cost per day to operate a mud pump factory

What does it take to maintain a successful business? If you said profit, you hit the critical component to any good business. However, if you said the right equipment and team, your thought process drills deeper. I bet the rest of you were shouting, “Customers is what it takes!”

Maintaining a successful business was a top discussion point at the recent Mountain States, Maryland-Delaware, and Virginia groundwater conferences I attended as a presenter. To get a well-rounded perspective on this important topic, I interviewed a driller within our community and a custom home-builder connected to our community.

First up, Charles “Buddy” Sebastian of Sebastian and Sons Well Drilling based in Michigan is a long-time industry friend and president of the Michigan Ground Water Association. Sebastian has presented talks on job costs, company sustainability and the future of drilling companies at the MGWA’s annual conference. He also just presented at the Montana Water Well Drillers Association Convention & Trade Show.

A. The first talk I did on knowing your cost at MGWA, I had a question from the audience that said: “You have your business figured out. What"s your exit plan?” I said, the day you start your business is the day you start planning to sell your business. What I mean is, to be able to sell your business you have to be able to set your market. You can either be the market setter or market followers. You have to be able to set the market that your business is solvent. To be solvent, you have to have enough money in your profit margin to maintain, repair and replace equipment. Then, beyond sustaining the business, you can’t just work for beer and pizza. So you have to have enough profit in there to pay the team and yourself.

A. Well, we have to set the going rate for drilling in our area to have enough profit dollars to complete the job, maintain the equipment, pay the team and invest in the future.

A. We are in some dangerous times for new equipment in our industry. Rig manufacturers are for sale for the second time in less than a decade, and the latest trend is to build smaller, less expensive rigs.

A. First of all, we have to stop pricing our product according to our competitor. We fix that by knowing our cost per hour and cost per day for equipment and project. That thinking that my competitor is drilling for $18, so I need to drill for $17 needs to go away. We need to know our costs on the first job and be profitable because it isn’t going to get any better if you don’t.

A. It is based on how many wells you do a year. I figure today’s drilling equipment’s life as 10 to 15 years, and yes, some older conventional rigs had a longer lifecycle. You know I did a cost analysis of some of my older table-drive rigs to replace belts, bearings, bushing and drivelines. What I saw was [that having] bushing and bearing that were relatively cheap to repair was no longer the case. Replacement parts were not built as good as the originals; importing cost had increased and, overall, these parts were becoming obsolete due to American manufacturers no longer making them. Conventional rigs are not as easy or cheap to repair as they were. You have to take into consideration downtime versus complete replacement.

A. OK, how about an $800,000 new rig that is going to be maintained to last 15 years. I use 2,080 working hours in a year, and I take into consideration 15 years of life. That comes out to $25 an hour to operate that rig.

That’s the per-hour cost to own that rig. That’s not interest, maintenance, repairs, tires, mud pumps or wearables. It’s just the cost to own the rig. Next, you have to take into account everything to operate and maintain the rig, including the labor to repair, update and replace. A good number to start with for a new $800,000.00 rig is about $75,000 a year to own and maintain it. The best advice I can give to a new rig owner is to save $25 an hour for every hour of rig operation to replace that rig.

A. The rig payment comes from profit. If you can’t pay the rig out of profit, you are in big trouble. We must make a business that is sustainable that can attract and hire good people and, on top of that, pay ourselves. We must know our costs.

Q. How does the industry value water at a cost that makes the drilling business sustainable? How do we change the stigma that a water well must cost X but even interior amenities such as cupboards can cost so much more?

A. First, we, as an industry, must start teaching the end-user the same statement. Water is a necessity for life. We, as an industry, have more invested in equipment overhead than any other construction trade. I have quickly over a million and a half dollars invested in providing water; often the homes we drill wells for do not have that in the building materials and builder labor. We need to sell that point to our customers that we are invested in them, and they need to invest in us to be sustainable to continue to provide water.

Next, I turned to Cameron Fox, owner of Fox Custom Builders in Kalamazoo, Michigan. Fox has built custom homes in West Michigan, all requiring private water wells. He helped me visualize how customers and homebuilders view new water wells.

A. Homeowners view their water wells as a non-negotiable necessity. Our customer usually addresses this part of the contract to the extent of “how will you make sure I get exceptional water pressure.”

A. Pricing is consistent throughout our area, so pricing is not outrageous. The drilling companies’ professionalism and expertise exclusively drive my priority when choosing an installer.

A. It is all about location. Location of the well may seem like a no brainer, but choosing a site, particularly on nonconforming lots or lake homes, can be somewhat problematic. Distance from property lines, septic systems and sewage ejection pumps can often become a balancing act. A drilling company willing to work with the footprint I have is invaluable.

A. Similar to any skilled trade, you can pay a premium for a professional company to complete premium work, or you can find an inexpensive alternative and deal with the consequential headaches. You get what you pay for.

A. I have had very positive experiences with the two drilling companies I use. Both are excellent, and overall I had similar experiences. The estimates and proposals aligned, and they both researched well logs on adjacent properties to present reasonable estimated well depths. One thing that makes me use one company over the other is when they go the extra mile to educate my customers on the process and me. I have a backup drilling company just because of schedules.

A. Every homeowner has a different pricing tolerance based on what is important to them. When building a vacation home, the money will be spent to upgrade materials requiring less maintenance. Homeowners with large families are more focused on added square footage than premium kitchen cabinets or heated floors. Ultimately, each homeowner is unique, and their money is allocated toward their “must-have” items.

A. With the significant increase in the cost of wood over the last 10 years paired with the massive jump in labor costs, framing the home is typically the most expensive component of new construction. Other added costs come from the special footing or extensive land improvements/excavation.

