dragon mud pump with mud tanks free sample

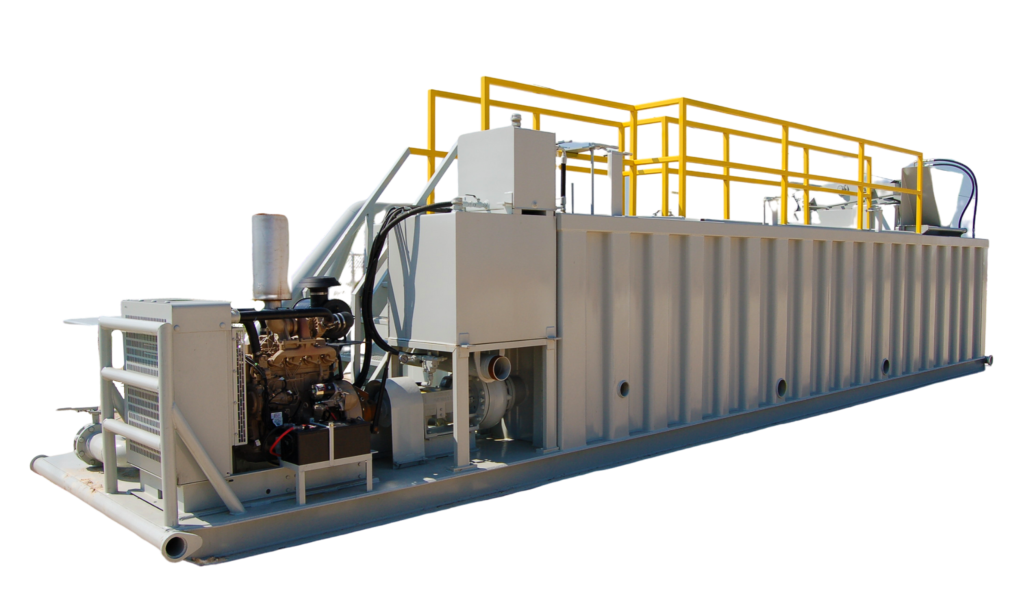

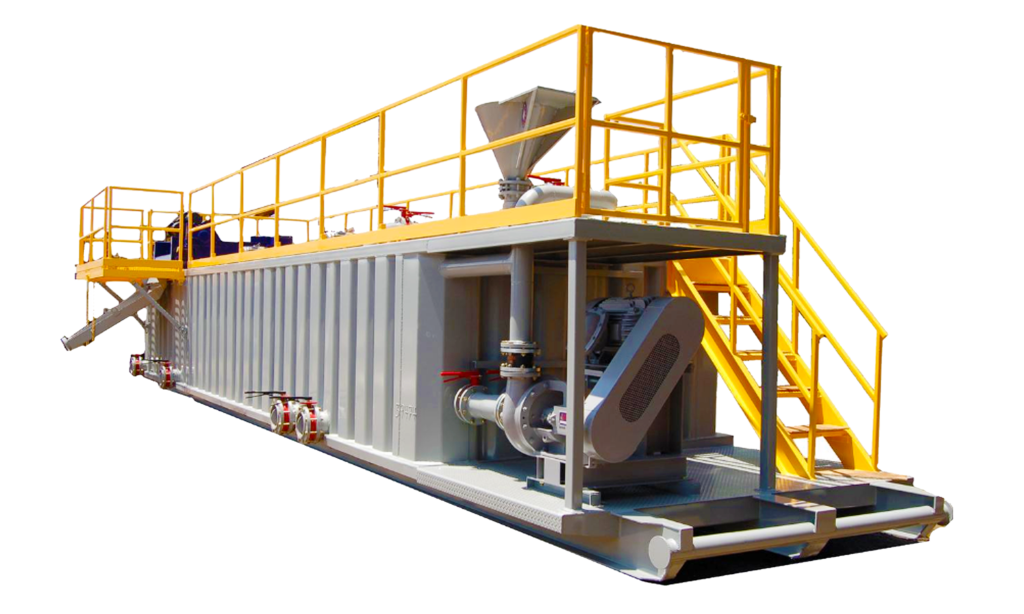

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

Dragon’s RANCO trailers are no stranger to a hard day’s work, so it is only natural that they are a part of Dragon. With more than 30 years of expertise in manufacturing tank trailers customers trust the Dragon name. In-house engineering, vast production capacity, and knowledgeable support teams deliver the severe-duty equipment and service you need every time, every where.

