drill mud pump quotes free sample

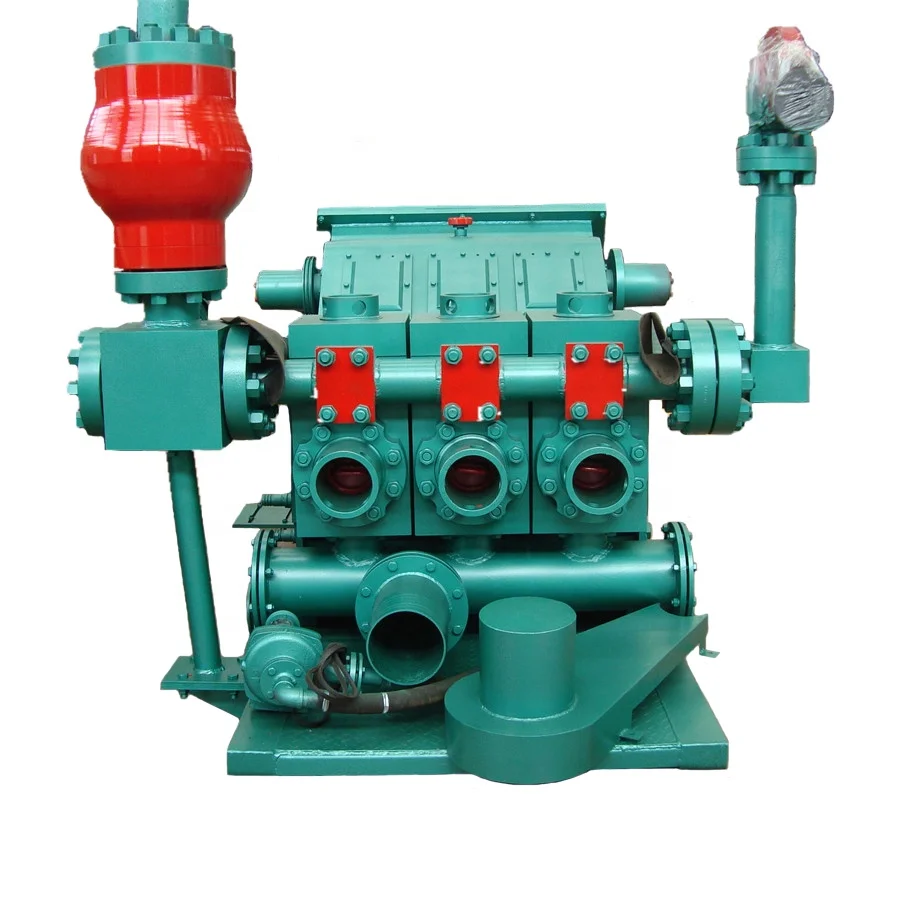

The NOV FC-1600 Triplex Mud Pump is made of rugged Fabriform construction and designed for optimum performance under extreme drilling conditions. It is compact and occupies less space, yet delivers unequaled performance. The pumps are backed by several decades of design and manufacturing experience, and are considered leaders in the field.

NOV FC-1600 Triplex Mud Pump is conservatively rated at relatively low rpm. This reduces the number of load reversals in heavily stressed components and increases the life of the fluid end parts through conservative speeds and valve operation.

The NOV FC-1600 Triplex Mud Pump design provides an inherently balanced assembly. No additional counterbalancing is required for smooth operation. No inertia forces are transmitted to the pumps’ mountings.

A Triplex Mud Pump sometimes referred to as a drilling mud pump or mud drilling pump. NOV FC-1600 Triplex Mud Pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

TTAAM-OM series centrifugal sand pump mainly supplies to solids control circulating system of the oilfield drill rig and can be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer to assure these equipment work efficiently.

The TTAAM-OM8×6×11 centrifugal sand pump applies to under 3000-meter-long drilling Rigs and also can be used to supply mud to the triplex mud pump as a filling pump.

The pump is constituted of pump shell, impellers, bearing block, pump axle, bearing, shaft coupling, wearing plate, seal apparatus, oil seal, motor and base.

