dragon mud pump free sample

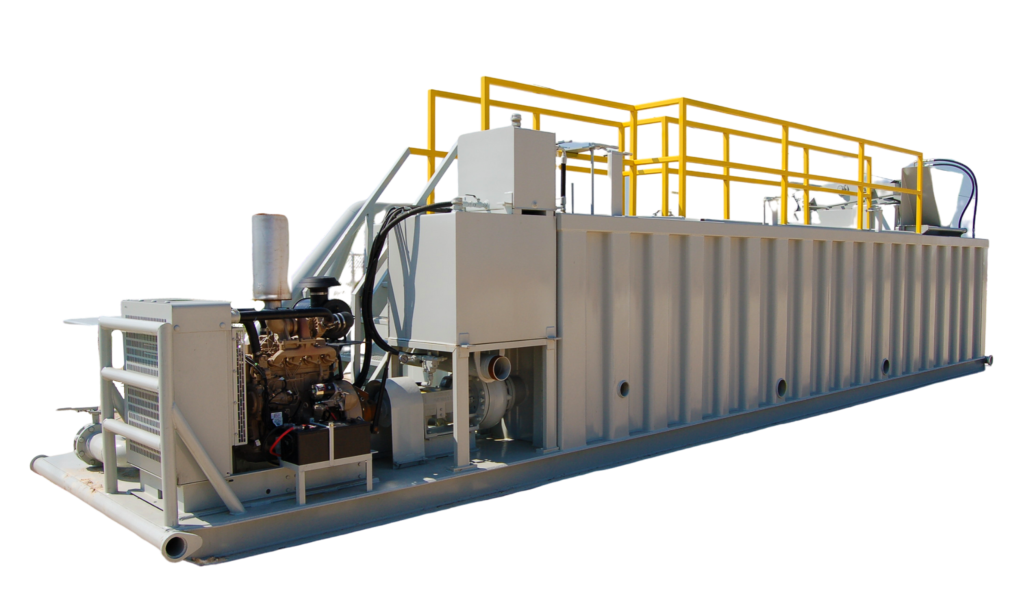

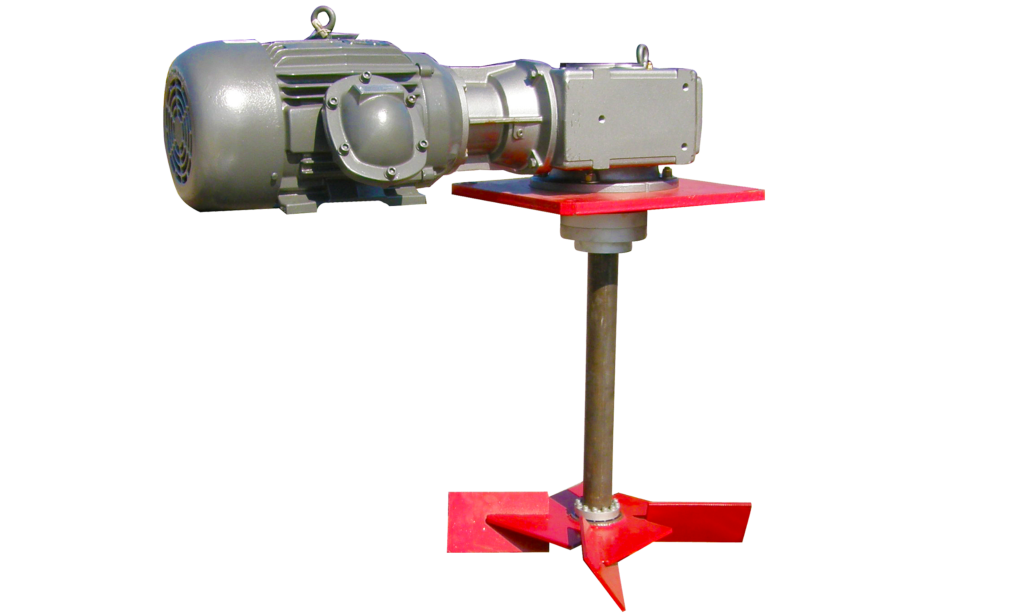

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

Created specifically for drilling equipment inspectors and others in the oil and gas industry, the Oil Rig Mud Pump Inspection app allows you to easily document the status and safety of your oil rigs using just a mobile device. Quickly resolve any damage or needed maintenance with photos and GPS locations and sync to the cloud for easy access. The app is completely customizable to fit your inspection needs and works even without an internet signal.Try Template

