best mud pump casting parts quotation

Your search for superb quality oil well Drilling Parts ends at one stop shop that is Vision Auto Industries. Finding multiple applications in various industries, the drilling parts offered by us are appreciated andread more...

p-500 / 50, mb-10 swivel, , ch-500/ 400/ 320/ 125 / 50/ t-50 mud swivel . Cardwell -6 w/o rig , bhel-2000 / 150 t swivel, wash pipe (short & long – russian work over mud swivel), a-50 (short), wash pipe with snap ring , rubber packing set are ready stock.read more...

Mud Pump Spare Parts, Conumables, Shale Shaker Screen, Shale Shaker Tension Bolt, Shale Shaker Cushion Rubber, Reeling Pins, Mud Tank Flapper Pins, Safety Pins, Safety Pins for Wiper Rubber, Drill Rod Wiper, BOP Spares, BOP Ram, BOP Studs, High Tensile Stud Bolts for Oilfield, Flanges, Butterfly Valves, Gate Valves, Globeread more...

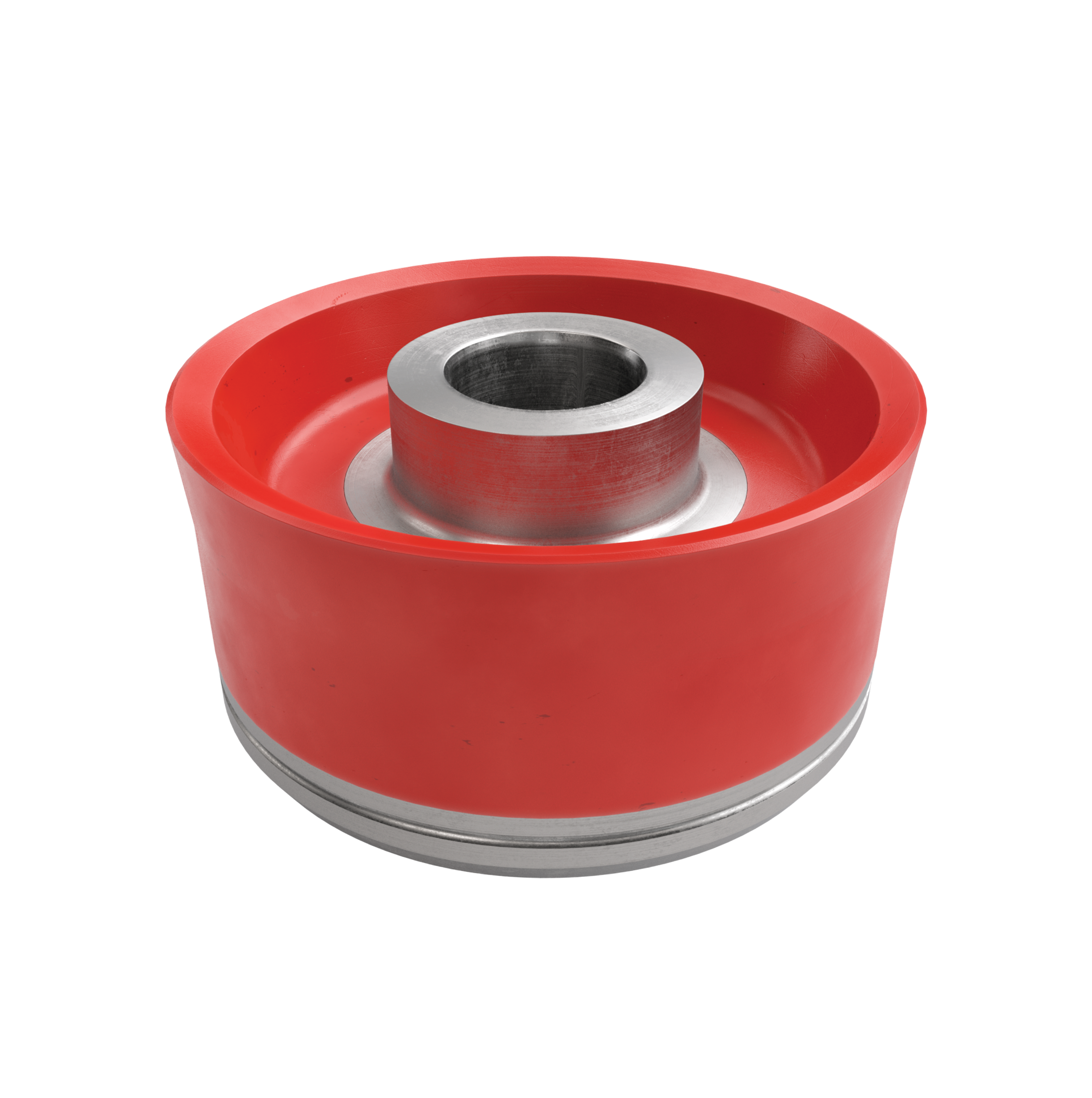

Keeping in pace with the specific need of our customers, we are engaged in offering a wide series of Mud Pump Spare Parts. Our offered item is developed under the supervision of our skilled workers using finest quality basic material. This is well regarded among the clients due to its corrosion resistance, fine finish andread more...

