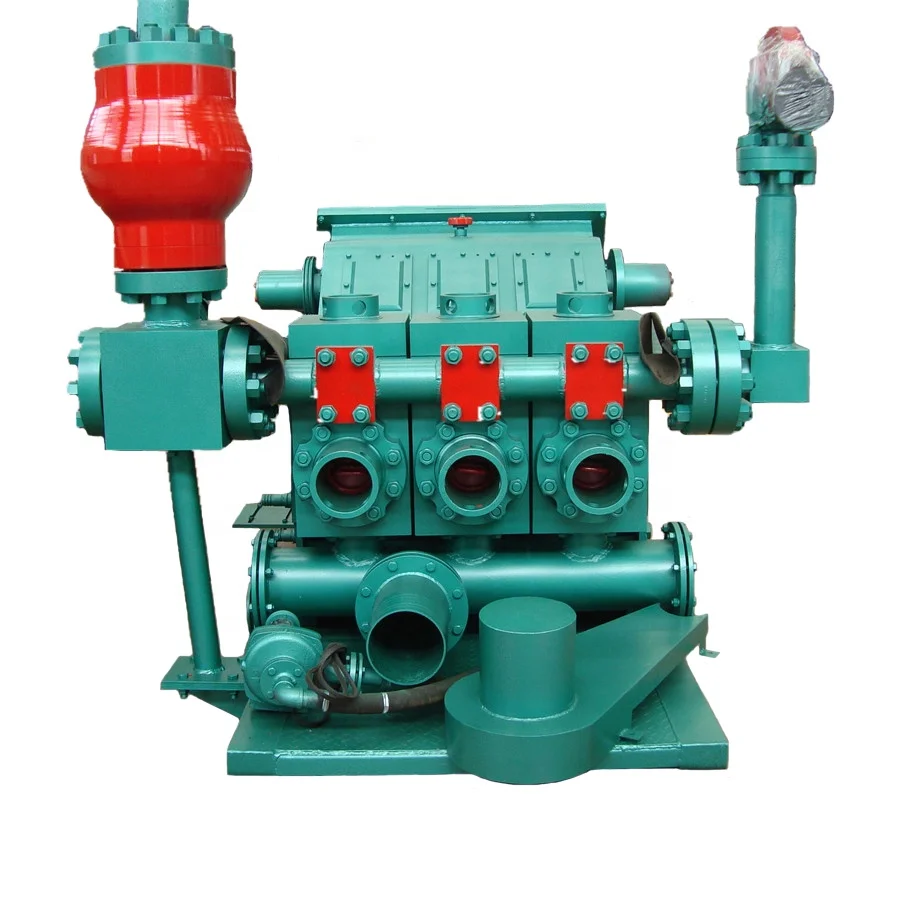

api 7k mud pump in stock

A wide variety of api 7k triplex mud pump options are available to you, such as 1 year, not available and 2 years.You can also choose from new, api 7k triplex mud pump,as well as from energy & mining, construction works , and machinery repair shops api 7k triplex mud pump, and whether api 7k triplex mud pump is 1.5 years, 6 months, or unavailable.

