components of a mud pump free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

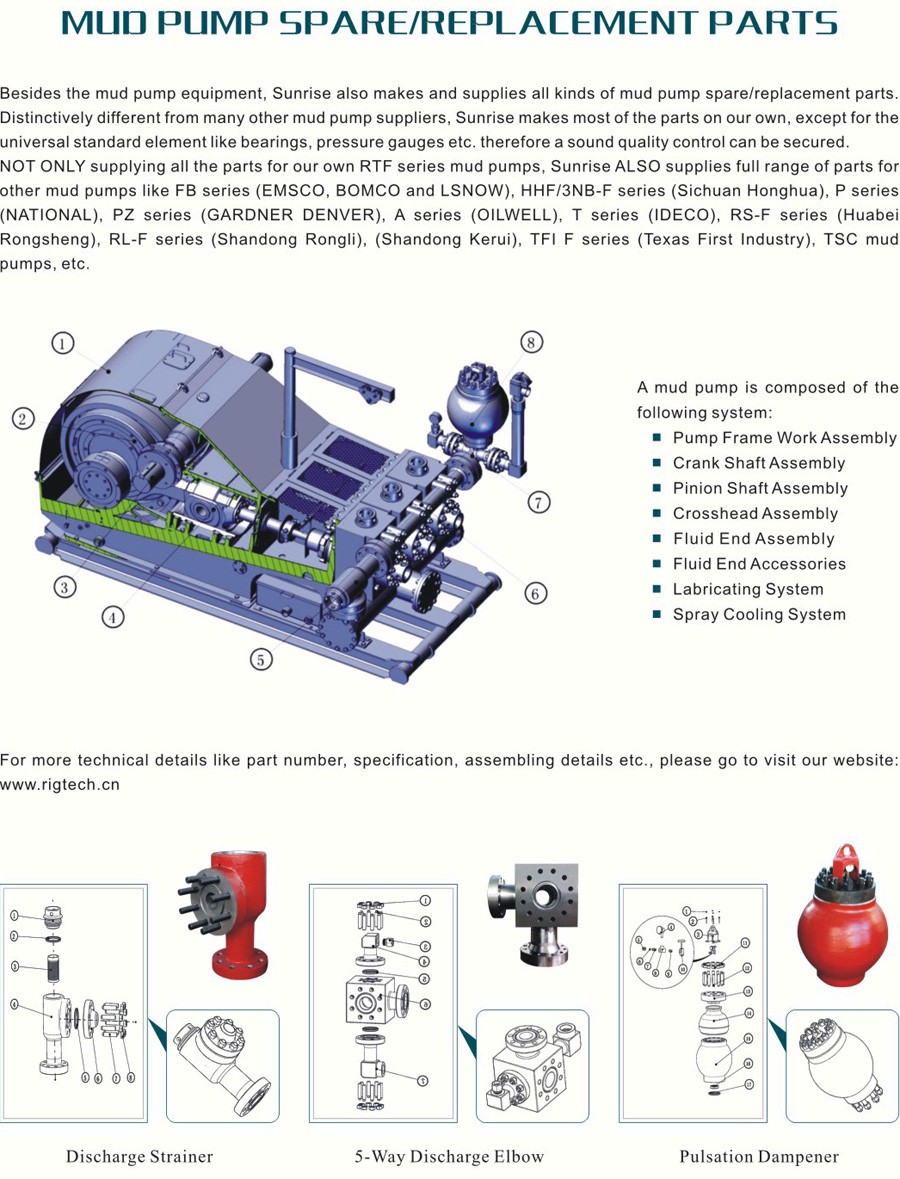

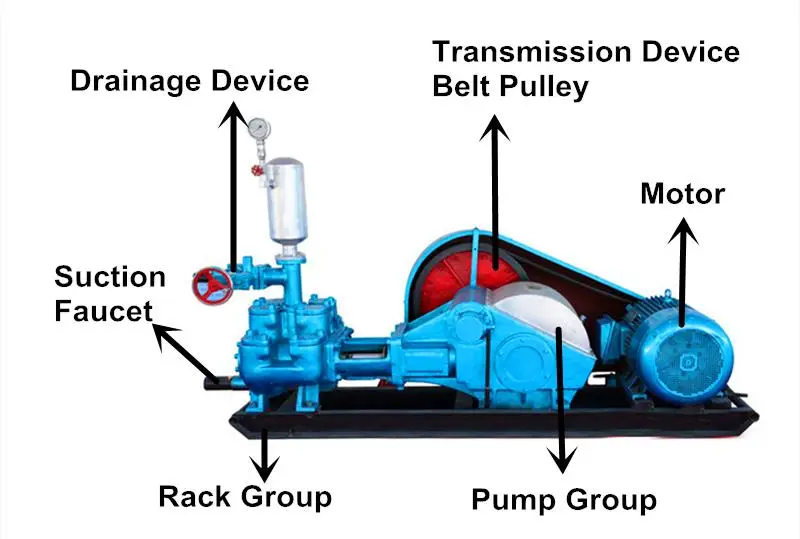

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

Mud pumps can be divided into single-acting pump and double-acting pump according to the completion times of the suction and drainage acting in one cycle of the piston"s reciprocating motion.

Mud pumps come in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pump is used. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplexes with five horizontal piston/plungers. The advantages that these new pumps have over convention triplex pumps is a lower mud noise which assists with better measurement while drilling (MWD) and logging while drilling (LWD) decoding.

The fluid end produces the pumping process with valves, pistons, and liners. Because these components are high-wear items, modern pumps are designed to allow quick replacement of these parts.

To reduce severe vibration caused by the pumping process, these pumps incorporate both a suction and discharge pulsation dampener. These are connected to the inlet and outlet of the fluid end.

The power end converts the rotation of the drive shaft to the reciprocating motion of the pistons. In most cases a crosshead crank gear is used for this.

Displacement is calculated as discharged liters per minute. It is related to the drilling hole diameter and the return speed of drilling fluid from the bottom of the hole, i.e. the larger the diameter of drilling hole, the larger the desired displacement. The return speed of drilling fluid should wash away the debris and rock powder cut by the drill from the bottom of the hole in a timely manner, and reliably carry them to the earth"s surface. When drilling geological core, the speed is generally in range of 0.4 to 1.0 m^3/min.

The pressure of the pump depends on the depth of the drilling hole, the resistance of flushing fluid (drilling fluid) through the channel, as well as the nature of the conveying drilling fluid. The deeper the drilling hole and the greater the pipeline resistance, the higher the pressure needed.

With the changes of drilling hole diameter and depth, the displacement of the pump can be adjusted accordingly. In the mud pump mechanism, the gearbox or hydraulic motor is equipped to adjust its speed and displacement. In order to accurately measure the changes in pressure and displacement, a flow meter and pressure gauge are installed in the mud pump.

