gardner denver mud pump manual factory

MAINTAIN PUMP RELIABILITY AND PERFORMANCE WITHGENUINE GARDNER DENVERPARTS AND SUPPORT SERVICESGardner Denver and OPI genuine pump parts aremanufactured to original tolerances and designed for optimumdependability. Design and material innovationsare the result of years of experience with hundreds of differentpump applications. Reliability in materials andquality assurance are incorporated in our genuine replacementparts.Your authorized Gardner Denver and OPI distributoroffers all the backup you’ll need. A worldwide networkof authorized distributors provides the finest product supportin the pump industry.Your local authorized distributor maintains a large inventoryof genuine parts and he is backed up for emergencyparts by direct access to the Gardner Denver MachineryInc. Master Distribution Center (MDC) in Memphis, Tennessee.Your authorized distributor can support your GardnerDenver and OPI pump needs with these services:1. Trained parts specialists to assist you in selectingthe correct replacement parts.2. Repair and maintenance kits designed with thenecessary parts to simplify servicing your pump.Authorized distributor service technicians are factory–trained and skilled in pump maintenance and repair. Theyare ready to respond and assist you by providing fast, expertmaintenance and repair services.For the location of your local authorized Gardner Denver and OPI distributor refer to the yellow pages of yourphone directory or contact:Distribution Center:Factory:Gardner Denver Machinery Inc.Gardner Denver Machinery Inc.Master Distribution Center1800 Gardner Expressway5585 East Shelby Drive Quincy, IL 62301Memphis, TN 38141 Phone: (217) 222–5400Phone: (901) 542–6100 Fax: (217) 224–7814Fax: (901) 542–6159INSTRUCTIONS FOR ORDERING REPAIR PARTSWhen ordering parts, specify Pump MODEL and SERIALNUMBER (see nameplate on unit). The Serial Numberis also stamped on top of the cylinder end of the frame(cradle area).All orders for Parts should be placed with the nearestauthorized distributor.Where NOT specified, quantity of parts required perpump or unit is one (1); where more than one is requiredper unit, quantity is indicated in parenthesis. SPECIFYEXACTLY THE NUMBER OF PARTS REQUIRED.DO NOT ORDER BY SETS OR GROUPS.To determine the Right Hand and Left Hand side of apump, stand at the power end and look toward the fluidend. Right Hand and Left Hand are indicated in parenthesisfollowing the part name, i.e. (RH) & (LH), when appropriate.15–514 Page 1

TABLE OF CONTENTSMaintain Pump Reliability And Performance With Genuine Gardner Denver Parts and Support Services . . . . . . . . . 1Instructions For Ordering Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Frame & Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 4Drive Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 6Fluid Cylinder & Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 8Steel–fitted Center Guided Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9With Polyurethane Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9With Carboxylated Nitrile Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Plunger Coupling & Piston Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Piston & Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Piston Lubricating Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Oil Pump & Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 14Piston Lubricating Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15, 16Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Valve Seat Puller Center Guided Type (Optional Equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19PageGardner Denver Unit Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Inside Back CoverFor Operating and Service Instructions see:SERVICE MANUAL 15–60015–514 Page 2

Order by Part Number and Description. Reference Numbers are for your convenience only.D74881PISTON LUBRICATING PUMPRef.No. Name of Part Qty. Part No.PUMP ASSEMBLY, Includes All Parts Shown . . . . . . . . . . . . . . . . . . . . . . .CA1221 CASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 C1K2A12 PLUG–SqHd PIPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 64AA63 COCK, Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90C314 IMPELLER ASSEMBLY, SHAFT & PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 C1K1A1A5 KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 35B46 SEAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 60BT118 GASKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 25D2129 FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 C1H4A210 SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 75A13011 BEARING–BALL (Inner) Includes Retaining Ring . . . . . . . . . . . . . . . . . . . . 1 12AK312 BEARING–BALL (Outer) Includes Retaining Ring . . . . . . . . . . . . . . . . . . . 1 12AK315–514 Page 11

