cummins mud pump engine free sample

It might be easier to make plug-and-play horsepower with today’s electronically controlled, common-rail diesels, but the dinosaurs in the world of compression ignition aren’t dead yet. Not even close. Head south or southwest in America and you’ll quickly find prime, rust-free examples of some of the most popular diesel trucks ever produced, the ’94-’02 Cummins-powered Dodge Rams. In particular, there are still a ton of ’98.5-’02 trucks—the version with the VP44-fueled, 24-valve head 5.9L—out and about on the roadways. In light of all the emissions system failures that plague today’s late-model diesels, many continue to hold on to these aged (but not forgotten) second generation Rams.

However, the 24-valve Cummins is notorious for its lack of high-horsepower capability and the reliability of its injection pump—the Bosch VP44 being at the center of both of those problems. The ultimate fix for a dead VP44 or a craving for serious horsepower has always been to turn to the proven P7100 (i.e. P-pump) that came standard on the 12-valve 5.9L Cummins from ’94-’98. Not only does a P-pump 24-valve conversion simplify things by killing off the majority of the truck’s electronics, but it also brings much improved durability into the picture. Be it for competition purposes or a goal of seeing your second-gen hit the million-mile mark, this swap is the end-all, be-all best upgrade for your 24-valve Cummins.

A failed PSG (the computer that’s affixed to the pump), rotor seizure, diaphragm failure, a worn out distributor or a lack of fuel supply can all kill the VP44. Excessive heat, miles and a couple key inferior internal components are key contributors, but any time the VP44 sees 0 psi of supply pressure from the lift pump it’s not long before it checks out. The factory engine-mounted electric lift pump proved unreliable, but while a later Chrysler in-tank pump fix seemed to help, the best way to ensure positive, steady supply pressure at all times comes in the form of an aftermarket, chassis-mounted electric lift pump.

The most pressing performance hinderances with the VP44 pertain to low fuel volume and a lack of available high-rpm fueling. For sure, increases in horsepower can be made, but it’s nowhere near the level of potential that exists with the P-pump. From the factory, the VP44 can only fuel to 3,200 rpm and most aftermarket tuners—even though they increase horsepower—don’t provide for fueling beyond 3,200 rpm. High rpm exceptions here include the Redline box from Blue Chip Diesel and Edge’s Competition Juice with Attitude, which raise fueling limits to 4,000 rpm and 3,600 rpm, respectively. However, a P-pump can be governed to virtually any rpm and many competition pumps reside on engines that are fueled well beyond 5,000 rpm.

P-pumping a ’98.5-’02 24-valve Cummins can be done 100-percent junkyard style with parts sourced from all over creation, but that can take time. For anyone looking to perform the swap in a weekend, a comprehensive aftermarket P-pump conversion kit is the way to go. Scheid Diesel’s kit comes with the OEM Cummins gear housing and gear housing gasket you’ll need, the front cover oil seal, the pump’s drive gear, pump bracket and brace, the timing plug, a throttle linkage kit, cam sensor adapter and the accommodating fuel lines (your choice of mild steel or stainless steel). When you take into consideration that they also build some of the nastiest P7100 pumps around, Scheid becomes a one-stop shop for P-pump 24-valve conversions.

Known for being the most affordable P-pump conversion kit on the market, Crazy Carl’s system comes with everything you need to perform the swap. But in addition, the company’s kit provides the option of an adjustable pump gear, the choice of upgrading to either a Cummins OE gear case or a billet one, the intake spacer plate (or tunnel ram intake plate) that’s required to clear the supplied P-pump injection lines and even the appropriate fuel shut-off solenoid (sold separately).

Another all-inclusive P-pump conversion kit is available through Industrial Injection. Like other kits, there are add-on options such as a P-pump and fuel shut-off solenoid, but also specific components that have to be selected. These items include the model year of the truck in order to get the correct cam sensor adapter, .078, .084, .093 or .120 injection line diameters and whether or not you want those lines to be stainless or mild steel.

Of course, none of the aftermarket P-pump conversion kits come with the P-pump itself, but that’s not as cut and dry as getting the right injection lines, front cover and other miscellaneous parts. From mild (for utmost reliability) to wild (for four-digit horsepower), the P7100 can be built to flow a certain amount of CCs, support a target amount of horsepower and be equipped with or without a fuel shut-off solenoid. As previously mentioned, Scheid Diesel knows the ins and outs of the P7100 as well as anyone and offers everything from a 12mm P7100 capable of supporting 4,500 rpm and 700rwhp to a 13mm P7100 spec’d to flow up to 850cc and handle more than 5,000 rpm.

