drilling formulas mud pump output quotation

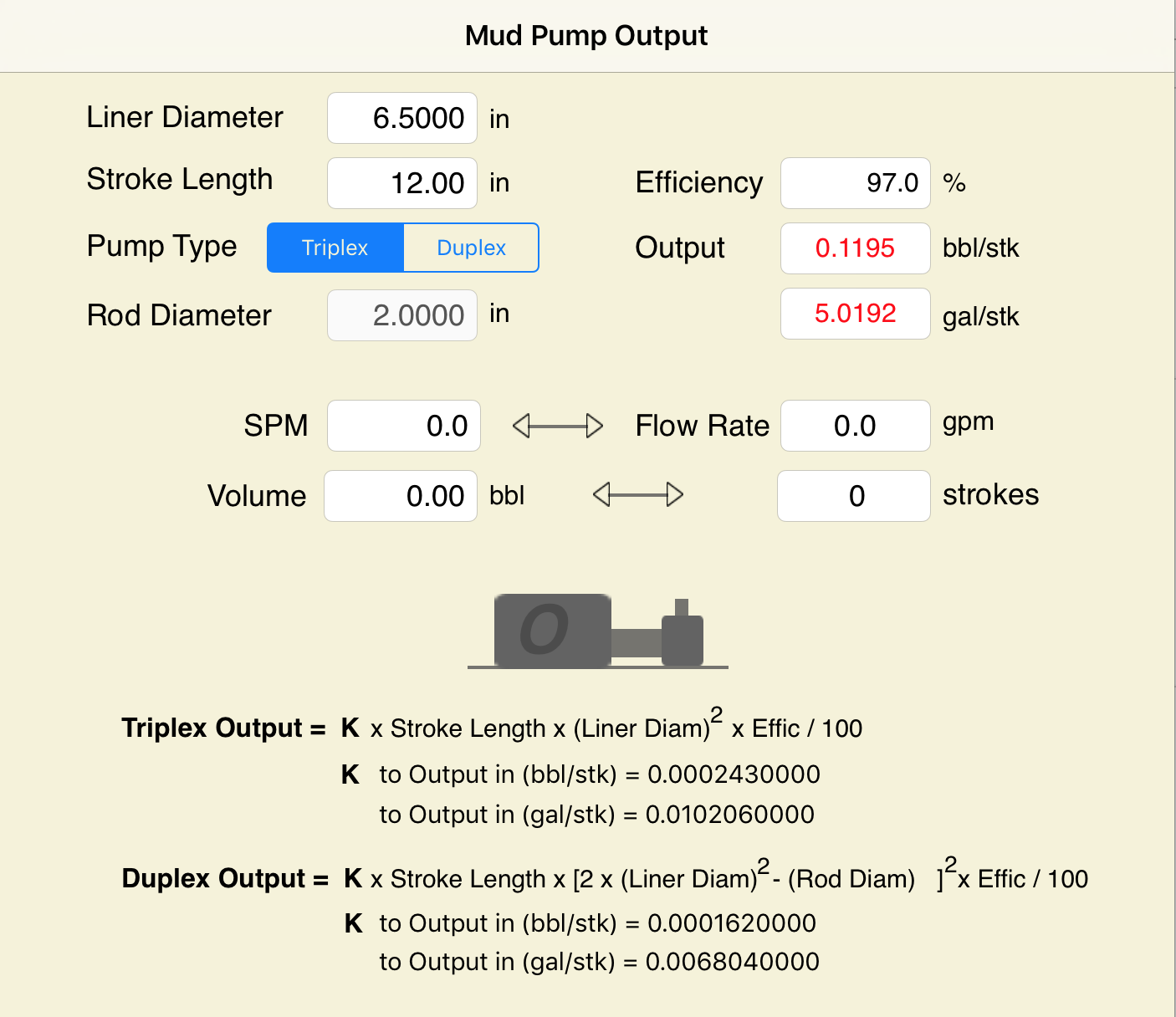

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Bourgoyne, A.J.T., Chenevert , M.E. & Millheim, K.K., 1986. SPE Textbook Series, Volume 2: Applied Drilling Engineering, Society of Petroleum Engineers.

Method 1: The concept of this method is to pump plugging material to plug the wash out. We will know how many stroks pump till pressure increase then we can calculate back where the washout is.