The construction department should have a special maintenance worker that is responsible for the maintenance and repair of the machine. Mud pumps and other mechanical equipment should be inspected and maintained on a scheduled and timely basis to find and address problems ahead of time, in order to avoid unscheduled shutdown. The worker should attend to the size of the sediment particles; if large particles are found, the mud pump parts should be checked frequently for wear, to see if they need to be repaired or replaced. The wearing parts for mud pumps include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be adopted to increase the service life of the wearing parts, which can reduce the investment cost of the project, and improve production efficiency. At the same time, wearing parts and other mud pump parts should be repaired rather than replaced when possible.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Centerline Manu-facturing introduces the CLM 7.5 x 10D hydraulic mud pump, a pump which utilizes common fluid end parts. Its advantages are said to be its flow capacity, rated pressure, size and weight. It is designed to pump 100 percent more rated flow than a standard 5x6 and up to 3.25 times the rated pressure. However, it only has a third of the weight and 77 percent of the length.

If you run a mud rig, you have probably figured out that the mud pump is the heart of the rig. Without it, drilling stops. Keeping your pump in good shape is key to productivity. There are some tricks I have learned over the years to keeping a pump running well.

First, you need a baseline to know how well your pump is doing. When it’s freshly rebuilt, it will be at the top efficiency. An easy way to establish this efficiency is to pump through an orifice at a known rate with a known fluid. When I rig up, I hook my water truck to my pump and pump through my mixing hopper at idle. My hopper has a ½-inch nozzle in it, so at idle I see about 80 psi on the pump when it’s fresh. Since I’m pumping clear water at a known rate, I do this on every job.

As time goes on and I drill more hole, and the pump wears, I start seeing a decrease in my initial pressure — 75, then 70, then 65, etc. This tells me I better order parts. Funny thing is, I don’t usually notice it when drilling. After all, I am running it a lot faster, and it’s hard to tell the difference in a few gallons a minute until it really goes south. This method has saved me quite a bit on parts over the years. When the swabs wear they start to leak. This bypass pushes mud around the swab, against the liners, greatly accelerating wear. By changing the swab at the first sign of bypass, I am able to get at least three sets of swabs before I have to change liners. This saves money.

Before I figured this out, I would sometimes have to run swabs to complete failure. (I was just a hand then, so it wasn’t my rig.) When I tore the pump down to put in swabs, lo-and-behold, the liners were cut so badly that they had to be changed too. That is false economy. Clean mud helps too. A desander will pay for itself in pump parts quicker than you think, and make a better hole to boot. Pump rods and packing last longer if they are washed and lubricated. In the oilfield, we use a petroleum-based lube, but that it not a good idea in the water well business. I generally use water and dish soap. Sometimes it tends to foam too much, so I add a few tablets of an over the counter, anti-gas product, like Di-Gel or Gas-Ex, to cut the foaming.

Maintenance on the gear end of your pump is important, too. Maintenance is WAY cheaper than repair. The first, and most important, thing is clean oil. On a duplex pump, there is a packing gland called an oil-stop on the gear end of the rod. This is often overlooked because the pump pumps just as well with a bad oil-stop. But as soon as the fluid end packing starts leaking, it pumps mud and abrasive sand into the gear end. This is a recipe for disaster. Eventually, all gear ends start knocking. The driller should notice this, and start planning. A lot of times, a driller will change the oil and go to a higher viscosity oil, thinking this will help cushion the knock. Wrong. Most smaller duplex pumps are splash lubricated. Thicker oil does not splash as well, and actually starves the bearings of lubrication and accelerates wear. I use 85W90 in my pumps. A thicker 90W140 weight wears them out a lot quicker. You can improve the “climbing” ability of the oil with an additive, like Lucas, if you want. That seems to help.

Outside the pump, but still an important part of the system, is the pop-off, or pressure relief valve. When you plug the bit, or your brother-in-law closes the discharge valve on a running pump, something has to give. Without a good, tested pop-off, the part that fails will be hard to fix, expensive and probably hurt somebody. Pop-off valve are easily overlooked. If you pump cement through your rig pump, it should be a standard part of the cleanup procedure. Remove the shear pin and wash through the valve. In the old days, these valves were made to use a common nail as the shear pin, but now nails come in so many grades that they are no longer a reliable tool. Rated shear pins are available for this. In no case should you ever run an Allen wrench! They are hardened steel and will hurt somebody or destroy your pump.

One last thing that helps pump maintenance is a good pulsation dampener. It should be close to the pump discharge, properly sized and drained after every job. Bet you never thought of that one. If your pump discharge goes straight to the standpipe, when you finish the job your standpipe is still full of fluid. Eventually the pulsation dampener will water-log and become useless. This is hard on the gear end of the pump. Open a valve that drains it at the end of every job. It’ll make your pump run smoother and longer.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

If you ended up on this page doing normal allowed operations, please contact our support at support@mdpi.com. Please include what you were doing when this page came up and the Ray ID & Your IP found at the

This section is intended to introduce the reader to various aspects of art that may be related to various aspects of the presently described embodiments. This discussion is believed to be helpful in providing the reader with background information to facilitate a better understanding of the various aspects of the present embodiments. Accordingly, it should be understood that these statements are to be read in this light, and not as admissions of prior art.

In order to meet consumer and industrial demand for natural resources, companies often invest significant amounts of time and money in finding and extracting oil, natural gas, and other subterranean resources from the earth. Particularly, once a desired subterranean resource such as oil or natural gas is discovered, drilling and production systems are often employed to access and extract the resource. These systems may be located onshore or offshore depending on the location of a desired resource. Further, such systems generally include a wellhead assembly mounted on a well through which the resource is accessed or extracted. These wellhead assemblies may include a wide variety of components, such as various casings, valves, pumps, fluid conduits, and the like, that control drilling or extraction operations.

As will be appreciated, drilling and production operations employ fluids referred to as mud or drilling fluids to provide lubrication and cooling of the drill bit, clear away cuttings, and maintain desired hydrostatic pressure during operations. Mud can include all types of water-based, oil-based, or synthetic-based drilling fluids. Mud pumps can be used to move large quantities of mud from surface tanks, down thousands of feet of drill pipe, out nozzles in the bit, back up the annulus, and back to the tanks. Operations come to a halt if the mud pumps fail, and thus, reliability under harsh conditions, using all types of abrasive fluids, is of utmost commercial interest.

Certain aspects of some embodiments disclosed herein are set forth below. It should be understood that these aspects are presented merely to provide the reader with a brief summary of certain forms the invention might take and that these aspects are not intended to limit the scope of the invention. Indeed, the invention may encompass a variety of aspects that may not be set forth below.

Some embodiments of the present disclosure generally relate to a self-aligning mud pump apparatus. In one embodiment, the self-aligning mud pump apparatus includes a housing and a rotatable crankshaft disposed in the housing. The self-aligning mud pump apparatus can include a crosshead disposed in the housing, as well as a crosshead guide disposed in the housing to constrain movement of the crosshead. The self-aligning mud pump apparatus can include a hub disposed in the housing and disposed on the crankshaft for converting a rotating motion of the crankshaft to a reciprocating motion of the crosshead via a connecting rod having a first end coupled to the hub and a second end coupled to the crosshead. The connecting rod can be coupled to the crosshead such that the connecting rod has five degrees of freedom with respect to the crosshead guide.