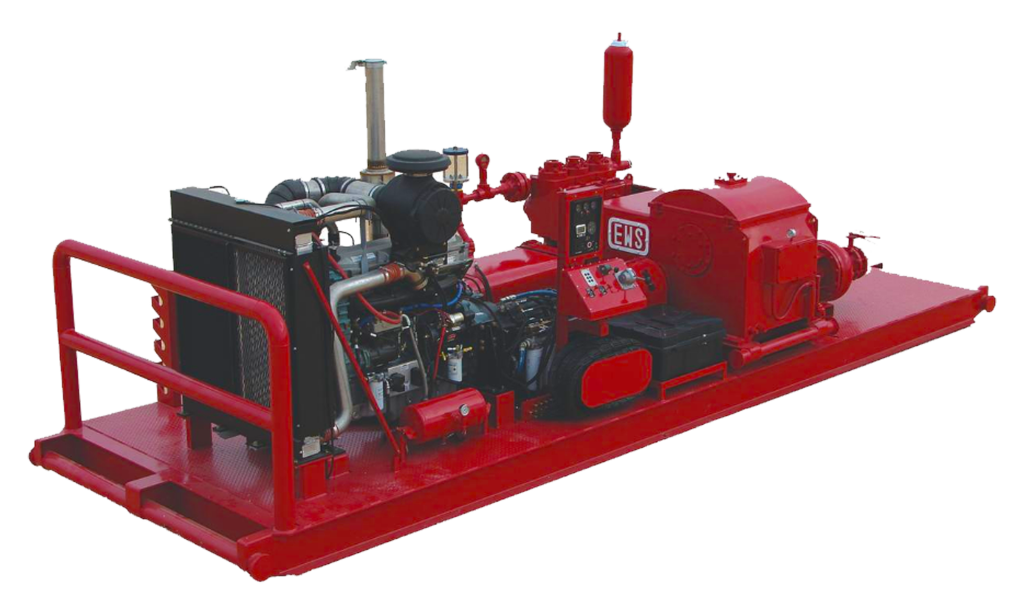

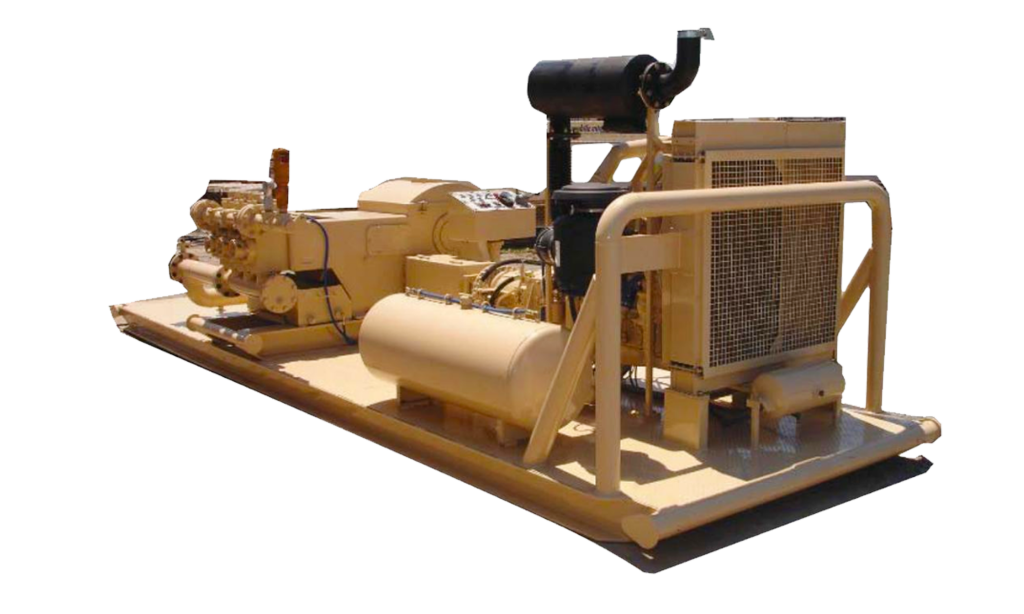

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Drill string: A column, or string, of pipe that transmits drilling fluid (via the mud pumps) and torque (from the Kelly drive or top drive) to the drill bit.

Frac job: Slang term for hydraulic fracturing, a process whereby an oil or gas well is stimulated by pumping special fluids into the reservoir, fracturing the formation.

Mud: Slang term for drilling fluid. A "mud man" is the drilling fluids technician responsible for formulating the mud, while a "mud logger" checks mud cuttings from the drill bit for traces of rock or oil and gas that provide a picture of conditions downhole.

Sliding: In directional drilling, sliding is used to describe a drilling interval in which rotary drilling (i.e., turning the entire drill string) is ceased and a mud motor is engaged to drive the drill bit and provide directional control. Because sliding significantly decreases rate of penetration, increases bit wear, and increases tortuosity, it is normally limited to drilling lateral sections of a horizontal well.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

8613371530291

8613371530291