drilling formulas mud pump output brands

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Bourgoyne, A.J.T., Chenevert , M.E. & Millheim, K.K., 1986. SPE Textbook Series, Volume 2: Applied Drilling Engineering, Society of Petroleum Engineers.

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

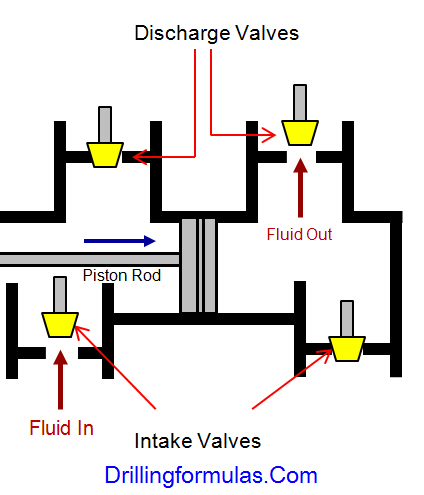

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

The driller’s method requires two circulations to kill the well. The first circulation is to circulate influx out of the well with original mud weight. The second circulation is to kill the well with kill weight fluid. During the first circulation, the bottom hole pressure remains constant due to maintain drill pipe pressure constant while circulating. For the second circulation, in order to maintain constant bottom hole pressure, casing pressure is held constant while circulating kill mud to the bit. Once the kill mud passes the bit, the drill pipe pressure will be held constant until the kill weight mud is on surface and there is no sign of influx in the annulus.

The Wait and Weight method requires only one circulation. The influx will be circulated out while the kill weight mud is displaced into the well simultaneously. While pumping the kill fluid from surface to the bit, drill pipe pressure schedule must be strictly followed. After that the drill pipe pressure is maintained constant until the kill mud returns back to surface. Some people call the Wait and Weight method as “Engineer’s Method” because there are more calculations compared to the Driller’s method.

For W&W method, kill weight mud must be prepared prior to circulation therefore the drill string is in static condition with no circulation for a while. There is high chance for wellbore to collapse and pack the drillstring.

Shoe will be exerted the maximum pressure when top of gas kick is at the casing shoe. Once the gas pass the shoe, the shoe pressure will remain constant. The W&W can reduce shoe pressure when the kill weight mud goes into the annulus before the top of gas arrives at shoe. If you have larger drillstring volume than annular volume, you will not be able to lower the shoe pressure using Wait and Weight method. However, if time to prepare the kill weight mud is very long, gas migration will increase shoe pressure. There will be a possibility that using W&W can create more shoe pressure due to gas migration while preparation of drilling mud.

Nowadays, oil-based drilling fluid is widely used for drilling operation. Gas will be soluble in oil based mud and it will not be able to detect at the bottom. Gas may expand when it moves almost to the surface and it is often above the shoe. Hence, W&W will not help reduce shoe pressure.

Around the world, there are a lot of drilling rigs which don’t have great capability to mix drilling fluid effectively, therefore, kill weight mud cannot not be mixed as quickly as the operation required for killing the well using W&W. The Driller’s Method will not have this issue because the circulation can be performed right away. Waiting for preparing kill weight mud for a long time can lead to increasing in shoe and surface pressure due to migration of gas.

If the bit nozzles are plugged during the first circulation of Driller’s method, drill pipe pressure is allowed to increase temporary by maintaining casing pressure constant until the drill pipe pressure stabilizes and then the new circulating pressure. During the second circulation of Driller’s method, if the plugged nozzles are encountered, casing pressure must maintain until the kill mud to the bit and then change to hold drill pipe pressure shown on the gauge.

Well ballooning effect is a natural phenomenon occurring when formations take drilling mud when the pumps are on and the formations give the mud back when the pumps are off. When ballooning is observed, it must be treated as kick. If W&W is utilized to manage this issue at the beginning, the additional mud weight can increase complexity of wellbore ballooning situation. More mud weight can induce more mud losses and the situation will be worse. Since the Driller’s method does not require additional mud weight hence there is no increasing in wellbore pressure. Therefore, the ballooning situation will not become worse.