Our triplex and quintuplex pumps, cementing and fracturing equipments are interchangeable to global famous brands: Weir spm, Serva, BJ, Gardner Denver, Halliburton, Oilwell, OPI and so on. We also make a full line of Module assy and fluid end expendables for popular mud pumps in the world, including continental Emsco, National, Gardner Denver, Oilwell, Ideco, Wheatly, Wilson,with, opi, Ellis Williams, etc.

Owners praise their Geoprobe® 3126GT geotechnical drill for its simplicity and safety so new drillers quickly travel the learning curve. Veteran drillers appreciate the attention to features addressing their field needs. Together all the standard features and available options minimize operating costs and come in at a price point lower than you might anticipate.

ENGINEERED FOR EFFICIENCY: with six functions along the centerline, use machine hydraulics and controls to side-shift the head, simplifying your geotech applications. Complete augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT — even direct push — without manipulating mast position or mobilizing multiple machines.

ENHANCED EASE AND SAFETY: boost geotechnical drill output and utilization with hands-free automatic drop hammer and integrated CPT head-feed rate control, including cone overload protection. Leverage small footprint to expand site access without sacrificing flow from mud pump or accessory storage. Bring new drillers up the learning curve quickly with easy controls and integrated safety features built to internationally-accepted standards.

ELEVATED SERVICE AND SUPPORT: respond to your clients needs, making a quick call to get answers to your field and geotechnical drill service questions with overnight part shipping available from industry-leading support team.

With drill rig service shops in Pennsylvania, Florida, and Kansas, you’ll have service support nearby for your routine maintenance or more in-depth drill rig remounting and refurbishment work. Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your geotechnical drill is constructed consistently and tested thoroughly to ensure easier service support.

Six functions along the 28-inch centerline head side shift simplify traditional geotechnical applications — augering, mud rotary, SPT, Shelby tubes, hard rock cores, CPT – and even direct push. Features GH63 percussion hammer 4-speed rotary head with 4,000 ft-lb, DH104 hands-free automatic drop hammer, CPT push/pull assembly, and a rod grip pull system. Head shifting speeds up drilling and minimizes the time driller spends in danger zone.

Drill mast features extend, swing, mast dump, oscillation, and fold. Mast dump provides 36.5 inches of vertical travel to allow room for a mud pan. Optional outriggers available.

Hands-free rotary and head feed controls on the 3126GT reduce strain on driller when completing applications like mud rotary. CPT feed rate and hydraulic limit functions are standard.

"This reduces the transport height of the 3126GT from 114 inches to 99 inches," Ryan Kejr, machine engineer lead, said. "We accomplish this with a simple, mechanical ratcheting actuator. This is easily accessible from the ground when the drill mast is in transport position."

TMG manufactures the first ever purpose-built combination SPT, CPT, DMT soil field testing and Wireline Rotary Core Test Drill Rig. Having the versatility to auger drill, rotary/mud drill, wireline rotary core drill, DMT test, SPT hammer test and full-function CPT test in ONE compact track mounted drill rig, is a first in the industry. Engineers can now invest in one machine to test soils using SPT or CPT and core sampling technologies.

The Crossover Rig (CSR-174) has a two-drilling position drillhead cart. Position one carries the 4-speed drillhead. The second position is blank and can be used for other tooling, autohammer, CPT push head, wireline core drilling, etc.

The size distribution of drilling muds is frequently adjusted during the drilling process. As such, the particle size distribution must be measured frequently, several times a day. Before the introduction of our LISST-Portable|XR, the practice had been to send a sample to a remote laboratory, and suffer the delays in getting results. The LISST-Portable|XR is designed for use at the drill site itself, giving immediate results in just a few minutes. This reduces dead time at the well, saving drilling costs.

By far the quickest method of measuring the PSD is laser diffraction, which has been in use since the 1970’s. Today it is used everywhere in industrial and scientific applications where there is a need for rapid, reliable and repeatable PSD measurements. The largest drawback for common use of laser diffraction in the drilling industry has been that most systems are heavy (~25-50 kgs), require 110/220VAC power and cannot be used outside of a laboratory environment (i.e. they cannot be used on site). The LISST-Portable|XR changes all that.