Certain embodiments of the present disclosure generally relate to a method for assembling self-aligning components of a pump. The method can include providing a crosshead of the pump and coupling a connecting rod to the crosshead with a first socket joint that allows three rotational degrees of freedom between the connecting rod and the crosshead. The method can also include coupling a piston to the crosshead with a second socket joint that allows three rotational degrees of freedom between the piston and the crosshead.

Various refinements of the features noted above may exist in relation to various aspects of the present embodiments. Further features may also be incorporated in these various aspects as well. These refinements and additional features may exist individually or in any combination. For instance, various features discussed below in relation to one or more of the illustrated embodiments may be incorporated into any of the above-described aspects of the present disclosure alone or in any combination. Again, the brief summary presented above is intended only to familiarize the reader with certain aspects and contexts of some embodiments without limitation to the claimed subject matter.

These and other features, aspects, and advantages of certain embodiments will become better understood when the following detailed description is read with reference to the accompanying drawings in which like characters represent like parts throughout the drawings, wherein:

FIG. 5B shows a cross-section of a lubricated pad, as an alternative for a roller bearing, for use in conjunction with the crankshaft of FIG. 5A in accordance with one or more implementations described herein.

FIG. 6B shows a schematic of an alternative crankshaft of a mud pump such as shown in FIG. 6A in accordance with one or more implementations described herein.

FIG. 6C shows a schematic of an alternative crankshaft of a mud pump such as shown in FIG. 6A in accordance with one or more implementations described herein.

FIG. 7A shows a schematic of a modular mud pump unit that can be used alone or in combination with a mirror-image modular unit, as shown in FIG. 7B, in accordance with one or more implementations described herein.

FIG. 8A shows a partial cross-section of a crosshead and connecting rod interface of a mud pump, in accordance with one or more implementations described herein.

FIG. 8C shows a partial cross-section of a crosshead and connecting rod interface of a mud pump, in accordance with one or more implementations described herein.

FIGS. 10A-10F depict various embodiments of a plunger piston in various sealing configurations in accordance with one or more implementations described herein.

Specific embodiments of the present disclosure are described below. In an effort to provide a concise description of these embodiments, all features of an actual implementation may not be described in the specification. It should be appreciated that in the development of any such actual implementation, as in any engineering or design project, numerous implementation-specific decisions must be made to achieve the developers" specific goals, such as compliance with system-related and business-related constraints, which may vary from one implementation to another. Moreover, it should be appreciated that such a development effort might be complex and time-consuming, but would nevertheless be a routine undertaking of design, fabrication, and manufacture for those of ordinary skill having the benefit of this disclosure.

When introducing elements of various embodiments, the articles “a,” “an,” “the,” and “said” are intended to mean that there are one or more of the elements. The terms “comprising,” “including,” and “having” are intended to be inclusive and mean that there may be additional elements other than the listed elements. Moreover, any use of “top,” “bottom,” “above,” “below,” other directional terms, and variations of these terms is made for convenience, but does not require any particular orientation of the components.

The present disclosure describes a variety of design changes to mud pump kinematics and construction to result in a less rigid, more robust and reliable mud pump. In a first embodiment described in greater detail below, load balancing is achieved by spacing hubs along the crankshaft of the mud pump with the bull gears disposed opposite one another, on the outermost ends of the crankshaft adjacent to the housing. In such an embodiment, the hubs are disposed along the crankshaft between the bull gears. In a second embodiment described in greater detail below, a novel crosshead design enables connection to both connecting rod and piston, resulting in self-aligning components with at least three degrees of rotational freedom and two degrees of translational freedom. In a third embodiment described in greater detail below, the present disclosure also includes various seal and/or piston sleeve assemblies that can be applied to a plunger style piston.

Generally speaking, FIG. 1 illustrates a wellsite system in which the disclosed mud pump can be employed. The wellsite system of FIG. 1 may be onshore or offshore. In the wellsite system of FIG. 1, a borehole 11 may be formed in subsurface formations by rotary drilling using any suitable technique. A drill string 12 may be suspended within the borehole 11 and may have a bottom hole assembly 100 that includes a drill bit 105 at its lower end. A surface system of the wellsite system of FIG. 1 may include a platform and derrick assembly 10 positioned over the borehole 11, the platform and derrick assembly 10 including a rotary table 16, kelly 17, hook 18 and rotary swivel 19. The drill string 12 may be rotated by the rotary table 16, energized by any suitable means, which engages the kelly 17 at the upper end of the drill string 12. The drill string 12 may be suspended from the hook 18, attached to a traveling block (not shown), through the kelly 17 and the rotary swivel 19, which permits rotation of the drill string 12 relative to the hook 18. A top drive system could alternatively be used, which may be a top drive system well known to those of ordinary skill in the art.

In the wellsite system of FIG. 1, the surface system may also include drilling fluid 26 (also referred to as mud) stored in a pit/tank 27 at the wellsite. A pump 29 supported on a skid 28 may deliver the drilling fluid 26 to the interior of the drill string 12 via a port in the swivel 19, causing the drilling fluid to flow downwardly through the drill string 12 as indicated by the directional arrow 8. The drilling fluid 26 may exit the drill string 12 via ports in a drill bit 105, and circulate upwardly through the annulus region between the outside of the drill string 12 and the wall of the borehole 11, as indicated by the directional arrows 9. In this manner, the drilling fluid 26 lubricates the drill bit 105 and carries formation cuttings up to the surface, as the drilling fluid 26 is returned to the pit/tank 27 for recirculation. The drilling fluid 26 also serves to maintain hydrostatic pressure and prevent well collapse. The drilling fluid 26 may also be used for telemetry purposes. A bottom hole assembly 100 of the wellsite system of FIG. 1 may include logging-while-drilling (LWD) modules 120 and 120A and/or measuring-while-drilling (MWD) modules 130 and 130A, a roto-steerable system and motor 150, and the drill bit 105.

FIG. 2 shows a cutaway side view of a prior art mud pump, illustrating various components of the power assembly, the portion of the pump that converts rotational energy into reciprocating motion. A pump as shown in FIG. 2 could be used as pump 29 of FIG. 1, although many other mud pumps, including those with designs described below in accordance with certain embodiments of the present technique, could instead be used as pump 29. Pinion gears 52 along a pinion shaft 48 drive a larger gear referred to as a bull gear 42 (e.g., a helical gear or a herringbone gear), which rotates on a crankshaft 40. Pinion shaft 48 is turned by a motor (not shown). The crankshaft 40 turns to cause rotational motion of hubs 44 disposed on the crankshaft 40, each hub 44 being connected to or integrated with a connecting rod 46. By way of the connecting rods 46, the rotational motion of the crankshaft 40 (and hub 44 connected thereto) is converted into reciprocating motion. The connecting rods 46 couple to a crosshead 54 (a crosshead block and crosshead extension as shown may be referred to collectively as the crosshead 54 herein). The crosshead 54 moves translationally constrained by guide 57. Pony rods 60 connect the crosshead 54 to a piston 58. In the fluid end of the pump, each piston 58 reciprocates to move mud in and out of valves in the fluid end of the pump 29.