Deepwater condition is high-pressure and low-temperature conditions which are ideal case for hydrate. Therefore, there is a high chance of hydrate formation in choke/kill lines and BOP when gas influx is taken in a deepwater well. Driller’s method will minimize hydrate issue because the circulation is established as soon as possible. The mud is still warm and the hydrate issue can possibly be mitigated. Conversely, killing the well using wait and weight method requires longer time to shut in because the kill mud must be properly prepared prior to circulating. The static condition will make the mud cool and it is a favorable condition for hydrate formation due to decreasing in temperature of drilling fluid.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Arindam Mukherjee Generally oil rig which may be a land rig in onshore region and submersible or jack up rig in offshore rig has been established after the detection of oil in "Airborne seismic geophysical survey".The flow parameter like "Mud weight", "Drilling fluid density" and " Specific gravity(SG)" have an impact on the control of pressure gradient .This pressure gradient have a clear relation to control the annular velocity of drilling fluid .

The sidewise figure have a clear indication that if the pressure difference will be maximum then the velocity of the drilling fluid at any of the section . So the control of "Pressure gradient" by drilling formulas that are related to the " Mud weight " , "Specific gravity of the drilling fluid" and "drilling fluid density"is the main fundamental thing to control the annulus velocity and again if we wont control the pressure gradient there will be lots of "Turbulence flow" instead of "Laminar flow" which may hamper the oil well stability .That is why control of "Annulus velocity" is important.

Again ,"Annular velocity" depend on the flow rate of drilling fluid .The flow rate of the drilling fluid is mainly control by pump output and if the pump output will be maximum then flow rate will be maximum and the pump output definitely depends on stroke length (S),liner diameter (D) and strokes per minute(SPM).If the liner diameter(D) is small then we can reduce the flow rate of mud , so if we have to reduce the flow rate of mud always we have to use small size of liner and also bigger the stroke length(S) can reduce the flow rate of pump to the oil well and in case of MDR (maximum drilling rate) which has been occured in control drilling specially in large diameter oil well annular velocity is an important factor , as "mud weight out" and " mud weight in" control the MDR and " Mud weight " is an important factor to control the annular velocity of drilling oil well . In case of " Duplex pump" rod diameter is an important parameter to control the flow rate of the mud . Generally smaller the " Rod diameter " smaller the flow rate .

Again "Annular velocity" of a fluid medium definitely depends on the "What type of fluid we are using whether it is Newtonian or Non-Newtonian " . Generally in Non -Newtonian fluid have less annular velocity than Newtonian liquid . The suspended mud particles here enhance the viscosity of drilling fluids and makes a tendency towards rheologically rigid fluidous behavior .and again if we mixed bentonite+Silica gel along with the mud , then "Annular velocity(AV)" get reduced .So , we can reduced the "Annular velocity "if we reduced its tendency towards pseudo elastic behavior .

"Circulation rate(Q)(gpm) is an important factor to control the annular velocity .generally maximum circulation rate has been occured within a Newtonian fluid .but as we are dealing with the Non- Newtonian liquid this fundamental thing doesnt matter .but "Annular velocity" is directly proportional circulation ratebut maximum circulation within the annulus may create the turbulence within the annulus section which may hampered the oil well drilling .

Inside Casing diameter(Dh) and Outside diameter of drill pipe (Dp) has a high impact on the control of annular velocity . as they are generally related to the lower most drilling formula :- AV(ft/min)=PO(bbl/min)*1029.4(Dh2 -Dp2) , where AV=Annular velocity(ft/min) and PO=Pump output(bbl/min)

Again Annular velocity of the mud or any type drilling fluid may hampered by the amount of total solids(Wcg) generated within the drilling hole .because exceptional amount of cuttings may create additional pressure on the wall of the drill pipe and the total solid generated within the drilling system may be calculated from the lowermost equation Wcg=350ch*L(1-P)SG ( where Wcg= Solids generated in pounds , Ch=capacity of the hole, bbl/ft, L= footage drilled , ft, SG= specific gravity of cuttings ,P=Porosity%) .

And finally the "Annular velocity " of no of Tubing section(T1,T2,T3) lowered in the oil well during telescopic drilling .As annular Velocity is directly proportional to annular capacity and this annular capacity will be maximum in the conductor casing and minimum in the liner section upto casing shoe .

So the parameter which maintain the Annular velocity depends on the several factor which can be calculated from the drilling equations . I shared my knowledge on this topic . Thank you for reading the article . stay connected and provides more and more idea .