The sample is poured into the integrated mixing chamber where it is suspended and recirculated using a built-in pump system and sonicated using the optional ultrasonic probe. The PSD is then measured and displayed on the touch panel display in one minute. The data are stored on board and offloaded at a convenient time to a PC for display in reports etc. All samples stored on the instrument can be viewed directly on the touch panel display.

The figures below show a comparison between the LISST-Portable|XR, the Malvern MasterSizer 2000 and the Malvern MasterSizer Micro. The data were obtained in the same laboratory by the same analyst and using the same protocol with respect to instrument settings (e.g. sonication, stirring, optical model) to the extent it was possible between the 3 different instruments. The samples were BARACARB® (a bridging agent), and a water-based drill mud. It is evident that the Sequoia LISST-Portable|XR performs just as well as the Malvern units in measuring these samples.

Yellow Jacket Drilling upholds high standards of safety and preventative maintenance to ensure our team and our drilling equipment are in peak performance at all times. We can devise new ways of accomplishing your project and are happy to help you determine the most appropriate and effective drill method for your job. Our attitude of excellence plays a role in everything we do. Maintaining an honest dialogue and keeping close personal contact with all involved is our way of ensuring your needs will be met. You benefit from high performance, a hassle-free job, and superior results.Learn More

Roller Cone and Drag Type Underreamers are just two more examples of our goal to bring expensive Oil Field technology to other drilling markets at an economical cost. We have been manufacturing both types of Underreamer designs for over 20 years and based on the feedback from our customers out in the field, we have been able to offer continual improvements.

The primary use for both of these tools is to open up the bore hole below the casing. Most drillers are trying to straighten up a dog leg down in a hole, which may be preventing advancement of the casing.

Our Underreamers can be opened up anywhere down in a hole and as many times as needed, but you must have adequate annular space for the blades or rollers to open up. Most drillers pull the casing up 3 or 4 feet and lower the underreamer below the casing and then open the tool and start drilling. The tools operate with either air or fluid pressure and require as little as 60 – 100 lbs. of pressure to force the cutter arms out.

The piston is carbonized steel to reduce abrasion and features a replaceable tungsten carbide jet nozzle to adjust to your individual compressor or mud pump output.

The simple, rugged design features easily replaceable components for long-term, trouble-free operation. The operation of our Underreamers is very simple. The tool is hydraulically operated by pump pressure which forces a spring loaded actuating piston downward. A cam attached to the lower end of the actuating piston forces the cutter arms out to the desired cutting diameter. When the pump pressure is shut off, a coil spring forces the piston upward causing, the cutter arms to retract back into the body.

The Mills Machine Underreamer is hydraulically operated by pump pressure which forces a spring loaded actuating piston downward. A milled opening in the side of the piston forces the cutter blades out to the desired cutting diameter. Adequate annular space is required to open the blades. When the pump pressure is shut off, a coil spring forces the piston upward causing the cutter blades to retract back into the body. The tool can be opened up anywhere down enabling you to open up as many zones as you like.

• The Mills Machine Underreamer is hydraulically operated by pump pressure which forces a spring loaded actuating piston downward. A cam attached to the lower end of the actuating piston forces the cutter arms out to the desired cutting diameter.

Adequate annular space is required to open the blades. When the pump pressure is shut off, a coil spring forces the piston upward causing the cutter arms to retract back into the body. The tool can be opened up anywhere down enabling you to open up as many zones as you like.

Mud pumps are the pumps deployed in the oil and gas industry, mainly to circulate drilling fluids and other kinds of fluids in and out of the drilled wells for exploration. The mud pumps transfer the fluids at a very high pressure inside the well using the piston arrangement. The number of pistons decides the displacement and efficiency of working of the mud pumps, originally only dual piston pumps and three-piston pumps were used, but the technological advancements have seen pumps with five and six pistons to come up. Currently the triplex pumps which have three pistons are used, but the duplex pumps having two pumps are still deployed in the developing countries.

Based on its types, global mud pump market can be segmented into duplex, triplex, and others. The triplex mud pumps will dominate the mud pump marking in the given forecast period owing to its advantages and ongoing replacement of duplex pumps with triplex pumps. Based on operation, the global mud pumps market can be segmented into electric and fuel engine.

