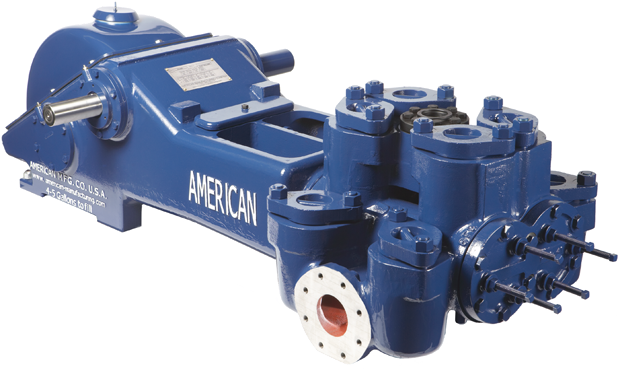

4 mud pump manufacturer

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

The 4-Inch heavy-duty slurry pump by EDDY Pump. Close coupled or flex coupled version pumps available in extra heavy-duty (HD) class. Depending on your needs, all of our pumps can be setup horizontal or vertical.

Our industrial pumps are non-clog pumps with no critical tolerances designed for high solids pumping applications. Our patented pump technology outperforms all centrifugal, vortex and positive displacement pumps in a variety of the most difficult pumping applications.

In harsh conditions with sand, sludge, rocks, slurry, normal dredge pumps clog, wear and fail more often. This leads to downtime for maintenance, hurting your bottom line. This is not the case with EDDY Pump since we have the tolerance to pump objects up to 12 inches!

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Mud Sucker Pro Series engine driven diaphragm pumps use check ball technology in the suction and discharge valve chambers to pump slurries, abrasive fluids, solids and general wastewater. Access to both the suction and discharge areas is available within seconds.

The Mud Sucker 4B-M includes a standard emergency pressure relief valve. Since a diaphragm pump is also a positive displacement pump, a pressure relief valve reduces the chances of damage in an over pressurization event.

The only diaphragm pump in the industry with an exclusive pump body designed to enhance the flow of slurries and debris laden liquids to prevent clogs.

Ships complete with safety guards. Pump operator does not come into contact with moving components when guards are in place (removed in illustration above for clarity).

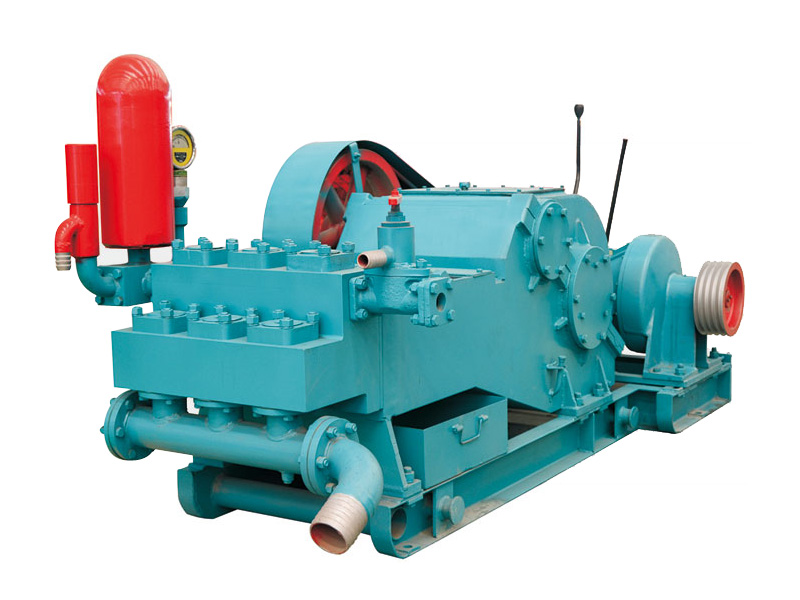

Rundong Company specializes in making drilling mud pumps and oil drilling rig components with over 20 years" experience. This is BW series triplex mud pump, a kind of horizontal type, 3-cylinder, single-acting reciprocating piston pump. The followings are about parameters of different types of BW drilling mud pumps.

Mud pump BW-250, which is a type of horizontal, 3-cylinder, single-acting reciprocating piston pump, comes with 2 liner diameters and 4-speed gear shift. The capacity and hole depth can be freely adjusted according to specific needs. The mud pump can be used for grout injection, in addition to working together with a drill rig with the maximum drilling depth of 1,500m. This pump is easy to move, offering low energy consumption, easy operation, great durability and high flexibility.

BW320-Z mud pump, as a kind of horizontal type, 3-cylinder, single-acting reciprocating piston pump, comes with 2 liner diameters and 4-speed gear shift. The capacity and drilling depth is freely adjustable. The pump can be used for cement injection and to work together with a drill rig with the maximum drilling depth of 1,800m.

Rundong is an experienced Chinese BW mud pump manufacturer and supplier, established in 1970. We are involved in the development, production and sale of oil equipment, such as downhole drilling motor, power torque, and more. Our reliable quality and reasonably priced mud pump is highly sought by customers from Kazakhstan, Libya and other countries. In addition, cementing tool, valve and fishing tool, etc. are also available at Rundong. Thanks for visiting our website! If you have any questions, please feel free to contact us.

Explore a wide variety of 4 inch mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These 4 inch mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these 4 inch mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right 4 inch mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of 4 inch mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

1. High pump pressure and large discharge capacity: higher pumping capacity and larger discharge capacity than the traditional three-cylinder mud pump, which can deliver more pressure and mud to the bottom of the well during drilling. Thereby increasing the rate of penetration.

2. Light weight and small size: The pump has lighter weight and smaller volume than the traditional three-cylinder F2200HL mud pump. It is suitable for small drilling area, such as offshore platforms.

4. High reliability: Four sets of main bearing design, two more main bearings than traditional three-cylinder mud pump. Thus reducing bearing load and improving reliability.

5. Convenient Maintenance: reasonable structural design, easy to maintain. The wear parts of the fluid end are interchangeable with the ones of 1600HL pump.

8613371530291

8613371530291