china diaphragm mud pump manufacturer

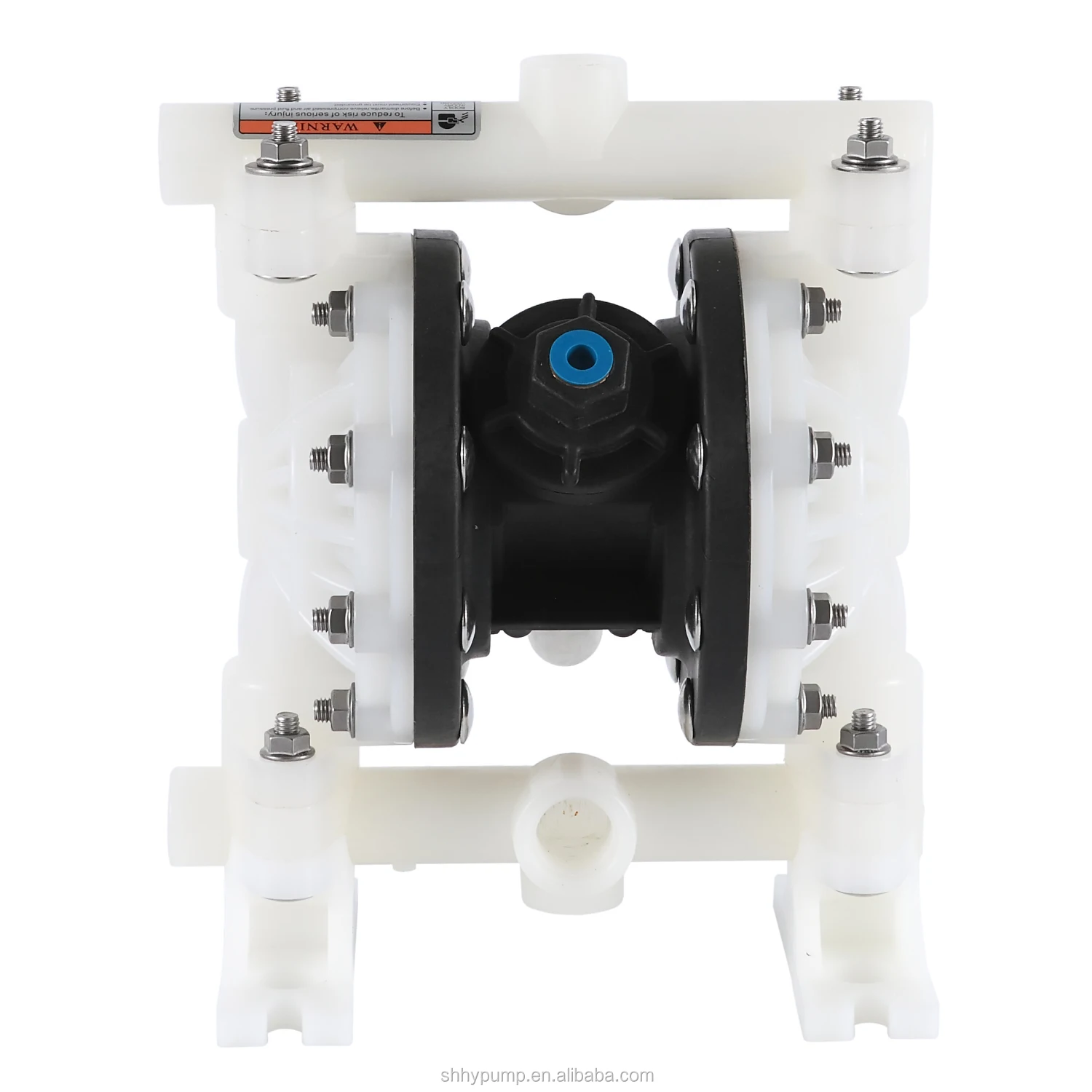

We are a China air operated double diaphragm pump manufacturers. AOBL series pneumatic diaphragm pump is a new type of conveying machinery, is currently China’s newest pump. This power supply adopts air compression, which can absorb all kinds of corrosive liquids, such as granular liquids, highly corrosive liquids, high-viscosity liquids, volatile liquids, flammable liquids, toxic liquids, etc.

A diaphragm pump is also referred to as a membrane pump which is really a positive displacement pump that utilizes a mix of the reciprocating action of the rubber, thermoplastic or teflon diaphragm and appropriate valves on each side from the diaphragm (check valve, butterfly valves, flap valves or other type of shut-off valves) to function a fluid.