The electric mud pumps will dominate the market during the given forecast period due to the advantage of eliminating the harmful carbon emission which is done in the case of fuel engine pumps. Based on its application, the global mud pumps market can be segmented into oil & gas, mining, construction, and others.

The major market driver for the global mud pumps market is the increasing exploration activities taking place in various regions of the world to satisfy the increased energy demand. The number of drilled wells has increased in recent years, which has certainly impacted the growth of the mud pumps market in both oil & gas and mining sectors.

Key market restraint for the global mud pumps market is the drift towards the cleaner sources of energy to reduce the carbon emissions, which will certainly decrease the demand for oil & gas and therefore will have a negative impact on the growth of the global mud pumps market.

Some of the notable companies in the global mud pump market are Mud King Products, Inc. Gardner Denver Pumps, Weatherford, Schlumberger, National Oilwell Varco, China National Petroleum Corporation, Flowserve Corporation, MHWirth, American Block, Herrenknecht Vertical Gmbh, Bentec GmbH Drilling & Oilfield Systems, Drillmec Inc, Sun Machinery Company, Shale Pumps, and Dhiraj Rigs.

The global mud pump market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Owing to the well-established production sector and stable exploration industry North America holds the largest market for the mud pumps. The onshore exploration activities of oil & gas have increased at a good rate in the North America region, which has certainly boosted the growth of the mud pumps market in the region.

The demand from Europe and Asia Pacific has also increased due to exploration activities in both the regions owing to the increased energy demand. The energy demand specifically in the Asia Pacific has increased due to the increased population and urbanization. The Middle East and Africa also hold significant opportunities for the mud pumps market with increased exploration activities in the given forecast period.

In August 2018, Henderson which is a leading company in sales and service of drilling rigs, and capital drilling equipment in Texas signed a contract with Energy Drilling Company for the purchase and upgrade of oil field equipment’s which included three 1600hp × 7500psi mud pumps. This will be the first refurbishment completed at Henderson’s new service center and rig yard.

In January 2018, Koltek Energy Services launched the 99-acre facility for the testing of the oil field equipment in Oklahoma. This will allow the oil field equipment manufacturers to test their equipment at any given time. The company has deployed the MZ-9 pump which has a power rating of 1000Hp.

Starting an oil drilling operation requires careful planning and consideration of a wide range of factors. It is important to have a clear understanding of the location, resources, regulations, financing, and most importantly the oil drilling equipment and technology, such as oil and gas valves that will be used to make the operation a success.

The oil rig equipment used in the oil and gas industry are highly complex structures made of tough components. They are manufactured to be very strong and durable as that’s the only way the resources under the earth can be obtained. To know these oilfield tools and get a better understanding of their functions, we’ve prepared this article for you, along with the different oil drilling processes and some other details.

Vertical drilling: This is the most traditional method of drilling for oil. A vertical well is drilled straight down into the earth to reach the oil deposit. This method is typically used for shallower oil deposits or for drilling into a specific layer of rock.

Horizontal drilling: This method involves drilling a well at an angle, typically between 80 and 90 degrees, to reach a specific layer of rock. Horizontal drilling is used to access oil deposits that are not located directly underneath the surface.

Directional drilling: This method is a combination of vertical and horizontal drilling. A well is drilled vertically to a certain point, then turns and drills horizontally to reach the oil deposit. This method is used to access oil deposits that are not located directly underneath the surface or to drill around obstacles.

Offshore drilling: This method involves drilling for oil in the ocean. Offshore drilling typically takes place in deep waters, and the wells are drilled from platforms or ships.

An oil rig is an essential onshore and offshore drilling tool. This large tool has many moving parts, with each having distinct functions in extracting oil and gas from the earth’s crust safely.

Drill pipe: The drill pipe is the long, hollow tube that connects the surface equipment to the drill bit and is used to pump drilling fluid to the bit.

Drill collar: The drill collar is a thick-walled, heavy piece of pipe located above the drill bit that helps to maintain the weight on the bit and prevent the drill pipe from bending.

Kelly: The kelly is a square or hexagonal piece of pipe that is used to connect the drill pipe to the swivel and rotates with the drill pipe to turn the bit.