Oil and Gas drilling process - Pupm output for Triplex and Duplex pumpsTriplex Pump Formula 1 PO, bbl/stk = 0.000243 x ( in) E.xample: Determine the pump output, bbl/stk, at 100% efficiency for a 7" by 12". triplex pump: PO @ 100%,= 0.000243 x 7 x12 PO @ 100% = 0.142884bbl/stk Adjust the pump output for 95% efficiency: Decimal equivalent = 95 + 100 = 0.95 PO @ 95% = 0.142884bbl/stk x 0.95 PO @ 95% = 0.13574bbl/stk Formula 2 PO, gpm = [3(D x 0.7854)S]0.00411 x SPM where D = liner diameter, in. S = stroke length, in. SPM = strokes per minute Determine the pump output, gpm, for a 7" by 12". triplex pump at 80 strokes per minute: PO, gpm = [3(7 x 0.7854) 1210.00411 x 80 PO, gpm = 1385.4456 x 0.00411 x 80 PO = 455.5 gpm

Example:Duplex Pump Formula 1 0.000324 x (liner diameter, in) x ( stroke lengh, in) = ________ bbl/stk -0.000162 x (rod diameter, in) x ( stroke lengh, in) = ________ bbl/stk Pump out put @ 100% eff = ________bbl/stk Example: Determine the output, bbl/stk, of a 5 1/2" by 14" duplex pump at 100% efficiency. Rod diameter = 2.0": 0.000324 x 5.5 x 14 = 0.137214bbl/stk -0.000162 x 2.0 x 14 = 0.009072bbl/stk Pump output @ 100% eff. = 0.128142bbl/stk Adjust pump output for 85% efficiency: Decimal equivalent = 85 100 = 0.85 PO@85%)= 0.128142bbl/stk x 0.85 PO@ 85% = 0.10892bbl/stk Formula 2

PO. bbl/stk = 0.000162 x S[2(D) - d] where S = stroke length, in. D = liner diameter, in. d = rod diameter, in. Example: Determine the output, bbl/stk, of a 5 1/2". by 14". duplex pump @ 100% efficiency. Rod diameter = 2.0in.: PO@100%=0.000162 x 14 x [ 2 (5.5) - 2 ] PO @ 100%)= 0.000162 x 14 x 56.5 PO@ 100%)= 0.128142bbl/stk Adjust pump output for 85% efficiency: PO@85%,= 0.128142bb/stkx 0.85 PO@8.5%= 0.10892bbl/stk Metric calculation Pump output, liter/min = pump output. liter/stk x pump speed, spm. S.I. units calculation Pump output, m/min = pump output, liter/stk x pump speed, spm. Mud Pumps Mud pumps drive the mud around the drilling system. Depending on liner size availability they can be set up to provide high pressure and low flow rate, or low pressure and high flow rate. Analysis of the application and running the Drill Bits hydraulics program will indicate which liners to recommend. Finding the specification of the mud pumps allows flow rate to be calculated from pump stroke rate, SPM. Information requiredo Pump manufacturer o Number of pumps o Liner size and gallons per revolution Weight As a drill bit cutting structure wears more weight will be required to achieve the same RoP in a homogenous formation. PDC wear flats, worn inserts and worn milled tooth teeth will make the bit drill less efficiently. Increase weight in increments of 2,000lbs approx. In general, weight should be applied before excessive rotary speed so that the cutting structure maintains a significant depth of cut to stabilise the bit and prevent whirl. If downhole weight measurements are available they can be used in combination with surface measurements to gain a more accurate representation of what is happening in the well bore.

Oil well control is the management of the dangerous effects caused by the unexpected release of formation fluid, such as natural gas and/or crude oil, upon surface equipment of oil or gas drilling rigs and escaping into the atmosphere. Technically, oil well control involves preventing the formation gas or fluid (hydrocarbons), usually referred to as kick, from entering into the wellbore during drilling or well interventions.

Formation fluid can enter the wellbore if the pressure exerted by the column of drilling fluid is not great enough to overcome the pressure exerted by the fluids in the formation being drilled (pore pressure).