Like all Dragon products, our frac tanks are built for the long haul. Manufactured using high-quality, durable materials and with rare attention to detail, Dragon open-top frac tanks get the job done right. Whether you call them frac tanks or mud tanks, you can count on Dragon Products to provide equipment that works overtime every time. If you"re in the fracking industry, you"ll also be interested to know that we have stimulation equipment to meet your needs.

While frac tanks are often used at fracking job sites, mining companies aren"t the only ones who put these workhorses to the test. Our mud tanks are capable of housing all manner of materials. Manufactured using the toughest materials, we have mud tanks for sale that are built to provide you with years of solid performance.

Smooth Wall, Round Bottom Frac Tanks: With smooth interior walls for easy cleaning, these hard-working frac tanks feature quarter-inch steel plate construction. The round bottom floor is ideal for storing thicker or higher viscosity liquids that require mixing or circulating because it permits more effortless movement of the fluid.

Corrugated Wall, V-Bottom Frac Trailers for Liquid Storage: Built from ¼" heavy-duty corrugated steel, this frac tank features chemical-resistant liners. Corrugated frac tanks store frac water, brine, processed water and other hydraulic fluids. At Dragon, we also carry insulated corrugated frac trailers. The V-bottom is great for storing liquids, which can easily be siphoned off at each end of the tank with the help of a channel that runs through the middle.

V-Bottom Frac Trailers With Smooth Walls: These mud tanks feature a v-bottom with integral formed side channels for easy draining. The drain/fill feature includes a 4″ drain at each end of the floor, 3″ fill pipe to roof, 4″ connection on front, 8″ flanged front manifold connection with inside flange and 4″ connection on roof.

Industrial Mini Frac Tanks: Smaller but just as mighty, this frac tank has an 8,500-gallon capacity and is suitable for liquid waste. The unit is movable via a roll-off trailer or truck.

Mud tanks are large, heavy-gauge steel containers that store liquids or solids. Because they have tires, air brakes, lights and mud flaps, frac tanks are considered semi-trailers. Typically holding up to 500 barrels of fluid (which translates to 21,000 gallons), these hard-working Dragon tanks are designed to arrive at the worksite empty and are filled on site with vacuum or water trucks.

Frac tanks may be used to house chemicals or liquids like petroleum products, manure, proppants and saline water. They are then hauled with the help of a roll-off trailer or truck. They can also be moved using a power-only tractor, particularly when long-distance moves are called for.

Here are answers to some of the more common questions we"ve received about frac tanks. If you have a different question, please feel free to give us a call. We"re always glad to help.

Frac trailers picked up their name when it became common practice for this type of tank to supply fracturing fluids at gas and oil wells. Initially, the term "mud tanks" was applied to these receptacles because workers used to dig mud pits in the earth and fill them with the materials that are now collected in mud tanks.

Oil and gas operations commonly use mud tanks to store filtered water that"s mixed with a proppant, which is then pumped down the well to fracture the formation and hold the fracture open. There are several other industries that also use frac trailers – any sector with a need for the large-scale temporary storage of non-toxic liquids. Some examples include:

Yes! Dragon Products is a family-owned and operated frac tank manufacturer with over 50 years of experience. Because we engineer and build our mud tanks right here in the U.S., we can control the quality of our products. Being based in the U.S. gives us a decided advantage – our extensive inventory of parts and equipment is ready to ship when you need it most. We have locations across the country. Find frac tanks for sale near you.

