centrifugal mud pump drilling supplier

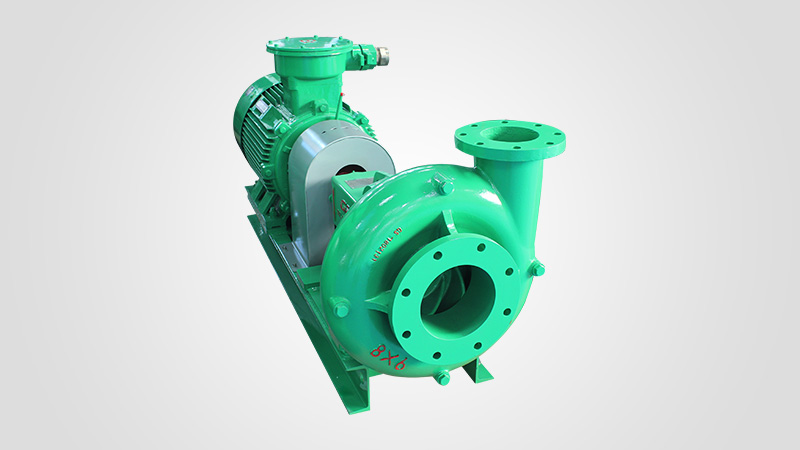

TTAAM-OM series centrifugal sand pump mainly supplies to solids control circulating system of the oilfield drill rig and can be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer to assure these equipment work efficiently.

The TTAAM-OM8×6×11 centrifugal sand pump applies to under 3000-meter-long drilling Rigs and also can be used to supply mud to the triplex mud pump as a filling pump.

The pump is constituted of pump shell, impellers, bearing block, pump axle, bearing, shaft coupling, wearing plate, seal apparatus, oil seal, motor and base.

Centrifugal mud pumps are rotodynamic pumps utilizing a rotating impeller that creates flow by energizing a fluid (mud). Centrifugal pumps are commonly used to agitate liquids allowing them to flow through pipes. The fluid (mud) enters the centrifugal pump impeller near the rotating axis and is then accelerated by the impeller. From there, the fluid (mud) flows radially outward into a diffuser or casing chamber and then exits into downstream piping.

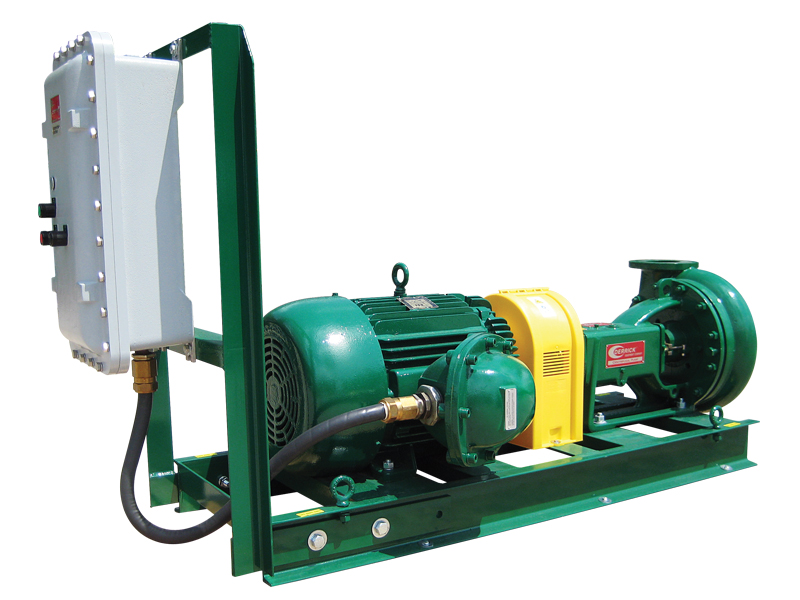

(10) Fully casting pump skid instead of welding to provide stable supporting for the pump and motor, in a result to improve the operation life of the coupling and ball bearings.

(11) Separation and Conveying Equipment company manufacture separation equipment and conveying equipment and the transfer pumps for the industrial process application. This allows being able to provide total package solutions to our clients for different applications.

GNSB Series Centrifugal pump is used for transferring slurry or mud or water. It can be used as feeding pump for desander, desilter, or used as mixing pump for Jet Mud Mixer. Also it can be used as trip pump, and supercharging pump for rig mud pump. All GN model centrifugal pump use tungsten carbide mechanical seal, with famous brand Bearing. And spare parts interchangeable with most of the international Brand pump which helps customer to source spare parts easily. Open impeller design that lowers axial thrust loads, and make it easier for installation, repair and maintenance.

The skid for supporting pump and motor is made from casting instead of welding to provide reliable operation and less vibration in a result to extend the pump and motor life.

GN Centrifugal pump has been exported to many overseas countries. The reliable quality and cost effective solutions has helped GN Solids Control to win many orders of centrifugal pump from the world. With our branches and partners around the world, clients can get GN centrifugal pump and parts from local warehouses to save delivery time.