Using conventional mud pump designs, pumping drilling fluids at above 50% capacity and/or for longer periods of time accelerates pump failure. With any combination of the design changes described below implemented, a mud pump may be operable at a higher capacity for longer periods of time. The design changes disclosed herein include load balancing embodiments, self-aligning power assembly embodiments, and piston sealing implementations.

Turning now to FIG. 3, a load-balanced mud pump is shown. Within a housing 33, a pinion shaft 48 is disposed, supported in roller bearings 51 at each opposing end of pinion shaft 48. Pinion shaft 48 is driven by a motor (not shown). A pair of pinion gears 52 rotate on the pinion shaft 48. Pinion gears 52 engage with bull gears 42, each of which rotate on a crankshaft 40. As can be seen in FIG. 3, the bull gears 42 are positioned adjacent to the housing 33 along the crankshaft 40, and pinion gears 52 are likewise positioned adjacent to the housing 33 along the pinion shaft 48. A plurality of hubs 44 are positioned along the crankshaft 40 between the bull gears 42 without any hubs positioned between the bull gears 42 and the walls of the housing 33.

By separating the largest, heaviest gears, i.e., the bull gears 42, toward the exterior along the crankshaft, an optimized load balance is accomplished. The position of the pinion gears 52 being substantially toward the exterior along the pinion shaft 48 further contributes to the load balance of the pump overall. In other embodiments, pinion gears 42 and bull gears 52 may be positioned further away from the walls of the housing while still remaining closer to the walls of the housing than to a midpoint along the pinion shaft 48 and crankshaft 40 respectively.

Each hub 44 is integrated with a connecting rod 46 (typically a forged metal) that couples at an interface to a crosshead 54, which will be discussed in further detail below. In turn, each crosshead 54 also couples at another interface to a plunger piston 58 (shown in FIG. 9A). Crosshead 54 is constrained in direction of movement by a guide, not shown in FIG. 3, discussed further below. In the fluid end, plunger piston 58 draws mud in and out by way of inlet 59 and outlet 61. Valve pots 63 are the machine openings to the fluid end of the mud pump.

FIG. 4A shows a schematic of a mud pump in accordance with one or more implementations described herein. Motors 31 couple operatively to a series of gear wheels 32. The gear wheels 32 rotate the pinion shaft 48. Pinion shaft 48 is supported in the housing 33 by a pinion shaft roller bearing 51 in the wall of housing 33 at either end of the pinion shaft 48. The pinion gears 52 are rotatable on pinion shaft 48. Pinion gears 52 engage bull gears 42, which are rotatable on the crankshaft 40. Crankshaft 40 is supported in the housing 33 on crankshaft roller bearings 56 in the walls of housing 33 at either end of the crankshaft 40. Bull gears 42 are positioned along crankshaft 40 at opposite ends of the crankshaft 40, adjacent to the walls of housing 33. Hubs 44 are positioned along the crankshaft between the bull gears 42. In the embodiment shown, the hubs 44 are spaced about evenly across the crankshaft 40. The crankshaft 40 passes through not the center of each hub, but at a position radially offset from the center of each hub, such that the hubs 44 are out of phase relative to one another to drive the pistons. Alternatively, embodiments are envisioned in which spacing is optimized for load balancing based on the weight and/or size of each individual hub 44 and connecting rod 46. Additionally, four hubs 44 are shown in FIG. 4A, though pumps having as few as two, or as many as five, hubs for driving reciprocal motion of crossheads are likewise contemplated in the present disclosure.

FIG. 4B shows a schematic of an alternative of a mud pump in accordance with one or more implementations described herein. Motors 31 couple operatively to a series of gear wheels 32. The gear wheels 32 rotate two separate pinion shafts, denoted pinion shafts 48A and 48B in FIG. 4B. Separate pinion shafts 48 enable easier repair of pump components, as there is sufficient room to, if needed, remove each pinion shaft independently. By comparison a single longer length pinion shaft may be of such a length as to be physically difficult to remove once the pump is rigged up in limited space at a wellsite. Pinion shafts 48 are supported in the housing 33 by at least a pair of pinion shaft roller bearings 51A and 51B in the wall of housing 33 on both sides of the housing 33. In order for each pinion shaft to rotate without wobbling under weight, at least two points of mechanical support are used. Thus, a mechanical support 55 affixed to (or integrated with) the housing 33 provides support to pairs of roller bearings 51A and 51B. A pinion gear 52 is rotatable on each separate pinion shaft 48. Pinion gears 52 engage bull gears 42, each of which is rotatable on the crankshaft 40. The positioning of the bull gears 42 and hubs 44 along the crankshaft 40 are, in FIG. 4B, similar to the configuration as described with respect to FIG. 4A.

FIG. 4C shows a schematic of an alternative of a mud pump in accordance with one or more implementations described herein. Motors 31 couple operatively to a series of gear wheels 32. The gear wheels 32 rotate two separate pinion shafts 48 coupled together at a coupler 65. The coupler 65 serves two purposes. First, the coupler 65 mechanically fastens the two pinion shafts 48 to one another such that the length of the fastened pinion shafts 48 is mechanically supported. Second, the coupler 65 serves to synchronize rotation of pinion shafts 48A and 48B, allowing the pinion shafts 48A and 48B to be rotated with respect to one another during assembly for proper rotational phase difference between the hubs 44 of the two shafts to drive the pistons. By disconnecting the coupler 65, each pinion shaft 48 can be replaced independent of the other. Pinion shafts 48 are supported in the housing 33 by at least a pair of pinion shaft roller bearings, denoted 51A and 51B, in the wall of housing 33 on both sides of the housing 33. As above, in order for each pinion shaft to rotate without wobbling under weight, at least two points of mechanical support are used. Thus, mechanical support 55 affixed to (or integrated with) the housing 33 provides an anchoring point for pairs of roller bearings 51A and 51B to hold up each pinion shaft 48A and 48B. A pinion gear 52 is rotatable on each separate pinion shaft 48. Pinion gears 52 engage bull gears 42, each of which is rotatable on the crankshaft 40. The positioning of the bull gears 42 and hubs 44 along the crankshaft 40 are, in FIG. 4C, similar to the configuration as described with respect to FIG. 4A.

In embodiments employing two independent separate pinion shafts, as shown in FIGS. 4B and 4C, the two segments of the pinion shaft 48 are indirectly rotationally coupled one to the other through the first bull gear 42, the crankshaft 40, and the second bull gear 42, respectively. In such embodiments, the two segments of pinion shaft 48 do not directly engage one another.

