bomco f 1600 mud pump parts in stock

A wide variety of f1600 mud pump parts options are available to you, such as 1 year, not available and 2 years.You can also choose from new, f1600 mud pump parts,as well as from energy & mining, construction works , and machinery repair shops f1600 mud pump parts, and whether f1600 mud pump parts is 1.5 years, 6 months, or unavailable.

A wide variety of bomco f1600 mud pump piston options are available to you, such as 1 year, not available.You can also choose from new, bomco f1600 mud pump piston,as well as from energy & mining, construction works , and machinery repair shops bomco f1600 mud pump piston, and whether bomco f1600 mud pump piston is 1.5 years, 6 months, or unavailable.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

The F Series mud pumps can meet the requirements of the same manufacturing technique and quality level as those of F series mud pumps of EMSCO, IDECO, GARDNER DENVOR, OILWELL etc. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

We export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc.. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

MKP offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends. Manufactured to the highest quality, our products offer the best performance and durability. 5000psi & 7500psi available.

standard one-and/or-two-piece configuration, with designs available for pressure of 5000psi(35.1Mpa), 7500psi(52.7Mpa), and 10000psi(70.3Mpa); discharge connections available on each side; suction connections on each side or front center.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

YINDA offers a complete line of accessories for OEM fluid end modules, CNC machining makes these accessories uniformly dimensional and interchangeable with OEM.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

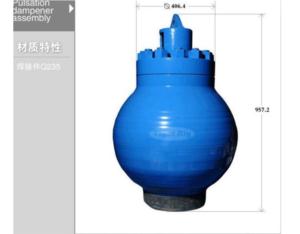

Hydraulic cylinder is forged of alloy steel. Three cylinders of one pump are interchangeable with each other. According to customers’ special requirements, to enhance the anti-corrosion performance, the surface of the hydraulic cylinder is supposed to be processed with chemical plating nickel. Pulsation dampener, shear relief valve and discharge strainer are separately mounted on the outlet.

This system is consisted of spray pump, cooling water tank and spray pipelines with the function of the necessary cooling and splashing to liners and pistons to prolong their lifetime.

The splashing pump is the centrifugal pump which can be driven by the belt mounted on the end of input shaft, or can be individually driven by a motor with water as the cooling and lubrication media.

The combination of forced lubrication and splashing lubrication is used for the power end. For the purpose of forced lubrication, the gear oil pump located at the oil tank feeds compressed oil to crossheads, extension rods and bearings respectively via the lubrication pipe lines. More ever, the operation situation of the gear oil pump can be observed by the manometer embedded in the after body of mud pumps.

Production Process: The bi-metal cylinder Liner of our company combined with the advantages of abrasion hot-forging out liner and anticorrosion high chrome inner liner. The out liner is made of high quality carbon steel by hot pressing forming. Its tensile strength is over 900000psi. The inner liner is made of high-chromium alloy by centrifugal casting.

Bi-metal Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a high chrome inner sleeve. These liners feature a centrifugally cast high chrome iron sleeve which is machined and heat treated to a minimum uniform bore hardness of 59-65HRC. Bi-metal Liners is the main expendable parts of the mud pump, it adapts double metal fix together.

The outer sleeve is forged steel with quality carbon steel,the inner sleeve is casted with high carbon and high chromimum use the technology of centrigual casting, after treatment ,the hardness of it can reach to a level of 59-67HRC.

Ceramic Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. Ceramic cylinder inner sleeve is used zirconia toughening alumina ceramics obtained the national patent, using zirconium oxide the characteristics of high fracture toughness and high hardness of alumina, the combination of these two can improve the fatigue strength of the product. Its coat uses 45 steel forging with good mechanical properties. After tempering heat treatment, hardness of HB235-265, the tensile strength is not less than 655 mpa.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

ERUI has an independent third-party inspection team, which strictly controls the quality of products, guarantees genuine products and eliminates fakes.

ERUI has been deeply engaged in the field of oil and gas energy for many years, integrating a large number of high-quality supply channels. Our products are comprehensive and the price advantage is obvious.

The time depends on the MOQ of the order. The delivery time for parts is generally 1-3 days, and equipment is 7-30 days. In addition, contact us to get the full time of the order.

We noticed you"re using an unsupported browser which may result in limited or no functionality for portions of our website. We recommend using Google Chrome, Mozilla Firefox, Microsoft Edge, or Safari for the best experience.

