEX PUMP(Ref#7719T) 700 hp at 150 rpm, fully rebuilt, Cat 3408 engines (approx. 15000 hours and run very well) Two available Price: $275,000 CDN each

NATIONAL 12P-160 TRIPLEX MUD PUMP(Ref#5586T) 3 available in India. 1600 HP, rated pump speed 140 strokes per minute, maximum fluid cylinder liner bore 6¾”, stroke 10", 10,000 PSI hydrostatic pressure of standard cylinder. 2.853 ratio of gears. 10" suction connection, 6" discharge connection. Valve pot mod .7., steel fluid ends, 5,000 psi pulsation dampener. Oilfield skid mounted. Performance Data: at 120 strokes per minute with 6¾” liners, pump will produce 4305 PSI and 574gpm. Set up for electric power. Dimensions and weight: 84,700lbs, 209"L x 113"W x 75"H. Built 1976. Located India, removed from offshore drilling rig.

NATIONAL 12P-160 TRIPLEX PUMPS(Ref#2355R) 3 available, driven by GE752 traction motor, 1600 hp, 12” stroke, 5000 psi, surge chamber, skid mounted, located Middle East Price: $310,000

NATIONAL 12P-160 TRIPLEX PUMPS(Ref#8938R) 3 available, overhauled by National Oilwell (ready in 2-3 weeks after purchase), 1600 hp @ 120 stroke per minute, 12” stroke, 5000 psi, skid mounted, GE Amerimex 752 traction motors, new liners, seats, valves and pistons Price: $295,000 each

NATIONAL 12P-160 MUD PUMP(Ref#2062Re) Refurbished, complete with South West fluid ends and DC traction motors, located Middle East, 3 available Price: $720,000 each

NATIONAL 8P80 TRIPLEX MUD PUMP(Ref#9073R) 800 hp, 6-1/2” x 8-1/2”, FS, FS FE w/QC caps and cylinder head caps, Oteco 3” shear relief valve, suction screen, 5 x 6” centrifugal charging pump, powered by Cat 3412 diesel engine, rod cooling pump, Oteco type D pressure gauge, mud valves, bull wheel, master skidded, complete, good condition Price: $275,000

NATIONAL OILWELL 850 HP MUD PUMP(Ref#15442T) Mattco API-9 fluid end rebuilt, very little use after rebuild, pulsation dampener, no engine, skid mounted Price:$22,000

NATIONAL 7-P-50(Ref#6302R) 750 hp, 8” stroke, 6” suction inlet, 4” discharge outlet, piston size 4-1/2” – 7”, max rod load 85,000#, approx. weight 11,500#, lubrication force fed, steel pump power end, double helical gears, 4.95:1 gear ratio, rod bearings sheel type replaceable, main bearings straight roler, pinion bearings spherical roller, crankshaft 1pc forged alloy steel, connecting rod knuckle joint, crosshead guide bronze replaceable, piston type fluid end Monoblock design, from high strength alloy steel, treated and sonic tested, Cat D379 diesel engine, 500 HP max linear bore size 3-1/2 – 6-1/4 x 7-3/4” stroke, test pressure 10,000 psi, gear ratio 2.742.8” suction line to 4 discharge stroke, location South America Price: $110,000

NATIONAL JWS 165 WELL SERVICE TRIPLEX PUMP WITH 140 BARREL WORK TANK(Ref#2633Tb) 5 x 6, Detroit 8V71 engine, standard transmission, skid mounted Price:$87,500

NOV JWS 340 TRIPEX MUD PUMPS(Ref#2345T) Two available, Skidded, Detroit Series 60 diesel engine DDEC V (475 hp), Allison 750 (6-speed) transmission with lock up control pane, Mission 4 x 5 centrifugal suction pump, 4” plungers, pulsation dampener, pressure gauge, safety valve, 10,000 psi fluid end, 5000 psi working pressure, NOV plug valve control manifold (4-valve) configured for 15k operation. Can be configured to kill wells, acidize, cement, reverse circulate, drill out frac plugs or run in tandem. Self-contained with fuel and fluid tanks and controls. Steel canopy over skids, covered battery boxes, new batteries and disconnect switches. Well maintained and in excellent condition. Low hours on pumps and motors. Ready to work. Price: $154,500 each

