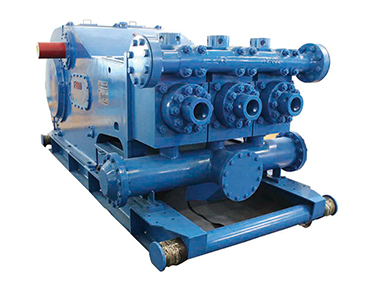

f 1600 mud pump specifications for sale

Units have all been fully inspected and all gears and bearings are within OEM running specifications. Fluid Ends have all been removed and have MPI inspection reports. New parts have all been installed if not within manufacture guidelines.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A wide variety of mud pumps f 1600 options are available to you, such as 1 year, not available and 2 years.You can also choose from new, used mud pumps f 1600,as well as from energy & mining, construction works , and machinery repair shops mud pumps f 1600, and whether mud pumps f 1600 is 1.5 years, 6 months, or unavailable.

Choose a used Emsco FB-1600 Triplex Mud Pump from our inventory selection and save yourself some money on your next shallow drilling oilfield project. This Emsco FB-1600 Triplex Mud Pump is used and may show some minor wear.

We offer wholesale pricing on new Emsco FB-1600 Triplex Mud Pump and pass the savings on to you. Contact us to compare prices of different brands of Mud Pump. This equipment is brand new and has never been used.

Our large network often has surplus Emsco FB-1600 Triplex Mud Pump that go unused from a surplus purchase or a project that was not completed. Contact us to see what Emsco FB-1600 Triplex Mud Pump we have in inventory. The surplus Emsco FB-1600 Triplex Mud Pump are considered new but may have some weathering depending on where it was stored. Surplus oilfield equipment is usually stored at a yard or warehouse.

We have refurbished Mud Pumpthat have been used and brought up to functional standards. It is considered a ready to use, working Mud Pump. Please contact us for more information about our refurbished Emsco FB-1600 Triplex Mud Pump. These Mud Pump have been used and brought up to functional standards. It is considered a working Mud Pump. Please contact us for more information about the product.

F series mud pumps are manufactured by SCOTON, authorized by BOMCO. The product is in compliance with API standard technical specification and quality requirements of the Company.

The stroke length of F series mud pumps is greater. They can be used at small number of strokes per minute to prolong the service life of fluid end module expendables.

It is small in size and reliable in operation. The suction valves and the discharge valves are interchangeable. And the main components of three cylinders and the fluid end modules are interchangeable.

The fluid end modules of F series mud pumps have greatly improved the performance of triplex mud pumps. In addition, the unique design makes it easy to inspect quickly and to repair.

F 1600 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 1600 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

Xi"an Kingwell Oilfield Machinery Co.,Ltd is a professional supplier for oilfield products according to the API standard. Our products have exported to USA, Canada, Australia, Egypt, India and Uae, etc with high quality and short supply and good service, our products have got good reputation home and abroad .

Equipped with latest machining facilities. Our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

We have a team of well qualified and experienced field support personnel for Training. According to customer"s requirements, we provide operation training service for our customers who cooperated with us.

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

Any interest of above products or relative parts, PLS feel free contact back, and we will offer a good price and show you our best service upon received from you.

The hydraulic cylinder, cylinder liner, piston, valve body, valve seat, valve spring, seal, valve cover, cylinder head of F1300 and F1600 are interchangeable

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

This website uses cookies to improve your experience while you navigate through the website. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may have an effect on your browsing experience.

Production Process: The bi-metal cylinder Liner of our company combined with the advantages of abrasion hot-forging out liner and anticorrosion high chrome inner liner. The out liner is made of high quality carbon steel by hot pressing forming. Its tensile strength is over 900000psi. The inner liner is made of high-chromium alloy by centrifugal casting.

Bi-metal Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a high chrome inner sleeve. These liners feature a centrifugally cast high chrome iron sleeve which is machined and heat treated to a minimum uniform bore hardness of 59-65HRC. Bi-metal Liners is the main expendable parts of the mud pump, it adapts double metal fix together.

The outer sleeve is forged steel with quality carbon steel,the inner sleeve is casted with high carbon and high chromimum use the technology of centrigual casting, after treatment ,the hardness of it can reach to a level of 59-67HRC.

Ceramic Liners combine the strength of a forged steel outer shell with the abrasion and corrosion resistance of a ceramic inner sleeve. Ceramic cylinder inner sleeve is used zirconia toughening alumina ceramics obtained the national patent, using zirconium oxide the characteristics of high fracture toughness and high hardness of alumina, the combination of these two can improve the fatigue strength of the product. Its coat uses 45 steel forging with good mechanical properties. After tempering heat treatment, hardness of HB235-265, the tensile strength is not less than 655 mpa.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

standard one-and/or-two-piece configuration, with designs available for pressure of 5000psi(35.1Mpa), 7500psi(52.7Mpa), and 10000psi(70.3Mpa); discharge connections available on each side; suction connections on each side or front center.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

YINDA offers a complete line of accessories for OEM fluid end modules, CNC machining makes these accessories uniformly dimensional and interchangeable with OEM.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

8613371530291

8613371530291