certified drilling mud pump for sale quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

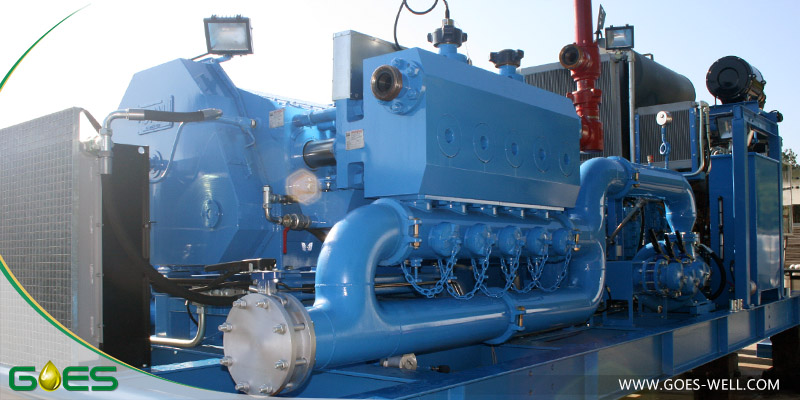

Explore a wide variety of triplex mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These triplex mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these triplex mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right triplex mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of triplex mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes mud pump for drilling rig wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

Alibaba.com has been an excellent wholesale supplier of mud pump for drilling rig for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply ofud pump for drillilling rig, you can find the product you want from the vast collection at Alibaba.com Whether it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has answer.

Explore the various mud pump for drilling rig products available for wholesale at Alibaba.com. Get a mud pump for drilling rig for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some mud pump for drilling rig options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

NOV 12-P-160 Mud Pump is rated at 1600 input horsepower (1193 kw) at 120 strokes per minute, with a 12-inch (304.8 mm) stroke. Multiple liner sizes allow pressures and volumes to handle circulation requirements in deep drilling applications.

Flexibility: Compact engineering provides higher efficiency in less space. The NOV 12-P-160 Triplex Mud Pump light weight and flexible design make it easily adaptable to a variety of rig configurations. This provides flexibility as drilling requirements and conditions change.

Fluid End Modules: NOV offers a choice of fluid end modules and valve covers for every P Series pump model to select the fluid end module that exactly matches drilling requirements. All pump models can be equipped with either the standard or premium forged, two-piece interchangeable fluid modules

The Patriot HT Piston is designed to perform in the harshest of drilling conditions. It is compatible with all applications and mud types and will withstand operating temperatures up to 300 degrees and pressures up to 7500 psi. Superior designed and ultra-durable high temp urethane allow the Patriot HT to out perform all other “extreme condition” mud pump pistons on the market. If you want to keep your pump performing, don’t settle for the cheap or the familiar – go with a Patriot Piston.