A. We build custom homes that meet each client’s specific wants and needs. Not only do we accomplish this but at the same time we build quality homes. Energy-efficient and structurally sound homes are the starting point for our homeowners. These are our core values and a starting point from where we build to create a functional and architecturally pleasing home that exceeds our homeowners’ expectations. Building a home is like entering into a serious relationship with someone you just met. You are going to spend hundreds of hours with them, answer multiple calls a day and then respond to their weekend emails. You have to get along, or you’ll both walk away from the process drained and upset. I have found the best way to get along is to require perfection from my employees and my subs. That’s it. I do not allow mediocrity; my customers know it, and it establishes a basis for trust.

A. The entry barrier has working capital to pay subcontractors and material suppliers between bank draw. I typically need 20-25% of the contract price in liquid assets to fund the project. Then it’s about managing my project and understanding the profit I need to sustain my business, pay my employees and, at the end of the day, I need to provide for my family.

We need customers and builders, and they 100% require the drilling industry to provide water. We have to establish our message of value to our customers. The problem cannot be solved with one company or region that cannot solve our image; it will take the entire community discussing how we make the change together. In the end, we need the same thing our builder requires, to be able to recruit and pay good men and women to progress our industry, buy the right technology to be successful, and provide the consumer with a quality product that they value.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Rig related costs Rig related costs are dependent on drilling efficiency, well depths, rig day rates, mud use and diesel fuel rates. Rig day rates and diesel costs are related to larger market conditions and overall drilling activity rather than well design. Rig related costs can range from $0.9 million to $1.3 million making up 12–19 per cent of a well’s total cost.

Casing costsCasing costs are driven by the casing markets, often related to steel prices, the dimensions of the well,and by the formations or pressures that affect the number of casing strings. Within a play, well depths are often the most variable characteristic for casing with ranges of up to 5,000 feet. Operators may also choose to run several casing strings to total depth or run a liner in lieu of the final casing string. Casing costs can range from $0.6 million to $1.2 million, making up 9–15 per cent of a well’s total cost.

Frack pumping costsFrack pumping costs can be highly variable, but are dependent on horsepower needed and number of frack stages. The amount of horsepower is determined by combining formation pressure, rock hardness or brittleness and the maximum injection rate. Pumping pressure, which includes a safety factor, must be higher than the formation pressure to fracture the rock. Higher pressure increases the cost. The number of stages, which often correlates with lateral length, is important since this fracturing process, with its associated horsepower and costs, must be repeated for each stage. The total costs for all stages can range from $1.0 million to $2.0 million, making up 14–41 per cent of a well’s total cost.

Completion fluid costs Completion fluid costs are driven by water amounts, chemicals used and frack fluid type, such as gel, cross-linked gel or slick water. The selection of fracking fluid type is mostly determined by play production type, with oil plays primarily using gel and natural gas plays primarily using slick water. Water sourcing costs are a function of regional conditions relating to surface access, aquifer resources and climate conditions. Water disposal will normally be done by re-injection, evaporation from disposal tanks, recycling or removal by truck or pipeline, each with an associated cost. Typically, about 20–30 per cent of the fluids flow back from the frack and require disposal. Operators typically include the first 30–60 days of flow back disposal in their capital costs. These costs can range from $0.3 million to $1.2 million making up 5–19 per cent of well’s total cost.

Proppant costsProppant costs are determined by market rates for proppant, the relative mix of natural, coated and artificial proppant and the total amount of proppant. Proppant transport from the sand mine or factory to the well site and staging make up a large portion of the total proppant costs. Operators use more proppant when selecting less costly proppant mixes, which are comprised of mostly natural sand as opposed to artificial proppants. A higher mix of artificial proppants has often been used for very deep wells experiencing high formation pressures. Overall, the amount of proppant used per well is increasing in every play. These costs can range from $0.8 million to $1.8 million making up 6–25 per cent of well’s total cost.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time d94a2288d76f819e65e1cc71545d07c7 63.210.148.230 02/24/2023 01:11 PM UTC

Maintaining /monitoring the mud pumps and mud pits during operations. Notifying the Driller immediately of any unexplained pit level increases/decreases Verify and record drilling fluid properties at ...

Perform daily inspections and maintenance on electrical equipment. Comply with the permit to work and isolation systems. Carry out periodic maintenance according to the guidelines Maintain, troubleshoot ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

Field Specialist - Directional Driller (DD)Have excellent Directional Driller experience?Do you enjoy working with cutting-edge energy equipment?Join our innovating Drilling Services Team!Our Drilling ...

Assist internal and external customers with troubleshooting of Rig Equipment (Top Drive, Catwalk, Wrench, Drawworks, VFDs, Generators, Mud Pumps, BOP) Expeditiously work to troubleshoot and resolve downtime ...

include but are not limited to safely and efficiently performing all tasks within the Rig Operations Areas of the Platform at the direction and under the supervision of the Crane Operator. Tasks may include ...

Our Technical Sales Representative (TSR) is responsible for building on a very high level of product line & operational knowledge and experience to proactively and strategically sell specific tools, technologies ...

Field Specialist - Directional Driller (DD)Have excellent Directional Driller experience?Do you enjoy working with cutting-edge energy equipment?Join our innovating Drilling Services Team!Our Drilling ...

include but are not limited to: Safely and efficiently performing all tasks on the rig floor and B.O.P. area under the direction and supervision of the Driller. Operating the tongs, slips, and spinners ...

Assist higher level technicians, as well as work independently with minimal supervision. Promote a safe and quality environment in which to work Perform preventative maintenance requirements and maintain ...

Please note that we are planning to come to the following countries for Recruitment Campaign in the month of May 2023 - Romania - Azerbaijan - Croatia Minimum requirement/ Basic Function Carries out the ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Driller, Derrickman and/or Motorman in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Crew Pusher and/or TRS Lead in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated by ...

are prominent in every aspect of drilling the well, manual handling of tubular and tools, making up or breaking out during making connections or tripping pipe. The position is responsible for the processes ...

are prominent in every aspect of drilling the well, manual handling of tubular and tools, making up or breaking out during making connections or tripping pipe. The position is responsible for the processes ...