Although the P7100 is fairly complicated internally, it is vastly more reliable than the electronic VP44. When people speak about the 5.9L Cummins’ million-mile durability, it almost always revolves around a 12-valve version equipped with the P-pump. As far as performance is concerned, the P7100 offers you the ability to sport a 160hp truck or one making north of 1,000 ponies with limitless high-rpm fueling potential. And when coupled to a 24-valve engine you get to take advantage of the higher flowing (4-valve) cylinder head, which means you can run a larger turbocharger without sacrificing low-end drivability. Finally, there are no electronics to worry about failing, namely the computer married to the VP44 that’s notorious for giving up the ghost at the most inopportune time.

Spoiler alert: there aren’t many drawbacks to swapping to a P-pump. Aside from cruise control functionality issues on some trucks (which can be solved with the right parts), harder cold starts are common, but usually only on trucks that live in colder climates and that have been fitted with performance-targeted timing advancement and/or grid heater deletes. However, cold start issues can easily be remedied with the use of a block heater and/or keeping timing advance conservative. For solid all-around performance, 16 to 19 degrees of timing is common in trucks driven in cooler temps.

About this Item Most of the power steering pump"s housing look identical with the pressure port pointing to the same direction, this is why, you should be aware of the direction of rotation because if you don not choose the right one, the pump will not work

4 Cyl JD Diesel Deck Engine. 19’ Mast, - 5k / 2k Winches, Autohammer, Breakout Wrench, (3) Leveling Jacks, Water Tank, Rig Is In Good Shape, Bed Is Rough. Truck Has Eaton 10 Speed Transmission, 96,000 Miles, A/C, 85% Tires, Mounted On 2006 Peterbilt 335, w/ Cummins. Good Condition.

Kohler Gas, Three Speed W/ Two Speed For Coring, Moyno Pump , Cathead, One Winch, Has Wheels To Move On Hard Surface And Skids Can Be Bolted To Drag Machine.

6 Cyl. Ford Deck Engine, Moyno Pump, Water Tank, (2) Auger Racks, 6-5/8" & 4-1/4" 50" Each Augers, Includes Side Port Swivel And 3 1/2" Air Hammer. Auger / Air / Mud Drilling. Well Maintained, Mounted On Ford 8000, w/ Cat Diesel. Good Condition.

Deutz 4 Cyl. Diesel Deck Engine, Rebuilt 4 1/2 X 5 Gardner Denver Mud Pump W/ Reinforcement Plates For Mounting, Automatic Hammer, Automatic Hammer Calibration Done In 2019, (3) Leveling Jacks, (2) Winches, Can Add A Third Winch, New WRM Top Feed Swivel 2JW, U-Joint For Augers 1-5/8 HEX, Extruder For Shelby Tubes Samples, New More Info »

Cummins Deck Engine. Breakout Wrench, 3L8 Moyno Water Pump, Wiggle Tail, Wireline Winch, Hyd. Leveling Jacks, Mounted On 1992 Ford Single Axle, w/ Diesel.

3L6 Moyno Mud Pump. Safety Driver Winch, Cathead, Aux Winch, Main Winch, (3) 36”Jacks With Controls In The Drivers Area, Ready To Work, Mounted On ATV Carrier, w/ 4BT Cummins. Good Condition.

Duetz 57HP Diesel Deck Engine, 18" Mast, Angle Drill Capabilities, In-Out And Side To Side Slide Base, 435 Bean Pump, 140 Lb. Auto Hammer, 3,200 Lb. Main Hoist, (1) Wire Line, Recovery Winch, (3) Hyd. Leveling Jacks, (2) Side Tool Boxes, (3) Rod Racks, Front Auger Rack, Approx. 444 Hours, New Engine Installed In 2015, More Info »

Deutz 5 Cyl. Diesel Deck Engine. One Owner Rig, Cathead, 10K LB. Main Winch, 4,000 Lb. Aux. Winch, 3L6 Moyno Pump, 500 Gallon Water Tank, 4,688 Hours On Deck Engine Rebuild, 161, 914 Miles On Truck, Mounted On 1990 Ford F800 4 x 2. Good Condition.