NATIONAL JWS300 MUD PUMP(Ref#2767R) Series 60 Detroit diesel, 14 liter engine w/Allison transmission, mounted on oilfield skid, major overhaul, completely unitized with fuel tank, fluid end rebuilt by Matco Price: $195,000

NATIONAL OILWELL VARCO 308T-7(Ref#3358T) 4” Ceramic plungers, external drip lubricated, pulsation dampeners, John Deere 400hp engine, bypass oil filter, electric start, 200 gal fuel tank, well maintained, Hansen gear 7.25:1, Cobra with cooler Price:$225,000

(2) NATIONAL C350 MUD PUMPS(Ref#3077N) Standby – not pump in 15 years. Pumped chalk continuously at 600 psi in a cement factory. Complete with electrics and electric motor, complete, bull wheels and guards, complete, fluid end, pistons, liners, and valves. Low hours. Located Europe. Price for both: $105,000 loaded in a 40’ container

NATIONAL G700 14” STROKE DUPLEX MUD PUMP(Ref#8312Ta) 700 HP, 14” stroke, cast iron fluid end, surge chamber, 285 gpm @ 3550 psi with 5” pistons or 805 gpm @ 1265 psi with 8” pistons, mounted on skid 10’ x 23’ with enclosure, sold as is Price: $27,500

NATIONAL 5-1/2 X 10” MUD PUMP(Ref#14556Ta) skid mounted with fuel tank, 471 Detroit diesel engine, 4 speed transmission, all new injectors Price: $16,500

NATIONAL C-100 DUPLEX MUD PUMP SYSTEM(Ref#10047R) National C100 duplex mud pump (currently has 5-1/2” liners), gear end and mud end is in good shape, powered by 671 Detroit engine, 1000 gallon fuel tank capacity, tndem trailer mounted (air brakes), fully winterized enclosure with heater unit, locking doors and parts shelves, stairways and rails, 8” steel suction line/hose/sand screen pot/pole winch for adjustment of suction depth, Price: $50,000

IDEAL 5 X 10 DUPLEX MUD PUMP(Ref#9068T)453 Detroit engine (tall, not short), mounted on 5th wheel trailer, new bearings in crane case Price: $18,500

PERONI PTO/C TRIPLEX MUD PUMP(Ref#6306R) 110mm (4.331”) bore x 190mm (7.480”) stroke, 5000 psig, 125 rpm, 151.6 gpm, 350 psig, stainless steel flud end, Cummins Big Cam, Model NTC-350, built 1980, Eaton 23-speed manual transmission, Philadelphia Model 13HP-2 gear reducer rated 496 hp ratio 14:1, input 1760 rpm, output 126 rpm, pressurized lubricant system, fuel tank 300 gal, trailer mounted, 11’7”H x 41’4”L x 8’1”W double frame triple axle, king pin to 5th wheel, air brakes and lights, approx. 68,700#, located South America Price: $90,000

HHF 500 TRIPLEX MUD PUMP(Ref#2565Tb) (Hongua International), year 2012, KTA 1150C (19-P750) engine, 6-3/4” cylinder diameter, 7-1/2” stroke, lots of spares Price: $150,000

NF-500 (CHINESE MANUFACTURED0 500 hp MUD PUMP(Ref#13723R) Manufactured 2011, 550 gpm@3000 psi, Cat C15 diesel engine, pulsation dampener, mounted on Galvanized jack-up base, located Australia Price: $280,000

SKYTOP BREWSTER 7-1/4 X 14” MUD PUMP(Ref#13399Rb) 379 Cat didsel engine, Matco hi pressure forged steel fluid end, quick change valve heads, Hydril dampener, brand new expendables sill in box Price: $59,500