Mud Pumps - Emsco/Bomco 1600 Mud Pump, Unitized 1600 Mud Pump Powered by Two GE 752 Motors Charging Pump, Liner Flush Pump, Relief Valve, Mud Gauge, Etc. ....Call For Price More Info

ZZ TOP OIL TOOLS is the professional manufacturer for the drill stem testing tools and surface testing equipment. All the DST tools are conformed with NACE MR 0175 with traceability,and the DST tools can be worked in H2S & CO2 above 175 F and full H2S, also with the skilled and experienced engineers, we can design the drill stem testing tools as per customer"s well condition. Moreover, we supply the training in our factory and operation instruction at the well site. The DST tools are exported to USA, Colombia, India, Pakistan, Iran, Brazil etc. and enjoy the good reputation from the customers.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

F-1300/1600TRIPLEX MUD PUMP BOMCO/ HT QTYItem HHA Part No. NOV Part No. Description Part No. /Pump 11-3161-0501-08 Nut, 1 1/4-8UN-2B(SPL) 12 1 7601-063024 1-1/4” Heavy Hex Nut 12 11-3161-0501-07 Stud, 1 1/4-8UN(12UNF)-2Ax195 12 2 7507-2108-00 Stud 12 3 11-3161-0509 6316-0043-00 AH36001-05.09 Discharge Manifold 1 4 B34521-095-530-69 7602-160025 GB3452.1-82 O ring, 95x5.3G 3 5 11-3161-0501-00 6316-0095-00 AH36001-05.01A.00 Fluid End - Studded 3 6 11-3161-0523 6316-0164-00 AH36001-05.27 Liner End Cover 3 11-3161-0519-00 AH36001-05.20A.00 Spray Pipe Assembly 1 7 7601-258749 ¼”x15” Galv Nipple 3 11-3161-0544 Bolt 1 1/16-8UN-2AX90 36 8 7601-033139 1"x5" Hex Head Cap Screw 36 GB5780-86 Bolt M27×90 36 9 11-3161-0536 T56-1007 Screw Plug, NPT 1 1/2 110 11-3161-0534 6317-0074-00 AH33001-05.39 Blind Suction Flange 111 B34521-345-700-69 7602-160025 GB3452.1-82 O ring 345x7.0 G 312 11-3161-0535 6316-0105-00 AH33001-05.40 Suction Flange 1 11-3161-0543 7601-063020 1" Heavy Hex Nut 3613 GB8841-86 Nut M27 3614 11-3161-0525-00 6316-0117-00 AH36001-05.32A.00 Suction Manifold 115 11-3161-0533-01 Diaphragm(Suction Dampener) 116 11-3161-0533-02 End Cover(Suction Dampener) 117 11-3161-0533-00 AH33001-05.35A.00 Suction Dampener 1 QTYItem HHA Part No. NOV Part No. BOMCO Part No. Description /Pump 0 11-3161-0522-00 AH36001-05.24.00 Piston Rod Clamp Assembly 3 1 7601-033137 1"x4" Hex Head Capscrew 6 2 7601-132033 1" Lockwasher 6 3 6316-0107-10 Piston Rod Clamp 3 4 11-3161-0518 6316-0094-00 AH36001-05.19A Piston Rod 3 5 11-3161-0524-00 As Specified AH36001-05.28.00 Piston 3 6 11-3161-0532-00 T57-3005.0 Piston Nut 3 7601-072058 Heavy Lock Nut 3 7 B34521-200-700-69 GB3452.1-82 O ring, 200x7.0 G 3 8 11-3161-0520 AH36001-05.22 Liner Locking Ring 3 9 11-3161-0517-00 Liner retainer Screw 3 AH36001-05.18.00 Liner Lock 310 11-3161-0521-XX AH36001-05.23A.00 Liner 311 11-3161-0531 AH33001-05.20A Piston Seal Ring 312 11-3161-0501-03 Nut, 1-8UNC-2B(SPL) 3613 11-3161-0501-02 Stud, 1-8UNC(14UNS)-2Ax185 3614 11-3161-0516 Liner retainer ring 3 AH36001-05.17 Liner Flange 315 