drilling mud pump manual in stock

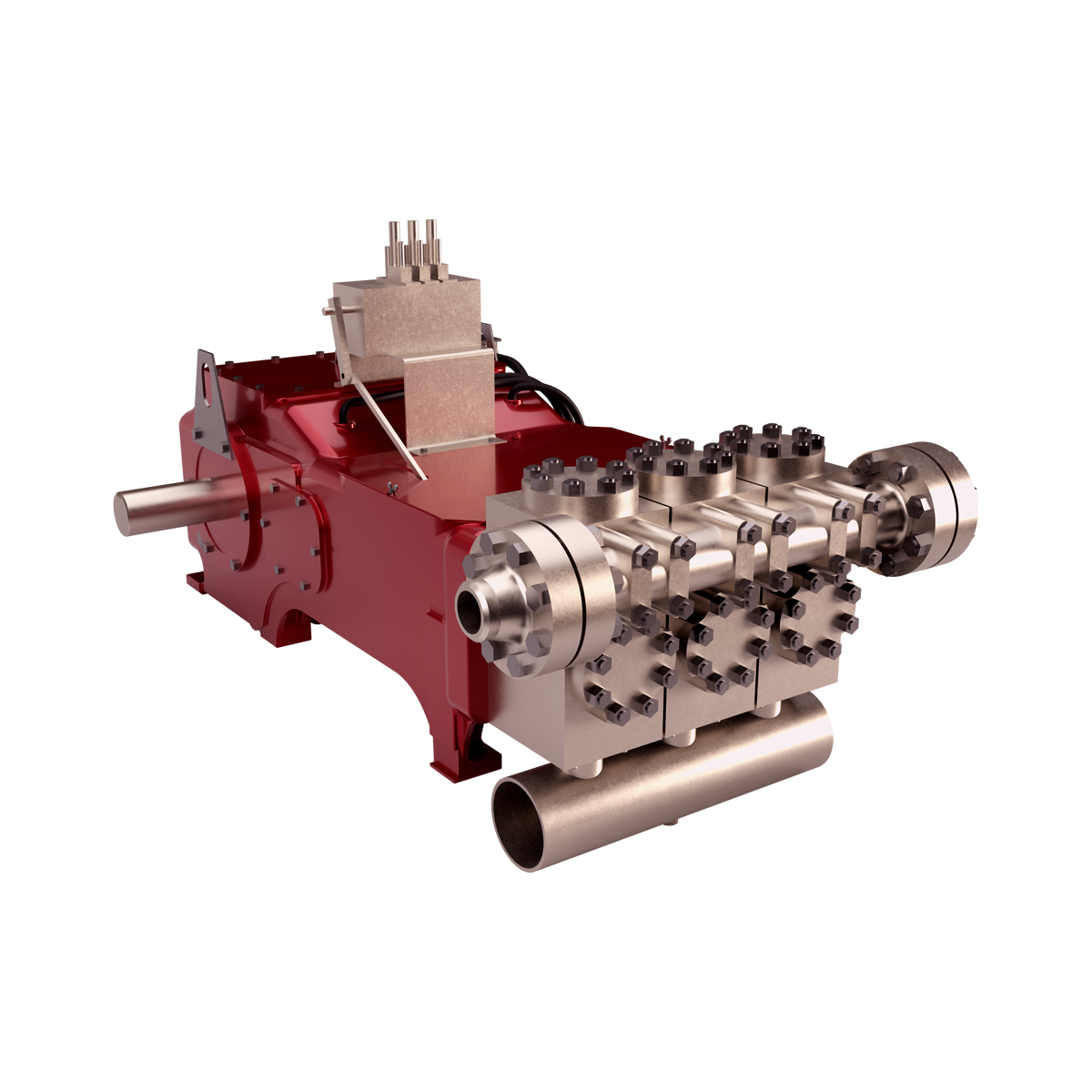

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

We stock fluid end parts for the5×6 mud pump, 5×6-1/4 FM45 mud pump, 5×8 mud pump, 5-1/2×8 mud pump, 5X10 mud pump, 4-1/2×5 mud pump, 7-1/2×8 mud pump, and 7-1/2X10 mud pump. The Gardner Denver mud pump model numbers for the above pumps are as follows: 5X6-FGFXG, 5X8-FDFXX, 5-1/2X8-FDFXX, 5X10-FDFXD, 4-1/2X5-FFFXF, 7-1/2X8-FYFXX, 7-1/2X10-FYFXD. We also handle Wheatley, Gaso, Worthington, Failing and Centerline parts and pumps. We also stock Foot Valve, Liner Puller, Valve Seat Puller, (4″ Inline Check Valve. Our Gardner Denver mud pump parts are not only competitively priced, they are also made in the USA. Oil Recommended by Gardner Denver. Call any of our experienced representatives to get the help and knowledge you deserve.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

What is the liner diameter of a triplex mud pump? click here for gardner denver mud pump operating and service manuals. the 2, 200- hp mud pump for offshore applications is a single- acting reciprocating triplex mud triplex mud pump manual pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. repair manuals - triplex pumps - industrial part relief valves industrial triplex pumps car wash triplex pumps stainless steel triplex pumps triplex field- proven mud pumps responsible for helping maintain drilling mud circulation throughout your drill string, quality mud pumps are essential parts of your equipment suite. service manual 3– 1– 606.

note: a triplex mud pump has three pump liners. 3– 1– 529 page 2 table of contents. triplex piston mud pumps for drilling companies with the need to pump slurries with bentonite, concrete, and other thick mud, elepump triplex, high pressure piston mud pumps are the ideal choice for long life and minimal maintenance. data input( see manufacturer " s site ) liner diameter, d liner length, l pump efficiency, η % d: = d in⋅ l: = l in⋅. these features reduce the number of load reversals in critical components and increase the life of fluid end parts. tx- 125, tx- 150, & tx- 200 triplex power pump installation operation & maintenance manual tx- 125, tx- 150, & tx- 200 english language iom- tx125- eng rev- 2. gardner