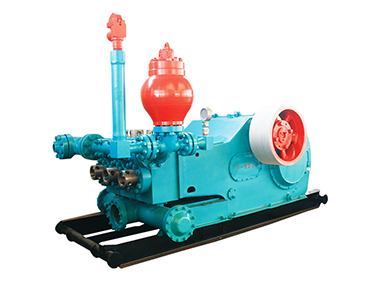

f 800 mud pump made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

ERUI has an independent third-party inspection team, which strictly controls the quality of products, guarantees genuine products and eliminates fakes.

ERUI has been deeply engaged in the field of oil and gas energy for many years, integrating a large number of high-quality supply channels. Our products are comprehensive and the price advantage is obvious.

The time depends on the MOQ of the order. The delivery time for parts is generally 1-3 days, and equipment is 7-30 days. In addition, contact us to get the full time of the order.

There are dozens of companies who manufacture mud pump in China ,but among them we have different levels ,this artical we list some of the most popular and leading mud pumps companies.

CNPC produces a series of API7K-compliant mud pumps ranging from F-500 to F-2200. F-2200HL is a tri-cylinder, single-action, heavy-duty, high-pressure drilling pump with a maximum power of 2,200HP, maximum working pressure of 52MPa, and maximum displacement of 77.65L/s. CNPC owns the intellectual property rights of this modern and high-tech product.

F-1300, F-1600, F-1300L and F-1600L mud pumps have a Max. pump pressure of 34.5MPa (5000Psi) and a displacement of 46.5L/S with a liner of Φ180mm. These two models are the first choice for medium and deep drilling rig as an assorted component.

F-1600HL, F-2200HL mud pumps with high-power and high-pressure are developed to meet drilling requirements of offshore deep-water, terrestrial and horizontal wells, especially in desert areas.

F1-800, F1-1600 light- weight series mud pumps are newly designed. Compared with same power F-series mud pumps, the advance of less volume and weight which are appropriate for the rigs working in swamp and helicopter-lifting rigs.

QDP-3000 five-cylinder mud pumps, with large power, high pressure, big displacement, small size and light weight, are especially suitable for offshore platform and drill ship.

LSPE has a long and profound history of petroleum drilling machinery manufacturing and technical foundation, which can date back to Lanzhou Petroleum Machinery Works. It is the former Lanzhou LS-National Oilwell Petroleum Engineering Co.,Ltd., a Sino-American joint venture established by and between LS Group and U.S.A.National Oilwell in Dec.2000. In April 2013, the total interest equity held by National Oilwell in the joint venture was transferred to LS Group and Lanzhou LS-National Oilwell Petroleum Engineering Co.,Ltd. was registered and renamed Lanzhou LS Petroleum Engineering Co., Ltd.

█ F-series triplex mud pump is compact in construction , light in weight, small in area covering, high in efficiency. All kinds of mud pumps are available as per different requirements and conditions.

█ Power end: the frame is of fabricated steel-plate construction. The internal stress is relieved after welding. Pinion shaft and crankshaft gear are integral herringbone gear. It operates smoothly with high efficiency and long service life. For crankshaft, both castings and forgings are available at your option.

█ Fluid end: module, valve assembly, liner, piston assembly conform to API spec 7K . The discharge flange connectionswith accessories conform to API Spec 6A.

Built in 1966, taking up 200,000 square meters field area, 110,000 square meters built-up area, with general assets of 150 million yuan, enterprise staff of 1100 people, professional and technical personnel of 170 people, and annual output of 350, is one of the three largest manufacturers of oil drilling mud pump and its accessories. The product covers various large oil fields all over the country with the home market occupation ratio reaching more than 50%, and export USA, Canada, Middle East and the former Soviet Union area,it is the world"s largest drilling equipment company-the United States NOV suppliers.The company passed ISO 9001 quality system certification in 1997 and has produced strictly according to international API Standard. Now it has become the first class networks supplier for petroleum, goods and materials to Petroleum and Gas Group Company of china.

Find 8X10 AH Centrifugal Slurry Pumps Made in China from China Manufacturer, Manufactory, Factory and Supplier - Shijiazhuang Naipu Pump Co., Ltd. on ECVV.com

Triplex mud pumps and triplex mud pump parts are already our featured products ever since start of our business. We supply quality EMSCO F-series mud pumps including F-500, F-800, F-1000, F-1300, F-1600, RLF-2200, and China National 3NB series mud pump, including 3NB350, 3NB500, 3NB-600, 3NB800, 3NB1000A/D, 3NB1300A/D, and 3NB1600. The full range of products can well satisfy any need from the clients.

Our F series mud pump are designed and manufactured on the basis of American Emsco F series mud pump strictly according to America Petroleum Institution API 7K Standard. All of its expendable parts are interchangeable with any other spare parts produced according to API standard. Therefore it is easy to repair and maintain internationally .

F series mud pump has a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of expendable parts in the fluid end greatly. The suction pulsation dampener has an advanced structure which is reliable to use and can make the pump realize its best suction performance.

SHANDONG BEYOND PETROLEUM MACHINERY CO.,LTD. is established on request of customer and aimed to supply best product and service for the customer. It focuses on to supply best solutions for the overseas oilfield customer on equipment & spares maintenance and supply.

China has become main supplier for oil production countries, but Chinese equipment has some special features different with European and American countries, and there exits big language and cultural difference between China and other countries, so it has become one big challenge for the overseas customer to get the exact equipment and parts they need in a short time. However, BEYOND takes root in China, and has very good cooperation relationship with most of famous factories, plus strong technical support and good advantage in language. Therefore, BEYOND is quite capable to help the customer to solve this challenge.

BEYOND products cover but not limited to: China-make oil drilling rigs, workover rigs, wellhead and downhole tools, drilling tools, OCTG and other related equipment and parts. Meanwhile, BEYOND can offer technical services, personnel training and maintenance guide towards China-made drilling rigs. Only if it is what you need, BEYOND can get it for you: from best factories, with most competitive price and within shortest lead time.

F 800 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F series mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

F series mud pump is applicable to the requirement of high pump pressure in oilfield and high displacement technology of well drilling with its solid and compact structure, small volume and outstanding operation performance.

F series mud pump has long stroke maintaining operation at lower frequency resulting in enhancing the performance of giving water effectively and prolonging the lifetime of the consumable hydrokinetic parts. The air-suction kit is advanced in structure and reliable at operation to reach the optimized absorbing target of air suction into linepipe.

F series mud pump powering side adopts the combined lubrication of forced and splashing lubrication featured with reliable lubrication and adding the operation lifetime of powering part.

This series pump is produced strictly according to API Spec 7K “the EquipmentSpecification of Well Drilling and Repairing”, and performed the EX-Work test under the specification thereof.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

The Made-in-China F series mud pumps have same reliable quality and performance as other USA products. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

Huaxin"s export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

Seal Rings for Liner packing are also important. Liner Seal Rings is designed and made with hard corner which is an integral part of seal rings and soft nitrile element rubber center. We could provide reliable liner Seal Rings for our customers could order them at the same time.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

8613371530291

8613371530291