Order by Part Number and Description. Reference Numbers are for your convenience only.PISTON LUBRICATING PIPINGRef.No. Name of Part Qty. Part No.Ref.No. Name of Part Qty. Part No.15–514 Page 16(Lube Oil Tank to Pump Group)1 SCREEN–OIL . . . . . . . . . . . . . . . . . . . . . . . 1 2WAJ5112 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H253 UNION–HAMMER, Wing . . . . . . . . . . . . . 1 64EB14 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H255 VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90A366 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H257 TEE–PIPE . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64G8G8 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H259 VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90A3610 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 1 29Q911 HYDRAULIC HOSE ASSEMBLY . . . . . . . 1 2009247∅ ELBOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64C612 PUMP PISTON LUBRICATING,*Includes Reference Number 13 . . . . . . . . 1 CA12213 KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 35B414 SCREW, Pump to Skid . . . . . . . . . . . . . . . 4 655ED04015 LOCKWASHER, Pump to Skid . . . . . . . . 4 95B316 WASHER, Pump to Skid . . . . . . . . . . . . . . 4 95A317 SHEAVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 73K1A3018 BUSHING–HUB . . . . . . . . . . . . . . . . . . . . . 1 22E16B19 BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 13C2820 AUXILIARY SHEAVE . . . . . . . . . . . . . . . . . 1 2012669∅ SET SCREW, Sheave . . . . . . . . . . . . . . . . 2 76F30(Pump to Liner Group)21 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 1 29Q1022 HYDRAULIC HOSE ASSEMBLY . . . . . . . 1 200924723 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 1 29Q2724 REDUCER–PIPE . . . . . . . . . . . . . . . . . . . . 1 64N325 VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90A2526 ELBOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64C527 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63G928 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64P3929 CLAMP–PIPE . . . . . . . . . . . . . . . . . . . . . . . 2 98H530 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 95A331 SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 75A6832 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63N12X15033 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64P3934 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63N12X15035 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64P3936 PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64A537 HYDRAULIC HOSE ASSEMBLY . . . . . . . 3 29R3038 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 3 29Q8339 COUPLING–PIPE . . . . . . . . . . . . . . . . . . . 3 64BK340 BAFFLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1PZ8041 NUT–ACORN . . . . . . . . . . . . . . . . . . . . . . . 6 50Q30(Frame to Lube Oil Tank Group)42 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63L3143 ELBOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64C944 TANK–LUBE OIL . . . . . . . . . . . . . . . . . . . . 1 201263945 PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 64A746 SCREW, Lube Tank to Skid . . . . . . . . . . . 4 655EE04047 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 95A548 PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64A649 COVER–LUBE OIL TANK . . . . . . . . . . . . . 1 201265550 NUT–WING . . . . . . . . . . . . . . . . . . . . . . . . . 2 50H1∅ PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 64A9∅ Not Shown on Drawing.* For Piston Lubricating Pump and Components Parts See Page 11.

Order by Part Number and Description. Reference Numbers are for your convenience only.VALVE SEAT PULLER – CENTER GUIDED TYPE(OPTIONAL EQUIPMENT)Ref.No. Name of Part Qty. Part No.1 HEAD (Not Included with 10012 Puller) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 100E13VALVE SEAT PULLER ASSEMBLY, Includes Ref. Numbers 2 thru 11 . . 1 100E122 HYDRAULIC JACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21167283 CENTER STEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173144 CENTER STEM NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173155 PULLER H BAR BASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21167276 CENTER BUSHING #5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2117316CENTER BUSHING #6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21175177 HYDRAULIC HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173188 HYDRAULIC PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173199 GAUGE ADAPTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 211732010 GAUGE COUPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2117322GAUGE COUPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 211732111 GAUGE 170 TON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2117323* CARRYING CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2117055* Not Shown on Drawing.15–514 Page 18

GARDNER DENVER UNIT RECORDThe following unit identification plate is provided as a convenience to you, our valued GardnerDenver customer. Please take the time to copy all the information from the actual nameplate ofyour unit. The model number, date manufactured and serial number will be required whencontacting the company or your distributor for information or replacement parts.200OPA496(Ref. Drawing)

Maintain Pump Reliability And Performance ...............i Maintenance Schedule.............................................11

SECTION 1................................................................ 1 Lube Oil Pump..........................................................18

Pressurized Pump Systems ...................................... 3 Main Bearings...........................................................21

Flammable, Hot, Cold Or Corrosive Fluidpumping.... 4 Crosshead Pins ........................................................24

Starting A New Pump ................................................ 8 Piston Rod ................................................................26

Gal. Per Liter Per Gal. Per Liter Per Pump shaft Input

Weight Complete Pump ............................................................................................................................. 17,410 lbs. (7897.04 kg)

Weight Complete Pump ............................................................................................................................. 21,650 lbs. (9820.27 kg)

Gal. Per Liter Per Gal. Per Liter Per Pump shaft Input

Weight Complete Pump .......................................................................................................................... 26,500 lbs. (12,020.19 kg)

Weight Complete Pump ........................................................................................................................... 40,500 lbs. (18370.48 kg)

