duplex mud pump for drilling rig quotation

Explore a wide variety of duplex mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These duplex mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these duplex mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right duplex mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of duplex mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

BW850 mud pump is a lightweight grouting machine. The pump is a horizontal double-cylinder double-acting reciprocating piston pump. The mud pump is mainly used to feed flushing fluid into the hole during geological drilling. It can be used with large-diameter drilling rigs with a depth of 200-800 meters, which can improve drilling efficiency and drilling quality.

Hanfa Group established in 1998 is a key enterprise in the industry of geological exploration and water well field, with the ability to research,manufacture and market. Now, the Group pursues high standard manufacturing and qualified products. It has more than 20 species such as water well drilling rig, core drilling rig, engineering drilling rig, DTH drilling rig,horizontaldirectional drilling rig, etc. These machines are mainly used in geological prospecting, exploration of railway and

We are professional manufacturer, and our factory mainly produce water well drilling rig, core drilling rig, DTH drilling rig, piling rig, etc. Our products have been exported to more than 50 countries of Asia, South America, Africa, and get a good reputation in the world.

2, Are your products qualified?Yes, our products all have gained ISO certificate,and we have specialized quality inspection department for checking every machine before leaving our factory.

4, Do you have after service?Yes, we have special service team which will offer you professional guidance. If you need, we can send our engineer to your worksite and provid the training for your staff.

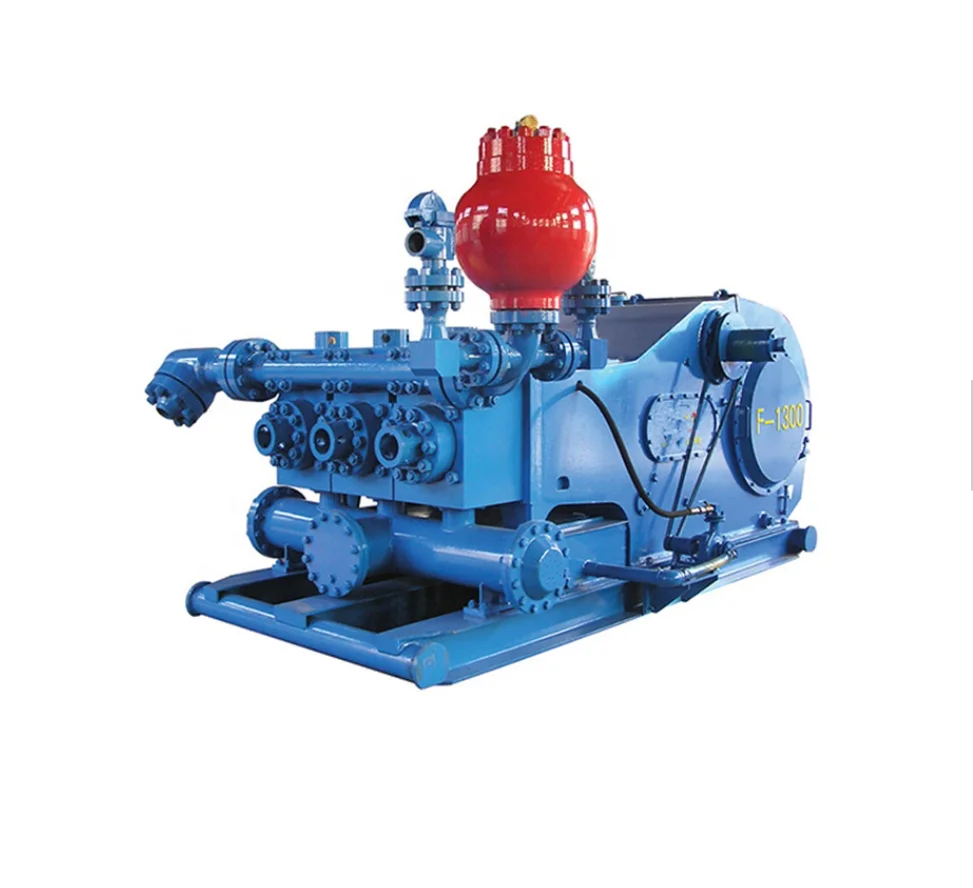

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The ROSCHEN Model RS-160-15 is a duplex reciprocating type power slush pump designed for maximizing volume without sacrifice of working pressure and compactness.

ROSCHEN Corporation is a specialty company serving agricultural, industrial and consumer markets globally for more than a century with innovative solutions, applications and quality products.

ROSCHEN has continued a proud heritage of pioneering solutions for our customers. Today, we use an array of advanced technologies in manufacturing, research and development to produce customized products and solutions for the many markets we serve.

As a global leader utilizing advanced technologies and customer-focused research and development, ROSCHEN provides innovative and cost-effective solutions to enhance crop yield and quality by controlling a broad spectrum of insects, weeds and disease, as well as in non-agricultural markets for pest control.