Method 2: The concept of this method is to pump material that can be easily observed from drill pipe pass through wash out into annular and over the surface. We can calculate the depth of washout bases on the combination volume of internal drill pipe volu

High-pressure mud pumps are positive displacement pumps. Simply, they convert mechanical power into hydraulic power. Their mechanical components (power ends) ar

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes, and why it is important? In order to understand that, you’ll need to know some basic information about mud pumps.

Knowing how a mud pump functions is important in understanding the role a pump stroke counter plays in rig operations. Mud pumps act as the heart of the drilling rig, similar to how our heart works. Just as our heart circulates blood throughout our bodies, a mud pump circulates essential drilling mud down the hole and back up to the surface. Mud tanks house drilling mud, and a mud pump draws the fluid from the mud pump. A piston draws mud in on the backstroke through the open intake valve and pushes mud through the discharge valve and sends it towards the rig. By circulating fluid, the mud pump ensures that the drill bit is cool and lubricated and that cuttings are flushed from the hole. The two main kinds of pumps used are duplex and triplex pumps, where the duplex pump has two pistons and the triplex pump has three. Whether the rig is using a duplex or triplex pump, it is important to know how many strokes per second the pistons are moving. The driller monitors strokes per minute to determine how much costly, yet essential, mud is being pumped into the system with the use of a mud pump stroke counter system. Now, that you know about mud pumps, you’ll need to know what’s in a stroke counter system.

Stroke Counter — The stroke counter stainless steel box is mounted on the driller’s console and is either square or rectangular in shape, depending on the number of pumps it is monitoring. Stroke counters will show strokes per minute and total strokes, and when a particular mud pump is operating the strokes/minute and total strokes will be displayed. Power is supplied by a 3.6 volt lithium battery, and the counter contains a crystal-controlled real time clock with 100 parts per million accuracy or better. Each counter is mounted to the console with 1/4” stainless steel hex head bolts, lock washers and nuts.

Micro Limit Switch — The micro switch is connected to a c clamp near the mud pump piston. The micro switch stainless steel rod (sometimes called a whisker) sticks out in the piston housing near the piston. As the piston passes the rod, it moves the rod and the switch sends an electronic signal back to the counter. The counter increases by one each time the piston moves the rod, counting the mud pump’s strokes. The switch’s signal is then transmitted to the stroke counter. These micro switches are built to stand up to demanding outdoor conditions. They can withstand shock, equipment vibration, extreme temperatures, water and dust.

Cable and Junction Box – A cable is connected to the back of the pump stroke counter and then to the junction box. From the junction box, the cables travel to the limit switches.

Pump Stroke Counters are like a blood pressure machine. Each time our heart pumps, a blood pressure machine reads our systolic and diastolic blood pressure by way of our pulse. A mud pump stroke counter functions in much the same way. Just as a blood pressure machine detects our pulse so too does a limit switch rod detect the movement of the piston. When the stainless steel rod is moved, the micro limit switch detects the movement. The signal is sensed as a contact closure, and it is transmitted to the stroke counter where the contact closure is converted to a logic pulse. The pulse feeds two separate circuits. The total strokes circuit reads and displays the closures one at a time, totaling them up to reveal the total strokes in the LED window. The second pulse is sent along a separate circuit which is a rate circuit. This rate circuit will average the closures against the real time clock. The result is displayed as the total strokes per minute.

Pump stroke counters are essential to drilling rig operations because they measure the efficiency of mud pumps. Knowing strokes per minute and total strokes of the pistons helps the driller to determine if the correct amount of mud is going down hole. Having this information aids in running a drilling rig at peak efficiency, assists in extending drill bit life, and avoids costly overuse of drilling rig mud. Unsure which pump stroke counter is right for your application? Give our friendly, knowledgeable staff a call or email. We’ll keep you turning right.