Regular inspection of machinery, as well as the bilge, pump rooms, and tanks. Ensure the engine room is neatly kept and all equipment is properly stowed. Examination of equipment such as turbines, condensers, ...

The drilling industry has roots dating back to the Han Dynasty in China. Improvements in rig power and equipment design have allowed for many advances in the way crude oil and natural gas are extracted from the ground. Diesel/electric oil drilling rigs can now drill wells more than 4 miles in depth. Drilling fluid, also called drilling mud, is used to help transfer the dirt or drill cuttings from the action of the drilling bit back to the surface for disposal. Drill cuttings can vary in shape and size depending on the formation or design of the drill bit used in the process.

Watch the video below to see how the EDDY Pump outperforms traditional pumps when it comes to high solids and high viscosity materials commonly found on oil rigs.

Solids control equipment including shakers, hydro-cyclones, and centrifuges are utilized to clean the drill cuttings from the drilling fluid, which then allows it to be reused and recirculated. The circuit includes the mixing of the drilling fluid in the rig tanks.

The drilling fluid is prepared to control fluid loss to the formation by the addition of chemicals or mineral agents. Commercial barite or other weighting agents are added to control the hydrostatic pressure exuded on the bottom of the well which controls formation pressures preventing fluid or gas intrusion into the wellbore.

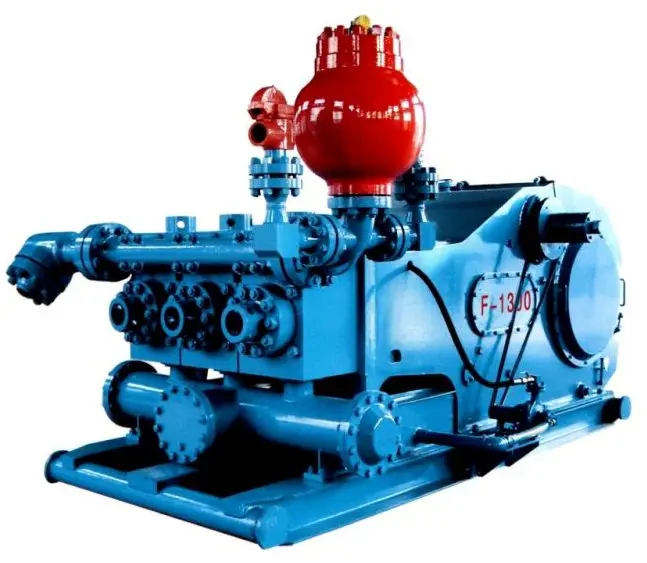

The fluid is charged into high-pressure mud pumps which pump the drilling mud down the drill string and out through the bit nozzles cleaning the hole and lubricating the drill bit so the bit can cut efficiently through the formation. The bit is cooled by the fluid and moves up the space between the pipe and the hole which is called the annulus. The fluid imparts a thin, tough layer on the inside of the hole to protect against fluid loss which can cause differential sticking.

The fluid rises through the blowout preventers and down the flowline to the shale shakers. Shale shakers are equipped with fine screens that separate drill cutting particles as fine as 50-74 microns. Table salt is around 100 microns, so these are fine cuttings that are deposited into the half-round or cuttings catch tank. The drilling fluid is further cleaned with the hydro-cyclones and centrifuges and is pumped back to the mixing area of the mud tanks where the process repeats.

The drill cuttings contain a layer of drilling fluid on the surface of the cuttings. As the size of the drill cuttings gets smaller the surface area expands exponentially which can cause rheological property problems with the fluid. The fluid will dehydrate and may become too thick or viscous to pump so solids control and dilution are important to the entire drilling process.

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator that must move the contents of the waste bin or roll-off box. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

Using the excavator method explained above, the unloading of 50 barrels of drill cuttings from the half round can take as long as two hours. This task is mostly performed by the solids control technicians. The prime duty for the solids control technicians is to maintain the solids control equipment in good working order. This involves maintenance for the equipment, screen monitoring and changing, centrifuge adjustments, and retort testing to prepare a daily operational summary of the solids control program.

Operating the excavator takes the technician away from these tasks and can lead to poorly performing equipment. Additionally, the excavator has the potential for abuse as some solids control technicians use the climate-controlled cab as a break area or refuge from the elements. Many times, these guys are found asleep on the job.

One solids control company reported the idle time for the excavator can be more than 8 hours for a 24-hour period with 8 hours of operation and 8 hours of shut down time. Fuel and time lost can cause an economic drag on rig operations. And lastly, there have been several accidents on each rig causing a potential for injury, loss of production, and lost revenue as the excavator must be repaired.

Offshore drilling rigs follow a similar process in which the mud is loaded into empty drums and held on the oil platform. When a certain number of filled drums is met, the drums are then loaded onto barges or vessels which take the drilling mud to the shore to unload and dispose of.

Oil field drilling operations produce a tremendous volume of drill cuttings that need both removal and management. In most cases, the site managers also need to separate the cuttings from the drilling fluids so they can reuse the fluids. Storing the cuttings provides a free source of stable fill material for finished wells, while other companies choose to send them off to specialty landfills. Regardless of the final destination or use for the cuttings, drilling and dredging operations must have the right high solids slurry pumps to move them for transport, storage, or on-site processing. Exploring the differences in the various drilling fluids, cutting complications, and processing options will reveal why the EDDY Pump is the best fit for the job.

The Eddy Pump is designed to move slurry with solid content as high as 70-80 % depending on the material. This is an ideal application for pumping drill cuttings. Drill cuttings from the primary shakers are typically 50% solids and 50% liquids. The Eddy Pump moves these fluids efficiently and because of the large volute chamber and the design of the geometric rotor, there is very little wear on the pump, ensuring long life and greatly reduced maintenance cost for the lifetime of the pump.

plumbed to sweep the bottom of the collection tank and the pump is recessed into a sump allowing for a relatively clean tank when the solids are removed. The Eddy Pump is sized to load a roll-off box in 10-12 minutes. The benefit is cuttings handling is quicker, easier, safer, and allows for pre-planning loading where the labor of the solids control technician is not monopolized by loading cuttings. Here, in the below image, we’re loading 4 waste roll-off bins which will allow the safe removal of cuttings without fear of the half-round catch tank running over.