Our food ingredients are used to enhance texture, color, structure and physical stability. The pharmaceutical additives are used for binding, encapsulation and disintegrant applications. Some of our products are increasingly being used as active ingredients in nutraceutical and pharmaceutical markets. Our lithium products are utilized in energy storage, specialty polymers and pharmaceutical synthesis.

Preferred Pump offers the best rewards program in the water well equipment industry. Check out our social media pictures to see what you"ve been missing!

Robust Design and metallurgy ensuring long life, under any soil and abrasion content. Duplex action for maximum flow and increased pressure. Easy maintenance with both hydraulic and engine driven options.

Ultimately, when you reach the depth where you can’t pull up the drill string, you’ve reached the rig’s capacity. Based on this criteria, though, the max capacity rating of the SIMCO 7000, SIMCO’s largest rig would be well over 5000 feet.

Realistically, with any mud rotary drill rig, you’ve reached maximum depth capacity when you can no longer move the cuttings out of the hole. This is where having mud pump options becomes important.

Generally, there are several different versions of mud pumps available. With the SIMCO 7000 you can choose between centrifugal and piston pumps and different sizes with different depths and borehole diameters to suit your specific drilling needs.

Because each rig is built to your specifications, choosing the best mud pump for your goals takes into consideration many additional factors. Bore hole size, drilling conditions, geology, the mud mixture, and the desired depth capacity all have bearing on which mud pump will be the best fit for your personal drilling rig. By offering these different options, SIMCO helps you avoid the pitfalls of spending more money for a capacity you don’t need.

Give our sales department a call at 800-338-9925 or reach out through our contact page to learn more about the options on the SIMCO 7000 or any of our outstanding drilling systems.

We provide a qualitative range of mud pumps, which are immensely used in construction, agriculture, waste water management and many other industries. These High Pressure Duplex Double Acting Mud Pumps are primarily reciprocating plunger devices designed for circulation of drilling fluid down the drill string and back up the annulus. Our range of pumps are suitable for pumping muddy water, sewage, polluted liquids & solids and also in swimming pool. Manufactured using latest technology, these pumps are high performing, abrasion resistant, easy to install and have long service life.We are looking for only Export Queries.

Salient Features: Power-End-Single-piece alloy iron casting for rigidity Bearings-Main bearings are Tapered roller adjustable type Gears- Continuous tooth herring bone gears, fitted with crank for easy and economical replacement Connecting Rod-Nodular iron solid construction.Crank end has high-lead bronze bushing. Cross head end has bronze bushing Crossheads-Solid-type alloy iron, reinforced around extra large cross head pin Lubrication-AII internal working parts are flood lubricated from large reservoir in crank case, Main & Jack shaft roller bearings are grease lubricated Fluid End -Valve pot type, of alloy iron, with separate bolted valve cover over each valve Fluid Liners-Removable, interchangeable within each size group, gives wide range pressures and capacities in any single pump Fluid Pistons-Taper fitted to piston rods. Different materials and types available Fluid Valves-Bottom stem-guided of wing-guided. Of various materials to suit conditions. Individually accessible for services Piston Rods-Made of steel, Taper fitted to pistons

Surge Chamber, stainless steel valves, metal-packed pistons, special jack shafts, top motor mount, mounting truck, trailer or skid, prime mover-diesel engine or electric motor. Due to continued Research Design Developments And Improvement Right to change Specifications. Given here Without Prior Notice Is Reserved.