FIG. 5A shows a schematic of a crankshaft of a mud pump in accordance with one or more implementations described herein. The pinion shaft 48 and pinion gear 52 may be configured as in any of the embodiments described above. As can be seen in FIG. 5A, the bull gears 42 are positioned adjacent to the housing 33 along the crankshaft 40. Pinion gears 52 may likewise be positioned adjacent to the housing 33 along the pinion shaft 48. A plurality of hubs 44 are positioned along the crankshaft 40 between the bull gears 42. An optimized weight load balance is accomplished by separating the largest, heaviest gears, the bull gears 42. In the embodiment of FIG. 5A, the crankshaft 40 spans a length less than the width of the housing 33. In lieu of roller bearings 56 in the walls of the housing 33 to support the crankshaft 40, mechanical supports 62 are attached to (or integrated with) the housing 33 to support the crankshaft 40. Lubricated pads 64 affix to the mechanical supports 62 so that the crankshaft 40 rotates freely. FIG. 5B shows a cross-section of an example of a lubricated pad, as an alternative for a roller bearing, for use in the embodiment shown in FIG. 5A. The lubricated pad 64 may include a lower pad 64A and an upper pad 64B, each conformed to curve around crankshaft 40. In a preferred embodiment, the lubricated pads are offset by 30° relative to a horizontal plane running through the crankshaft 40, as shown. The surface of lower pad 64A and upper pad 64B are lubricated. Additional lubricant can be added to the surfaces in contact with the crankshaft 40 in the gap between lower pad 64A and upper pad 64B.

FIG. 6A shows a schematic of an alternative of a mud pump in accordance with one or more implementations described herein. Load balancing is achieved in the embodiment of FIG. 6A by positioning the bull gears 42 adjacent to one another, centered on the crankshaft 40 and having none of the hubs 44 positioned on the crankshaft 40 therebetween. Motors 31 couple operatively to a series of gear wheels 32. The gear wheels 32 rotate pinion shaft 48. Pinion shaft 48 is supported in the housing 33 by pinion shaft roller bearings 51 in the walls of housing 33 on both sides of the housing 33. Pinion gears 52A and 52B are rotatable on pinion shaft 48, and are positioned adjacent to one another without engaging one another. The pinion gears 52A and 52B may be helical in design, as shown in FIG. 6B. Pinion gears 52 engage bull gears 42, each of which is rotatable on the crankshaft 40. In the embodiment of FIG. 6A, the crankshaft 40 spans a length less than the width of the housing 33. In lieu of roller bearings 56 in the walls of the housing 33 to support the crankshaft 40, mechanical supports 62 are attached to or integrated with the housing 33 to brace or support the crankshaft 40, and lubricated pads 64, such as those shown in FIG. 5B, affix to the mechanical supports 62 such that the crankshaft 40 rotates freely.

In the embodiment shown in FIG. 5A, four hubs 44 are shown, and three mechanical supports 62 are shown between the hubs 44. In the embodiment shown in FIG. 6A, four hubs 44 are shown and four mechanical supports 62 are shown. As with the previously described embodiments, pumps having as few as two, or as many as five, hubs are likewise contemplated in the present disclosure, along with a number of mechanical supports to adequately support the weight of the hubs 44 along the crankshaft 40, as can be readily determined by one of ordinary skill in the art.

FIG. 6C illustrates an alternative embodiment, having bull gears 42 centered along the crankshaft relative to the walls of the housing 33, with hubs 44 disposed along crankshaft 40 axially away from each of the bull gears 42. Mechanical supports 62 extend from the housing 33 to positions between hubs 44. Any numerical combination of hubs and mechanical supports is contemplated by the present disclosure, to the extent that the mechanical supports 62 adequately bear the load of the crankshaft bearing the bull gears 42 and hubs 44. The load is balanced across the length of the crankshaft so as to minimize wobble during high or full capacity usage of the pump.

FIG. 7A shows a schematic of a modular unit that, when coupled with a mirror-image modular unit, is operable as a mud pump in accordance with one or more implementations described herein. By providing independent modules of mud pump power end components, the overall mud pump is scalable. Expensive downtime is reduced with quick repair by interchanging modules, should any component in one module fail. The interchangeable mud pump module shown in FIG. 7A is contained within a housing 33, and a mechanical support 55 is affixed to (or integrated with) the housing 33. A crankshaft 40 is disposed within the housing 33, and a pinion shaft 48 is disposed within the housing 33. A first end of the crankshaft is adapted to couple rotatably to a crankshaft of a second adjacent mud module (which would be coupled at the right side of FIG. 7A). The second end of the crankshaft is rotatably supported in the housing 33, such as by mechanical supports 62 having lubricated pads 64 about the crankshaft 40. As shown, the crankshaft 40 has a plurality of hubs 44 and a bull gear 42 disposed thereon. The bull gear 42 is positioned at the second end of the crankshaft adjacent the housing 33, opposite the end of the crankshaft 40 that is supported in the wall of the housing 33. The mud pump module can also include a rotatable pinion shaft 48 for driving the crankshaft 40. The pinion shaft 48 has disposed thereon a pinion gear 52 engaging the bull gear 42 on the crankshaft 40. When a module such as shown in FIG. 7A is coupled to another that is configured as a mirror image of the one shown in FIG. 7A (as seen in FIG. 7B), a scalable, load-balanced mud pump that is easily repaired is achieved. With a smaller footprint and less weight, substantially less effort is used in rig-up as well. FIG. 7B shows the crankshaft 40 of each module coupled together with a coupler 65. Coupler 65 serves to both provide mechanical strength where the coupler 65 fastens the two crankshafts 40 together, as well as serving to synchronize the rotation thereof, and allow rotation of the crankshafts relative to one another to position each of the hubs 44 properly out of phase with respect to one another for driving the pistons.

A further improvement upon the mud pump design addresses the overall rigidity of the components about the crosshead. When the connection of the connecting rod or piston to the crosshead is not in proper alignment, premature wear may occur on these components, leading to pump failure. By implementing the kinematics of the present disclosure, five degrees of freedom of movement between the connecting rod and the crosshead guide can be achieved: three degrees of rotational freedom and two degrees of translational freedom. Rather than a simple cylindrical pin to couple the connecting rod to the crosshead, the present disclosure envisions a crosshead as shown in FIGS. 8A and 8B having a pin 75A with a spherical main body 75B seated in a bearing to secure the connecting rod within the crosshead block.

FIG. 8A shows a cutaway cross-section of the crosshead and connecting rod interface, in accordance with one or more implementations described herein. In some instances, a crosshead comprises a block that the connecting rod end is inserted into or about, with the connecting rod held rigidly in place by a cylindrical pin through the connecting rod and crosshead. By comparison, the crosshead design of the present disclosure offers additional degrees of freedom of movement. Turning now to FIG. 8A, guides 57 hold the crosshead 54 in place for reciprocating motion. Crosshead 54 comprises a crosshead top 54T, a crosshead bottom 54B, and crosshead side plates 54S. Connecting rod 46 is inserted into the crosshead 54 and secured in place by a pin 75A having a spherical main body 75B. The spherical main body 75B may be integrated with a pin, or a sphere component may be placed about a cylindrical pin. The ends of pin 75A engage with crosshead side plates 54S to hold pin 75A in place while connecting rod 46 is engaged with the cross head 54. A two-piece bearing 76 fastened about the spherical main body 75B of pin 75A facilitates swiveling motion of the connecting rod 46 about the pin 75A. Crosshead side plates 54S secure in place via screws (or like fasteners) through holes 74 in crosshead side plates 54S after the connecting rod 46, bearing 76, and pin 75A are inserted in the crosshead 54. A brace plate 54C provides structural reinforcement to the pin 75A when secured in place to crosshead side plates 54S with fasteners through screw holes 74.

