gardner denver pz-10 mud pump free sample

9 gardner denver pz 10 mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 55%, pumps accounts for 11%.

A wide variety of gardner denver pz 10 mud pump options are available to you, such as 1 year, not available.You can also choose from new, gardner denver pz 10 mud pump,As well as from energy & mining, construction works gardner denver pz 10 mud pump.And whether gardner denver pz 10 mud pump is unavailable, {2}, or {3}.

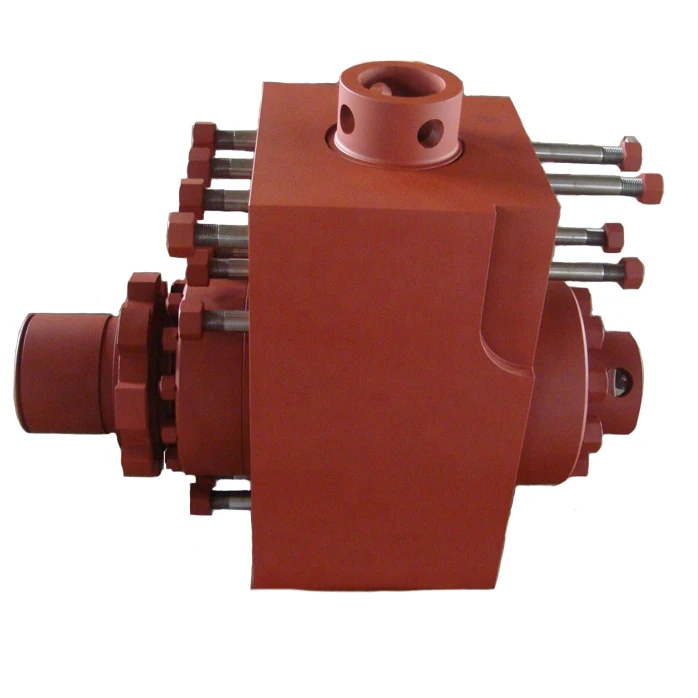

Gardner Denver PZ-10 Style Triplex Mud Pump is a 10 in stroke pump. It is a used for deep drilling. It is a mega powerful and reliable deep well triplex pump with an efficient 1,350 HP rating capacity.

Lots of times it’s hard to find high quality aftermarket mud pump parts at a great value. And we know how difficult it can be to find all the right pump bearings and replacement parts in one site.

The good news is that in today’s world, you can find the right aftermarket mud pump supplies for a fraction of the OEM cost. Whether you’re looking for new parts for your PZ10mud pumps or just browsing thru our parts break-down diagram, now at DrillingParts you can find ALL your high quality aftermarket mud pump parts in one place.

If you know the model number of your Gardner Denver Style pump you"re trying to fix, Drillingpart"s Interactive Diagrams will easily show the parts to identify your needs.

There’s no need to waste time calling, emailing, texting and leaving messages for different suppliers. Let our marketplace Quote Request System easily find the right mud pump parts for you.

MUD PUMP PERFORMANCE CHARTPUMP MODEL PZ-11 MAX I.H.P. 1600 MAX S.P.M. 115 STROKE LENGTH 11 MAX-P.S.I. G.P.R. 4 5000 1.80 4 5000 2.27 5 5000 2.80 5 5000 3.09 5 5000 3.39

OEM GARDNER DENVERITEM NO. 1 2 3 4 5 5A 6 7 7A 8 9 9A 9B 9C 10 10A 11 12 13 14 15 16 17 18 19 20 21 22 23 24 PART NO. 1377YXX 2975SEE DETAILS FOR P.N.