OILWELL 14PDH(ref#3813R) 7-1/4 x 14, Matco fluid end with screw type valve, covers and cylinder heads, Detroit 8V71 diesel engine, surge chamber, pip-off valve, 10 groove pully, 5-1/2” liners, mounted on oilfield skid, 1 year warranty on motor, Price: $90,000

OILWELL DUPLEX MUD PUMP(Ref#1190N) Rebuilt with all new fluid end parts and rebuilt gear end, Detroit 8V71 diesel engine, mounted on oilfield skid, hand clutch, belt drive, belt guard, pulsation dampener, pressure gauge, pressure relief valve, cleaned and painted, factory specs:

OILWELL 4 X 6 MUD PUMP(Ref#8578T) New belts, diesel power, new mud end parts, mounted on skid on 8’ x 16’ gooseneck trailer, ready to work Price: $28,000

DRESSER OMEGA TRIPLEX PLUNGER PUMP MODEL JL3000(Ref#362T) 3000 hp, built 1999, unmounted, rebuilt, freshly painted, and not used since Price: $165,000

EWS 440 UNITIZED MUD PUMP PACKAGE(Ref#599N) refurbished Detroit Series 60 engine, refurbished Allison transmission, input horsepower rating 440 max, 320 max pump speed rating, 6” stroke length, 4-1/2” maximum piston size, 3000 psi fluid end working pressure rating, 3” (as required) discharge connection size, 6” (as required) suction connection size, 2” NPT accessory connection size, API#4 valve size, API#S-2 piston rod end, 35 gallon cancase oil capacity, 24 gallons liner wash capacity, internal gear ratio: 4.58:1, 6.517:1. Price: $200,000

DRAGON W-440 TRIPLEX 6” MUD PUMP(Ref#7756Ta) skid mounted on 8’ x 28’ skid, Detroit 60 Series 8 cyl Turbo diesel power plant with 440 hp, on board fuel tank, M310 Series control panel Price: $132,500

L & L SMC T135-5 TRIPLEX 6” MUD PUMP(Ref#7756Tc) mounted on 7’ x 21’ skid, Cat 6 cyl turbo diesel engine, in-line style system, hyd tanks Price: $29,500

MCFARLAND P38 PUMP(Ref#3917Ta) low hours, 1”, 10,000 psi set up, pump can be configured for 18,000 or 25,000 psi, 60 hp electric motor, skidded Price: $27,500

FAMMCO TRIPLEX PUMP(Ref#2760T) 2 x SPM 600 HP 10K, 3-1/2 x 6’ stroke plunger, powered by (2) Cat C12 400 hp diesel engines, (2) Allison HT750 trans., (2) 4 x 5 cent pumps, (2) 5 x 6 slurry mixing pumps, 6 bbl mixing tub, 14 bbl averaging tub, mounted on 2002 tandem axle 8’6”W x 50’ step deck trailer Price on Request

GARDNER DENVER PZ-11(Ref#10748R) approx. 7000 hours, Cat 3512C (1476 hp), 5000 psi fluid end cylinder, 5-1/2” piston cylinder, antifreeze heaters, WPT W21-CG-300 Type 1 PTO clutch, 16 groove drive sheave, 16 groove bullwheel, 16 groove Kevlar belt with necessary guards, 5 x 6 x 11 charge pump c/w 50 hp@1200 rpm electric motor. Discharge plumbing: 2” 5M XXH B/W Oteco gate valve, 4” 5M XXH b/w Oteco gate valve, 3” 5M Oteco popoff valve w/1502 connection, 2” 5M type D Oteco mud gauge with 1502 connection, Hydril 20 gal 5M pulsation damper. Mounted on oilfield skid with separate, with expendables cabinet, knowledge box and removable engine skid for breaking the engine and pump into separate smaller loads. Winterization package, oilfield lighting, explosion proof starters for charge pump, rod oiler pump and liner wash pumps. Price: $695,000 - Make Offer