Oil well control is one of the most important aspects of drilling operations. Improper handling of kicks in oil well control can result in blowouts with very grave consequences, including the loss of valuable resources and also lives of field personnel. Even though the cost of a blowout (as a result of improper/no oil well control) can easily reach several millions of US dollars, the monetary loss is not as serious as the other damages that can occur: irreparable damage to the environment, waste of valuable resources, ruined equipment, and most importantly, the safety and lives of personnel on the drilling rig.

In order to avert the consequences of blowout, the utmost attention must be given to oil well control. That is why oil well control procedures should be in place prior to the start of an abnormal situation noticed within the wellbore, and ideally when a new rig position is sited. In other words, this includes the time the new location is picked, all drilling, completion, workover, snubbing and any other drilling-related operations that should be executed with proper oil well control in mind.

HSP = 0.052 × MW × TVD", where MW (Mud Weight or density) is the drilling-fluid density in pounds per gallon (ppg), TVD is the true vertical depth in feet and HSP is the hydrostatic pressure in psi.

Formation pressure is the pressure exerted by the formation fluids, which are the liquids and gases contained in the geologic formations encountered while drilling for oil or gas. It can also be said to be the pressure contained within the pores of the formation or reservoir being drilled. Formation pressure is a result of the hydrostatic pressure of the formation fluids, above the depth of interest, together with pressure trapped in the formation. Under formation pressure, there are 3 levels:

The normal hydrostatic pressure gradient for freshwater is 0.433 pounds per square inch per foot (psi/ft), or 9.792 kilopascals per meter (kPa/m), and 0.465 psi/ft for water with dissolved solids like in Gulf Coast waters, or 10.516 kPa/m. The density of formation water in saline or marine environments, such as along the Gulf Coast, is about 9.0 ppg or 1078.43 kg/m3. Since this is the highest for both Gulf Coast water and fresh water, a normally pressured formation can be controlled with a 9.0 ppg mud.

As discussed above, once the fluids are trapped within the formation and not allow to escape there is a pressure build-up leading to abnormally high formation pressures. This will generally require a mud weight of greater than 9.0 ppg to control. Excess pressure, called "overpressure" or "geopressure", can cause a well to blow out or become uncontrollable during drilling.

Pump pressure, which is also referred to as system pressure loss, is the sum total of all the pressure losses from the oil well surface equipment, the drill pipe, the drill collar, the drill bit, and annular friction losses around the drill collar and drill pipe. It measures the system pressure loss at the start of the circulating system and measures the total friction pressure.

Slow pump pressure is the circulating pressure (pressure used to pump fluid through the whole active fluid system, including the borehole and all the surface tanks that constitute the primary system during drilling) at a reduced rate. SPP is very important during a well kill operation in which circulation (a process in which drilling fluid is circulated out of the suction pit, down the drill pipe and drill collars, out the bit, up the annulus, and back to the pits while drilling proceeds) is done at a reduced rate to allow better control of circulating pressures and to enable the mud properties (density and viscosity) to be kept at desired values. The slow pump pressure can also be referred to as "kill rate pressure" or "slow circulating pressure" or "kill speed pressure" and so on.

In Canada the formula is depth in meters x density in kgs x the constant gravity factor (0.00981), which will give the hydrostatic pressure of the well bore or (hp) hp=bhp with pumps off.

Fluid level drop is the distance the mud level will drop when a dry string(a bit that is not plugged) is being pulled from the wellbore and it is given by:

Kick is the entry of formation fluid into the wellbore during drilling operations. It occurs because the pressure exerted by the column of drilling fluid is not great enough to overcome the pressure exerted by the fluids in the formation drilled. The whole essence of oil well control is to prevent kick from occurring and if it happens to prevent it from developing into blowout. An uncontrolled kick usually results from not deploying the proper equipment, using poor practices, or a lack of training of the rig crews. Loss of oil well control may lead into blowout, which represents one of the most severe threats associated with the exploration of petroleum resources involving the risk of lives and environmental and economic consequences.

Tripping is the complete operation of removing the drillstring from the wellbore and running it back in the hole. This operation is typically undertaken when the bit (which is the tool used to crush or cut rock during drilling) becomes dull or broken, and no longer drills the rock efficiently. A typical drilling operation of deep oil or gas wells may require up to 8 or more trips of the drill string to replace a dull rotary bit for one well.