denver duplex mud pumps and parts are widely used in the drilling industry. featuring superior construction and high quality materials, elepump mud pumps are built to last. our reliable brand models such as the f- 1000, fd- 1600, 12- p- 160, and 14- p- 220 operate with high performance, easy maintenance, and durability to meet the toughest demands. triplex plunger pump 5” stroke model tee99e parts list 3– 1– 529 6th edition august, 1998.

for one revolution of the mud pump drive, each pump piston would therefore have pumped the equivalent of one stroke" s total liner volume. what is mud pumping?

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

Drilling valves and seats Our line of roughneck valves and seats sets industry standards by meeting the demands of today’s hostile drilling environments encountered by contractors worldwide.

We, at Waters, provide high-standard, quality built mud pumps and its parts for oil and gas drilling operations on sale! We provide both sparingly used mud pumps and its parts to our customers in Houston and other areas in the United States.

The drop-down menu at the top lists the items we usually have in-stock. All of them are also normally available for sale or for rent. Rental products also include additional systems such as Triplex Mud Pumps (Diesel or Electric), Mud Tanks and Solids Control Equipment. For fast and easy equipment request, we have provided online forms customized to each specific area of interest. The photos below illustrate just a few of the items available in our inventory.

The mud pump is an integral part of drilling operations. Also called mud drilling pump, it is a kind of plunger pump or a reciprocating piston, which circulates the drilling fluid through the drill string and back up the annulus. The operation takes place under very high pressure of about 7,500 psi or 52,000 kPa.

Waters provide mud pumps of varying configurations and sizes according to our customer’s requirements. Every oil rig requires a different kind of mud pumps and parts. That is why, at Waters, we offer customized mud pumps according to your requirements. Be it the triplex or three-piston pump for the petroleum rig or the duplex mud pumps, we have with us a wide range of products to satisfy your oil rig specifications.