Mud cleaning systems such as mud shaker pumps and bentonite slurry pumps move the material over screens and through dryers and centrifuges to retrieve even the finest bits of stone and silt. However, the pump operators must still get the raw slurry to the drill cuttings treatment area with a power main pump. Slurry pumps designed around the power of an Eddy current offer the best performance for transferring cuttings throughout a treatment system.

Options vary depending on whether the company plans to handle drill cuttings treatment on-site or transport the materials to a remote landfill or processing facility. If the plan is to deposit the cuttings in a landfill or a long-term storage container, it’s best to invest in a pump capable of depositing the material directly into transport vehicles. Most dredging operations rely on multiple expensive vacuum trucks, secondary pumps, and extra pieces of equipment.

Using an EDDY Pump will allow a project to eliminate the need for excavators/operators to load drill cuttings, substantially lowering both labor and heavy equipment costs. The EDDY Pump also allows a company to eliminate vacuum trucks once used for cleaning the mud system for displacing fluids. Since the pump transfers muds of all types at constant pressure and velocity throughout a system of practically any size, there’s little need for extra equipment for manual transfer or clean up on the dredge site.

The EDDY Pump can fill up a truck in only 10 minutes (compared to an hour) by using a mechanical means such as an excavator. For this reason, most companies can afford one piece of equipment that can replace half a dozen other units.

This application for the Eddy Pump has the potential to revolutionize the drilling industry. Moving the excavator out of the “back yard” (the area behind the rig from the living quarters) will make cuttings handling a breeze. Trucking can be easier scheduled during daylight hours saving on overtime and incidences of fatigued driving. Rig-site forklifts can move the roll-off boxes out of the staging area and into the pump loading area. The operator can save money on excavators rental, damages, and keep the technician operating the solids control equipment.

The EDDY Pump is ideal for drilling mud pump applications and can be connected directly onto the drilling rigs to pump the drilling mud at distances over a mile for disposal. This eliminates the need for costly vacuum trucks and also the manpower needed to mechanically move the drilling mud. The reasons why the EDDY Pump is capable of moving the drilling mud is due to the hydrodynamic principle that the pump creates, which is similar to the EDDY current of a tornado. This tornado motion allows for the higher viscosity and specific gravity pumping ability. This along with the large tolerance between the volute and the rotor allows for large objects like rock cuttings to pass through the pump without obstruction. The large tolerance of the EDDY Pump also enables the pump to last many times longer than centrifugal pumps without the need for extended downtime or replacement parts. The EDDY Pump is the lowest total life cycle pump on the market.

Recycling and reusing drilling fluids is becoming increasingly common on jobs with mid-size horizontal directional drill (HDD) projects where previously that practice was uncommon.

Recycling isn’t for every job – it would not be practical on jobs with small machines making short bores – but contractors who are recycling on larger projects with 30,000 to 60,000 pound pullback equipment are reporting surprising cost savings resulting in overall lower project costs.

Savings come from using less water and drilling additives, less time in mixing fluids, reduced clean-up requirements and significant reduction in costs of hauling water to make the fluid and dispose of it after a job is complete.

Mud recycling is standard procedure on HDD projects with big drill rigs – to not recycle fluids on a long, deep bore with a big machine using a mud motor would make the logistics of handling fluids unmanageable and cost prohibitive, and the physical size of recyclers used on these projects would not permit their use on work sites of the mid-size drill rigs that do utility work.

American Augers, Richard Levings, director of product management:Yes, the cost of disposing drilling fluid has become too expensive and often is very difficult to access an approved disposal location. Higher levels of cleaning equipment and new technology will be employed to decrease disposal costs and reduce fluid system wear. Just having a fluid cleaning system is not enough, making it a priority and a focus is necessary to be successful.

Ditch Witch, Seth Matthesen, senior HDD product manager: Yes, in certain areas and certain types of jobs. HDD projects in adverse, rocky soil conditions use much more mud per foot, making it necessary for operators to either spend more time disposing of drill fluid or obtain fluid recyclers that can handle drills with more pullback range. This trend is more likely in urban areas where operators must drive much further to a dump site. Some cities are also implementing tighter restrictions for dumping liquids, making disposal even more costly.

Elgin Separation Solutions, Raymond Pietramale, marketing manager: Packaged mud recycling systems feature an all-in-one unit design, and the use of mud recycling has proven beneficial when used with mid to large size directional drilling rigs. The ability to continuously recycle drilling fluid and decrease the solids slurry waste saves costs associated with new fluid use and less waste for contractors to pay to haul off. The cost savings and environmental friendly impact is a significant trend being seen across the industry.

Mud Technology International (MTI), John Miller, chief executive officer:In this age of environmental consciousness for global sustainability, it is imperative that we look at every HDD job to determine how we can minimize the impact of our operations. Recycling, even with the smaller rigs, reduces the amount of water used, Bentonite needed and fluid haul off; saving time, money and making a contribution to the protection of our planet.

manager:Due to the difficulty and cost of disposing of drilling fluids in many locations across North America and Europe, we expect to see more contractors using reclaimers with smaller horizontal directional drills. The decision really depends on overall job-site mud volume, soil type and the kind of mud mixture. For recycling with smaller rigs, the decision whether to use a reclaimer will be driven by return on investment. It could be more cost-effective to just vacuum excavate the returns and pay disposal fees than purchasing a reclaimer and hauling it to job sites.

American Augers: Depending on the fluid system, a bore can be started with a given amount of fluid, and run the entire bore with that volume of fluid. The soil will consume some fluid so fresh water must be added as needed, but it will not be necessary to continuously run vacuum units to clean up and haul away fluid to be disposed.