LINER (REFER TO GUIDE TO ORDERING CHART FOR TYPE (Y) AND FOR SIZE (XX)) LINER SEAL WEARPLATE (8477-4 PART NUMBER SOUTHWEST MFG. FOR GARDNER DENVER OEM) GARDNER DENVER OEM 8477-53 WEARPLATE GASKET PISTON (REFER TO GUIDE TO ORDERING CHART FOR SIZE (XX) AND FOR TYPE (YY)) PISTON BUSHING (FROM 1-5/8 TO 1-1/2 STRAIGHT BORE) PISTON O-RING PISTON ROD (CLAMP TYPE WITH ELASTIC STOP NUT) PISTON ROD (SCREW TYPE WITH ELASTIC STOP NUT) PISTON ROD ELASTIC STOP NUT *FOR 2-PC. STUDDED PISTON ROD ASSEMBLY REFER TO GUIDE CHART FOR ORDERING ROD CLAMP (CONSIST OF 9A, 9B, 9C) HOSE (1/2 X 30 WITH 1/2 MALE X 3/8 MALE CONNECTIONS) SPRAY PIPE ROD CLAMP BOLT (5/8 X 5-1/2 GRADE 8 BOLT W/ LOCK NUT AND WASHER) PONY ROD (CLAMP TYPE) PONY ROD (SCREW TYPE) VALVE VALVE INSERT (IF REQUIRED) VALVE SPRING VALVE SEAT HYDRAULIC SEAT PULLER KIT COMPLETE (REFER TO TOOLS SECTION OF CATALOG FOR DETAILS) THREADED FLANGE SCREW GLAND PLUG (COMPLETE WITH VALVE GUIDE, SCREWS, AND BUSHING) HP VALVE COVER PLUG SEAL (P113U URETHANE AVAILABLE) VALVE GUIDE (COMPLETE WITH BUSHING #4700I) VALVE GUIDE BUSHING (4700IU URETHANE AVAILABLE) VALVE GUIDE SCREW VALVE COVER STUD (WITH SW PART# HHN1000-8 1-8 HEAVY HEX NUT) POWER END STUD (WITH SW PART# HHN1250-7 1-1/4 7 HEAVY HEX HUT) LINER RETAINER STUD (WITH SW PART# HHN1250-7 1-1/4 7 HEAVY HEX NUTS)

VALVES & SEATS OEM GD PZ-11/PZ-10TYPESOUTHWEST (Full Open) FULL OPEN-ROUGHNECK FULL OPEN-ROUGHNECK (High Temp) FULL OPEN-ROUGHNECK (w/Replaceable Urethane Insert) 3 WEB DOUBLE ANGLE O-RING 3 WEB (High Temp) 3 WEB STANDARD PLATE 4 WEB 4 WEB (High Temp)

DESCRIPTION OEM DISCHARGE CROSS FOR PZ-11, PZ-10, PZ-9, PZ-8, PZ-7 GARDNER DENVER W/ 5" DISCHARGE LINE SPOOL FOR OEM PZ-11 DISCHARGE CROSS DISCHARGE STRAINER FOR OEM PZ-7 THRU PZ-11 PUMPS STUD FOR PZ-11 OEM DISCHARGE CROSS 5" 5000 PSI CONNECTION

TORQUE SPECIFICATIONS FOR OEM FLUID END ASSEMBLY GARDNER-DENVER PZ-11/PZ-10 5000 P.S.I. TORQUE TYPE (EXPRESSED IN FOOT-POUNDS) COPPERCOTE MOLY GREASE DRY (NOT RECOMMENDED)NO MORE FORCE THAN ONE MAN ON 3" WRENCH/CHEATER COMBINATION

We export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc.. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

The HENDERSON team is capable can refurbish these two (2) mud pumps to like-new condition for your drilling operations. Have a service provider? No problem. We’ll sell them to you as-is.

