f 1300 triplex mud pump factory

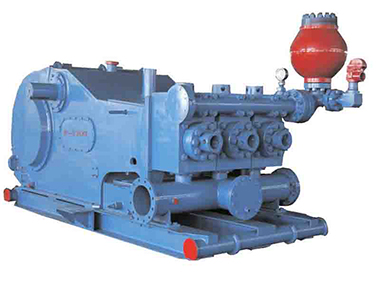

F 1300 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 1300 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

3)Corrosion resistance, high temperature resistance, high pressure resistance, abrasion resistance, aging resistance, ozone resistance and oil resistance. Long service life.

Manufactured by Long Shine Plant, F-1300 and F-1600 mud pumps can meet the requirements of the same manufacturing technique and quality level as those of F series mud pumps .They feature advanced structural design, reliable use, easy maintenance and compact occupied area. To reduce drilling workers" labor intensity and make the operation easy on site, liners are designed to be fitted into the frame from the frame top. A mini hoist with 500Kg lifting capacity is mounted on the frame for disassembling and changing liners.

Suction inlets of F-1300 and F-1600 mud pumps are fitted with 12"flanges, F-1300 and F-1600 mud pumps are fitted with API#7 valve pots. The suction valve and the discharge valve are interchangeable. Cylinders are made of forged alloy steel and nickel plated to improve their corrosion resistance. Three cylinders of each pump are interchangeable. Valve-over-valve (through type cylinder) design reduces the cylinder volume and promote the volumetric efficiency.

Notes: Cylinders, liners, pistons, valve and seats, valve springs, seal rings, valve covers and cylinder covers at the fluid end of F-1300 and F-1600 mud pumps are all interchangeable.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

A wide variety of f 1300 triplex mud pump options are available to you, such as 1 year, 2 years and 3 years.You can also choose from new, f 1300 triplex mud pump,as well as from energy & mining, construction works , and machinery repair shops f 1300 triplex mud pump,and whether f 1300 triplex mud pump is 1.5 years, or 6 months.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

Kingwell Mud pumps are single horzontal triplex piston pumps, in the deep and ultra-deep wells, the drilling process cycle of drilling fluid, cleaning the bottom of the well to carry cuttings, cooling and lubricationg bits and reinforced sidewall, used in conjunction with high pressure water jet bit rock crusher help improve drilling speed; Meanwhile, can also provide a mobile drilling mud pit as a driving force.

Xi"an Kingwell Oilfield Machinery Co.,Ltdis a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce Rig parts and accessories, API mud pump and spare parts, DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Equipped with latest machining facilities. Our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

We have a team of well qualified and experienced field support personnel for Training. According to customer"s requirements, we provide operation training service for our customers who cooperated with us.

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

Any interest of above products or relative parts, PLS feel free contact back, and we will offer a good price and show you our best service upon received from you.

We can supply many kinds of mud pump spare parts to fit your drilling needs, suiting to almost all popular mud pumps in the world.. Such as valve, valve seats, liner, piston, fluid end parts, crankshaft Assembly, Pinionshaft assembly, valve cover, liner cage, liner nut, valve seat puller, extension rod and piston rod, bearing, cylinder etc.

The valve and seat are made of forged alloy steel with deep carburized wear surface. We offer a full range of valves and seats which include full open valve and seat, 3 web / 4 web design valve and seat.

The valve comes with full open seat features four guide wings. They are either inertia welded to the valve body or uniformly forged with valve body. The urethane insert can be easily snapped on.

The 3 web / 4 web seat comes with stem guided valve. The urethane insert is tightened by steel plate and nut. It can be easily replaced with minimum down time. They offer long lasting service life under harsh service conditions.

A: After you confirm our PI, we will request you to pay. T/T , L/C, Western Union are the most usual ways we are using. If you want to use other way, please tell me, we can discuss.

A: First we discuss order details, production details by email, Whats app or Wechat. Then we issue you an PI for your confirmation. You will be requested to do pr-epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 7-15 days if we don’t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

Production Process: The bi-metal cylinder Liner of our company combined with the advantages of abrasion hot-forging out liner and anticorrosion high chrome inner liner. The out liner is made of high quality carbon steel by hot pressing forming. Its tensile strength is over 900000psi. The inner liner is made of high-chromium alloy by centrifugal casting.

Bi-metal Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a high chrome inner sleeve. These liners feature a centrifugally cast high chrome iron sleeve which is machined and heat treated to a minimum uniform bore hardness of 59-65HRC. Bi-metal Liners is the main expendable parts of the mud pump, it adapts double metal fix together.

The outer sleeve is forged steel with quality carbon steel,the inner sleeve is casted with high carbon and high chromimum use the technology of centrigual casting, after treatment ,the hardness of it can reach to a level of 59-67HRC.

Ceramic Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. Ceramic cylinder inner sleeve is used zirconia toughening alumina ceramics obtained the national patent, using zirconium oxide the characteristics of high fracture toughness and high hardness of alumina, the combination of these two can improve the fatigue strength of the product. Its coat uses 45 steel forging with good mechanical properties. After tempering heat treatment, hardness of HB235-265, the tensile strength is not less than 655 mpa.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

HNA also supplies other expendable fluid end parts such as Threaded Ring, Liner Clamp, Rod Clamp, Valve Pot Cover, Liner Cage, Wear Plate, Valve Guide which all fit the request of most popular

Increase is a quality trading company of replacement parts for the wide variety of mud pumps, centrifugal pumps, rig parts, and swivel parts found on the World market today.

Over a 1,000,000 of interchangeable mud pump parts, centrifugal pump parts, rig parts and swivel parts in stock for all major manufactures such as: mud pump spares and the mud pump spare parts / mud pump replacement parts that we offer.

These parts include; mud pump liners, mud pump pistons, triplex single action pistons, piston rods and clamps, pony rods, threaded rings and caps, valve guides, liner packing cage assemblies, duplex pump spares and duplex mud pump parts, triplex pump spares and triplex mud pump , piston rods, gland brass and junk rings, full open valves and valve seats, web valves and web valve seats, stuffing box and gland nut, and mud pump gasket and mud pump rubbers.

Salvex handles surplus, bankruptcy, overruns, obsolete inventory, disposal, insurance claims, online auctions, liquidation sale, foreclosure, lockout, seized, scrap, salvage, new, used, damaged, refurbished, and asset recovery.

The ceramic sleeve material is manufactured from alumina oxide, known for its wear resistance, and has proven run times in all types of operating conditions. The outer hull material for large bore liners is manufactured from alloy steel to increase yield strength and aid in fatigue resistance. KERUI ceramic liners are corrosion resistant and have a smoother surface finish for reduced friction and heat.

Kerui is an independent manufacturer of replacement parts. Kerui is neither a licensee, nor is it affiliated with any of the Original Equipment Manufacturers named throughout unless specifically noted. Any names and trademarks used herein are solely for identification purposes and are not intended to cause confusion as to the source of the parts. The OEM’s named throughout do not sponsor, promote, warranty or endorse Kerui’s products. Part number usage is for identification purposes only.

8613371530291

8613371530291