Whatever your needs may be, Dragon Products has the frac tanks for sale that are best suited to your work site. We"re the frac tank manufacturers who are here for you 24/7 with the support you need for all your projects. We offer a full range of haulers, including liquid tank trailers. We also have tank and trailer parts. Check out our specs and let us know how we can help!

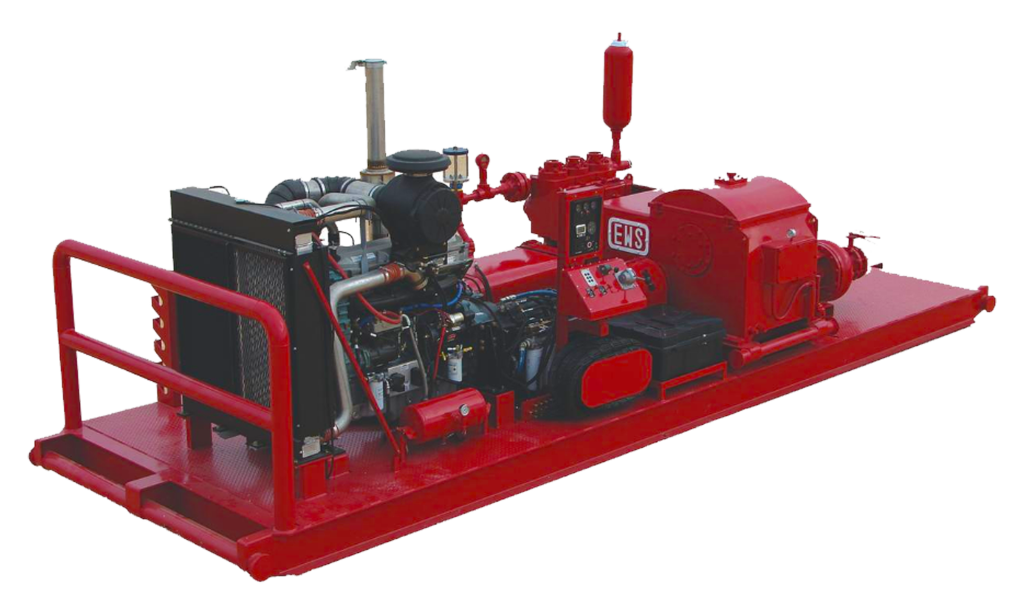

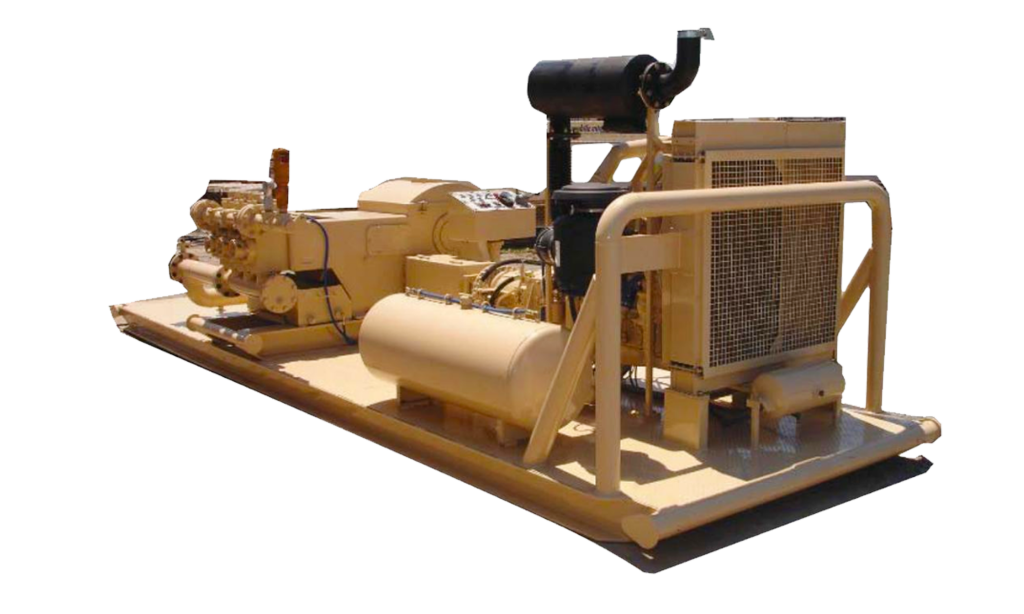

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Cavitation is an undesirable condition that reduces pump efficiency and leads to excessive wear and damage to pump components. Factors that can contribute to cavitation, such as fluid velocity and pressure, can sometimes be attributed to an inadequate mud system design and/or the diminishing performance of the mud pump’s feed system.

Although cavitation is avoidable, without proper inspection of the feed system, it can accelerate the wear of fluid end parts. Over time, cavitation can also lead to expensive maintenance issues and a potentially catastrophic failure.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump “knocking,” which typically sounds like marbles and stones being thrown around inside the equipment. However, the process of cavitation starts long before audible signs reveal themselves – hence the name “the silent killer.”

Mild cavitation begins to occur when the mud pump is starved for fluid. While the pump itself may not be making noise, damage is still being done to the internal components of the fluid end. In the early stages, cavitation can damage a pump’s module, piston and valve assembly.

The imperceptible but intense shock waves generated by cavitation travel directly from the fluid end to the pump’s power end, causing premature vibrational damage to the crosshead slides. The vibrations are then passed onto the shaft, bull gear and into the main bearings.

If not corrected, the vibrations caused by cavitation will work their way directly to critical power end components, which will result in the premature failure of the mud pump. A busted mud pump means expensive downtime and repair costs.

To stop cavitation before it starts, install and tune high-speed pressure sensors on the mud suction line set to sound an alarm if the pressure falls below 30 psi.

Although the pump may not be knocking loudly when cavitation first presents, regular inspections by a properly trained field technician may be able to detect moderate vibrations and slight knocking sounds.