MAINTAIN PUMP RELIABILITY AND PERFORMANCE WITHGENUINE GARDNER DENVERPARTS AND SUPPORT SERVICESGardner Denver and OPI genuine pump parts aremanufactured to original tolerances and designed for optimumdependability. Design and material innovationsare the result of years of experience with hundreds of differentpump applications. Reliability in materials andquality assurance are incorporated in our genuine replacementparts.Your authorized Gardner Denver and OPI distributoroffers all the backup you’ll need. A worldwide networkof authorized distributors provides the finest product supportin the pump industry.Your local authorized distributor maintains a large inventoryof genuine parts and he is backed up for emergencyparts by direct access to the Gardner Denver MachineryInc. Master Distribution Center (MDC) in Memphis, Tennessee.Your authorized distributor can support your GardnerDenver and OPI pump needs with these services:1. Trained parts specialists to assist you in selectingthe correct replacement parts.2. Repair and maintenance kits designed with thenecessary parts to simplify servicing your pump.Authorized distributor service technicians are factory–trained and skilled in pump maintenance and repair. Theyare ready to respond and assist you by providing fast, expertmaintenance and repair services.For the location of your local authorized Gardner Denver and OPI distributor refer to the yellow pages of yourphone directory or contact:Distribution Center:Factory:Gardner Denver Machinery Inc.Gardner Denver Machinery Inc.Master Distribution Center1800 Gardner Expressway5585 East Shelby Drive Quincy, IL 62301Memphis, TN 38141 Phone: (217) 222–5400Phone: (901) 542–6100 Fax: (217) 224–7814Fax: (901) 542–6159INSTRUCTIONS FOR ORDERING REPAIR PARTSWhen ordering parts, specify Pump MODEL and SERIALNUMBER (see nameplate on unit). The Serial Numberis also stamped on top of the cylinder end of the frame(cradle area).All orders for Parts should be placed with the nearestauthorized distributor.Where NOT specified, quantity of parts required perpump or unit is one (1); where more than one is requiredper unit, quantity is indicated in parenthesis. SPECIFYEXACTLY THE NUMBER OF PARTS REQUIRED.DO NOT ORDER BY SETS OR GROUPS.To determine the Right Hand and Left Hand side of apump, stand at the power end and look toward the fluidend. Right Hand and Left Hand are indicated in parenthesisfollowing the part name, i.e. (RH) & (LH), when appropriate.15–514 Page 1

TABLE OF CONTENTSMaintain Pump Reliability And Performance With Genuine Gardner Denver Parts and Support Services . . . . . . . . . 1Instructions For Ordering Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Frame & Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3, 4Drive Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5, 6Fluid Cylinder & Manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7, 8Steel–fitted Center Guided Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9With Polyurethane Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9With Carboxylated Nitrile Insert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Plunger Coupling & Piston Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Piston & Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Piston Lubricating Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Oil Pump & Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13, 14Piston Lubricating Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15, 16Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Valve Seat Puller Center Guided Type (Optional Equipment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19PageGardner Denver Unit Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Inside Back CoverFor Operating and Service Instructions see:SERVICE MANUAL 15–60015–514 Page 2

Order by Part Number and Description. Reference Numbers are for your convenience only.D74881PISTON LUBRICATING PUMPRef.No. Name of Part Qty. Part No.PUMP ASSEMBLY, Includes All Parts Shown . . . . . . . . . . . . . . . . . . . . . . .CA1221 CASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 C1K2A12 PLUG–SqHd PIPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 64AA63 COCK, Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90C314 IMPELLER ASSEMBLY, SHAFT & PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 C1K1A1A5 KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 35B46 SEAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 60BT118 GASKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 25D2129 FRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 C1H4A210 SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 75A13011 BEARING–BALL (Inner) Includes Retaining Ring . . . . . . . . . . . . . . . . . . . . 1 12AK312 BEARING–BALL (Outer) Includes Retaining Ring . . . . . . . . . . . . . . . . . . . 1 12AK315–514 Page 11