11-3161-0515 AH36001-05.16A Wear Plate 316 11-3161-0514 AH36001-05.15 Liner Seal Ring 617 11-3161-0501-00 Cylinder Assembly 3 6316-0095-00 Fluid End - Studded 3 AH36001-05.01A.00 Fluid End Studded Assy. 318 11-3161-0513 6316-0039-00 AH36001-05.14A Valve Pot Cover 319 11-3161-0512 6316-0092-00 AH36001-05.13 Cover Seal 320 11-3161-0527 6397-0575-00 AH33001-05.12 Valve Guide - Upper 321 11-3161-0529 6397-0603-00 AH33001-05.14 Retainer - Upper Valve Guide 322 11-3161-0541-00 Spring Guide 323 11-3161-0510 AH33001-05.16A Valve Spring 624 11-3161-0511-00 AH36001-05.12A.00 Valve Assembly 625 11-3161-0505-00 6316-0004-00 AH36001-05A.05.00 Valve Guide with Bushing Lower 326 11-3161-0501-07 Stud, 1 ¼-8UN(12UNF)-2Ax195 12 7507-2108-00 Stud 1227 11-3161-0501-08 Nut, 1 ¼-8UN-2B(SPL) 12 7601-063024 1 1/4" Heavy Hex Nut 1228 Stud 429 Copper Block 130 11-3161-0504-00 Spacer Assembly 3 AH36001-05A.04.00 Flashboard Assy. 331 11-3161-0507 Positioning Panel 3 AH36001-05A.07 Alignment Ring 332 11-3161-0508 AH36001-05.08 Cylinder Head Seal Ring 333 11-3161-0506-00 6316-0123-00 Cylinder Head Plug 3 AH36001-05A.06.00 Cylinder Head 334 11-3161-0502 6316-0106-00 AH36001-05.02 Tread Ring 335 11-3161-0501-04 Stud, 1 ½-8UN(12UNF)-2Ax170 30 7507-2109-00 Stud 3036 11-3161-0501-06 Nut, 1 ½-8UN-2B(SPL) 60 7601-063017 1-1/2" Heavy Hex Nut 4537 11-3161-0503 AH36001-05.03 Cylinder Cover 3 6316-0122-00 Cylinder Head 3 QTYItem HHA Part No. NOV Part No. BOMCO Part No. Description /Pump 1 11-3161-0411 6316-0093-00 AH36001-04.10 Fluid Baffle Disc 3 2 11-3161-0423 Bolt, 3/8-16UNC-2A×40 12 7601-033029 Hx. Hd. Capscrew 3/8X7/8" 12 GB5780-86 Bolt M10×25 12 3 11-3161-0409 End cover 3 4 Dust Ring 3 5 11-3161-0408 Gasket 3 6 11-3161-0405 Diaphragm stuffing box Stuffing box lock spring (Locking 7 11-3161-0410 Spring) Double Lip Oil Seal (Oil Seal, 8 11-3161-0407 5"*6.25"*0.625") Stuffing box spring (HHA: Oil Seal 9 11-3161-0406 ring)10 B34521-160-700-69 O Ring,160x7.0G 3 7602-160039 O-Ring 3 GB3452.1-82 O-Ring Φ160×7 311 11-3161-0412 6316-0028-00 AH36001-04.11 Crosshead Extension 312 11-3161-0422 Bolt, 1-8UNC-2Ax70 24 Socked Hd. Drld. Capscew 1"X2- 7501-1269-00 12 1/2" GB70-85 Bolt M24×65 2413 11-3161-0402 Crosshead slide (Upper slide) 3 6316-0024-00 Crosshead Guide 3 AH36001-04.02 Crosshead Guide (Upper) 314 11-3161-0401 6316-0022-00 AH36001-04.01A Crosshead 315 11-3161-0417 Crosshead Bearing, 254941QU 3 6301-0038-00 AH36001-04.19 Crosshead Bearing16 11-3161-0413 6316-0087-00 AH36001-04.12A Crosshead Pin 317 11-3161-0416 6316-0026-00 AH36001-04.18 Crosshead pin retainer 318 11-3161-0415 Crosshead slide (Lower slide) 3 6316-0024-00 Crosshead Guide 3 AH36001-04.17 Crosshead Guide (Lower) 319 11-3161-0421 Bolt, 1-8UNC-2Ax60 6 7501-0117-00 Drld. Hx. Hd. Capscew 1"X2-1/4" 6 T52-7008K Bolt M24×60 620 7501-0058-00 Drld. Hx. Hd. Capscew 1"X2-1/2" 12 T52-7009K Bolt M24×70 18 QTYItem HHA Part No. NOV Part