Pin 75A having a spherical main body 75B allows for rotational movement in the RX, RY, and RZdirections (defined with Y-axis in the direction of reciprocal motion into the page), in that connecting rod 46 is free to move rotationally about the spherical main body 75B of the pin 75A. Such freedom of movement is facilitated by bearing 76. FIG. 8B shows a cutaway profile of the crosshead and connecting rod interface of FIG. 8A. As can be seen, the connecting rod 46 includes two apertures, the larger of which is engaged about a hub 44 on the crankshaft 40, and the smaller of which fits into the crosshead 54 that reciprocates through guide 57. Employing the pin 75A having a spherical main body 75B, the connecting rod 46 with bearing 76 is free to swivel about the pin 75A, thereby achieving three degrees of rotational freedom in the RX, RY, and RZdirections.

Turning to FIG. 8B, at least two degrees of translational freedom are achieved between the connecting rod 46 and the crosshead guide 57. Translational movement in the direction TYis the intentional reciprocating movement of the assembly to move the piston. Keys 66 keep crosshead 54 aligned with guide 57 during reciprocating motion. Returning to FIG. 8A, a gap is defined between the crosshead side plates 54S and bearing 76, providing sufficient freedom in the design for translational movement of the connecting rod 46 within the crosshead 54 in the TXdirection along the X-axis. In some embodiments, the spherical main body 75B may slide along pin 75A when the components are physically separate parts; alternatively, in embodiments in which the spherical main body 75B is integral to pin 75A, the pin 75A may be configured to translate along its axis between side plates 54S.

Turning to FIG. 8C, another embodiment demonstrating at least two degrees of translational freedom of the connecting rod 46 with respect to the crosshead guide 57 is shown. Separate pieces of bearing 76 can be seen clearly, providing spherical seating for spherical main body 75B of pin 75A. In assembly, pieces of bearing 76 can be fastened about spherical body 75B of pin 75A (e.g., with a fastener extending through tabs of the bearing 76 and the connecting rod 46, as shown at the top of FIG. 8C). Ends of pin 75A are shown engaged with the crosshead side plates 54S. Variable gaps intentionally imposed between bearing 76 and crosshead side plates 54S, as well as between bearing 76 and connecting rod 46, provide sufficient design latitude for incorporating a degree of mechanical give for translational movement of the connecting rod 46 in the TXdirection, as denoted by the double-sided arrow.

In a still further embodiment, FIG. 9A shows an illustration of a crosshead and piston interface in accordance with one or more implementations described herein. The end of piston 58 that connects to the crosshead 54 may be formed as a spherical knob. In one embodiment, the spherical knob may be integral to the piston 58; alternatively, the spherical knob may be a separate component fastened to the piston 58. Optionally, the piston 58 may have a sleeve 93 disposed thereon, so as to vary the effective diameter of the piston 58, which will be discussed further below. Turning to FIG. 9A, the knob of piston plunger 58 reciprocates along the Y-axis, forced by movement of crosshead 54, where spherical knob 90 of plunger piston 58 is enclosed in the crosshead 54. FIG. 9B shows a cutaway of the crosshead and piston interface shown in FIG. 9A. A lubrication channel 106 into the interior of the fluid-end side 92 of the crosshead 54 delivers lubricant to the spherical knob 90 of plunger piston 58. A bearing 107 further facilitates rotational movement. In an embodiment, the bearing 107 comprises more than one bearing component having a spherical seat to receive the spherical knob 90 of plunger piston 58, each of the bearing components of bearing 107 being configured to fasten together about the spherical knob 90 of plunger piston 58 in assembly. Thus, five degrees of freedom of movement are provided between the crosshead 54 and the plunger piston 58 in the fluid-end side 92 of the crosshead 54: the plunger piston 58 is able to swivel in three rotational directions with respect to the crosshead due to the spherical knob 90, and translational movement is permitted in the TXand TZdirections due to intentional play between the bearing 107 and crosshead housing.

A further improvement upon the mud pump design addresses the issue of seal failure about the piston. In some embodiments of mud pumps, a piston having a moveable sealing head at the fluid end is employed. However, failure of the mud pump occurs when the seal erodes in the harsh working conditions, or when the sealing head fails, such as by breaking off. As an alternative, the present disclosure describes a headless plunger piston having a seal 101 (and optionally sleeve 93) disposed about the piston 58. A variety of means are disclosed for monitoring the seal 101. Additionally, the sleeve 93 may be variable in size depending on the pumping pressure desired in a given application.

Turning now to FIG. 10A, plunger piston 58 is shown in detail, with reciprocating motion in the TYdirection. A directional seal 101 is disposed about the plunger piston 58 on the fluid end. A lubricated pad 94 is provided at the power end of the plunger piston 58, to which oil may be reapplied to lubricate the plunger piston 58. In a cavity 95 defined between the seal 101 and the lubricated pad 94, a drain port 96 may be included so that the quality of the seal 101 at the fluid end can be monitored. As the seal 101 fails, mud will leak in under and around the seal 101, and empty out of the drain port 96.

In an alternative embodiment, as shown in FIG. 10B, a lubricated pad 94 is provided at the power end of the plunger piston 58. Similar to as shown in FIG. 10A, in a cavity 95 formed between the seal 101 and the lubricated pad 94, a drain port 96 may be included so that the quality of the seal 101 at the discharge end can be monitored. Additionally, an injection port 98 to the cavity 95 may be provided such that water can be injected into the cavity to flush any leakage mud out of the drain port 96. In an embodiment, the water may be injected at a relatively low pressure. As the seal 101 fails, mud will leak in under and around the seal, and be forcibly flushed by the injected water out of the drain port 96. The injected water also serves to clean and protect the wetted area of the plunger piston 58.

In an alternative embodiment, as shown in FIG. 10C, a lubricated pad 94 is provided at the power end of the plunger piston 58, as in previous embodiments. An oil port 100 allows lubricant to be added, while an oil drain 102 allows lubricant to flush out, keeping the surface of the piston 58 continually renewed with lubricant. This embodiment is also depicted as having a cavity 95, drain port 96 and injection port 98, as described above. The lubricated pad 94 can be optionally isolated from the area where mud leakage may be present by an additional directional seal 97 that is not in contact with the pressurized mud in the fluid end. The flow and temperature of oil lubricant added may or may not be controlled.