Gardner Denver offers Pump University, a mobile classroom that travels to facilities and/or drilling rigs and trains rig crews on best practices for pumping equipment maintenance.

Severe cavitation will drastically decrease module life and will eventually lead to catastrophic pump failure. Along with downtime and repair costs, the failure of the drilling pump can also cause damage to the suction and discharge piping.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump ‘knocking’… However, the process of cavitation starts long before audible signs reveal themselves – hence the name ‘the silent killer.’In 2017, a leading North American drilling contractor was encountering chronic mud system issues on multiple rigs. The contractor engaged in more than 25 premature module washes in one year and suffered a major power-end failure.

Gardner Denver’s engineering team spent time on the contractor’s rigs, observing the pumps during operation and surveying the mud system’s design and configuration.

The engineering team discovered that the suction systems were undersized, feed lines were too small and there was no dampening on the suction side of the pump.

There were also issues with feed line maintenance – lines weren’t cleaned out on a regular basis, resulting in solids from the fluid forming a thick cake on the bottom of the pipe, which further reduced its diameter.

Following the implementation of these recommendations, the contractor saw significant performance improvements from the drilling pumps. Consumables life was extended significantly, and module washes were reduced by nearly 85%.

Although pump age does not affect its susceptibility to cavitation, the age of the rig can. An older rig’s mud systems may not be equipped for the way pumps are run today – at maximum horsepower.

We add hundreds more free sound effects every week for instant download and work with some of the best professional sound designers and libraries to bring you fresh, exciting new content. All our sounds are 100% legal to use, recorded by ourselves or our contributors. We own the copyrights or are authorised to distribute them meaning you can use our audio with absolute confidence. We take great pride in the quality of the sounds in our library and check every single one to make sure they meet our strict quality guidelines.

All our sound effects and music are royalty free, which means while we or our contributors retain all copyrights, we grant you a license to use them in your work and you can use our sounds for free without having to pay any royalties or other fees.

8613371530291

8613371530291