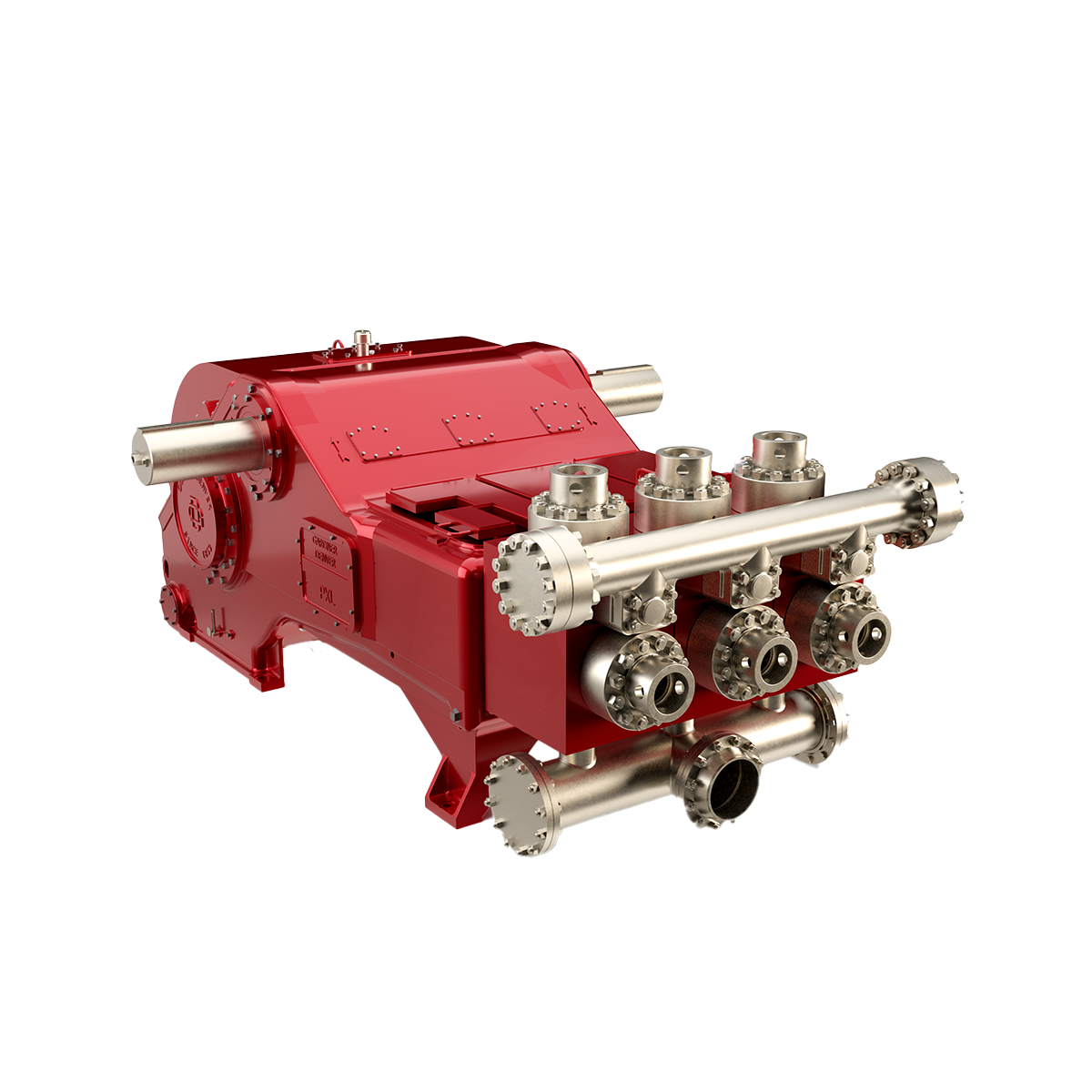

The effectiveness of triplex mud pumps for sale determines the success of drilling operations in rigs. Circulation of the drilling fluid or mud is a continuous process that calls for uninterrupted operations of the mud pumps. Finicky about how our equipment work, we at ShalePumps, go to extreme lengths before engineering modern beasts for continuous drilling operations in rigs.

Our state of the art Houston facility develops high performing mud pumps for drillings rigs by a combination of the best materials, and structural dynamics to put together some of the best equipment. Designed to be adapted for various drilling applications in rigs through designs that incorporate various liner sizes, the triplex mud pumps for sale that leave the assembly line at ShalePumps are mean and mighty workhorses. The triplex mud pumps feature high performance steel power ends, balanced forged steel crankshaft, steel herringbone gears and anti-friction roller bearings. Striking the right balance between weight and performance, the triplex mud pumps for sale we make are best for drilling operations in rigs.

The triplex mud pumps manufactured at ShalePumps have extended continuous duty cycles, and foolproof lubrication systems for smooth drilling operations in rigs. With mud pumps from ShalePumps the drilling operations in rigs will never be the weak link, but a pivot that spells success.

ShalePumps, LLC is proud to introduce the SP-1614 1600 HP Continuous Duty Triplex Drilling Pump. Engineering and rated for 1600 horse power at 110 strokes per minute with a 14” stroke capable of 7500 PSI. Manufactured in our Houston Texas facility, this pump defines longevity, quality and capability. The SP-1614 is designed to incorporate minimum weight and maximum performance using a high performance steel power end, a balanced forged steel crank shaft, steel herringbone gears and anti friction roller bearing throughout. Multiple liner sizes are available to allow variance in pressure and output volume for a variety of drilling applications. Download the performance chart for more detailed information.

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

We noticed you"re using an unsupported browser which may result in limited or no functionality for portions of our website. We recommend using Google Chrome, Mozilla Firefox, Microsoft Edge, or Safari for the best experience.

Duplex Pumps - Used Emsco D-500 16" stroke, 500hp duplex pump only. 268 gpm @ 2720 psi @ 65rpm with 4 3/4" pistons. 751 gpm @ 970 psi @ 65 rpm with 7 1/2" Pistons More Info

Duplex Pumps - Used 3 1/2" - 5" x 10" stroke duplex pump,96 HP, 83 GPM @ 1500 PSI @ 85 RPM with 3 1/2" Pistons or 182 GPM @ 772 PSI @ 85 RPM with 5" pistons. More Info

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

8613371530291

8613371530291