Ditch Witch:Recycling fluid reduces water volume and removes the need for multiple trucks to haul and process water for the job site providing significant fuel cost savings. In addition to cost savings, HDD operators also see improvements in rig uptime by removing the need to mix drilling mud during the time the rig remains inactive.

Drilling-fluid recyclers also benefit the environment. With less fluid to clean up, transportation of fluid is reduced lessoning the carbon footprint by decreasing the overall emissions.

Elgin: Decreased costs on drilling fluid use; decreased costs on waste disposal; environmentally friendly; and increased profits for drilling contractors.

Thunder Products:Cost savings.A drill stays productive instead of having down time waiting on a vac.Far less drilling fluid is used.It is the most effective way to increase margins.

Vermeer:The main factor is reduced mud costs – not only water and additives but travel time to dispose of the used drilling mud, travel time to get additional water, the labor that goes into mixing mud and reducing idle time of the drill. If a reclaimer is used, it helps maintain the operation and allows contractors to use mud volumes needed for the job. There are many other factors playing into the decision to use a reclaimer,including the type and size of a project.

American Augers:Savings are very project and location dependent. The variable costs range from state to state and often from city to city. Disposal costs alone can vary immensely. An estimate would be on average of 50 percent or more savings when you consider disposal cost, equipment cost, consumables cost, labor, wear on equipment, mileage and work stoppage due to traffic delays.

Ditch Witch:An HDD rig with 30,000 pounds of pullback can pump approximately 20,000 gallons of fluid during the course of a project (this can vary depending on job-site conditions). Using the Ditch Witch MR90 specifically, the same volume could be pumped using only 1,500 gallons of drilling mud, saving 18,500 gal of water and as much as $1,500 spent for additives.

Elgin:Our experience is that when faced with the combined cost of disposal and new raw material costs, the installation of a recycling system can reduce total expenses by as much as 50 percent, depending on the sophistication of the recycling system deployed and the level of fluid reuse deployed.With that said, median savings will range from 15 to 30 percent. Drillers that manage a minimum of six jobs with a 40,000-pound rig will experience a tangible return on investment.

MTI: Using 50 to 70 gallons per minute as a base and a 1,000-gallon mixing system, not recycling requires mixing a new tank of mud every 14 to 20 minutes. Recycling provides the ability to reuse the mud, and only add water and chemicals as needed. This can result in great cost savings.

Thunder:Anywhere from $1,000 to $2,000 per day. There are savings on the dump fees of the vac or several vacs), savings on the driver and fuel hauling the vac, and savings on the amount of drilling fluids used.The productivity of the drill goes up.

Vermeer:Savings vary by job depending on the distance and difficulty of getting water, labor costs to get water to the job site and cost of hauling mud. Other variables are the type of soil, additive costs and whether mud can be processed at required rates. Disposing of high-cost additives instead of reusing fluids is a big factor in the overall cost of a project.

Can you provide brief examples of one or two recent projects with this size equipment that documented the cost savings and other benefits of recycling?

American Augers: On a recent 8-inch pipeline project, the right-of-way was very tight and the number of equipment on site needed to be reduced. The fluid cleaner being compact and productive, allowed the contractor to run continuously without having units in and out hauling fluid away.

Another pipeline project installing 16-inch steel pipe was in an environmentally sensitive area. Both mud motor and reaming passes required approximately 200 gpm flow rates. Once again, it was not feasible to operate any other way than recycling the drilling fluid.

Ditch Witch:Sonoma Underground Services switched to our recycler to reduce its mud-related costs. By recycling drilling fluid, the company reduced the amount of water and mud needed on the job site and eliminated daily vacuuming. On the most water-consuming day, the operators began with 2,000 gallons of mud and ended with 1,750, gaining three hours of drilling time by eliminating disposal runs and saving close to $2,000 for the day.

On another project, MasTec used recycling on a FTTH project. The company saved up to $100,000 per month throughout the length of the project from increased production and savings of drill fluid and disposal.

Elgin: Due to confidentiality we provide our customers, it would not be appropriate to comment on the specific savings achieved.However, Elgin can safely indicate that it has sold more than two dozen mud systems in the last two years to customers that were utilizing 40,000-pound pullback drills. Each of these customers identified a need to reduce operating expenses and lower their disposal costs.

Thunder:In Ohio, a contractor was not using a mud recycler and he was running three vacs to keep his 36,000-pound rig drilling. At some point during the day his rig would be down waiting on water or a vac, and every day his drill crew was idle 30 percent of the time.He introduced our recycler and began saving $2,000 per day. The rig went from 70 percent utilization to 95 percent utilization. Plus, mud pumps last longer.

American Augers:Yes, current margins in the industry will force contractors to employ fluid recycling. Fluid containment and reducing risk of frac outs is paramount. Increasing annular flow to increase velocities to better clean the hole is necessary, and that is made possible by utilizing a fluid cleaning system.

Ditch Witch: Yes. As city restrictions on waste disposal get tighter, contractors will be forced to find other solutions, such as recycling, for HDD job sites.

Elgin: In today’s urban areas, environmental concerns regarding ground contamination of mud pits plays a major factor. Communities and businesses are taking on an increased role in maintaining the environment around them. The use of a mud reclaimer promotes a leave-no-trace ideal when drilling operations are complete.

Thunder: In time it will become the norm. Mud recyclers pay for themselves rather quickly and it goes a long way on increasing margins. In the HDD market now we are seeing it work its way down into the smaller rigs. Five years from now they will become the norm, not just to increase contractor margins but environmental regulations will also drive it.

Vermeer:We expect to see an increased demand for reclaimers. It still is unclear if contractors will use individual reclaimers to support each drill or, if they will purchase a larger reclaimer and position it in a centrally located area to support multiple job sites. We’ve seen a few customers testing this business model.

Ditch Witch:This already is gradually happening. It will be a natural progression for companies to develop a product line to fit all drilling units in the marketplace. The market always is adapting to meet customer demands. We take customer feedback seriously and look for ways to improve their production times, ROI and save costs long term.