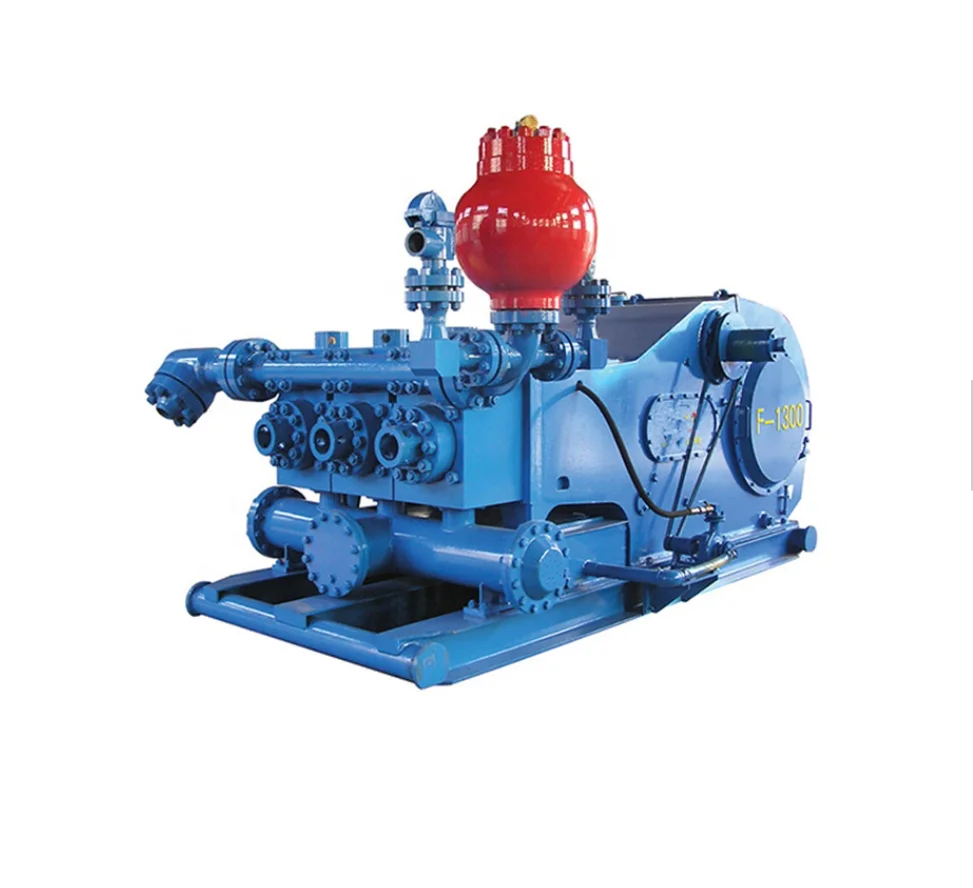

● The power end of F series mud pump adapts combined lubricating system of forced and splash lubrication, Reliable to lubricate and increased the service life of power end.

3. Detailed description:The Kingwell Mud pump liners used for mud pumps include premium Chromium Liners, Ceramic Liners, Chromium-plated Liners and Hardened Liners. Each liner combine the strength of a forged steel outer shell with the abrasionand corrosion resistance of a high chromium iron inner sleeve and honed to a mirror-like finish for smooth and even wear during the of the liner.

1). Technical Support and Production Ability: Although we are one relatively new company, but we have the most professional engineers with tens of years experience in mud pump. And we have hundreds of highly skilled workers working on the pump parts and pump assembling with numerous advanced machines. Our production ability has been siteaudited by supervising inspectorate like France BV (Bureau Veritas), DNV(Det Norske Veritas) and SGS-CSTC(Standards Technical Services Co., Ltd.)

2). Quality Assurance: Ten professional inspectors performstrict quality inspection from the initial forgings, castings, other rawmaterials, each finished machined parts until the final assembling of the pump. Each part assembled on the pump will be well tested and highly qualified. Andfor each pump finished, it will be running tested in our test center for atleast 4 hours. Quality certificate, Inspection report and testing report will beattached when pump is delivered. 12 Months quality guarantee will be offered for each pump.

3). Competitive Price:We are one of the top pump manufacturers in China. We have the greatest advantages in price. We can not offer you the lowest price in China, but most competitive price but with very good quality.

4). Quick Delivery: Usually we will keep some pump model in stock so that we can make fast delivery for clients with urgent need. For pump we do not have in stock, we can also deliver with 40 days.

We specialize in drilling. We provide drilling and workover RIGS, three-cylinder mud pumps (F&3NB series), solid control systems and their components. High quality drilling and workover engineering services

Business. We provide high quality EMSCO F-series mud pump, including F-500, F-800, F-1000, F-1300, F-1600, RLF-2200 and China 3NB series mud pump, including 3NB350, 3NB500, 3NB-600, 3NB800, 3NB1000A/D, 3NB1300A/D, 3NB1600. A full range of products can fully meet any needs

Bi-metal Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a high chrome inner sleeve. These liners feature a centrifugally cast high chrome iron sleeve which is machined and heat treated to a minimum uniform bore hardness of 59-65HRC. Bi-metal Liners is the main expendable parts of the mud pump, it adapts double metal fix together.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

This certification was awarded after an audit of American Mfg Company"s quality control and manufacturing procedures by the American Petroleum Institute. While we"ve always manufactured our parts in accordance with ISO and API 7K guidelines, this certification places us in and elite group of U.S. manufacturers, and is another step as we strive to become THE premier manufacturer of American-made mud pumps and components in the marketplace today.

8613371530291

8613371530291