Mud pump liner selection in today"s drilling operations seldom (at best) considers electrical implications. Perhaps, with more available useful information about the relationships between mud pump liner size and operational effects on the electrical system, certain potential problems can be avoided. The intent of this paper is to develop those relationships and show how they affect an electrical system on example SCR rigs.Introduction

There, seems to be little consideration for the relationships between liner size and demand on a rig"s engine/generator set(s). Yet, consideration for this relationship can prove to be very helpful to drillers and operators in efficiency of a rig"s electrical system. In order to develop the relationships and help drillers and operators understand the importance of each, relationships between liner size, pump speed, pump pressure, and electrical power will be developed. Only basic physical laws will be used to develop the relationships; and, once developed, the relationships are readily applied to realistic examples utilizing a mud pump manufacturer"s pump data. Finally, conclusions will be drawn from the examples.DEVELOPMENT OF RELATIONSHIPS BASIC RELATIONSHIPS

where HHP= Hydraulic horsepower, GPM = Mud pump volumetric flow rate in gallons per minute, and PST Mud pump output pressure in pounds peer square inch.

Hydraulic horsepower is reflected to the mud pump motor via a multiplier for mechanical efficiency. it follows that motor horsepower is then represented by

Over the past several years, hundreds of oil field personnel have told me that they have enjoyed this book. Some use it as a secondary reference source, some use it as their primary source for formulas and calculations, and some use it to reduce the volume of materials they must carry to the rig floor or job site. Regardless of the reason people use it, the primary purpose of this book is to provide a convenient source of reference to those people who don’t use formulas and calculations on a regular basis.

In the preface to the first edition, I mentioned a driller who carried a briefcase full of books with him each time he went to the rig floor. I also spoke of a drilling supervisor who carried two briefcases of books. This book should reduce the number of books each of them needs to perform his job.

This book is still intended to serve oil field workers for the entirety of their careers. I have added several formulas and calculations, some in English field units and some in metric units. I have also added the Volumetric Procedure, the Lubricate and Bleed Procedure (both Volume and Pressure Methods), and stripping procedures (both the Strip and Bleed Procedure and the Combined Stripping and Volumetric Procedure).

This book has been designed for convenience. It will occupy very little space in anyone’s briefcase. It has a spiral binding so it will lay flat and stay open on a desk. The Table of Contents and the Index make looking up formulas and calculations quick and easy. Examples are used throughout to make the formulas as easy as possible to understand and work, and often exact words are used rather than symbols.

This book is dedicated to the thousands of oil field hands worldwide who have to use formulas and calculations, whether on a daily basis or once or twice a year, and who have problems remembering them. This book should make their jobs a little easier.

This chapter introduces the concept of density in oil field terminology, which refers to specific weight. Specific weight is in the units of lb/ft3 or lb/gallon (ppg). This chapter refers to the specific weight as mud weight. Density is used only when referring to the SI-metric values of kg/m3, kg/liter, and gram/cm3 (which are actual density values in that unit system) and for the term ECD. This chapter describes the mud weight, and specific gravity in USCS/British units and SI units. Following this, it provides an understanding of hydrostatic pressure using formulae and equations. It also explains pressure gradient in USCS/British units and SI units. Furthermore, it explains some capacity formulas for annular capacity between casing or hole and drill pipe, tubing, or casing. Finally, it illustrates some temperature and conversion formulas.

This chapter introduces the various units of weight that are used in the drilling profession. The use of the term densityin the book is explained as it pertains to the calculations presented in the book. Basic equations for mud weight and specific gravity are presented.

The term density as used in USCS/British oil field terminology is a slang term for a value that is actually specific weight. Specific weight is in the units of lb/ft³ or lb/gallon (ppg). Actual density in the USCS/British would be the specific weight term divided by 32.2 ft/sec² and would result in a USCS/British density of slug/ft³. Neither the density term nor the actual density term is used in this book. This book uses the term mud weight (MW) for specific weight (lb/ft³or ppg). Density is used only when referring to the SI-metric values of kg/m³, kg/liter, and gram/cm³ (which are actual density values in that unit system) and for the term ECD.

The most complete manual of its kind, this handy book gives you all the formulas and calculations you are likely to need in drilling operations. New updated material includes conversion tables into metric. Separate chapters deal with calculations for drilling fluids, pressure control, and engineering. Example calculations are provided throughout.

Presented in easy-to-use, step-by-step order, Formulas and Calculations is a quick reference for day-to-day work out on the rig. It also serves as a handy study guide for drilling and well control certification courses. Virtually all the mathematics required out on the drilling rig is here in one convenient source, including formulas for pressure gradient, specific gravity, pump output, annular velocity, buoyancy factor, volume and stroke, slug weight, drill string design, cementing, depth of washout, bulk density of cuttings, and stuck pipe.

8613371530291

8613371530291