Elgin:Over the past several years, there have been new companies enter the reclaimers market. With the projected increase in HDD drilling activities, we expect to see more companies enter the market. In addition, there are companies which manufacture similar equipment for the oil and gas industry entering the HDD arena due to the current drop in that market.

The HMI HM-1 hydraulic mudjacking pump was the first concrete raising product engineered and manufactured by HMI, just over 40 years ago. It’s reliability and superior engineering maintains its place in the market, but has also acted as the springboard for other, more advanced models / options which offer various options of engine horsepower, hopper size, pumping pressure, and so much more.

Our largest, self-propelled, multi-functional pump. This rugged and durable pump is the top-of-the-line mudjacking unit. With the highest available pumping pressure, largest material hopper, most horsepower and versatility.

Our most popular model, the self-propelled, hydraulic mudjacking pump drives circles around the competition. Affordable and durable, the Power Pump is a great way to start-up or add to a concrete raising business.

Whether you live in a rural area or simply prefer getting your water from a private source, installing a well on your property has numerous benefits. You won’t have to pay a monthly water bill, and you’ll have some control over your water’s mineral and chemical contents. However, drilling deep enough to access clean water can be expensive, and you’ll need to store and purify the water once it gets to the surface.

On average, drilling a water well costs$3,500–$15,000, depending on several geological and technological factors. You may be able to dig a shallow well yourself, but it’s best to hire a professional contractor for a well that will provide water for an entire home. This guide outlines the well installation process and its costs.

Though $3,500 to $15,000 is a wide range, it’s hard to narrow it down without knowing the specifics of your property. The cost of your project depends on the following factors.

The deeper you need to dig, drill, or drive, the longer the job will take and the more labor it will require. Most residential wells need to be at least 50 feet deep and have an average depth of 300 feet, but how far you need to drill to hit water depends on geographic factors. Accessing state and local geological surveys and learning about existing wells in your area will give you a better idea of the depth you’ll need. The table below includes price ranges for various depths.

Shallow, residential water wells are the least expensive to dig or drill. Sand point wells, which are shallow and can be driven by hand or machine, are similarly inexpensive but don’t usually provide a home’s entire water needs. Geothermal wells are relatively inexpensive on their own, but installing one costs tens of thousands of dollars.

Artesian wells that drill into an aquifer are more costly to drill but less expensive to run. Irrigation wells are the most expensive because they handle the highest volume of water, though residential irrigation is much less pricey than commercial irrigation.

Digging is the least expensive way to create a well, but it’s limited to about 100 feet in depth. Digging can also be thwarted by highly compacted or rocky soil. You can create a shallow well of up to 50 feet by driving a small-diameter pipe into the ground and removing the soil from inside. However, most residential-scale well projects require a drill to excavate.

Modern well systems consist of much more than a hole in the ground and a bucket on a rope. Here are some mechanical components that go into a working water well.

Well-casing pipe supports and protects the well’s walls, so it needs to be sturdy. This pipe is typically made from polyvinyl chloride (PVC), the most affordable option ($6–$10 per linear foot). Galvanized or stainless steel casing is also available for a premium ($30–$130 per foot). Steel may be necessary for earthquake-prone areas, as it’s much less susceptible to cracking and breaking. Casing pipe costs $630–$2,400 depending on its length.

Most wells need electrical wiring to operate the pump and pressure switch. These components aren’t expensive ($50–$150), but a licensed electrician needs to install them, costing $150–$500.

Some people assume that well water is cleaner than municipal water, but municipal water goes through a strict treatment process that water from private wells doesn’t. If you’re using a well for drinking water or other residential applications, you’ll need a purification system to rid the water of contaminants before you can use it. Whole-home water treatment systems cost $500–$3,000, plus another $200–$400 for installation.

Once the water is brought to the surface and purified, it needs to be stored and pressurized so you can use it in your home. A 2-gallon water tank can cost as little as $100, but if you’re going to use well water for most of your needs, you’ll probably need a large pressure tank that costs between $1,400 and $2,400.

One of the most critical parts of the well system is thewater pump, which brings groundwater to the surface. A hand pump for a shallow well can cost as little as $150–$500, but most electronic pumps cost between $300 and $2,000, depending on how powerful they are. A shallow well can sometimes use an aboveground surface pump, but a deep well usually requires a powerful, more expensive submersible pump that sits below the water line and pushes the water up. Some artesian wells can get away without using a pump system since the groundwater is already under pressure and may be pushed to the surface naturally.

Your location determines your climate, water table depth, and type and condition of the bedrock. It will also affect labor costs. For example, Florida is a relatively inexpensive place to dig a well because it has a high water table and an average cost of living. The price is higher in desert states like California, Texas, and Arizona.

You’ll need to check with your state and local government about permits for any project that involves digging in the ground. Permits can cost anywhere from $5 to $500 depending on where you live, but a well drilling company can help you determine which ones you need.

The farther a well is located from your house, the more expensive materials and labor will be. You’ll require longer pipes and electric lines, usually at an additional cost of $50–$150 per linear foot.

Drilling an existing well deeper is less expensive than installing an entirely new well. Redrill fees are usually $300–$600, and a professional can typically complete the job in a day.

Dry and rocky soil conditions, as well as dense bedrock or heavy clay, can make well drilling more difficult and thus more expensive. You may require heavy or specialized machinery, which can add up to 150% of the base price to your total.

Before drinking water from your well, you’ll want to test its quality to make sure it’s safe. Do-it-yourself (DIY) water testing kitsare available for $50–$150, but if this is going to be your home’s primary water supply, you should hire a pro. This can cost between $100 and $500, but it’s well worth checking for the presence of viruses, bacteria, fungi, heavy metals, radon, pesticides, and other contaminants.

If you’re installing a well to live off the grid, you’ll also need a way of dealing with wastewater that doesn’t involve hooking up to the municipal water system. Many professional well drillers can install a well and septic system at the same time, which will save you money on labor. Aseptic tank installationcosts $2,000–$7,000 on its own or $5,000–$22,000 when combined with a well system.

