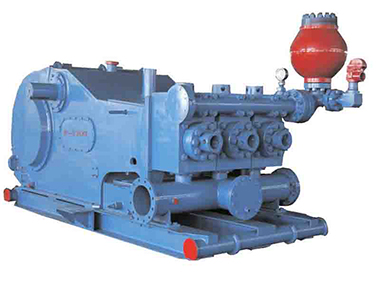

f 1300 mud pump specifications in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Salvex handles surplus, bankruptcy, overruns, obsolete inventory, disposal, insurance claims, online auctions, liquidation sale, foreclosure, lockout, seized, scrap, salvage, new, used, damaged, refurbished, and asset recovery.

F 1300 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 1300 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

Quick DetailsWarranty:1 YEARAfter-sales Service Provided:Field maintenance and repair service, Field installation, commissioning and training, Video technical support, Online supportCondition:NewApplicable Industries:Energy & MiningLocal Service Location:NoneShowroom Location:NoneType:Triplex single action, triplex cylinder single acting piston typeModel Number:F seriesModel:Rgf-1300/Rsf-1300/3nb-1300fMax liner dia. x stroke mm:170x191, 170x229, 170x254, 180x305, 180x305Rated stroke r/min:165, 150, 140, 120Rated power hp:500, 800, 1000, 1300, 1600Lubrication:Force + splashInlet flange:8"", 10"", 12""Outlet flange:4"", 5""Valve:API#5, API#6, API#7Supply AbilitySupply Ability:1000 Set/Sets per YearPackaging & DeliveryPackaging Details:Container or nudePort:QingdaoLead Time :

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

Compact, safe, suction valve and discharge valve are interchangeable, main components of hydraulic cylinder and fluid end on each pump are interchangeable;

Durable f luid end great ly improves the performance of triplex mud pump; furthermore,its independent structure makes examination and maintenance convenient.

F series mud pumps are manufactured by SCOTON, authorized by BOMCO. The product is in compliance with API standard technical specification and quality requirements of the Company.

The stroke length of F series mud pumps is greater. They can be used at small number of strokes per minute to prolong the service life of fluid end module expendables.

It is small in size and reliable in operation. The suction valves and the discharge valves are interchangeable. And the main components of three cylinders and the fluid end modules are interchangeable.

The fluid end modules of F series mud pumps have greatly improved the performance of triplex mud pumps. In addition, the unique design makes it easy to inspect quickly and to repair.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

Kingwell Mud pumps are single horzontal triplex piston pumps, in the deep and ultra-deep wells, the drilling process cycle of drilling fluid, cleaning the bottom of the well to carry cuttings, cooling and lubricationg bits and reinforced sidewall, used in conjunction with high pressure water jet bit rock crusher help improve drilling speed; Meanwhile, can also provide a mobile drilling mud pit as a driving force.

Xi"an Kingwell Oilfield Machinery Co.,Ltdis a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce Rig parts and accessories, API mud pump and spare parts, DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Equipped with latest machining facilities. Our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

We have a team of well qualified and experienced field support personnel for Training. According to customer"s requirements, we provide operation training service for our customers who cooperated with us.

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

Any interest of above products or relative parts, PLS feel free contact back, and we will offer a good price and show you our best service upon received from you.

8613371530291

8613371530291