3L8 Moyno Mud Pump. Breakout Table And Breakout Wrench, Auto Hammer (Replaced 2016), (4) Winches, Wireline 1800#, Main Winch 7000#, High Speed Aux 1800#, Low Speed Aux 3200#, 12250 Hours, Professionally Refurbished In 2013, 2250 Hours Since Refurbished, Mounted On ATV Carrier, w/ 4BT Cummins Turbo Diesel. Good Condition.

4 Cyl. Ford Deck Engine. Auto Hammer, 3L6 Moyno Pump, In/Out Slide Base, (2) Winches, 200 Gallon Water Tank, Front Hyd. Winch, (3) Leveling Jacks, Mounted On Yanmar C-60R, w/ Diesel.

3L6 Moyno Mud Pump, PTO, NO Deck Engine. (3) Hyd. Jacks, Safety Driver Hoist, Pullmaster Main Hoist, Auger Rack. Mounted On 1986 Muskeg Bombardier. Good Condition.

Bean Mud Pump, 6 Cyl. Ford Deck Engine. One Owner Rig, (3) Hyd. Jacks, Hyd. Safety Hammer, (3) Winches, In/Out & Side/Side Slide Base, 45" Of 6 1/4" HS Auger, 100" Of NW Rod. Mounted On 1986 Ford 8000, w/ 3208 Cat. Good Condition.

4 Cyl. Deck Engine, 7" Stroke, Hyd. Cathead, Wiggle Tail, (3) Hyd. Jacks, Capable Of Drilling From Rear & Both Sides Of Rig. Mounted On 95 Ford F-350 w/ V8. Good Condition.

PTO, No Deck Engine. 1500 Gallon Water Tank, 3" Bowie Loading Pump, Heated Pump Box & Water Tank, Jake Brake, A/C. Mounted On 89 Ford 9000, w/ 3306 Cat. Excellent Condition.

3L8 Moyno Mud Pump, Cummins Diesel Deck Engine. Tandem Axle, (4) Hydraulic Leveling Jacks, (2) Winch Lines, Breakout Wrench, Side Port Swivel, Angle Drilling Attachments, (2) Swivel Auger Racks Mounted On The Rig, Drillers Stand, Sliding Drawworks, (Side To Side Also Back & Forward), Mounted On 89 Kodiak 70 Series, w/ 3208 Cat Diesel. Good More Info »

Bean 35 Mud Pump, Tooling For Auger Work And Diamond Core To 2000", Injection Pump, Low Hours, 71 XXX Miles On Carrier. Mounted On 76 International 4X4.

3L8 Moyno Mud Pump, (2) Winches, Toolboxes, Auger Rack, Hyd. Leveling Jacks, Electric Over Hyd. Controls, Deck Mtd. Hyd. Drive 2,000 PSI Steam Cleaner / Power Washer. Mounted On 90 International 4 X 2 w/ DT466 185 HP. Good Condition.