One benefit of installing your own well is that you’ll no longer need to pay municipal water bills. You’ll only need to pay for the electricity to operate the pump (about $3–$4 per month), plus maintenance costs of $100–$250 per year. Compared to a monthly utility bill of $20–$40, you can save up to $500 a year.

It’s possible to install a well yourself, but it’s more complicated than digging or drilling a hole in the ground. Here’s what you can expect from the process, whether you do it yourself or hire a professional.

Well installation professionals have the tools and experience to drill plus install the casing, pump, well cap, and other hardware. They also know how to adjust the process if they encounter anything unexpected under the soil and can help you apply for permits. You’ll pay at least $1,500 in labor costs on top of the well equipment and may pay $10,000 or more for deep wells in poor soil conditions.

Digging or driving a shallow well in an area with a high water table is within the capability of dedicated DIYers. However, you must ensure you go deep enough to get to truly clean water beneath the contaminated runoff in the upper layers of soil. These shallow, driven wells also provide a limited water supply. You can rent a drill rig for $600–$800 per day for larger, deeper wells, but this will only give you the borehole; you’ll also have to install all the hardware yourself.

Wells require maintenance and occasionally require repair. Here are signs that you may need a professional well company to do an assessment. You may only have to pay a service fee if yourhome warranty covers well pumpsor well systems.

Drilled or dug wells can last as long as the walls hold up, but the equipment that runs them usually needs to be replaced every 20–30 years. The pump may fail, or the casing pipe may develop leaks. Replacements can cost up to $10,000 in materials and labor. You can extend your equipment’s lifespan by performing regular checks and maintenance or by hiring a well company to do these for you.

It’s also possible for a well to run dry. This isn’t likely or always permanent since aquifers and other sources may need time to fill back up. A well may fill with sediment over time, which will need to be pumped and cleaned out. In rare cases, you may need to dig deeper or find a different fracture to regain water flow.

It’s widely claimed that having a functional well will raise your property value, but there’s no data on how much of a return on investment (ROI) you can expect. The consensus is that a well that yields drinking water will add more value than an irrigation well, but a nonfunctional or contaminated well will be a liability. Wells are generally more valuable in rural areas or where people want to live off the grid.

Research your yard’s soil and the depth you’ll need to drill before purchasing a DIY well drilling kit. Just because the kit can go 100 feet into the ground doesn’t mean you’ll hit clean water.

It’s important to acknowledge that many DIY well drilling kits are sold within the “doomsday prepper” market. These kits are unlikely to be sufficient if you intend to use your well to fulfill most or all of your residential water needs. You’re better off at least consulting with local professionals who will know about your area’s geological features and water levels before starting the project. These professionals can help you make informed decisions about well installation.

A properly installed well can save you money on your utility bills and provide a private, unmetered water source. Make sure to budget for the drilling of the actual borehole and the equipment needed to pump and store the water, as well as water testing and purification if you intend to drink it. Your system should last for many years once it’s set up.

It can be worth it to install a well, depending on your needs and budget. Drilling a private well is a large investment, but if you live in a rural area or an area with poor water quality, it could increase your property value. Consult with local professionals before beginning to drill or dig.

The average well installation cost is $3,500–$15,000, including drilling and the casing, pump, and storage tank. Price can also depend on the depth of the borehole, ranging between $25 and $65 per foot.

The cost to hook a well up to a home’s plumbing system depends on the machinery used to pump and carry the water. Piping and electrical lines cost $50–$150 per foot, a purification system costs $300–$5,000, and a pressurized storage tank costs $1,400–$2,400.

The time it takes to install a well depends on its depth and the conditions of the soil and bedrock, but drilling can usually be completed in a day or two. Installing the pump system takes another day. After that, it depends on how long and extensive the pipes and electrical system need to be. The whole process should take about a week.

Pumps tend to be one of the biggest energy consumers in industrial operations. Pump motors, specifically, require a lot of energy. For instance, a 2500 HP triplex pump used for frac jobs can consume almost 2000 kW of power, meaning a full day of fracking can cost several thousand dollars in energy costs alone!

So, naturally, operators should want to maximize energy efficiency to get the most for their money. Even a 1% improvement in efficiency can decrease annual pumping costs by tens of thousands of dollars. The payoff is worth the effort. And if you want to remotely control your pumps, you want to keep efficiency in mind.

In this post, we’ll point you in the right direction and discuss all things related to pump efficiency. We’ll conclude with several tips for how you can maintain pumping efficiency and keep your energy costs down as much as possible.

In simple terms, pump efficiency refers to the ratio of power out to power in. It’s the mechanical power input at the pump shaft, measured in horsepower (HP), compared to the hydraulic power of the liquid output, also measured in HP. For instance, if a pump requires 1000 HP to operate and produces 800 HP of hydraulic power, it would have an efficiency of 80%.

Remember: pumps have to be driven by something, i.e., an electric or diesel motor. True pump system efficiency needs to factor in the efficiency of both the motor AND the pump.

Consequently, we need to think about how electrical power (when using electric motors) or heat power (when using combustion engines) converts into liquid power to really understand pump efficiency.

Good pump efficiency depends, of course, on pump type and size. High-quality pumps that are well-maintained can achieve efficiencies of 90% or higher, while smaller pumps tend to be less efficient. In general, if you take good care of your pumps, you should be able to achieve 70-90% pump efficiency.

Motor efficiency is also an important factor here. Motor efficiency depends on the fuel type, whether electricity or hydrocarbon, which in turn depends on availability and cost.

AC motors can achieve 90%+ efficiency when converting electrical to mechanical energy. Combustion engines are much less efficient, with typical efficiency ratings coming in at ~20% for gasoline and ~40% for diesel. Your choice of engine or motor type will depend on the availability and cost of fuel or electricity in your area.