In an alternative embodiment, as shown in FIG. 10D, a lubricated pad 94 is provided at the power end of the plunger piston 58. An oil port 100 allows lubricant to be added through cavity 103 to the lubricated pad 94, while an oil return 104 allows lubricant to circulate, keeping the surface of the plunger piston 58 continually renewed with lubricant. The oil return 104 enables control of the temperature of the lubricant, by inclusion of a heat exchanger 110 to cool the oil. The heat exchanger 110 employed may be of any type familiar to one of ordinary skill in the art. Cavity 95 is defined between seal 101A and an additional directional seal 101B. Additional directional seal 97 prevents oil from entering the fluid end from cavity 103, and mixing with any leaking mud in cavity 95. An injection port 98 to the cavity 95 may be provided such that water can be injected into the cavity 95 to clean the plunger piston 58. In such an embodiment, the water may be injected at a relatively high pressure, in contrast with the low pressure injected water described with respect to FIG. 10C, and forcibly flush leaking fluid from cavity 95. The lubricated pad 94 is thus fluidly isolated from the area around the seal 101 where mud leakage may be present. The embodiment shown in FIG. 10D does not include a drain port 96, but high-pressure water injected into cavity 95 can exit past the seal 101B into the fluid end of the pump.

An alternative embodiment, as shown in FIG. 10E, is similar to that shown in FIG. 10D, but also includes a cavity 99 with a drain port 96. The cavity 99 is provided between the end of the seal 101A and the directional seal 97. The drain port 96 allows the quality of the seals 101 to be monitored. Additionally, the injection port 98 and the cavity 95 between the sealing elements 101A and 101B allow water to be injected into the cavity 95, which can aid the directional seal elements such as 101B in the fluid end by providing resistance to mud leaking under the seal 101B from the working space of the pump.

In embodiments including a drain port 96, as the seals 101 fail, mud may leak and be forcibly flushed out of the drain port 96. Injected water also serves to clean and protect the wetted area of the plunger piston 58. When there is no mud particulate in the flow out of the drain port 96, the seal 101 is in good working condition; however, when there is mud particulate in the flow out of the drain port 96, it is indicative that the seal 101 has begun to fail.

FIG. 10F shows a detailed view of a scraper seal 112 that may be added to the fluid-end side of a seal 101. Scraper seal 112 may be selected from various known geometries of scraper or wiper styles that serve to clean the piston 58 when drawn towards the power-end of the pump.

Additionally, as the plunger piston 58 may be a headless plunger, a sleeve 93 can be disposed about the piston 58. The sleeve 93 may vary in thickness, and be selected to vary the overall effective piston diameter based on desired pressure in the mud pump. The sleeve 93 is disposed about the plunger piston 58 at the fluid end of the plunger piston 58 in fluid communication with the mud. When a sleeve 93 is employed, the seal 101 and lubricating pad 94 are disposed about the sleeve 93 positioned about the piston 58. In each of the embodiments shown in FIGS. 10A-10E, a sleeve 93 can optionally be disposed about the piston to vary piston diameter based on desired pressure in the fluid end of the pump.

FIG. 11A and FIG. 11B show a piston 58 having a sleeve 93 to manipulate the overall effective diameter of the piston 58. As previously stated, changing the diameter of the piston 58 by the addition of sleeve 93 can allow variation of the pressure in the mud pump. For example, FIG. 11A shows a first sleeve 93A that when in place about the piston 58 produces an overall diameter of 5.5 inches (approximately 14 cm). By comparison, FIG. 11B shows a second sleeve embodiment 93B that when in place about the piston 58 produces an overall diameter of 8 inches (approximately 20 cm).

Finally, wear and stress on components of the mud pump can be reduced during start-up of the mud pump. FIG. 12A and FIG. 12B provide schematics of a discharge valve in a fluid end of a mud pump. Without a discharge valve in the fluid end of a mud pump, the pistons are compressing fluid during the start-up of the mud pump, which can create unnecessary overload of the components. In such embodiments, mud pump flow is adjusted by changing the speed of the electrical motor driving the mud pump. By comparison, as can be seen in FIG. 12A, a discharge valve 108 is added to the fluid flow in the fluid end of the mud pump between inlet 59 and outlet 61 (e.g., at the end of a pump liner 115). During start-up of the mud pump, the discharge valve 108 can be opened (for example, by rotation) to provide direct fluid communication between the inlet 59 and the outlet 61. Such free fluid communication reduces the load on components of the mud pump, from electrical motor 31 to piston 58. Additionally, each section of the mud pump can be substantially instantaneously shut down to adjust flow. FIG. 12A shows discharge valve 108 closed with fluid communication blocked indicated by arrow 109. FIG. 12B shows discharge valve 108 open with fluid communication freely flowing indicated at arrow 109.

While the aspects of the present disclosure may be susceptible to various modifications and alternative forms, specific embodiments have been shown by way of example in the drawings and have been described in detail herein. But it should be understood that the invention is not intended to be limited to the particular forms disclosed. Rather, the invention is to cover all modifications, equivalents, and alternatives falling within the spirit and scope of the invention as defined by the following appended claims.

The invention relates generally to offshore drilling systems which are employed for drilling subsea wells. More particularly, the invention relates to an offshore drilling system which maintains a dual pressure gradient, one pressure gradient above the well and another pressure gradient in the well, during a drilling operation.

Deep water drilling from a floating vessel typically involves the use of a large- diameter marine riser, e.g. a 21 -inch marine riser, to connect the floating vessel"s surface equipment to a blowout preventer stack on a subsea wellhead. The floating vessel may be moored or dynamically positioned at the drill site. However, dynamically-positioned drilling vessels are predominantly used in deep water drilling. The primary functions of the marine riser are to guide the drill string and other tools from the floating vessel to the subsea wellhead and to conduct drilling fluid and earth-cuttings from a subsea well to the floating vessel. The marine riser is made up of multiple riser joints, which are special casings with coupling devices that allow them to be interconnected to form a tubular passage for receiving drilling tools and conducting drilling fluid. The lower end of the riser is normally releasably latched to the blowout preventer stack, which usually includes a flexible joint that permits the riser to angularly deflect as the floating vessel moves laterally from directly over the well. The upper end of the riser includes a telescopic joint that compensates for the heave of the floating vessel. The telescopic joint is secured to a drilling rig on the floating vessel via cables that are reeved to sheaves on riser tensioners adjacent the rig"s moon pool. The riser tensioners are arranged to maintain an upward pull on the riser. This upward pull prevents the riser from buckling under its own weight, which can be quite substantial for a riser extending over several hundred feet. The riser tensioners are

adjustable to allow adequate support for the riser as water depth and the number of riser joints needed to reach the blowout preventer stack increases. In very deep water, the weight of the riser can become so great that the riser tensioners would be rendered ineffective. To ensure that the riser tensioners work effectively, buoyant devices are attached to some of the riser joints to make the riser weigh less when submerged in water. The buoyant devices are typically steel cylinders that are filled with air or plastic foam devices.