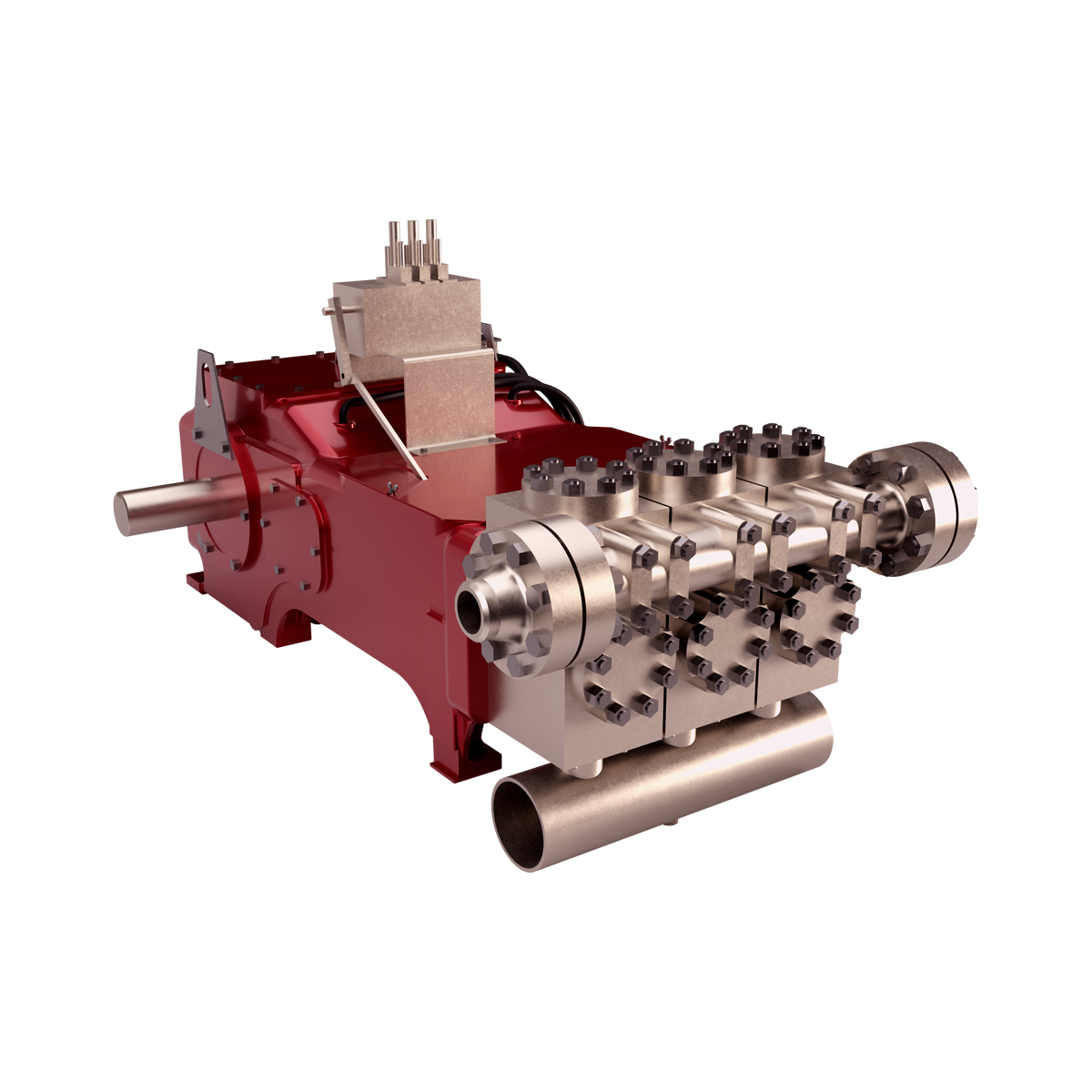

Owing to the years of industrial experience, we have been able to serve our esteemed clients with a wide variety of Duplex Mud Pump Part. These parts of pumps are manufactured by our industry-experts using advanced machinery and premium quality material. Further, we check these parts on different parameters previous to theirread more...

We are Authorized dealers for HAINUAO AO brand of mud pump spares which are compatible with mud pumps of EMSCO, GARDNER-DENEVER, NATIONAL OILWEL, IDECO, SKYTOP/BREWSTER, OPI WERTH WILSON and GASO and are an OEM replacement, approved by the API and are designed for the longest service.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

Humble Industries, Inc. is an independent manufacturer of replacement parts. Humble Ind. is neither a licensee, nor is it affiliated with any of the original equipment manufacturers named above. The manufacturers names or trademarks used herein are solely for identification purposes and are not intended by Humble Ind. to cause confusion as to the source, sponsorship, or quality of the parts manufactured by Humble Ind. The original manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Humble Ind. products.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

The Mudmaster Cast Iron 2x3x11 - Centrifugal Mud Pump, also known as the Mission Type S Pump 2x3x11 pump, is one of the best-selling oil field pumps on the market. First manufactured in 2010, this pump is strong, durable, easy to use, and incredibly versatile. Furthermore, the fact that this mud pump has a small footprint makes it ideal for use in areas with limited space.