Order by Part Number and Description. Reference Numbers are for your convenience only.PISTON LUBRICATING PIPINGRef.No. Name of Part Qty. Part No.Ref.No. Name of Part Qty. Part No.15–514 Page 16(Lube Oil Tank to Pump Group)1 SCREEN–OIL . . . . . . . . . . . . . . . . . . . . . . . 1 2WAJ5112 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H253 UNION–HAMMER, Wing . . . . . . . . . . . . . 1 64EB14 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H255 VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90A366 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H257 TEE–PIPE . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64G8G8 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63H259 VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90A3610 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 1 29Q911 HYDRAULIC HOSE ASSEMBLY . . . . . . . 1 2009247∅ ELBOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64C612 PUMP PISTON LUBRICATING,*Includes Reference Number 13 . . . . . . . . 1 CA12213 KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 35B414 SCREW, Pump to Skid . . . . . . . . . . . . . . . 4 655ED04015 LOCKWASHER, Pump to Skid . . . . . . . . 4 95B316 WASHER, Pump to Skid . . . . . . . . . . . . . . 4 95A317 SHEAVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 73K1A3018 BUSHING–HUB . . . . . . . . . . . . . . . . . . . . . 1 22E16B19 BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 13C2820 AUXILIARY SHEAVE . . . . . . . . . . . . . . . . . 1 2012669∅ SET SCREW, Sheave . . . . . . . . . . . . . . . . 2 76F30(Pump to Liner Group)21 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 1 29Q1022 HYDRAULIC HOSE ASSEMBLY . . . . . . . 1 200924723 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 1 29Q2724 REDUCER–PIPE . . . . . . . . . . . . . . . . . . . . 1 64N325 VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 90A2526 ELBOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64C527 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63G928 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64P3929 CLAMP–PIPE . . . . . . . . . . . . . . . . . . . . . . . 2 98H530 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 95A331 SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 75A6832 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63N12X15033 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64P3934 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63N12X15035 TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64P3936 PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64A537 HYDRAULIC HOSE ASSEMBLY . . . . . . . 3 29R3038 ADAPTOR–HOSE . . . . . . . . . . . . . . . . . . . 3 29Q8339 COUPLING–PIPE . . . . . . . . . . . . . . . . . . . 3 64BK340 BAFFLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 1PZ8041 NUT–ACORN . . . . . . . . . . . . . . . . . . . . . . . 6 50Q30(Frame to Lube Oil Tank Group)42 NIPPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 63L3143 ELBOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64C944 TANK–LUBE OIL . . . . . . . . . . . . . . . . . . . . 1 201263945 PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 64A746 SCREW, Lube Tank to Skid . . . . . . . . . . . 4 655EE04047 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 95A548 PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 64A649 COVER–LUBE OIL TANK . . . . . . . . . . . . . 1 201265550 NUT–WING . . . . . . . . . . . . . . . . . . . . . . . . . 2 50H1∅ PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 64A9∅ Not Shown on Drawing.* For Piston Lubricating Pump and Components Parts See Page 11.

Order by Part Number and Description. Reference Numbers are for your convenience only.VALVE SEAT PULLER – CENTER GUIDED TYPE(OPTIONAL EQUIPMENT)Ref.No. Name of Part Qty. Part No.1 HEAD (Not Included with 10012 Puller) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 100E13VALVE SEAT PULLER ASSEMBLY, Includes Ref. Numbers 2 thru 11 . . 1 100E122 HYDRAULIC JACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21167283 CENTER STEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173144 CENTER STEM NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173155 PULLER H BAR BASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21167276 CENTER BUSHING #5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2117316CENTER BUSHING #6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21175177 HYDRAULIC HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173188 HYDRAULIC PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 21173199 GAUGE ADAPTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 211732010 GAUGE COUPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2117322GAUGE COUPLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 211732111 GAUGE 170 TON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2117323* CARRYING CASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2117055* Not Shown on Drawing.15–514 Page 18

GARDNER DENVER UNIT RECORDThe following unit identification plate is provided as a convenience to you, our valued GardnerDenver customer. Please take the time to copy all the information from the actual nameplate ofyour unit. The model number, date manufactured and serial number will be required whencontacting the company or your distributor for information or replacement parts.200OPA496(Ref. Drawing)

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

8613371530291

8613371530291