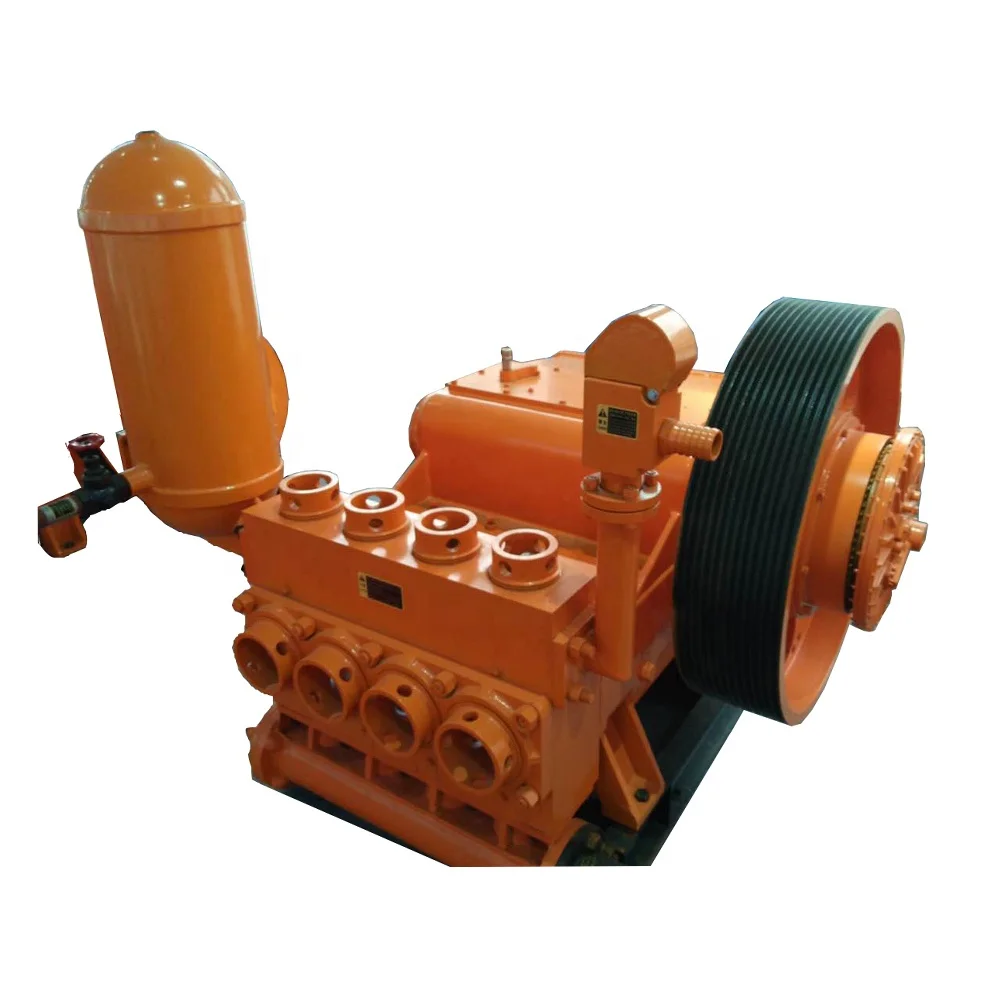

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

What is a 5.9-liter Cummins diesel engine? Well, for hardcore enthusiasts, it"s arguably one of the most popular oil-burners ever produced. Cummins engines were dominant in agriculture long before their debut in heavy-duty trucks. The 12-valve 5.9-liter Cummins I-6 engine was developed and installed in Dodge pickups starting in 1989, creating one of the most legendary partnerships in automobile history.

Although Cummins" 5.9-liter (B-Series) engine was produced in many different configurations, for this report we"re starting at the beginning. The powerplant was originally designed for medium-duty commercial trucks, but in 1989, Dodge"s truck division began installing the first version of this engine, which is more commonly referred to as the "12-valve," in on-highway pickup trucks.

If you were buying a new Dodge Ram truck in 1989 (aka First Generation), you had options. You could choose a worthy 360ci gas-powered V-8 engine, or a powerplant that had the performance characteristics of a big-rig"s engine: a 5.9-liter Cummins diesel. With the engines installed in Dodge Ram rigs, sales went through the roof. Coupled with a beefy five-speed manual transmission or a heavier-duty version of the A727 three-speed automatic, the 5.9-liter Cummins was an engine everyone wanted.

Unlike other diesel engines during this time, the 5.9-liter Cummins was the only one that featured direct injection. It didn"t need glow plugs, nor was it naturally aspirated. This hoss was turbocharged (Holset H1C), and consumers loved the powerplant because of its perceived reliability, huge torque output (for the time), and excellent fuel economy. If you can believe it, their 160-horsepower and 400 lb-ft of torque rating was class-leading performance.

The Bosch-built fuel-injection systems found hanging on 5.9-liter Cummins diesel engines have changed several times throughout the I-6 powerplant"s 18-year run. The original 12-valve was equipped with a camshaft-driven, rotary-style injection pump called a "VE" pump. The unit has proven its reliability over the years, but it has the least power potential.

Although there are many ways to increase the horsepower and torque of a VE-equipped 5.9-liter Cummins, it isn"t the most popular pump for performance. With only a few hand tools, fueling can be increased enough to enable the engine to make 70 more horsepower than its stock output, but this injection pump is stingy when it comes to fuel quantity.