A wide variety of centrifugal mud pump for drilling rig options are available to you, such as 1 year, not available and 3 years.You can also choose from new, centrifugal mud pump for drilling rig,as well as from energy & mining, construction works , and machinery repair shops centrifugal mud pump for drilling rig, and whether centrifugal mud pump for drilling rig is 1.5 years, 6 months, or unavailable.

During the 1950’s the Mission” 1780 type “W” pumps were introduced to replace duplex pumps while creating the first low pressure mud system. The use of a high quality concentric type centrifugal pump allowed abrasive fluids to be mixed and transferred while reducing initial and maintenance costs for the drilling industry. The low-pressure mud system with Mission 1 780 Type “W” centrifugal pumps became the industry standard.

As well depths increased so did the need for heavier mud weights. When the mud weight began exceeding 14 ppg the need for a pump that could withstand greater horsepower loads arose. During the 1970’s Mission organized a design team that engineered the Mission Magnum. The Magnum was designed to have the same footprint, flange locations, and drive shaft diameter as the 1780 “W”. This allowed a 1780 to be replaced by a Magnum without any skid modifications. The Magnums were originally engineered with a 2-1/2″ shaft (3″ between the bearings), double row bearings with an engineered life of over 2 years at 200 HP, larger impellers and heavier frames. The Magnum allowed drilling contractors to upgrade their centrifugal pumps and mix heavier fluids.

The National Oilwell Varco” Mission centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud. This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications. These pumps are designed for a wide range of flow rates, from a few gallons per minute to thousands of gallons per minute.

Each pump contains the finest materials, engineering and craftsmanship available in the industry. Described are like features of these pump lines and unique features are described on the following pages.

National Oilwell Varco utilizes unique design features developed for slurries. Three major differences from most pump designs include the concentric casing, wider impellers and increased re-circulation areas. Each feature contributes to reducing wear when handling abrasive fluids.

All of the pumps feature a concentric casing. This casing averages 37% thicker than conventional pump casings, and up to 50% thicker for the larger, mud pumping models. They are pressure rated at 1 .5 times the flange rating and are designed with a 1 /8″ erosion allowance. The concentric style casing has proven to offer the greatest pump life and reduced downtime. The walls of a concentric style casing are an equal distance from the impeller throughout the impeller circumference, which results in a smooth flow pattern. A volute style casing has a cutwater point that disturbs the fluid flow pattern creating an eddy. The concentric casing eliminates vibration, turbulence and aeration that is caused by the cutwater point in conventional volute pumps. It also reduces the high bearing loads and shaft deflection even at near shutoff flows.

The shaft is much larger in diameter than conventional pump shafts for heavy-duty performance, minimum deflection and increased operating life of the seal or packing. With a 2-1/2″ diameter at the seal area and 3″ diameter between the bearings these pumps can be direct connected or belt driven.

Centrifugal Pumps were introduced by National Oilwell in the 50s to create a low pressure mud system. Their high quality Mission pump allowed abrasive fluids to be mixed and transferred at a lower cost. The Mission centrifugal pump became the standard for the drilling industry and Givens International is proud to be a distributor. As well depths and mud weights increased, Mission expanded their line of centrifugal pumps to handle greater horsepower loads and mix heavier fluids.

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

In a volute-shaped pump casing, an impeller that can rotate rapidly is installed, and there are 2 to 8 blades on the impeller. There are two interfaces on the pump casing. The inlet to the center of the impeller is the inlet, which is connected with the suction pipeline. The tangential line of the pump casing is the outlet and is connected to the discharge pipeline. The main working part of the centrifugal pump is the impeller. Followed by the suction chamber, the pump body (pump), the pump cover, the shaft seal device, the axial force balance device, the bearing, the coupling, the bracket, the extrusion chamber, and the like. When the impeller rotates, the liquid can continuously suck from the suction port, discharge from the discharge port, and cause the liquid to generate pressure and discharge it to a high place.

Mud centrifugal pumps are mainly design for solids control circulating system of oilfield drill rig. It can be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer, to assure these equipments work efficiently.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Rig Parts Oilfield Supply Co., Ltd ( RPS ) is committed to providing the world with the best drilling equipments and services at the best prices, especially mud pump and parts, plunger pump parts, handling tools and solid control equipments.

drilling mud pump, triplex mud pump, centrifugal pump, slurry pump, mud suction pump, mud sucking pump, pond mud pump, suction mud pump, small mud pump, centrifugal mud pump, and mini mud pump

Centrifugal Pump"s effect is for transferring drilling fluid or industrial suspension slurry, it can pump viscous and corrosive liquids by use of modern design theory. Compared with the general pump, our pump is with excellent performance, high traffic, high temperature, long service life, easy maintenance, high reliability and remarkable energy saving advantages. Now it is widely used around the world on onshore and offshore drilling field. We will provide customers with the best pumps to meet different conditions and requirements.

TRSB series centrifugal pump is widely used in Oil Sludge Dewatering Systems, oil & gas drilling, Drilling Waste Management, city bored piling, trenchless HDD, mining, Coal Bed Gas Solids Control System, Oil Mud Seperation, environment protection, Water Drilling etc.

8613371530291

8613371530291