Mud pump: The mud pump is used to pump drilling fluid (or “mud”) down the drill pipe and out of the drill bit, helping to cool and lubricate the bit and carry cuttings to the surface.

Top drive: A mechanical device that is used to rotate the drill string and apply weight to the drill bit. It’s mounted on the derrick above the rotary table.

This is the tall, heavy tower that serves as a lifting device. Without the derrick, there’s no way the drill string can be lifted. And the drill string plays an important role in the operation of the system, so the derrick counts a lot.

This is a motor suspended from the derrick; it’s responsible for turning the drill string and enhancing the process of drilling a borehole into the ground. The top drive acts as an ideal alternative to the rotary table since it allows for drilling longer sections of pipe.

Just as the name implies, it’s a pump that helps move and circulate fluid through the oil drill system. It dispenses fluid down the drill string and back up the annulus under high pressure.

One of the essential oil exploration tools for locations that have many sand deposits. Sand pump is used for oil or fluid tanks that are filled with sand. It rotates around the central axis using a grooved disk to move the sand to somewhere off the site.

This oil rig equipment separates the cuttings of the oil well from the drilling fluid by running the shales through a vibrating screen. With this, the fluid will be able to flow back into the well for reuse, hence saving cost.

This tool removes the entrained gas within the drilling fluid or mud to reduce hydrostatic pressure. There are two types: centrifugal degasser and vacuum degasser. The centrifugal degasser is less efficient than the former.

During drilling, oil can come out of the oil well under high pressure. This can be disastrous if the operator doesn’t control the pressure. But with the blowout preventer, the uncontrollable release of natural crude oil from the oil well can be controlled to safety. It has an industrial ball valve that can close the fluid flow.

Leading companies in the industry, up to oil & gas valves and butterfly valve manufacturers are inclined to invest in technological development to ensure security and safety of oil drilling equipment. In fact, to meet the increasing demand of the market, the oil and gas industry is moving towards including unconventional sources of energy production.

Oil drilling is a complex and highly regulated process that requires a significant investment of time, money, and equipment. Before starting an oil drilling operation, there are several major considerations that must be taken into account to ensure that the project is successful.

Power Systems: An oil drilling system cannot be operated without adequate power supply, which is primarily derived from the large diesel engine. The power system is installed on the rig, usually at the ground level.

Resources: Another major consideration when starting oil drilling is the resources that will be required for the operation. This includes equipment, personnel, and materials. It is important to have a clear understanding of the costs associated with these resources, as well as the availability of them in the area.

Regulation: Oil drilling is a highly regulated industry, and it is important to be familiar with the regulations that apply to the operation, such as the API and ASME. This includes obtaining the necessary permits and approvals, as well as compliance with environmental and safety regulations.

Financing: Starting an oil drilling operation requires a significant investment of capital. It is important to have a clear understanding of the costs associated with the project and to secure the necessary financing. This includes identifying potential investors and lenders, as well as understanding the terms and conditions of any funding.

Technology: The oil and gas industry is constantly evolving, and it is important to stay up-to-date with the latest technology and techniques. This includes advancements in drilling methods, safety and environmental protection, as well as data analysis and management.

Besides the essential oil drilling equipment mentioned in this guide, another very important tool is the valve. It ensures the smooth flow of fluid and acts fast in opening and stopping the flow.

Serving as one of the leading industrial valve manufacturers, Dombor supplies different types of valves, including ball valves, butterfly valves, gate valves, globe valves, check valves, and many more that assist in regulating the flow of fluid and smoothening the oil drilling operation. To get the best products and enjoy outstanding services, you can reach out to us, one of the reliable valves manufacturers.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

According to World Oil, new investments in exploration of new oil wells have taken the U-turn, subsequently pushing shale gas and oil drilling activities most prominently in North America, Argentina, and China

Estimated to surpass the valuation of US$ 800 Mn, the market is pegged for over 4% year on year revenue growth in 2019. Onshore applications of mud pumps hold clear dominance over offshore, and accounts for over 70% share of the mud pumps market revenue.