Tripping out of the hole means that the entire volume of steel (of drillstring) is being removed, or has been removed, from the well. This displacement of the drill string (the steel) will leave out a volume of space that must be replaced with an equal volume of mud. If the replacement is not done, the fluid level in the wellbore will drop, resulting in a loss of hydrostatic pressure (HSP) and bottom hole pressure (BHP). If this bottom hole pressure reduction goes below the formation pressure, a kick will definitely occur.

Swabbing occurs when bottom hole pressure is reduced due to the effects of pulling the drill string upward in the bored hole. During the tripping out of the hole, the space formed by the drillpipe, drill collar, or tubing (which are being removed) must be replaced by something, usually mud. If the rate of tripping out is greater than the rate the mud is being pumped into the void space (created by the removal of the drill string), then swab will occur. If the reduction in bottom hole pressure caused by swabbing is below formation pressure, then a kick will occur.

If the density of the drilling fluid or mud in the well bore is not sufficient to keep the formation pressure in check, then a kick can occur. Insufficient density of the drilling fluid can be as a result of the following :

Another cause of kicks is drilling accidentally into abnormally-pressured permeable zones. The increased formation pressure may be greater than the bottom hole pressure, resulting in a kick.

large number of directional wells are drilled from the same platform. If the drilling well penetrates the production string of a previously completed well, the formation fluid from the completed well will enter the wellbore of the drilling well, causing a kick. If this occurs at a shallow depth, it is an extremely dangerous situation and could easily result in an uncontrolled blowout with little to no warning of the event.

Improper fill on trip occurs when the volume of drilling fluid to keep the hole full on a Trip (complete operation of removing the drillstring from the wellbore and running it back in the hole) is less than that calculated or less than Trip Book Record. This condition is usually caused by formation fluid entering the wellbore due to the swabbing action of the drill string, and, if action is not taken soon, the well will enter a kick state.

A sudden increase in penetration rate (drilling break) is usually caused by a change in the type of formation being drilled. However, it may also signal an increase in formation pore pressure, which may indicate a possible kick.

If the rate at which the pumps are running is held constant, then the flow from the annulus should be constant. If the annulus flow increases without a corresponding change in pumping rate, the additional flow is caused by formation fluid(s) feeding into the well bore or gas expansion. This will indicate an impending kick.

If there is an unexplained increase in the volume of surface mud in the pit (a large tank that holds drilling fluid on the rig), it could signify an impending kick. This is because as the formation fluid feeds into the wellbore, it causes more drilling fluid to flow from the annulus than is pumped down the drill string, thus the volume of fluid in the pit(s) increases.

A decrease in pump pressure or increase in pump speed can happen as a result of a decrease in hydrostatic pressure of the annulus as the formation fluids enters the wellbore. As the lighter formation fluid flows into the wellbore, the hydrostatic pressure exerted by the annular column of fluid decreases, and the drilling fluid in the drill pipe tends to U-tube into the annulus. When this occurs, the pump pressure will drop, and the pump speed will increase. The lower pump pressure and increase in pump speed symptoms can also be indicative of a hole in the drill string, commonly referred to as a washout. Until a confirmation can be made whether a washout or a well kick has occurred, a kick should be assumed.

wellbore greater than the pressure of the fluids in the formation being drilled, but less than formation fracture pressure. It uses the mud weight to provide sufficient pressure to prevent an influx of formation fluid into the wellbore. If hydrostatic pressure is less than formation pressure, then formation fluids will enter the wellbore. If the hydrostatic pressure of the fluid in the wellbore exceeds the fracture pressure of the formation, then the fluid in the well could be lost into the formation. In an extreme case of lost circulation, the formation pressure may exceed hydrostatic pressure, allowing formation fluids to enter into the well.

Secondary oil well control is done after the Primary oil well control has failed to prevent formation fluids from entering the wellbore. This process uses "blow out preventer", a BOP, to prevent the escape of wellbore fluids from the well. As the rams and choke of the BOP remain closed, a pressure built up test is carried out and a kill mud weight calculated and pumped inside the well to kill the kick and circulate it out.

Shut-in procedures are usually developed and practiced for every rig activity, such as drilling, tripping, logging, running tubular, performing a drill stem test, and so on. The primary purpose of a specific shut-in procedure is to minimize kick volume entering into a wellbore when a kick occurs, regardless of what phase of rig activity is occurring. However, a shut-in procedure is a company-specific procedure, and the policy of a company will dictate how a well should be shut-in.