When the level of a chamber of either kind of pump is elevated (the diaphragm upgrading); pressure decreases, and fluid is attracted in to the chamber. Once the chamber pressure later increases from decreased volume (the diaphragm moving lower), the fluid formerly attracted was forced out. Finally, the diaphragm upgrading once more draws fluid into the chamber, finishing the cycle. This course of action is comparable to those of the cylinder within an car engine. Diaphragm Pumps generate a hermetic seal between your drive mechanism and also the compression chamber, allowing the pump to transfer, compress, and evacuate the medium with no lubricant.

We are a China air operated double diaphragm pump manufacturers. AOBL series pneumatic diaphragm pump is a new type of conveying machinery, is currently China"s newest pump. This power supply adopts air compression, which can absorb all kinds of corrosive liquids, such as granular liquids, highly corrosive liquids, high-viscosity liquids, volatile liquids, flammable liquids, toxic liquids, etc.

Diaphragm pump drive have two types: electric and air(pneumatic).Air Operated model is AODD Pmmp. Electric Operated model is EODD pump.We are in CHINA, Now we sell our products all over the world.

A North American chocolate refinery needed to quickly upgrade all of their pumps that weren"t constructed using FDA-compliant materials. The upgraded pumps also needed to adhere to rigid plant protocols.

Food safety and compliance challenges require fast resolutions. The chocolate refinery needed to upgrade non-compliant pumps almost immediately. These pumps not only needed to be constructed using FDA-compliant materials, but plant cleaning process protocols also required that they be easy to tear down and rebuild.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

2. It can pump flowing liquid, and can also transport some medium that is not easy to flow. It combines many advantages of conveying machinery such as self-priming pump, submersible pump, canned pump, mud pump and impurity pump.

4. No rotating parts, no shaft seals, the diaphragm completely separates the pumped medium from the moving parts of the pump, and will not leak to the outside. And when the toxic, volatile or corrosive medium is pumped, it will not cause environmental pollution and endanger personal safety.

Piston membrane pumps are our business. Our only business! We make them Robust & Tough! Josef Emmerich founded the company in 1945 and still today the company is privately owned with a manufacturing facility composed of meticulous craftsmen. Exactly as you would expect from Germany.

Emmerich Manufactured Pump Parts such as Multi-safe Membranes, diaphragms for diaphragm pulsation dampeners, valve seats, sealing rings, etc. are made from a wide variety of materials such as Perbunan (NBR), Neoprene (CR), Hypalon (CSM), Viton (FPM) and Vulkollan (AU).Since 1975, JOSEF EMMERICH PUMPENFABRIK GmbH has had its own in-house production of rubber parts.

Design and manufacture of pumps are by means of state of the art processes and certification to DIN ISO 9001 guaranteed quality. Product development is formed by innovative design and material technology utilizing individual customer requirements.

All manufactured pumps are checked on the processor controlled test stand. Automatically recorded reports of performance are provided to the customer.

The Diaphragm Pump of NEWDOSE can make the operation of it more safe and reliable by adding auxiliary valves and adopting double diaphragms with alarms. However, it has some disadvantages. The diaphragms of Diaphragm Pumps are easy to break, especially the fixed stroke diaphragm pumps. Once its diaphragms break, the metering fluid and the hydraulic oil system will pollute each other and cause damages, which will bring grave consequences. Let’s take a look at what is the structure principle of the Diaphragm Pumps.

The Diaphragm Pumps of NEWDOSE are composed of a motor, drive mechanism, and pump head. The rotation generated by the motor will become the reciprocating motion of the worm gear through gearing, thereby completing the working process of suction and discharge. Adjust tappet motion through turning the regulating handwheels, and achieve the purpose of flow changing through changing the telescopic distance of diaphragms. The mechanical pump of NEWDOSE has the features of no leakage, high precision of measurement, and low noise, and it’s used broadly in the industries of oil, chemical, pharmacy, textile, and so on.

Because of the isolating effect of the diaphragms, electric diaphragms pumps structurally achieves the actual isolation between the measured fluid and the drive lubrication mechanism. The high-tech structural design and the selection of new materials have greatly increased the service life of the diaphragm, coupled with the excellent corrosion resistance of PTFE (Teflon), Diaphragm Pumps now become the main type of pump in fluid metering applications.

The mechanical diaphragm metering pump of NEWDOSE uses damping stroke slide bars, which not only keep the advantages of traditional spring reset metering pumps, such as the simple structure, fewer faults, and easy to maintenance, but also overcome the fatal weakness caused by the invalid eccentric travel, such as the big pipeline impact, high mechanical vibration, broken materials, flow linearity difference, loud noise, and so on.

8613371530291

8613371530291