ace mud pump service free sample

In addition to freeze-thaw cycles and damage caused by salt and other ice melting chemicals, driveways are threatened by a host of other common hazards, including lawn fertilizer, oil, gas, anti-freeze, UV rays, and acidic rain, among others. An unsealed driveway will definitely become a major problem in the future due to rotting, broken, and cracked concrete. By this stage, you’re looking at complete tear-out and replacement, which is admittedly expensive. Save yourself some money and use our penetrating hydrophobic concrete sealer to protect your driveway and keep it looking great.

Unlike acrylic sealers that form a film on the concrete surface, this penetrating sealer chemically alters the concrete’s surface by glassifying it to create a clear waterproof resistant membrane protecting the surface from water penetration that causes damage. At the same time, the appearance (color) and texture of the surface is not changed in any way like other sealers do.

180 mud pump clamp products are offered for sale by suppliers on Alibaba.comAbout 27% % of these are mud pump, 19%% are pumps, and 6%% are mining machine parts.

A wide variety of mud pump clamp options are available to you, such as 1 year, not available and 2 years.You can also choose from new, used mud pump clamp,as well as from energy & mining, construction works , and machinery repair shops mud pump clamp, and whether mud pump clamp is 1.5 years, 6 months, or unavailable.

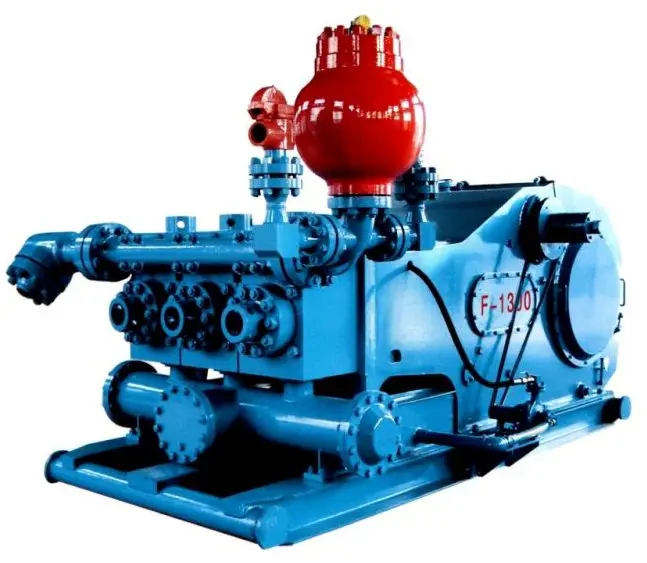

Cavitation is an undesirable condition that reduces pump efficiency and leads to excessive wear and damage to pump components. Factors that can contribute to cavitation, such as fluid velocity and pressure, can sometimes be attributed to an inadequate mud system design and/or the diminishing performance of the mud pump’s feed system.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump “knocking,” which typically sounds like marbles and stones being thrown around inside the equipment. However, the process of cavitation starts long before audible signs reveal themselves – hence the name “the silent killer.”

Mild cavitation begins to occur when the mud pump is starved for fluid. While the pump itself may not be making noise, damage is still being done to the internal components of the fluid end. In the early stages, cavitation can damage a pump’s module, piston and valve assembly.

The imperceptible but intense shock waves generated by cavitation travel directly from the fluid end to the pump’s power end, causing premature vibrational damage to the crosshead slides. The vibrations are then passed onto the shaft, bull gear and into the main bearings.

If not corrected, the vibrations caused by cavitation will work their way directly to critical power end components, which will result in the premature failure of the mud pump. A busted mud pump means expensive downtime and repair costs.

As illustrated in Figures 1 and 2, cavitation causes numerous pits to form on the module’s internal surface. Typically, cavitation pits create a stress concentration, which can reduce the module’s fatigue life.

Washouts are one of the leading causes of module failure and take place when the high-pressure fluid cuts through the module’s surface and damages a sealing surface. These unexpected failures are expensive and can lead to a minimum of eight hours of rig downtime for module replacement.

To stop cavitation before it starts, install and tune high-speed pressure sensors on the mud suction line set to sound an alarm if the pressure falls below 30 psi.

Although the pump may not be knocking loudly when cavitation first presents, regular inspections by a properly trained field technician may be able to detect moderate vibrations and slight knocking sounds.

Gardner Denver offers Pump University, a mobile classroom that travels to facilities and/or drilling rigs and trains rig crews on best practices for pumping equipment maintenance.

Program participants have found that, by improving their maintenance skills, they have extended the life of fluid end expendables on their sites. They have also reported decreases in both production and repair costs, as well as reductions in workplace hazards.

Severe cavitation will drastically decrease module life and will eventually lead to catastrophic pump failure. Along with downtime and repair costs, the failure of the drilling pump can also cause damage to the suction and discharge piping.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump ‘knocking’… However, the process of cavitation starts long before audible signs reveal themselves – hence the name ‘the silent killer.’In 2017, a leading North American drilling contractor was encountering chronic mud system issues on multiple rigs. The contractor engaged in more than 25 premature module washes in one year and suffered a major power-end failure.

Gardner Denver’s engineering team spent time on the contractor’s rigs, observing the pumps during operation and surveying the mud system’s design and configuration.

The engineering team discovered that the suction systems were undersized, feed lines were too small and there was no dampening on the suction side of the pump.

Following the implementation of these recommendations, the contractor saw significant performance improvements from the drilling pumps. Consumables life was extended significantly, and module washes were reduced by nearly 85%.

Although pump age does not affect its susceptibility to cavitation, the age of the rig can. An older rig’s mud systems may not be equipped for the way pumps are run today – at maximum horsepower.

Ace Pump Repair & Drilling is Caldwell’s best choice for pump repair and well drilling services. For over a decade we have provided complete pump and well water services to residential, commercial, and industrial customers. Our technicians have the experience and professionalism you seek to start any new installation or repair project. We offer well drilling and installation, pump repair & replacement, pump installation and proper maintenance for any home or business. Our family owned and operated business is committed to providing a quality water supply and reliable service. We proudly serve Caldwell, Nampa, Boise, Eagle, Emmett, Meridian and the rest of Treasure Valley ID. We offer free consultations along with great customer service.

Young is an above average-athlete who beats defenders off the dribble with nifty hesitation moves, pump-fakes, and the threat that he’ll bomb 3s from anywhere; Sexton is simply faster than 99 percent of his opponents, and he knows it

8613371530291

8613371530291