Even with the pump cranked up, more conservative fuel injectors present a bigger roadblock to better performance. Luckily, though, there is plenty of aftermarket support for getting more power and torque: upgraded turbos, injectors, as well as internal pump parts like governor springs, fuel pins, and more. Although the VE may leave a lot on the table in terms of performance, VE-equipped trucks with modifications can certainly be made more fun to drive.

In 1994, the 5.9-liter Cummins was similar in many ways to the 1989-1993 engine. It had the same displacement, and reused the first-generation"s block, connecting rods, and head. However, the diesel experienced a few changes that made it even more popular, and capable of significant power output. The biggest and most exciting change was the introduction of Bosch"s P7100 inline injection pump (P-pump), which replaced the VE pump.

While today it"s all but impossible to associate a P-pump with anything emissions-related, this injection pump was introduced for 5.9-liter Cummins engines to help the powerplants meet emission standards in 1994. Unlike the VE, the P7100 offered higher injection pressures that slashed particulate matter and promoted better combustion.

Because of the improvements made to the 5.9-liter in 1994, the output increased. Depending on the transmission being used, a P7100-equipped 12-valve can churn out 175 horsepower and 420 lb-ft of torque. When you think about diesel performance, P-pumped 5.9-liter Cummins diesel engines are the first to be thought of.

This injection pump is one of the most preferred models for racing and performance-centered competition. In fact, 1,000 horsepower can be achieved because of the almost endless fuel supply. With tuning and upgrades, this version of the second-generation 5.9-liter can also withstand hundreds of thousands of miles.

Halfway through 1998, Dodge Ram trucks were forever changed. That is when the first ever (and least popular) electronically controlled fuel-injection system for the 5.9-liter Cummins engine debuted. The setup featured a high-pressure, Bosch-branded VP44 injection pump, also known as the "VP." The change was the result of more strict emissions standards with which the Cummins/Dodge Ram partnership was forced to comply.

The VP wasn"t the only change that year, however. This was also when first versions of the 24-valve, 5.9-liter engines were introduced. The new four-valves-per-cylinder design improved the engine"s efficiency and allowed it to crank out even more horsepower and torque than its predecessor. The initial 24-valve version of the 5.9-liter produced 235 horsepower and 460 lb-ft of torque with a manual transmission. With an automatic, outputs were lower (215 horsepower and 420 lb-ft of torque).

The improved 5.9-liter offered performance and drivability improvements and allowed for better coolant flow than its 12-valve predecessor. However, this came with issues of its own. The 24-valve"s VP injection pump offered the least reliability, and although these engines were workhorses, at any time the injection pumps could fail. Failed lift pumps would inevitably starve the injection pump of fuel, causing it to die as well. This became a common repair in the late 1990s and early 2000s.

Another big change was the engine block. Some of the 5.9-liter castings are stamped with the number "53," and their thinner walls are susceptible to cracking and can often develop coolant leaks. Despite the advancements over the 12-valve, when 53-stamped engines are introduced to higher cylinder pressures, they are known to be nightmares—so much so that some were repaired under warranty back in the day.

As each of the big-three truck manufacturers" diesels drew closer to making 500 lb-ft of torque, the incentive to win grew. In 2001 (and for 2002 models), Dodge offered a high-output version of the 24-valve which allowed them to eclipse 500 lb-ft with the help of a new Holset HY35W turbocharger. With an output of 245 horsepower and 505 lb-ft of torque, the 24-valve was here to stay. The high-output, VP-equipped 5.9-liter Cummins was backed with a tough six-speed NV5600 transmission.

Although it seemed Cummins was headed in the right direction for on-road performance, when it came to diesel competitions (dyno, drag racing, sled pulling), the VP44"s shortcomings left a lot on the table. Luckily, like the other versions before it, VP44-equipped trucks now have plenty of aftermarket support to improve on stock performance: plug-and-play tuners, upgraded turbos, larger injectors, and more.

Despite its issues, the VP44-equipped 24-valve edition of the 5.9-liter was highly desirable. There are a lot of late-2000s Cummins purists out there, but their favorite version of the engine only lasted until 2003, when, once again, the 5.9-liter diesel powerplant experienced yet another set of changes, bringing back that nostalgic reliability. It is also when a new body style was introduced, and the term "Third Generation" was born. Not only is this 100-percent electronically fueled engine one of the most popular versions of the 5.9-liter Cummins, the truck it powers is revered by Dodge Ram fans.