A mud pump is pivotal to rig drilling operations and at Watersintl, we attach great importance to the quality, make and build of every drilling rig mud pump that we offer for rental. With competition causing margins to shrink, the way to financial and operational success is mud pump rental.Operational efficiency is the key to success and a mud pump can actually be the single biggest contributor to drilling operations. With a lot riding on the capacity and rugged build of a mud pump, a rental is definitely a better choice.

We, at Waters, believe in quality over quantity. For the past five decades, we have gathered enough inputs and experiences to ensure our clients go satisfied after the purchase of our mud pumps and parts.

We, therefore, offer a comprehensive price range on our mud pumps for drilling in Houston. We have both sparingly used and new mud pumps to suit our customers’ requirements. Whatever your budget is, we will provide you the best choice in mud pumps and promise to deliver quality products at an affordable price range.

We know how difficult it is to find that one perfect part or the whole mud pump to fit in your drilling operations. That is why; we keep minimum delivery time to ensure our customers do not suffer downtime.

If you are looking for a mud pump, we would be happy to help! Just call us with your requirements or talk to our experts to know more about our mud pumps and other products!

At Watersintl, our specialization in equipment for drilling, lends us with greater exposure on the all- important mud pump, permitting us to offer the best models. Choose from a wide range of models that feature on our list of equipment available for rental. Benefit from our technical expertise that improves the operational efficiency and reliability of every single mud pump we offer on rent. The inspection routines and servicing that we follow transforms every mud pump into a rugged workhorse that will help you improve operational ability. Browse through our extensive list of drilling equipment and benefit from qualitative superiority and our reputation as one of the very best in the industry.

UDS International designs and manufactures heavy-duty centrifugal mud pump parts and equipment with innovative designs for optimum output and reliability.

Mud pumps are an important part of your drilling, tunneling and/or mining dynamics, helping to maintain drilling mud circulation through your drilling rig column, which improves the efficiency of drilling operations and reduces wear on your equipment.

UDS effective mud pump parts and equipment have the durability to meet the demands of high pressures, a range of ground conditions and are easy to maintain.

A properly serviced pulsation dampener is critical for your mud pumps’ efficiency, safety, and performance. Unfortunately, there aren’t many resources available to educate personnel on executing safe and effective servicing procedures. Please review the following steps with your personnel for safe pulsation dampener maintenance.

.jpg)

We carry mud pumps, connecting rods, and more than 2,000 drawings and blueprints of oilfield equipment and supplies. We can fill your orders with one-of-a-kind designs for:

Our vast inventory of fluid-end and gear-end parts for duplex pumps includes more than 500 duplex liners, as well as cages and stuffing boxes. If you can’t find the model you are looking for below, let us find it for you.

With more than $1,500,000 in parts and supplies, we have one of the largest inventories of drilling supplies in the United States. Have us serve your draw-work needs with a single phone call. We can build you a new EC 450 or EC 700 model down to the last detail, as well as custom draw-works services.

We carry more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. Though we keep in stock connecting rods primarily for GA550 and GA750 models, other options are available, including custom connecting rods for most duplex and triplex mud pumps.

We now offer crossheads and guides for both EMSCO D-375 and DB-550 duplex pumps. We also have slides and shoes for certain models. If you don’t see a part you need, let us find it for you.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

A washout occurs when fluid and solids enter the area behind or underneath a valve seat and erode the sealing surface. Washouts are usually caused by one of three issues: a worn or cracked valve seat, improper cleaning of the valve seat and deck which creates a poor seat seal, and excessive sand content in your drilling fluid. Worn or cracked valve seats can allow fluid to enter the area around the valve seat and seat deck, creating a wash point on the valve seat and causing it to cut into the fluid cylinder and seat deck.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

8613371530291

8613371530291