electric motor for mud pump brands

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

15 Models below. Made in USA. Gas, Diesel or Electric diaphragm pump, or mud / sludge pump. Easily maneuverable, the gas diaphragm pump is built for performance; Ideal for seepage dewatering, high suction lift, cleaning septic tanks, pumping industrial waste and marine tanks, small wellpoint systems and dewatering in sandy, muddy waters. Honda or Briggs gasoline engine or Electric diaphragm pump with motor.

Durable design with enclosed gears in oil bath, self cleaning flow path, dry run without damage, auto priming. Built in polyurethane flapper / check valve assures self-priming to 20 feet. This unit has steel suction strainer, two NPT hex nipples and wheel kit with 10" semi-pneumatic transport wheels for portability.

Diaphragm Mud pump Suction & discharge port size cannot be reduced. Cast aluminum construction with thermoplastic rubber diaphragm. Also called a mudhog. 90 degree rotatable base on all models to fit through narrow gates. As a alternate in a centrifugal pump dredge pump design see 316F-95 2" mud pumps. Trash pumps, centrifugal Dredge Pump. Hoses and accessories.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

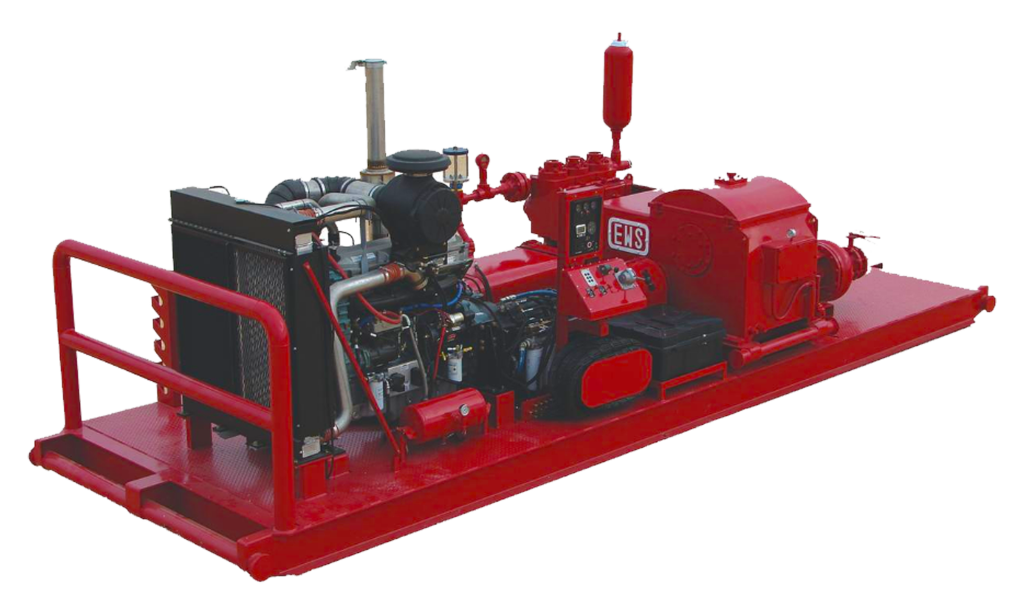

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

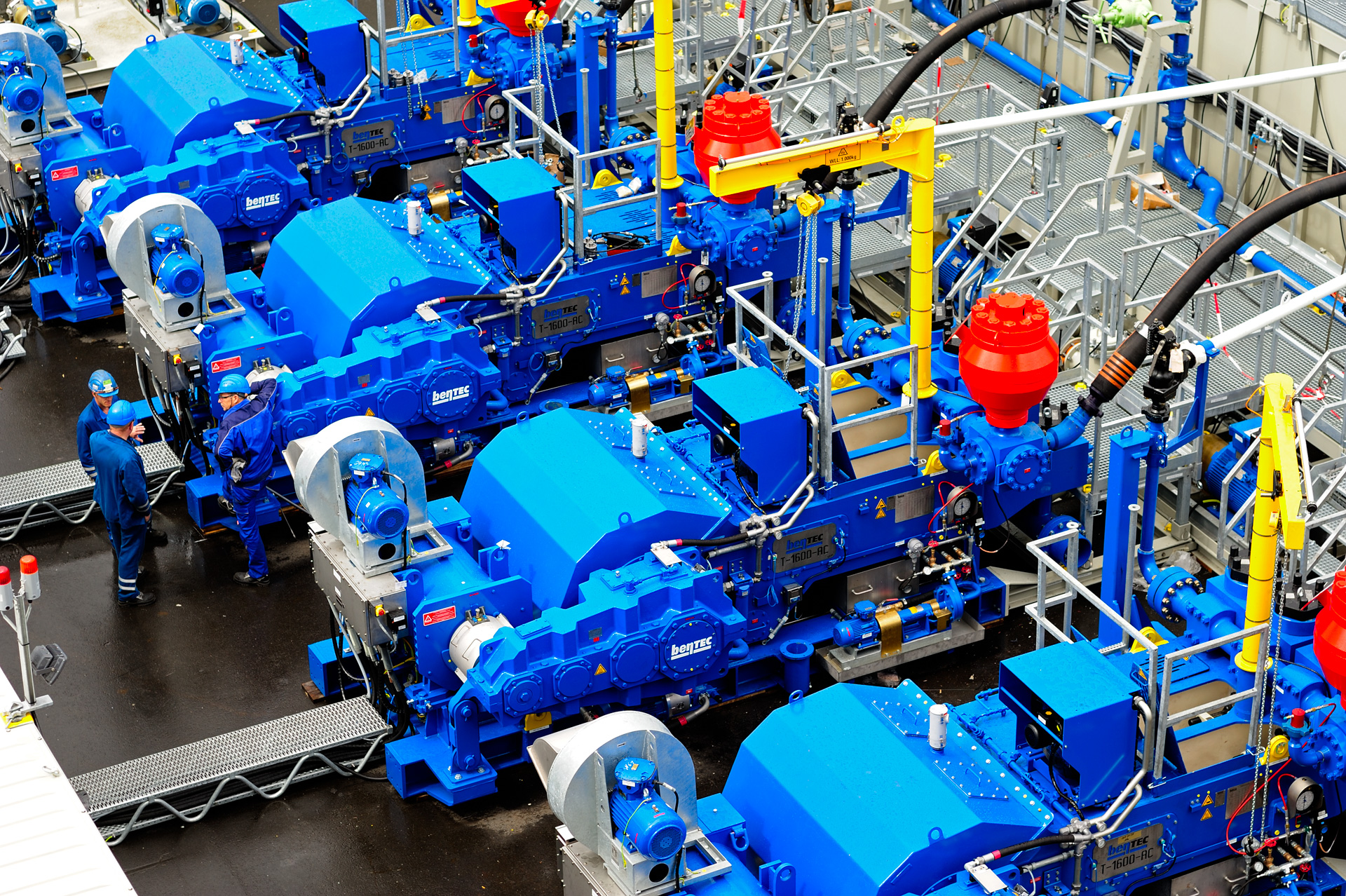

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

This design eliminates the need for chain or belt tensioning systems. The two-stage helical gear feeds directly into a forged/welded crankshaft, which is balanced and provides quiet and vibration-reduced operation.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

Cameron AC electric motors improve the performance of your mud pumps, drawworks, and rotary tables. Custom configuration is available, and ATEX, ABS, and DNV certification can be provided for new motors. Our flexible design offers you a choice between a tapered shaft or BullShaft to meet specific application requirements.

Cameron AC traction motors are designed and manufactured to handle deep drilling applications. Available in 400-hp, 550/600-hp, 1,150-hp, and 1,500/1,600-hp models, these inverter motors are designed specifically for 460-V to 690-V duty and deliver maximum efficiency. To meet varying installation requirements, our AC motors are available in vertical or horizontal designs.