Gal. Per Liter Per Gal. Per Liter Per Pump shaft Input

Weight Complete Pump .......................................................................................................................... 40,500 lbs. (18,370.48 kg)

Weight Complete Pump .......................................................................................................................... 41,750 lbs. (18,937.47 kg)

Gal. Per Liter Per Gal. Per Liter Per Pump shaft Input

Weight Complete Pump .......................................................................................................................... 46,250 lbs. (20,978.63 kg)

Worth) : gardner denver well servicing pumps 4747 south 83rd east avenue tulsa, oklahoma 74145 chaparral 2121 west 44th street odessa, tx 79768 geoquip 7533. however, gardner denver – a gardner denver co. ecngardner denver® 300wpd996 revision b april opi- 600 well servicing pump operating and service manual rental pump supplied by. therefore, in the beginning of this manual the gardner denver hd- 2250 is a multi- the user is introduced to dangers inherent in purpose pump for various applications such the operation of a high pressure pump. gardner denver 6” fxg mud pump ( ref# 6200t) 3” and 5” pistons and liners, pressure relief valve, new valves and springs, 80 hp engine, manual clutch, 50 gal fuel tank, 20 bbl circulating tank, hard line, mounted on 18’ load trailer with new tires price: $ 32, 500. search among 422, 616 industrial products; search amongst our 232, 663 catalogs; search amongst 755 projects; search amongst 64, 513 news & trends. com has been visited by 10k+ users in gardner denver pump manual the past month. gardner denver product pumps 4747 south 83rd east avenue tulsa, oklahomafaxemail: com. download center – vacuum pumps documents click on the brochures, drawings, manuals and software sections, in order to see the available documents for vacuum pump range.

the user of any air compressor package manufactured by gardner denver, is hereby warned that failure to follow the preceding safety and operation precautions can resu lt in injuries or equipment damage. , does not state as fact or does not mean to imply that the preceding list of safety and operating. for the location of your local authorized gardner denver distributor, refer to the yellow pages of your phone directory or contact: factory ( tulsa) : service center ( odessa) : factory ( ft.