GARDNER DENVER PZ9 TRIPLEX MUD PUMPS(Ref#7062T) Two Available, each complete with Cat 3508 diesel engines, pulsation dampener, and mud tanks with desander, desilter, etc. Price for Package: $110,000

GARDNER DENVER PZ9 TRIPLEX MUD PUMP(Ref#14850R)2 units available, no power, fully serviced to OEM specs in July 2008 and stored since then Price for both: $430,000

GARDNER DENVER PZ8(Ref#862T) Rebuilt, complete, 8” stroke, 750 hp, alloy steel modular flud cylinders, 6-1/2” liners, liner wash system, API 7 valve pots, gear reducer, steel billet fluid end, pulsation dampener, suction connection, FF discharge connection, 4.5 gear ratio, skid mounted, 130”L x 88”W x 54”H POR

GARDNERDENVER PZ7(Ref#8588N) US manufactured, freshly rebuilt, new Detroit Series 60 engine, Allison transmission, pulsation dampener, complete and ready to go. Price: $375,000

GARDNER DENVER PZ7 STYLE TRIPLEX MUD PUMP(Ref#1245Nb) Reconditioned, inspected and tested. 550 hp input, Cat D379PCTA diesel engine (reconditioned), air start, muffler, standard instrument gauge panel, mounted on Cat rails, new 20CB500 air clutch, reconditioned radiator. Belt drive assembly consisting of pump drive sheave, pump drive belts with belt guard, engine drive sheave, engine drive belts with belt guard, pillow block bearings. Reconditioned Continental Emsco PD-45 12 gallon 5000 psi WP pulsation dampener. New O’Drill/MCM ORV 21050 2” 1,000 – 5,000 psi WP shear relief valve. New O’Drill/MCM 2” 0 – 6,000 psi WP type D mud pressure gauge. PZ7 fluid modules complete with suction manifold and discharge strainer cross. New CA-122 liner wash pump, pinion driven with spary nozzle system, water tank and hoses. New fluid end expendables with 6” liners. (3) runner oilfield type master skid with loading hitches. New 5 x 6” R.H. centrifugal 178 series charge pump, 1-7/8 shaft, 10” impeller size, belt driven off pinion shaft, drive belts with belt guard. New 6” fgure 400 hammer union. New 4” 5000 psi WP gate valve, new 200 gallon air receiver tank, new air controls. Price: $455,000

Fitted with 5" Liner and pistons, bare pump, no extras, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED.

Fitted with 5” liners and pistons with washing and lubricating system, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED, skid mounted with a rebuilt Detroit Diesel V1271 w/ Twin Turbo, 550 HP, with a chain case and a manual transmission

Fitted with liner & pistons, with rod washing & lubrication system, bare pump no extra"s, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED, skid mounted with New CAT C13 (440 HP) diesel power unit, w/hand clutch, belt drive, belt guard, fuel tank.

Fitted with 5" Liner and pistons, w/washing & lubricating system, THIS PUMP REQUIRES PRESSURE LUBRICATION OF THE POWER END (AUXILIARY OIL PUMP REQUIRED) THIS IS NOT INCLUDED, skid mounted with New CAT C15 (540 HP) diesel power unit, with manual transmission with 4 to 1 gear case, fuel tank.

GARDNER DENVER PAH(Ref#10664Rc) rebuilt, Detroit 8V92 diesel engine, Allison 5960 transmission, new pistons, liners, valves, rebuilt engine Price: $210,000

Manufactured 2008, Cat C-9 new genset, 10 bbl tank, shaker, charging pump, Allison HT750 transmission, 1600 hours, mounted on mobile 52’ trailer Price: $290,000

GARDNER DENVER PAH MUD PUMP(Ref#7546T) 8V92 Detroit diesel engine, Allison transmission, choke manifold on unit and charge pump, pistons and liners, Price on Request

MUD KING PAH MUD PUMP(Ref#12669T) Detroit Series 60 engine, Allison 750 transmission, 3” centrifugal pump, 90 bbl 2-compartment circulating tank Price: $290,000