Unlike conventional traction motors, Cameron AC motors have a unique design that meets the requirements of oil and gas applications. A key characteristic of the motor is the ability to provide a high level of torque at speeds ranging from 0 to 800 rpm (select motors can achieve a maximum speed up to 3,000 rpm). The torque generated at a wide range of speeds can enhance the performance of a broad array of drilling equipment driven by these motors.

The AMT line of diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as mud or sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. AMT Diaphragm pumps are available with a choice of drivers to meet your application requirements: gasoline, diesel or single or three phase electric motor. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 40 strokes per minute for electric motor models and 60 strokes per minute for engine driven models. Each unit includes a 2 or 3 inch NPT steel suction strainer, two NPT nipples and a wheel kit for portability.

Matched sets of Pinion gear with hardened tooth profile and single piece bull gear with modified herring bone hardened tooth to enlarged tooth to increase AMGA class rating with contact area for extended life and improved reliability

Pulsation dampeners are made of forged steel rather than cast steel, improving reliability. All high pressure parts are hydrostatically tested. Internal components are changeable with off the shelf consumables.

Central lubrication manifold system with Stainless Steel tubing for feeding all main, eccentric, and pinion bearings. Pressurized lubrication is also provided to the upper and lower crosshead slide for longer crosshead life

Discharge Manifold with 5 1/8” API 5,000 psi RTJ flanged both sides, manufactured from a single trepanned, heat treated alloy steel forgingLoadmaster Universal Rigs, Inc.

Loadmaster Universal Rigs, Inc. and Loadmaster Engineering, Inc. are separate corporations which manage and control their own affairs. Each of these companies has its own separate identity, but in advertising and in our brochures we may sometimes use the word "Loadmaster". The use of such term is for convenience only and is not intended as an accurate description of corporate relationships.

8613371530291

8613371530291