The maximum practical water depth for current drilling practices with a large diameter marine riser is approximately 7,000 feet. As the need to add to energy reserves increases, the frontiers of energy exploration are being pushed into ever deeper waters, thus making the development of drilling techniques for ever deeper waters increasingly more important. However, several aspects of current drilling practices with a conventional marine riser inherently limit deep water drilling to water depths less than approximately 7,000 feet. The first limiting factor is the severe weight and space penalties imposed on a floating vessel as water depth increases. In deep water drilling, the drilling fluid or mud volume in the riser constitutes a majority of the total mud circulation system and increases with increasing water depth. The capacity of the 21 -inch marine riser is approximately 400 barrels for every 1,000 feet. It has been estimated that the weight attributed to the marine riser and mud volume for a rig drilling at a water depth of 6,000 feet is 1,000 to 1,500 tons. As can be appreciated, the weight and space requirements for a drilling rig that can support the large volumes of fluids required for circulation and the number of riser joints required to reach the seafloor prohibit the use of the 21 -inch riser, or any other large-diameter riser, for drilling at extreme water depths using the existing offshore drilling fleet.

The second limiting factor relates to the loads applied to the wall of a large- diameter riser in very deep water. As water depth increases, so does the natural period of the riser in the axial direction. At a water depth of about 10,000 feet, the natural period of the riser is around 5 to 6 seconds. This natural period coincides with the period of the

water waves and can result in high levels of energy being imparted on the drilling vessel and the riser, especially when the bottom end of the riser is disconnected from the blowout preventer stack. The dynamic stresses due to the interaction between the heave of the drilling vessel and the riser can result in high compression waves that may exceed the capacity of the riser.

In water depths 6,000 feet and greater, the 21 -in riser is flexible enough that angular and lateral deflections over the entire length of the riser will occur due to the water currents acting on the riser. Therefore, in order to keep the riser deflections within acceptable limits during drilling operations, tight station keeping is required. Frequently, the water currents are severe enough that station keeping is not sufficient to permit drilling operations to continue. Occasionally, water currents are so severe that the riser must be disconnected from the blowout preventer stack to avoid damage or permanent deformation. To prevent frequent disconnection of the riser, an expensive fairing may have to be deployed or additional tension applied to the riser. From an operational standpoint, a fairing is not desirable because it is heavy and difficult to install and disconnect. On the other hand, additional riser tensioners may over-stress the riser and impose even greater loads on the drilling vessel.

A third limiting factor is the difficulty of retrieving the riser in the event of a storm. Based on the large forces that the riser and the drilling vessel are already subjected to, it is reasonable to conclude that neither the riser nor the drilling vessel would be capable of sustaining the loads imposed by a hurricane. In such a condition, if the drilling vessel is a dynamically positioned type, the drilling vessel will attempt to evade the storm. Storm evasion would be impossible with 10,000 feet of riser hanging from the drilling vessel. Thus, in such a situation, the riser would have to be pulled up entirely.

In addition, before disconnecting the riser from the blowout preventer stack, operations must take place to condition the well so that the well may be safely abandoned. This is required because the well depends on the hydrostatic pressure of the mud column extending from the top end of the riser to the bottom of the well to

overcome the pore pressures of the formation. When the mud column in the riser is removed, the hydrostatic pressure gradient is significantly reduced and may not be sufficient to prevent formation fluid influx into the well. Operations to contain well pressure may include setting a plug, such as a storm packer, in the well and closing the blind ram in the blowout preventer stack.

After the storm, the drilling vessel would return to the drill site and deploy the riser to reconnect and resume drilling. In locations like Gulf of Mexico where the average annual number of hurricanes is 2.8 and the maximum warning time of an approaching hurricane is 72 hours, it would be necessary to disconnect and retrieve the riser every time there is a threat of hurricane in the vicinity of the drilling location. This, of course, would translate to huge financial losses to the well operator.

A fourth limiting factor, relates to emergency disconnects such as when a dynamically positioned drilling vessel experiences a drive off. A drive off is a condition when a floating drilling vessel loses station keeping capability, loses power, is in imminent danger of colliding with another marine vessel or object, or experiences other conditions requiring rapid evacuation from the drilling location. As in the case of the storm disconnect, well operations are required to condition the well for abandoning. However, there is usually insufficient time in a drive off to perform all of the necessary safe abandonment procedures. Typically, there is only sufficient time to hang off the drill string from the pipe/hanging rams and close the shear/blind rams in the blowout preventer before disconnecting the riser from the blowout preventer stack.

The well hydrostatic pressure gradient derived from the riser height is trapped below the closed blind rams when the riser is disconnected. Thus, the only barrier to the influx of formation fluid into the well is the closed blind rams since the column of mud below the blind rams is insufficient to prevent influx of formation fluid into the well. Prudent drilling operations require two independent barriers to prevent loss of well control. When the riser is disconnected from the blowout preventer stack, large volumes of mud will be dumped onto the seafloor. This is undesirable from both an economic and environmental standpoint.

A fifth limiting factor relates to marginal well control and the need for numerous casing points. In any drilling operation, it is important to control the influx of formation fluid from subsurface formations into the well to prevent blowout. Well control procedures typically involve maintaining the hydrostatic pressure of the drilling fluid column above the "open hole" formation pore pressure but, at the same time, not above the formation fracture pressure. In drilling the initial section of the well, the hydrostatic pressure is maintained using seawater as the drilling fluid with the drilling returns discharged onto the seafloor. This is possible because the pore pressures of the formations near the seafloor are close to the seawater hydrostatic pressure at the seafloor. While drilling the initial section of the well with seawater, formations having pore pressures greater than the seawater hydrostatic pressure may be encountered. In such situations, formation fluids may flow freely into the well. This uncontrolled flow of formation fluids into the well may be so great as to cause washouts of the drilled hole and, possibly, destroy the drilling location. To prevent formation fluid flow into the well, the initial section of the well may be drilled with weighted drilling fluids. However, the current practice of discharging fluid to the seafloor while drilling the initial section of the well does not make this option very attractive. This is because the large volumes of drilling fluids dumped onto the seafloor are not recovered. Large volumes of unrecovered weighted drilling fluids are expensive and, possibly, environmentally undesirable.

After the initial section of the well is drilled to an acceptable depth, using either seawater or weighted drilling fluid, a conductor casing string with a wellhead is run and cemented in place. This is followed by running a blowout preventer stack and marine riser to the seafloor to permit drilling fluid circulation from the drilling vessel to the well and back to the drilling vessel in the usual manner.

In geological areas characterized by rapid sediment deposition and young sediments, fracture pressure is a critical factor in well control. This is because fracture pressure at any point in the well is related to the density of the sediments resting above that point combined with the hydrostatic pressure of the column of seawater above.

These sediments are significantly influenced by the overlying body of water and the circulating mud column need only be slightly denser than seawater to fracture the formation. Fortunately, because of the higher bulk density of the rock, the fracture pressure rapidly increases with the depth of penetration below the seafloor and will present a less serious problem after the first few thousand feet are drilled. However, abnormally high pore pressures which are routinely encountered u

8613371530291

8613371530291