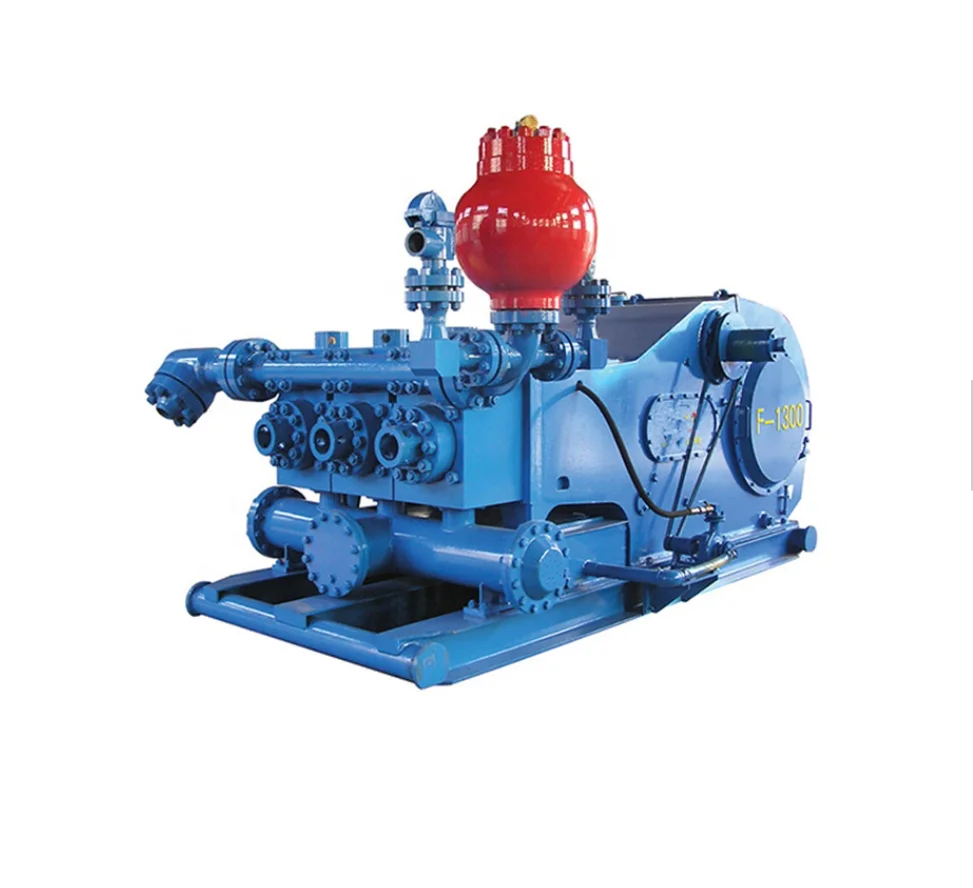

Mud pump is one of the most important equipments in the drilling operation which discharge high viscosity,heavy density and low sand contented fluid to well bottom in order to cool drill bit,flush well ,crush the rock and take out debris.

Mud pump is designed and manufactured in compliance with API Speck 7K"Specification for Drilling Equipment".All wearing parts of fluid end(valve,valve seat,liner and ect) can be interchanged acc to API specification.

MTI"s Platinum Level Certified Horizontal Directional Drills are the highest-level, preowned drills you will find on the market today. This is a sensible option for the contractor who needs a great operating rig but wants to save money compared to buying new

Platinum Level Drills are sold ready to go to work on your jobsite. To be Platinum Level Certified*, a drill must first meet certain MTI qualifications and standards regarding age, hours, wear, and overall condition.

If a drill meets our qualifications and standards, it will then go through our meticulous 80-point inspection. During this process, the drill is fully serviced, and all known issues are repaired by our highly skilled mechanics in coordination with our Quality Control Department, who test drill with the machine multiple times. The process is continued until the drill meets our Platinum Level Standards for operation.

Gold Level Certified Drills will go through our 80-point inspection process, like Platinum Level Drills. These drills will be serviced and/or repaired by our highly trained mechanics. However, the percentage of wear tolerance on wearable parts is slightly lower than our Platinum level. Our Quality Control Department will test drill the machine multiple times, until it meets our Gold Level standards for operation.

Additionally, we invite all customers to bring their crew and drill with the machine to make sure they are satisfied with the operation before it leaves. For those who cannot make it to our facility, your salesman will send you an HD video of the final test drill on the machine before it is shipped.

MTI"s Silver Level Horizontal Directional Drills are for our most budget conscious customers. They provide a superior value to a contractor that may be shopping at an auction, through a third-party, or equipment listing site. This customer does not mind completing some repairs themselves to save the most money up front.

Once our Silver Level Drills are inspected, a condition report is created and available for the customer. Despite not going through the same refurbishing processas our other levels, we still service these drills and make sure all main functions are working. So, you can be confident that even with a Silver Level Certified Drill we are still minimizing the risk of buying used.

The choke and kill manifold is a necessary device for successful control on well kick and implementation of oil and gas well pressure control technologies. It is designed, manufactured and inspected in accordance with 16C.

Choke manifold consists of choke valves, gate valves, line pipes, fittings, pressure gauges and other components. It is adopted to execute new drilling-well’s technique of balance pressure, which can avoid pollution of oil-layer, improve the speed of drilling and control blowout effectively. One end of the device connects with the side flange of BOP spool. When BOP closes, it can control the finite pressure from casing by adjusting the choke valve’s opening, so balanced drilling can work under minimum pressure-difference.

Kill manifold consists of check valves, gate valves, line pipes, pressure gauges. In case of increase in well head pressure, the kill manifold can provide a means of pumping heavy drilling fluid into the well to balance bottom hole pressure so that well kick and blowout can be prevented. In this case, by using blow down lines connected to the kill manifold, the increasing well head pressure also can be released directly for bottom hole pressure release. or water and extinguishing agent can be injected into the well by means of kill manifold.

ISO 9002 certified distributor of a wide range of pumps & related process equipment including: diaphragm, progressive cavity, Leakproof canned motor centrifugal, Hastelloy C process centrifugal, corrosion resistant gear, epoxy, internal gear, Hydra-cell high pressure diaphragm, centrifugal, Iwaki centrifugal, modular drum and container, centrifugal, side channel & vertical inline, centrifugal & multi-stage centrifugal. Custom manufacturer of fiberglass sump & spill-stop pumps. Services include pump repair, re-building industrial mechanical equipment to factory standards & dynamic balancing. UL certified for rebuilding Class I, Group C & D, Division I, XP equipment. Factory authorized service for most products.

8613371530291

8613371530291