Source:shut-in on a kick, proper kill procedures must be done immediately. The general idea in well kill procedure is to circulate out any formation fluid already in the wellbore during kick, and then circulate a satisfactory weight of kill mud called Kill Weight Mud (KWM) into the well without allowing further fluid into the hole. If this can be done, then once the kill mud has been fully circulated around the well, it is possible to open up the well and restart normal operations. Generally, a kill weight mud (KWM) mix, which provides just hydrostatic balance for formation pressure, is circulated. This allows approximately constant bottom hole pressure, which is slightly greater than formation pressure to be maintained, as the kill circulation proceeds because of the additional small circulating friction pressure loss. After circulation, the well is opened up again.

There will always be potential oil well control problems, as long as there are drilling operations anywhere in the world. Most of these well control problems are as a result of some errors and can be eliminated, even though some are actually unavoidable. Since we know the consequences of failed well control are severe, efforts should be made to prevent some human errors which are the root causes of these incidents. These causes include:

An effective oil-well-control culture can be established within a company by requiring well control training of all rig workers, by assessing well control competence at the rigsite, and by supporting qualified personnel in carrying out safe well control practices during the drilling process. Such a culture also requires personnel involved in oil well control to commit to following the right procedures at the right time. Clearly communicated policies and procedures, credible training, competence assurance, and management support can minimize and mitigate well control incidents. An effective well control culture is built upon technically competent personnel who are also trained and skilled in crew resource management (a discipline within human factors), which comprises situation awareness, decision-making (problem-solving), communication, teamwork, and leadership. Training programs are developed and accredited by organizations such as the International Association of Drilling Contractors (IADC) and International Well Control Forum (IWCF).

IADC, headquartered in Houston, TX, is a nonprofit industry association that accredits well control training through a program called WellSharp, which is aimed at providing the necessary knowledge and practical skills critical to successful well control. This training comprises drilling and well servicing activities, as well as course levels applicable to everyone involved in supporting or conducting drilling operations—from the office support staff to the floorhands and drillers and up to the most-experienced supervisory personnel. Training such as those included in the WellSharp program and the courses offered by IWCF contribute to the competence of personnel, but true competence can be assessed only at the jobsite during operations. Therefore, IADC also accredits industry competence assurance programs to help ensure quality and consistency of the competence assurance process for drilling operations. IADC has regional offices all over the world and accredits companies worldwide. IWCF is an NGO, headquartered in Europe, whose main aim is to develop and administer well-control certification programs for personnel employed in oil-well drilling and for workover and well-intervention operations.

Jerome Schubert, "Managed-Pressure Drilling: Kick Detection and Well Control" Section: "Kick Detection While Drilling", Society of Petroleum Engineers, Journal of Petroleum Technology (JPT), archived 2010/01/15.

Mr. Carter has over fifty five years" experience in domestic and international engineering and management positions in the area of drilling, completion and E&P waste management with Conoco, Baroid, and several other drilling contractors. He has conducted seminars and schools on fluids, rig equipment, and drilling engineering related subjects associated with drilling optimization, cost reduction, and well control. Tom has served as Chairman of the API standardization committee (SC 13) on Drilling and Completion Fluid Materials. He was a SPE Distinguished Lecturer in 1993 and served as the Editor of the SPE reprint series book on drilling fluids. Currently, he is a member of the Chevron Clear Leader Center serving as a Technical Learning Advisor in Houston. He coordinates and has teaching participation in several subject areas such as Coiled Tubing Operations, Directional Drilling, Drilling Fluids, Drilling Practices, Fundamentals for Drilling and Completion, HPHT Drilling and Completions, and Solids Control and Waste Management. He is still active in several industry organizations and was President of the Houston chapter of the American Association of Drilling Engineers, Coordinator for the SPE North American Forum Series, Membership Chairman of the editorial committee for the Journal of Petroleum Technology and on the Board of Directors for the Ocean Energy Center Society (Ocean Star rig museum in Galveston). He has published 20 technical publications and holds five U.S. patents. He graduated with a BS in Geology from Centenary College in Shreveport, Louisiana in 1963.

8613371530291

8613371530291