Electric motors are more efficient than combustion engines, but site location and the cost of fuel can make the choice of combustion engines more practical.

Now that we have a better understanding of the pump efficiency metric, let’s talk about how to calculate it. The mechanical power of the pump, or the input power, is a property of the pump itself and will be documented during the pump setup. The output power, or hydraulic power, is calculated as the liquid flow rate multiplied by the "total head" of the system.

Remember: we’re trying to find the ratio of power in to power out. Since rations require equal units on both sides, we"ll have to do some conversions to get our hydraulic power units in HP. You"ll see how this is done in the example below.

IMPORTANT: to calculate true head, you also need to factor in the work the pump does to move fluid from the source. For example, if the source water is below the pump, you need to account for the extra work the pump puts in to draw source water upwards.

*Note - this calculation assumes the pump inlet is not pressurized and that friction losses are minimal. If the pump experiences a non-zero suction pressure, or if there is significant friction caused by the distance or material of the pipe, these should be factored in as well.

Every foot of water creates an additional 0.434 PSI of pressure, so we"ll find the elevation head by converting the change in elevation in feet to the suction pressure created by the water.

You"ll notice that the elevation head is minimal compared to the discharge pressure, and has minimal effect on the efficiency of the pump. As the elevation change increases or the discharge pressure decreases, however, elevation change will have a greater impact on total head.

Obviously, that’s a fair amount of math to get at the pump efficiency, considering all of the units conversions that need to be done. To avoid doing these calculations manually, feel free to use our simple pump efficiency calculator.

Our calculations use static variables (pump-rated horsepower and water source elevation) and dynamic variables (discharge flow and pressure). To determine pump efficiency, we need to measure the static variables only once, unless they change.

If you want to measure the true efficiency of your pump, taking energy consumption into account, you could add an electrical meter. Your meter should consist of a current transducer and voltage monitor (if using DC) for electrical motors or a fuel gauge for combustion. This would give you a true understanding of how pump efficiency affects energy consumption, and ultimately your bank account.

Up until this point, we’ve covered the ins and outs of how to determine pump efficiency. We’re now ready for the exciting stuff - how to improve pump efficiency!

One of the easiest ways to improve pump efficiency is to actually monitor pumps for signs of efficiency loss! If you monitor flow rate and discharge (output power) along with motor current or fuel consumption, you’ll notice efficiency losses as soon as they occur. Simply having pump efficiency information on hand empowers you to take action.

Another way to increase efficiency is to keep pumps well-maintained. Efficiency losses mostly come from mechanical defects in pumps, e.g., friction, leakages, and component failures. You can mitigate these issues through regular maintenance that keeps parts in working order and reveals impending failures. Of course, if you are continuously monitoring your pumps for efficiency drops, you’ll know exactly when maintenance is due.

You can also improve pump efficiency by keeping pumps lubricated at all times. Lubrication is the enemy of friction, which is the enemy of efficiency (“the enemy of my enemy is my friend…”).

The best way to ensure lubrication is to monitor lube tanks or sumps and make sure you always have lubrication on hand. You can also monitor lubricant consumption for significant changes. If lubricant usage goes up, it could signal that friction has increased in the system.

A fourth way to enhance pump efficiency is to ensure your pumps and piping are sized properly for your infrastructure. Although we’re bringing this up last, it’s really the first step in any pumping operation. If your pumps and piping don’t match, no amount of lubricant or maintenance will help.

Pipes have physical limits to how much fluid they can move at a particular pressure. If pipes aren’t sized properly, you’ll lose efficiency because your motor will have to work harder. It’s like air conditioning - if your ductwork isn’t sized appropriately for your home, you’ll end up paying more on your energy bill.

In this post, we’ve given you the full rundown when it comes to calculating and improving pump efficiency. You can now calculate, measure, and improve pump efficiency, potentially saving your business thousands of dollars annually on energy costs.

For those just getting started with pump optimization, we offer purpose-built, prepackaged solutions that will have you monitoring pump efficiency in minutes, even in hazardous environments.

The temporary shutting in of wells is the one thing that oil companies are trying to avoid at all costs. That’s because restarting production is expensive and wells are not guaranteed to return to their flow rate. The doubts are so great that some experts wonder whether the current round of shut downs, far from preserving the resource, won’t accelerate oil depletion instead. Some Russian engineers are even considering burning excess oil, rather than downsizing production.

The COVID-19 crisis resulted in a quick and dramatic drop in demand for oil, estimated to be in the 25 to 30 per cent range in April. Much of this decline is expected to be reversed by the end of the year, but faced with a massive drop in oil prices and a lack of storage tanks, oil companies face a difficult dilemma: should they ride out this unprofitable streak or should they decrease production to cut their losses?

To the lay person, the option to cut production seems obvious. But an oil well is not a tap with a flow that can be adjusted as needed. Either it operates at full capacity or not at all. Valves are installed, but they’re only used during brief maintenance periods or emergency stops. Oil companies know that the decision to shut down for an extended period has three serious consequences:

An oil field is a complex structure, where different grades of oil have settled over time in a porous type of rock such as sandstone. Drilling and pumping releases this mixture of oil and gas. Any cessation of the extraction process may result in the clogging of this porous rock with sediment or paraffin, which means that production may permanently be reduced by half, or even stop completely, when pumping resumes. This loss of productivity does not always occur and it is sometimes possible to repair part of the damage by injecting chemicals into the well. But it’s easy to understand why oil companies would seek to avoid damage to their property and costly remediation work.

In addition to the geological constraints, the shut down process is risky in and of itself. To close a well, a special drilling rig is used to inject a thick mud at the well head to block the flow of oil and gas. This blocks the pores of the rock to a lesser degree, alters the pressure inside the well and inevitably complicates any attempt to resume production. The well itself is also plugged by pouring cement into it.

To restart production, it is necessary to bring a new rig, drill the cement plug, and pump the sludge blocking the well head. The hope is that oil will sta

8613371530291

8613371530291