GARDNER DENVER TRIPLEX MUD PUMP(Ref#8245Rb) Completely rebuilt, new paint, skid mounted, new Detroit 671 engine 165 hp @ 1800 rpm, new fuel tank, lines and fluid end, multi speed transmission and clutch, 12 volt DC starting and operating system, 5” suction, 1742 to 10,000 psi discharge pressure, 8 – 138 gpm capacity, full functional control panel, mounted on oilfield skid, dims 240”L x 90”W x 60”H 12,000# Price: $39,500

KERR 2200 AND 3500 OR FMC M1214 TRIPLEX MIST PUMPS(Ref#7999T) Cat engines, 4 speed transmissions, rigged up with secondary containment, onboard lighting, winterization canvas for cold weather operations, Also available with Cummins or John Deere engines Priced from $77,500 to $97,500

GARDNER DENVER PQ172 TRIPLEX MIST PUMP(Ref#7827Ta) Deutz F3L914 45hp 3 cyl air cooled diesel engine with electric start, manual transmission, gauges, 4’H x 4’W x 7.5’ long, 3” hardline, 22 bbl mixing tank, skid mounted Price: $17,500

GARDNER DENVER GXP TRIPLEX 6 X 16 MUD PUMP(Ref#11010T) Skid mounted, twin Detroit 671 diesel engines, 30 ton, dimensions: 28’L x 11’W x 8’H Price: $32,500

GARDNER DENVER GXR 800 HP DUPLEX MUD PUMP(Ref#12423Rb) Matco steel fluid end, pulsation dampener, fuel tank, gauges, controls, starter, mounted on oilfield skid, completely rebuilt engine and fluid end Price: $125,000

GARDNER DENVER FXN 7-1/4 X 14 MUD PUMP(Ref#1403T) Cat 3408 engine air start with pump drive and belt guard, PD55 Hydril dampener, 750 gallon fuel tank, mounted on heavy duty drop deck tandem trailer, low hours Price: $87,500

GARDNER DENVER FXN 7-1/2” X 14” DUPLEX MUD PUMP(Ref#8312Tb) 500 hp, on skid with Cat D343 engine, capable of 200 gpm @ 3000 psi with 4” pistons or 775 gpm @ 940 psi with 7-1/2” pistons, sold as is Price: $27,500

GARDNER DENVER FXN 7” X 14” DUPLEX MUD PUMP(Ref#6637Ta)Forged steel fluid end, quick change caps, Cat 3412 diesel engine, Hydril K20 3000 pulsation dampener, Demco 2” relief valve, belt drive, type F3000# pressure gauge, rod oiler pump, speed sensor, electric start, air clutch, skidded with roof, 3-1/2” x 20’L vibrating hose Price: $76,000

GARDNER DENVER FZ-FXZ MUD PUMP(Ref#4087Tb) 7-1/2 x 12, Tier 1 Detroit diesel 60 Series, 12.7L 500 hp, good gear and fluid ends, same-trailer mounted, 500 gal fuel capacity Price: $90,000

GARDNER DENVER FXZ 6-1/2” X 12” MUD PUMP(Ref#10287Tb) Detroit 8V71 engine, hauled on 3 axle skid trailer with 1989 TTRAC International truck Price: $69,500

GARDNER DENVER FXN DUPLEX MUD PUMPS(Ref#8214R) Two available, 14” stroke, 2” rod size, 400 hp, 75 strokes per minute, cast fluid ends, unitized on oilfield skid with Cat 3406 diesel engines, air start, new filters, oil and coolant, air receiver on deck, fluorescent lighting, drive belts with air clutch. Gone over and in good operating condition, ready to be put into service. Pumps currently have new 6” liners with production being 480 gpm @ 1000 psi. All fluid end parts are brand new and never used, including the valves, gears, liners, pistons, rods, head gasket, and rod packing, equipped with pulsation dampener. 32’ long x 11’ wide x 7’ high 50,000# weight Price: $72,500 each

