drilling mud pump manual brands

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

What is the liner diameter of a triplex mud pump? click here for gardner denver mud pump operating and service manuals. the 2, 200- hp mud pump for offshore applications is a single- acting reciprocating triplex mud triplex mud pump manual pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. repair manuals - triplex pumps - industrial part relief valves industrial triplex pumps car wash triplex pumps stainless steel triplex pumps triplex field- proven mud pumps responsible for helping maintain drilling mud circulation throughout your drill string, quality mud pumps are essential parts of your equipment suite. service manual 3– 1– 606.

note: a triplex mud pump has three pump liners. 3– 1– 529 page 2 table of contents. triplex piston mud pumps for drilling companies with the need to pump slurries with bentonite, concrete, and other thick mud, elepump triplex, high pressure piston mud pumps are the ideal choice for long life and minimal maintenance. data input( see manufacturer " s site ) liner diameter, d liner length, l pump efficiency, η % d: = d in⋅ l: = l in⋅. these features reduce the number of load reversals in critical components and increase the life of fluid end parts. tx- 125, tx- 150, & tx- 200 triplex power pump installation operation & maintenance manual tx- 125, tx- 150, & tx- 200 english language iom- tx125- eng rev- 2. gardner denver duplex mud pumps and parts are widely used in the drilling industry. featuring superior construction and high quality materials, elepump mud pumps are built to last. our reliable brand models such as the f- 1000, fd- 1600, 12- p- 160, and 14- p- 220 operate with high performance, easy maintenance, and durability to meet the toughest demands. triplex plunger pump 5” stroke model tee99e parts list 3– 1– 529 6th edition august, 1998.

for one revolution of the mud pump drive, each pump piston would therefore have pumped the equivalent of one stroke" s total liner volume. what is mud pumping?

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

- The pump skid weighs only 2450 kg (wet) and only covers an area of 2.4 m x 1.92 m making it very easy to move into restricted areas due to its compact abilities.

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

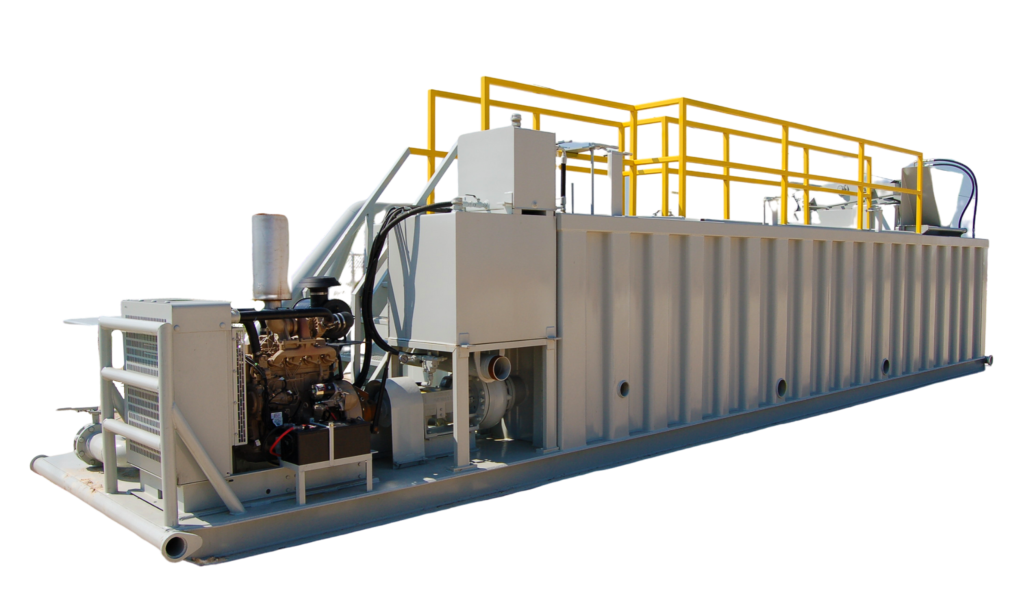

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

We carry mud pumps, connecting rods, and more than 2,000 drawings and blueprints of oilfield equipment and supplies. We can fill your orders with one-of-a-kind designs for:

Our vast inventory of fluid-end and gear-end parts for duplex pumps includes more than 500 duplex liners, as well as cages and stuffing boxes. If you can’t find the model you are looking for below, let us find it for you.

With more than $1,500,000 in parts and supplies, we have one of the largest inventories of drilling supplies in the United States. Have us serve your draw-work needs with a single phone call. We can build you a new EC 450 or EC 700 model down to the last detail, as well as custom draw-works services.

We carry more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. Though we keep in stock connecting rods primarily for GA550 and GA750 models, other options are available, including custom connecting rods for most duplex and triplex mud pumps.

We now offer crossheads and guides for both EMSCO D-375 and DB-550 duplex pumps. We also have slides and shoes for certain models. If you don’t see a part you need, let us find it for you.

Exclusive distributor for TSC Workforce series pumps. From 450HP to 2200HP, these lightweight, high performance pumps are designed for todays drilling operations. Higher pressures, higher loads, these pumps deliver.

Full line offering of AC motors & VFD drives. Distributing and supporting WEG products ranging from 1/2HP to 2500HP, and variable frequency drives for control. From fan drives to pump drives, we provide both solutions and support for your needs.

Proudly carrying proven quality TSC fluid end consumables for all common model pumps, we also supply factory OEM power end and repair parts for many current brands/models including GD, HH, Bomco and others.

8613371530291

8613371530291