No. BOMCO Part No. Description /Pump 1 B0093-16-59 GB93-87 Spring Washer, 16 3 11-3161-0316 Bolt, 5/8-11UNC-2Ax50 3 2 GB5783-86 Bolt, M16×45 3 3 11-3161-0313 AH36001-03.11 Flange 1 11-3131-0302 6317-0021-00 AH36001-03.02 1 4 Pinion Shaft 11-3161-0302 6316-0027-00 AH36001-02.01A 1 11-3161-0301 Key 2 5 7504-7501-00 Square Key 2 AH36001-03.01 Key 2”x2”x11⅜” 2 11-3161-0314 Bolt, 1/2-13UNC-2A*35 24 6 7601-033220 Hx Hd Capscrew (1/2" x 1-1/2") 24 GB5782-86 Bolt M12×35 24 B0093-14-59 Spring Washer, 14 24 7 7601-132016 Lockwasher (1/2") 24 GB93-87 Washer 12 24 11-3161-0305 AH36001-03.05 Gasket, End cover 2 8 7502-0841-00 Oil Seal Carrier Gasket 2 11-3161-0303 Sleeve, seal 2 9 6301-0002-00 AH36001-03.03 Oil Seal Wear Ring 2 11-3161-0304 End cover 210 6317-0023-00 AH36001-03.04 Oil Seal Carrier 2 11-3161-0315 Bolt, 7/8-9UNC-2Ax52 1611 7601-033600 Hx Hd Capscrew (7/8" x 2") 16 GB5782-86 Bolt M22×50 16 B0093-22-59 GB93-87 Spring Washer, 22 1612 7601-132019 Lockwasher (7/8") 16 11-3161-0306 AH36001-03.06 Gasket, Bearing housing 213 7502-0840-00 Pinion Bearing Carrier Gasket 2 11-3161-0307 Bearing housing 214 6317-0024-00 AH36001-03.07A Pinion Bearing Carrier 2 11-3161-0312 AH36001-03.09 Bearing, 4G32844H 215 Pinion Shaft Bearing 7602-021267 2 Torrington 220RU91-R3 11-3161-0308 Retainer Ring 216 AH36001-03.10 Baffle 217 11-3161-0309 AH36001-03.12 Gasket, Oil trough 2 11-3161-0310-00 Oil trough 218 AH36001-03.13.00 Oil Collecting Box 219 11-3161-0311 AH36001-03.08A Oil seal, 9.125”x10.375”x0.625” 2 7602-213118 Oil seal (JM9891-LUP) 2 QTYItem HHA Part No. NOV Part No. BOMCO Part No. Description /Pump 1 Stud 4 2 Washer 4 3 11-3161-2708-00 AH33002-08.00 Guard, Pressure Gauge 1 Pressure Gauge, 0~25MPa 4 11-3161-2710-01 Y-60 1 (0~3630psi) 5 6 11-3161-2709-00 PJC1 –L8 Bleeder Valve 1 7 8 11-3161-2706 AH33002-06 Tee, NPT1/4” 1 9 11-3161-2707 AH33002-07 Joint, NPT1/4” 110 11-3161-2710-02 JZR3-L8 Check valve (Needle valve) 111 11-3161-2704-03 Nut, 1 ½-8UN-2B(SPL) 12 T57-20011 Nut M39×3 1212 11-3161-2704-02 Stud, 1 ½-8UN(12UNF)-2Ax120 12 T53-4002 Stud AM39×2-M39×3×110 1213 11-3161-2705 AH33002-05A Cover 114 11-3161-2703-00 AH33002-03.00 Bladder 115 11-3161-2704-00 AH33002-04A.00 Dampener Body 116 11-3161-2702 AH33002-02 Plug (Bottom) 117 11-3161-2701 T58-5001 Ring Gasket, R39 1 QTYItem HHA Part No. NOV Part No. BOMCO Part No. Description /Pump 11-3161-0801-00-1 AH36001-08B.01.00 1 Guard 1 11-3161-0801-00-2 AH36001-08B.01.00A 2 11-3161-0828 Ball valve, 1-11 1/2NPSC 1 Q11F-16 Ball Valve G1” 1 3 11-3161-0827 AH36001-08B.11.00 Liner Wash Pump 1 4 11-3161-0821 Hose, L=750 1 Hose Φ38×Φ53 L=750 1 5 11-3161-0803-00 Seat assembly 1 AH36001-08B.03.00 Support Assy. 1 6 11-3161-0812-00 Water case 1 AH36001-08C.01.00 Water Tank 1 7 11-3161-0818 Hose, L=1500 1 Hose Φ22×Φ37 L=1500 1 8 B1171-A3708 GB1171-74 V belt, A3708 2 9 11-3161-0802 AH36001-08B.02 Belt pulley 1

8613371530291

8613371530291