GARDNER DENVER FXZ 7-1/4 x 12”(Ref#8810R) Trailer mounted, suction rod, suction strainer, twin GMC 150 hp engines, flywheel, belt guards, totally rebuilt 2011 Price: $100,000

GARDNER DENVER FXZ 7 X 12 MUD PUMP(Ref#6602RD) only 1300 hours on new 12 Liter Volvo engine, air clutches, skid mounted, 20’L x 9’7”W x 8.4”H, 40,000# Price: $45,000

GARDNER DENVER 5-1/2 X 8 FXN DUPLEX MUD PUMP(Ref#6678T) Cast fluid end, 671 Detroit, Spicer 6853-C transmission, hydraulic pump, air controls, 1” hyd hoses, skidded Price: $44,500

GARDNER DENVER 5 1/2 X 10 MUD PUMP(Ref#3261Rb) 6 cylinder Cummins diesel engine, hand clutch, 5 speed transmission, 5-1/2” liners, skid mounted, 10” stroke, ready to work Price on Request

GARDNER DENVER 5 X 10 MUD PUMP(Ref#1480Tb) air driven, used with cement for grouting wells, sitting 3-4 years, valves will need rebuilding, trailer mounted, air over hydraulic brakes, includes 28 joints of 21’ pipe Price: $39,500

GARDNER DENVER 5 X 10 MUD PUMP(Ref#5882Tb) 453 Detroit engine, battery start, mounted on oilfield skid with axles, starts and runs Price: $14,500

GARDNER DENVER FDFXDH MUD PUMP(Ref#14457T) 4” inlet, 3” outlet, pulsation dampern, new piston and rods, engine has been removed Price: $40,000

5-1/2 x 8” GARDNER DENVER MUD PUMP(Ref#4523N) Manufactured 1960’s, rebuilt a couple years ago, skid mounted, 4 cylinder Detroit engine, used Supercharger, 637 hours on it, runs good, needs cosmetic work Price: $32,500

GARDNER DENVER 5 X 6 MUD PUMP(Ref#302Tb) 2 available, unmounted, rebuilt pumps, need normal expendables (neoprene is old in the valves etc) Price: $17,500

GARDNER DENVER FG-FXG 5 X 6 MUD PUMP(Ref#3510R) Detroit diesel engine, mounted on tandem axle trailer, one suction and one discharge hose included Price: $39,500

GARDNER DENVER 5 X 6 MUD PUMP(Ref#13203T) electric drive, in custom skid, fully rebuilt gear end and fluid end, excellent condition Price: $22,500

GARDNER DENVER FXF-DE8 4 X 5 MUD PUMP(Ref#10148T) Manufactured 1996, new condition of gear and fluid ends, no engine, new 4” liners, new pistons, new chrome rods, new valves, new liner studs in head, new suction flange and gasket, new 2” steel discharge flange Price: $13,500

4 x 5 GARDNER DENVER PISTON MUD PUMP(Ref#7097Rb) bull wheel or can be connected to hydraulic motor, 75% condition, needs some work Price: $5,500

GARDNER DENVER 5 X 6 HYDRAULICALLY DRIVEN MUD PUMP(Ref#2505T) approx. 2500 hours, unmounted, (taken off a rig), fluid ends have not been rebuilt POR

GARDNER DENVER PE5U 4X5 TRIPLEX MUD PUMP(Ref#11077c) powered by Cat 3306 diesel engine, Eaton 5-speed transmission, manifold, enclosed building Price: $72,500

GARDNER DENVER PE5 TRIPLEX MUD PUMP(Ref#4692Ta) Detroit 6V71 engine, electric start, radiator, 2” Shear relief valve, Spicer manual transmission, skidded Price: $25,000

GARDNER DENVER TEE PUMP(Ref#1654T) Manufactured 1998, 1602 hours, 4" plungers with hydraulic charge pump, Detroit Series 50 (rebuilt), 5 speed, Skid mounted with fuel tank, Rebuilt expendables with seals, valves, seats, packings and gaskets. Price: $72,500

GARDNER DENVER T

8613371530291

8613371530291