Growing oilfield explorations and land drilling activities will continue to encourage mud pumps demand, according to Persistence Market Research. In its recently released intelligence study, PMR offers exclusive insights on the competition landscape of global mud pumps market. The study analyses the market performance over an eight-year projection period, i.e. 2018-2026.

A senior research analyst refers to the global market for mud pumps as a moderately consolidated landscape, around 55% of which belongs to the top 10 performers.

The analyst explains, "Tier 1 manufacturers of mud pumps account for an average 40% value share in market, whereas over 50% share is contributed by Tier 2 companies. While market leaders are zooming in on NPD for R&D investments, innovation and direct distribution are also the most commonly used differentiating strategies". Elaborating further on competition tracking, the analysts says, "Key market players are concentrating more on strengthening their regional footprint and entering new territories. They are thus prominently opting for strategic collaborations and joint ventures with leading regional players, in addition to frequent M&A of regionally active distributors".

Owing to the slumping oil & gas industry over the recent past, drilling rig equipment has faced substantially dwindling revenue till 2017. The scenario is however gradually improving since this year.

According to World Oil, new investments in exploration of new oil wells have taken the U-turn, subsequently pushing shale gas and oil drilling activities most prominently in North America, Argentina, and China.

On the backdrop of towering oil & gas prices due to lowering production, a recent appeal by IEA (International Energy Agency) asks the OPEC and non-OPEC countries to up their oil & gas production output. The demand for new oil wells is thus likely to create a plethora of growth opportunities for manufacturers of mud pumps and other drilling equipment.

As oil well explorations at remote sites is constantly on the rise, manufacturers of mud pumps are innovating their existing product lines to cater to demands of remote sites such as efficient operability in a wide range of environmental conditions. Regional oil & gas industry players are focusing on strategically acquiring specialized contractors for remote site projects.

Mud Pumps Market Segmentation by Key Players National Oilwell Varco, Gardner Denver, Schlumberger Limited (Cameron International), WeatherFord International plc, Flowserve Corporation, CNPC Baoji Oilfield Machinery Co., Ltd., Honghua Group Ltd., MHWirthTrevi Group (Drillmec), Bentec GmbH Drilling & Oilfield Systems:https://www.persistencemarketresearch.com/market-research/mud-pumps-market.asp

Although triplex mud pumps have been holding the lion"s share of over 65% in the global market revenue primarily due to their lightweight and cost effective attributes, the consistent quest for advanced technological features and superior performance has been introducing a number of innovative mud pumps in the market. The most recent of these innovations include hexa mud pumps, quintuplex mud pumps, and quadraplex mud pumps.

For advanced technology drilling rigs, a majority of manufacturers are prioritizing development of quintuplex mud pumps owing to their ability to deliver a significantly improved flow rate that eventually curtails overall operational costs. PMR projects that the revenue growth of quintuplex mud pumps will reach its peak in 2019, i.e. above 4%.

Sustained activities for hydrocarbon exploration, coupled with strong presence of a majority of mud pumps manufacturers, enable North America to secure the top market position in terms of mud pumps demand. Onshore applications are likely to witness around 5% year on year revenue growth in the next couple of years, which is clearly due to ever-increasing hydraulic fracturing and shale gas exploration activities in the region.

On the other side, Chinese market for mud pumps is slated for considerable expansion owing to the discovery of new oil reservoirs within Western China, according to Persistence Market Research.

Do you wish to keep your jobsite clean and save money at the same time? Then the MUDPUPPY 255 - 2SC might be the perfect choice for you. Thanks to this Mud Puppy you will significantly reduce the wear of the mud pump, drill string and other essential parts of your drill. The MUDPUPPY 255 - 2SC is the bigger brother of the MUD PUPPY 170 - 2SC and therefore has a larger patent Mud Tank. You can set up the MudPuppy in just a few minutes. No settling pit to dig and fill. You only need 3.785 litres of water. Clean mud means a clean hole. The job site will be clean and dry. With this machine you can mix only the amount of mud needed to drill the hole.

Our MudPuppy continues to sell because of its effectiveness in the field. Backed by quality and a guarantee, the MudPuppy of our partner will perform around the clock (24 hours a day, 7 days a week, not like other machines on the market) for your drilling project.

8613371530291

8613371530291