The pump is made from cast iron and weighs 250 pounds. It has a six-vane impeller with an 8.5-inch diameter and offers clockwise and counterclockwise rotation for user convenience. It has a flow rate of up to 800 gallons per minute and head pressures of up to 350 feet. It pressures up to 150 PSI and has a round-bodied gear end. It has a 3500 pump speed limit for oil and a 2400 speed limit for grease.

The Mudmaster Cast Iron 2x3x11 - Centrifugal Mud Pump needs only a small mounting space. It is closely coupled and comes with a 50 or 60 HZ explosion-proof motor. Bearings can run at temperatures of up to 180 degrees Fahrenheit and do not have to be lubricated under normal operating conditions. A sight oil gauge makes it easy to ensure the pump has enough oil to operate properly at all times. As an added benefit, the fluid end is designed to make it easy for users to replace parts as needed in the field, without having to take the pump apart and transport it to another location for repairs.

This pump also has an open impeller design to lower the axial thrust load as well as an impeller retention bolt to protect the pump from damage when run counter-clockwise. The lip seals and exclusion deals are designed to retain lubricants while protecting the pump from contamination when in operation. It has a single-piece casing and is shipped fully assembled and ready to operate.

MudMaster"s centrifugal pumpsare ideal for use in a range of industries, as they can move large quantities of liquid in a short period of time, and can handle liquids that contain solids and/or abrasive chemicals. Oil refineries use these pumps to move crude oil to refining process units, storage tanks, or pipelines. Chemical plants use them to pump corrosive fluids, flammable fluids, viscous fluids, chemicals, and liquids.

The agricultural industry uses centrifugal pumps to power farm equipment and irrigate fields while water treatment plants use them to either move water from one place to another or to circulate water in the plant itself. Paper mills, power plants, mining companies, food processing plants, and the ship-building industry also benefit from all the Mudmaster Cast Iron 2x3x11 - Centrifugal Mud Pump has to offer.

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We"ve been striving to be an excellent business enterprise partner of you for Vertical Roller Mills, Horizontal Solid Slurry Pump, Centrifugal Centrifugal Pump, We warmly welcome all perspective inquiries from home and abroad to cooperate with us, and look forward to your correspondence.

Slurry pumps run as the key part in the mining process, power plant, metallurgy and other relevant industries are supposed to perform at an optimal standard. Atlas Pump guarantee to keep the slurry pumps at optimal performance throughout the entire working life by our highest quality spare parts. Atlas Pump promise to be the reliable back of the worldwide partners to provide the qualified and cost-effective spare parts to deal with the maintenance and emergency situations.

Atlas Pump manufacture multiple series slurry pumps and suitable spare parts (hard metals & rubbers). Including wet parts (impeller, volute, FPL insert, throat bush…), bearing assembly (shaft, bearing housing, ceramic coating shaft sleeve, end cover, cover shim…), and the seals (gland seal, mechanical seal and expeller seal) etc…

Aircraft Brake System Market Growth & Trends to 2023 Profiling Honeywell, Safran, United Technologies, Meggitt, Parker Hannifin, Crane Aerospace & Electronics – Press Release | High Pressure Diesel Water Pump

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Factory Price Mud Pump - SPARE PARTS – Tiiec , The product will supply to all over the world, such as: Poland, Puerto Rico, Zurich, Look forward to the future, we"ll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let"s develop market by fully utilizing our in depth advantages and strive for building.

The aerospace and defense market is one of the most prevalent and influential industries in the global economy. In the aerospace sector, flight vehicles can require up to a million individual parts and require many support systems to operate and maintain these vehicles. In the defense sector, military modernization is the driving catalyst all over the world. With our new state-of- the art facility in Lima, Ohio (completion in late 2021) and our streamlined mass production facility in Coldwater, Ohio, we offer the latest in manufacturing output with detailed emphasis on quality control. Our quality and engineering departments work in tandem to offer this market the development of new and innovative processes and breadth of alloys that can deliver our clients the best value for their application.

Alibaba.com offers 5,168 mud pump parts products. such as hydraulic. You can also choose from electric, diesel engine. As well as from high pressure. And whether mud pump parts is oem, or odm.

180 mud pump clamp products are offered for sale by suppliers on Alibaba.comAbout 27% % of these are mud pump, 19%% are pumps, and 6%% are mining machine parts.

A wide variety of mud pump clamp options are available to you, such as 1 year, not available and 2 years.You can also choose from new, used mud pump clamp,as well as from energy & mining, construction works , and machinery repair shops mud pump clamp, and whether mud pump clamp is 1.5 years, 6 months, or unavailable.

8613371530291

8613371530291