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

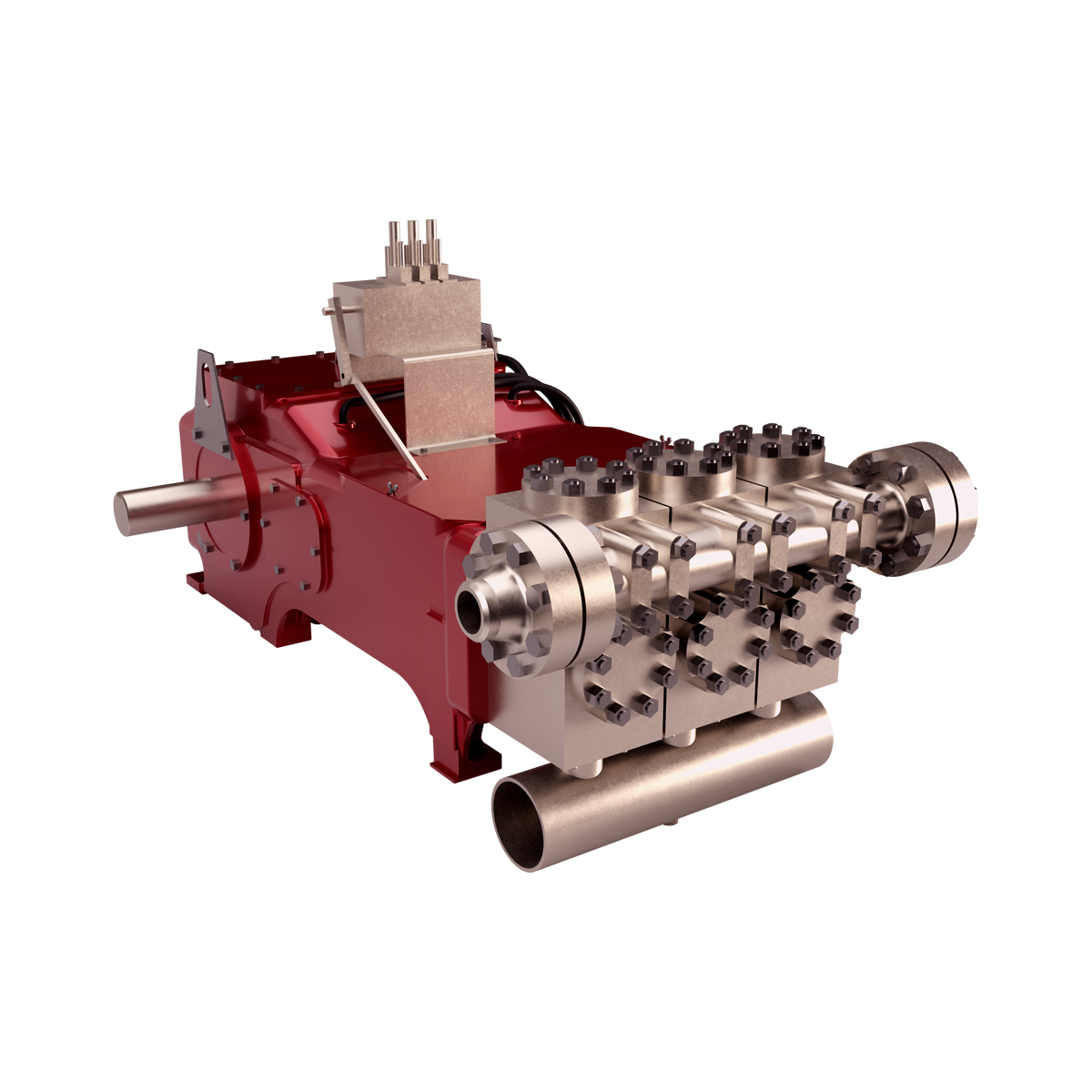

Pump Parts - Gardner Denver GD45T Triplex Injection Pump, Pumps & Parts, Used frame for Gardner Denver GD45T (PS-25) triplex pump, bare case , More Info

Pump Parts - Gardner Denver PA-8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PA-8 Triplex Mud Pump (predecessor to the Gardner Denver PAH), 4.5" metal plungers x 8" stroke, c... More Info

Pump Parts - Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump Package, 4.5" Metal plungers x 8" stroke, Detroit 8V-71 d... More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used power end for Gardner Denver (SMC) PE-5 (T-165-5) triplex pump, 5" stroke, no fluid end , More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used power end for Gardner Denver PE-5 Triplex Mud Pump, 5" stroke, no fluid end , More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used fluid end for Gardner Denver PE-5 3x5 Triplex Mud Pump, steel, c/w valves, covers, suction manifold , More Info

Pump Parts - Gardner Denver PE-5Y 3x5 Triplex Well Servicing Reversing Mud Pump Package, Pumps & Parts, Used Gardner Denver PE-5Y 3x5 Triplex Well Servicing Reversing Mud Pump Package... More Info

Pump Parts - Gardner Denver PG-3 Triplex Mud Pump, Pumps & Parts, Used powerend for Gardner Denver PG-3 Triplex Pump, c/w factory gear box 3.79:1 ratio , More Info

Pump Parts - Gardner Denver PQ-2 Triplex Injection Pump, Pumps & Parts, Used bronze fluid end for Gardner Denver PQ-2 triplex pump, bare, no internals , More Info

Pump Parts - Gardner Denver PS-25 Triplex Injection Pump, Pumps & Parts, Used stainless steel high pressure fluid end assembly to fit Gardner Denver PS-25 triplex pump, 1 1/4" plunger... More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver TEE 4 x 5 Triplex Mud Pump, "POWER END ONLY, NO FLUID END", 4" metal plungers x 5" stroke, c... More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, 6 used frames for Gardner Denver TEE triplex pumps, 8 used chaincase housings, 2 crankshafts , More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, Crate of parts for Gardner Denver TEE / PE-5 triplex pumps, bearing housings, crossheads, oil pumps, covers, man... More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, Used frame & parts for Gardner Denver TEE 4 x 5 Triplex Mud Pump, c/w bearing housings, conrods, crossheads, pon... More Info

Pump Parts - Gardner Denver TEE 4x5 Triplex Mud Pump Package, Pumps & Parts, Used Gardner Denver TEE 4x5 Triplex Mud Pump Package, 4" Metal Plungers, x 5" Stroke, Bronze Fluid End, Ch... More Info

Pump Parts - 2007 Gardner Denver THE 5.5" x 5" Triplex Mud Pump, Pumps & Parts, Used Gardner Denver THE Triplex Mud Pump, 5.5" Pistons x 5" Stroke, Steel fluid end, c/w 4.75:1 ratio p... More Info

Pump Parts - Gardner Denver TQB Triplex Injection Pump, Pumps & Parts, Used bare power frame for Gardner Denver TQB Triplex Injection Pump , More Info

8613371530291

8613371530291