Third Generation 5.9-liter engines utilized a Bosch-built CP3 injection pump, which over time has proven to be one of the most reliable and efficient fueling platforms. An electric lift pump sends diesel to the CP3 where it is pressurized and sent into the fuel rail. Once in the rail, fuel is distributed into each of the six fuel injectors. The revision allowed the engine to stay EGR-free for at least a few years.

The new fueling strategy included solenoid-activated injectors, an updated cylinder head, and a stronger 5.9-liter engine block. The injectors were 8-hole (2003-2004) and 5-hole (2004.5-2007) designs which, once again, helped with emissions. The new cylinder head featured a rocker box that accommodated the injectors and crossover tubes as well as heavier-duty intake and exhaust valves.

From 2003 to 2007, Cummins offered two different turbochargers for its 5.9-liter engine. A Holset HE341CW was used in 2003. It features a mechanically controlled internal wastegate that holds higher-than-stock boost pressures. However, to better comply with emissions regulations, the 2004.5 to 2007 engines came with Holset"s HE351CW. This "charger is similar to the HE341CW but the wastegate is electronically controlled. This new turbocharger allows for a noticeable boost in performance and lowered emissions output.

Finally, CP3-equipped 5.9-liters are the easiest Cummins engines to modify. Their ECMs are so easily manipulated that making over 500 horsepower and 1,000 lb-ft of torque is a breeze.

When it comes to the engine, the revisions over the years have made it tough as nails. When making power, the problem lies within the drivetrain for trucks of this vintage.

The 48RE four-speed automatic transmission that backs common-rail 5.9-liter engines is a common fail point when you start adding power. It"s even problematic on unmolested, stock powerlants.

Emission concerns have played a huge part in the evolution of the 5.9-liter Cummins. Because of that, we"ve seen Cummins adapt and overcome, which resulted in better versions of the engine. The 5.9-liter is and always will be one of the most iconic diesel engines in the automotive industry.

Dirt Every Day hosts Fred Williams and Dave Chappelle decide to build a budget bouncer from a Dodge truck with a V-10 engine. With an engine like a supercar, they name it the Rock Viper, then they add nitrous and turn it into a mud bouncing machine! Sign up for a free trial to MotorTrend+ todayand start watching every episode ofDirt Every Day, plus more of the best automotive content anywhere!

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Thanks to sharing much of its mechanical makeup and even some of the exact same hard-parts with its big brother, the 6BT, the 4BT Cummins can support a substantial amount of horsepower. Exactly how much remains to be seen, as specific parts combinations vary from application to application. However, we can unequivocally say that for embarking on an all-out horsepower effort with the 4BT, everything starts with the injection pump—and there is no debate as to which pump you need. It has to be the Bosch P7100. No, not the single plunger VE rotary and no, not even the A-series pump. Of course, you’ll need more than simply the right injection pump, but like the 6BT, everything revolves around the “P-pump.”

In our experience, the 4BT’s stock rotating assembly—which was only subjected to 105 hp in factory form—can handle up to 400 horsepower and 800 lb-ft of torque without breaking a sweat. In more serious builds, we’ve seen balanced and blueprinted 4BT’s with lowered compression, head work, head studs, properly spec’d turbochargers, and the right fueling modifications live just fine at more than 700 hp. For two examples of the latter and one of the former, we’re bringing three high horsepower 4BT builds to life below. These real-world applications, each one being specifically built to handle its own unique task, never skip a beat—whether they’re at the track, blasting through the mud, or hauling hay.

Years ago, when diesel drag racing was beginning to pick up steam, Wayne Robbins decided to campaign something unique in a world dominated by the 5.9L Cummins. His lightweight Ford Ranger was powered by a 4BT and he swung for the fences. Built for utmost strength and longevity at TFS Performance, the engine’s main bearing saddles and caps were line-bored, the crankshaft was balanced, and the block was bored with a torque plate installed. The rest of the no-frills 4BT build entailed 11:1 compression Arias pistons, a custom roller cam from Scheid Diesel, 9/16-inch head studs, and a cylinder head benefitting from oversized valves. The original BorgWarner S200 over S300 compound turbo arrangement yielded 707 horsepower on the dyno, but later on an S300/S400 upsizing uncorked the 4BT to the tune of 824 horsepower (along with 1,267 lb-ft of torque).

8613371530291

8613371530291